Page 1 :

UNIT 3, TRANSMISSION SYSTEM, SYLLABUS: Clutch: its need and types, Gearboxes: Types of gear transmission, Shift, mechanisms, Over running clutch, Fluid coupling and torque converters, Transmission, universal joint, Propeller shaft, Front and rear axles types, Stub axles, Differential and its, types, Four wheel drive., INTRODUCTION TO THE TRANSMISSION SYSTEMS IN AUTOMOBILE:, The power developed by the engine has to reach the road wheels for moving the vehicle., Transmission system deals with this objective. It transmits power to wheels as and when, required by varying speed and torque., The most common transmission systems that have been used for the automotive industry are:, 1. Manual transmission,, 2. Automatic transmission,, 3. Semi-automatic transmission,, 4. Continuously-variable transmission (C.V.T.), 1. MANUAL TRANSMISSION:, The first transmission invented was the manual transmission system. The driver needs to, disengage the clutch to disconnect the power from the engine first, select the target gear, and, engage the clutch again to perform the gear change. This will challenge a new driver. It, always takes time for a new driver to get used to this skill., 2. Automatic Transmission:, An automatic transmission uses a fluid-coupling torque converter to replace the clutch to, avoid engaging/disengaging clutch during gear change. A completed gear set, called, planetary gears, is used to perform gear ratio change instead of selecting gear manually. A, driver no longer needs to worry about gear selection during driving. It makes driving a car, much easier, especially for a disabled or new driver. However, the indirect gear contact of the, torque converter causes power loss during power transmission, and the complicated planetary, gear structure makes the transmission heavy and easily broken., 3. Semi-Automatic Transmission:, A semi-automatic transmission tries to combine the advantages of the manual and automatic, transmission systems, but avoid their disadvantages. However, the complicated design of the, semiautomatic transmission is still under development, and the price is not cheap. It is only, used for some luxury or sports cars currently., 4. Continuously Variable Transmission (C.V.T.):, The Continuously Variable Transmission (C.V.T.) is a transmission in which the ratio of the, rotational speeds of two shafts, as the input shaft and output shaft of a vehicle or other, machine, can be varied continuously within a given range, providing an infinite number of, possible ratios. The other mechanical transmissions described above only allow a few, different gear ratios to be selected, but this type of transmission essentially has an infinite, number of ratios available within a finite range.

Page 2 :

It provides even better fuel economy if the engine is constantly made run at a single speed., This transmission is capable of a better user experience, without the rise and fall in speed of, an engine, and the jerk felt when changing gears., , Purpose of Clutch:, In vehicles with a manual transmission or manual transaxle the power flows through a clutch., This device engages and disengages the manual transmission or transaxle and the engine., When the driver pushes the clutch pedal down, the clutch disconnects or disengages from the, engine flywheel. No engine power can flow to the transmission or transaxle. When the driver, releases the clutch pedal the clutch engages. This allows power to flow to the transmission., Functions of Clutch:, 1. It can be disengaged. This allows engine cranking and permits the engine to run freely, without delivering power to the transmission., 2. While disengaged it permits the driver to shift the transmission into various gears., 3. While engaging, the clutch slips momentarily. This provides smooth engagements and, lessens the shock on gears, shafts, and other drive train parts., 4. When engaged, the clutch transmits power from the engine to the transmission. All, slipping has stopped., Requirements of Clutch:, 1. Torque transmission, The clutch should be able to transmit the maximum torque of the engine under all condition., 2. Gradual engagement, The clutch should positively take the drive gradually without occurrence of sudden jerks., 3. Heat dissipation, During clutch application large amount of heat are generated. The rubbing surfaces should, have the sufficient area and the mass to absorb heat., 4. Dynamic balancing, This is necessary particularly in the high speed clutches., 5. Size, The size of the clutch must be smallest possible so as to occupy minimum amount of space., 6. Vibration Damping, Suitable mechanism should be used within the clutch, to eliminate noise produced in the, transmission., 7. Inertia, The clutch rotating parts should have minimum inertia. Otherwise, when the clutch is, released for gear changing, the clutch plate will keep on spinning causing hard shifting and, gear clashing in spite of synchronization., 8. Clutch free pedal play, To reduce effective clamping load on the carbon thrust bearing and wear there of sufficient, free pedal play must be provided in the clutch.

Page 3 :

9. Ease of operation, For higher torque transmission the operation of disengaging the clutch must not be tiresome, for the driver., Types of Clutch:, The following are the main types of clutches., 1. Friction clutches, 2. Fluid flywheel, Friction clutches are mainly classified into:, • Single plate clutch, • Multi plate clutch, • Centrifugal clutch, • Diaphragm spring clutch, • Semi centrifugal clutch, Dry clutch:, In this type of clutch friction plate is always dry. There is no oil inside the clutch assembly., Wet clutch:, The construction of wet clutch is similar to that of dry type except that here the clutch plates, are always wetted by oil circulation., Many types of wet clutches are used in trucks, simple type is spray type. Its construction is, similar to that of dry type except that a different type of friction material is used and the, construction of clutch plate is also different. The oil is sprayed through holes in clutch plate, by a nozzle. This type of clutch is suitable for small trucks., All these types of clutches are attached to the engine flywheel which acts as the, driving member along with the pressure plate., Single Plate Clutch, 1. Thrust Spring (Coil Spring) Type:, The main components of clutch are clutch plate, clutch facing, pressure plate, springs, and bearing., A simplified sketch of a single plate clutch is given. Friction plate is held between the, flywheel and the pressure plate. There are springs arranged circumferentially, which provide, axial force to keep the clutch in engaged position. The friction plate is mounted on a hub, which is splined from inside and is thus free to slide over the gearbox shaft. Friction facing is, attached to the friction plate on both sides to provide two annular friction surfaces for the, transmission of power. A pedal is provided to pull the pressure plate against the spring force, whenever it is required to be disengaged. Ordinarily it remains in engaged position., When the clutch pedal is pressed the pressure plate is moved to the right against the, force of springs. This is achieved by means of a suitable linkage and a thrust bearing. With, this movement of the pressure plate the friction plate is released and the clutch is disengaged., In actual practice the construction of the clutch differs. The pressure plate, the springs,, the release levers and the cover form a sub assembly called the cover assembly. This can be

Page 4 :

mounted directly to the engine block by placing the clutch plate in between the flywheel and, the pressure plate with the clutch shaft inserted in place., , 2. Diaphragm Spring Type Single Plate Clutch:, The construction of diaphragm spring type single plate clutch is similar to that of the, single plate type clutch with thrust spring except that here diaphragm spring is used instead of, the ordinary coil springs. In the free condition the diaphragm spring is of conical form, but, when assembled it is constrained to an approximately flat condition because of which it, exerts a load upon the pressure plate., Diaphragm spring is supported on a fulcrum retaining ring so that any section through, the spring can be regarded as a simple lever. The pressure plate is movable axially, but it is, fixed radially with respect to cover. This is done by providing a series of equally spaced lugs, cast upon the back surface of the pressure plate. The drive from the engine flywheel is, transmitted through the cover, pressure plate and the friction plate to the gear box input shaft.

Page 5 :

MULTI PLATE CLUTCH:, The multi plate clutch is an extension of single plate type where the number of, frictional and metal plates is increased. The increase in the number of friction surfaces, obviously increases capacity of the clutch to transmit torque, the size remains fixed., Alternatively the overall diameter of the clutches is reduced for the same power transmission, as a single plate clutch. This type of clutch therefore used in some heavy transport vehicles, the racing cars where high torque needs to be transmitted. Besides, it also finds application in, case of scooters and motorcycles, where space available is limited., A simplified diagram of multi-plate clutch is given. The construction is similar to that, of single plate type except that all the friction plates on this are in two sets, i.e., one set of, plates slides in the grooves on the flywheel and other one slides on splines on the pressure, plate hub. Alternate plates belong to each set.

Page 6 :

CENTRIFUGAL CLUTCH:, In this type of clutch, the springs are eliminated altogether and only centrifugal force is used, to apply the required pressure for keeping the clutch in engagement position. The advantage, of the centrifugal clutch is that no separate clutch pedal is required. The clutch is operated, automatically depending upon the engine speed. This means that car can be stopped in gear, without stalling the engine. Similarly while starting, the driver can first select the gear, put, the car into the gear and simply press the accelerator pedal. This makes driving very, comfortable and easy. The following figure shows a schematic diagram of a centrifugal, clutch. As the speed increases, the weight A flies, thereby operating the bell crank lever B, that presses the plate C. This force is transmitted to the plate D by means of springs E. The, plate D containing friction lining is thus pressed against the flywheel F thereby engages the, clutch. Spring G serves to keep the clutch disengaged at low speed say 500 rpm. The stop H, limits the amount of centrifugal force.

Page 7 :

FUNCTIONS OF TRANSMISSION:, The important functions of transmission system are;, 1. To vary the torque, 2. To vary the speed of the vehicle, 3. To provide neutral position, 4. To move the vehicle in reverse direction, NECESSITY OF TRANSMISSION:, Before discussing the necessity of transmission, we should understand the following factors, a) Variation of resistance to the vehicle motion at various speeds., b) Variation of tractive effort to the vehicle available at various speeds., TYPES OF GEAR BOX:, The transmission can be classified into manual and automatic types. The manual transmission, is conventionally called gear boxes. The following are the important gear boxes used in, automobiles:, 1. Sliding mesh gear box, 2. Constant mesh gear box, 3. Synchromesh gear box, SLIDING MESH GEAR BOX:, It is the simplest gear box. The following figure shows 4-speed gear box in neutral position. 4, gears are connected to the lay shaft/counter shaft. A reverse idler gear is mounted on another, shaft and always remains connected to the reverse gear of countershaft. This “H” shift pattern, enables the driver to select four different gear ratios and a reverse gear., Gears in Neutral:, When the engine is running and clutch is engaged the clutch shaft gear drives the, countershaft gear. The countershaft rotates opposite in direction of the clutch shaft. In neutral, position only the clutch shaft gear is connected to the countershaft gear. Other gears are free, and hence the transmission main shaft is not turning. The vehicle is stationary.

Page 8 :

First or low shaft gear:, By operating the gear shift lever the larger gear on the main shaft is moved along the shaft to, mesh with the first gear of the counter shaft. The main shaft turns in the same direction as, that of the clutch shaft. Since the smaller countershaft is engaged with larger shaft gear a gear, reduction of approximately 4:1 is obtained i.e. the clutch shaft turns 4 times for each, revolution of main shaft.

Page 9 :

Second speed gear:, By operating the gear shift lever the third gear on the main shaft is moved along the shaft to, mesh with the third gear of the counter shaft. The main shaft turns in same direction as clutch, shaft. A gear reduction of approximately 3:1is obtained.

Page 10 :

Third speed gear:, By operating the gear shift lever, the second gear of the main shaft and countershaft are, demeshed and then the third gear of the main shaft are forced axially against the clutch shaft, gear. External Teeth on the clutch shaft gear mesh with the internal teeth in the third and top, gear. The main shaft turns in same direction as clutch shaft. A gear reduction of, approximately 2:1is obtained i.e. the clutch shaft turns 2 times for each revolution of main, shaft.

Page 11 :

Fourth speed gear/ Top or High-Speed Gear:, By operating the gear shift lever the third gears of the main and countershaft is demeshed and, the gears present on the main shaft along with the shaft is forced axially against the clutch, shaft gear. External teeth present on the main shaft engage with the internal teeth present on, the main shaft. The main shaft turns along with the clutch shaft and a gear ratio of, approximately 1:1 is obtained.

Page 12 :

Reverse gear:, By operating the gear shift lever, the last gear present on the main shaft is engaged with the, reverse idler gear. The reverse idler gear is always in mesh with the counters haft gear., Interposing the idler gear between the counter-shaft reverse gear and main shaft gear, the, main shaft turns in the direction opposite to the clutch shaft. This reverses the rotation of the, wheels so that the wheel backs.

Page 13 :

CONSTANT MESH GEAR BOX:, In this type of gear box, all the gears on the main shaft are in constant mesh with the, corresponding gear on the lay shaft. The gears on the main shaft, which is splined, are free., The dog clutches are provided which are free to slide on the main shaft. The gears on the lay, shaft are fixed. When the left sliding dog clutch slides to the left by means of the selector, mechanism, its teeth are engaged with those on the clutch gear and we get the direct gear., The same dog clutch, however, when it slides to the right makes contact with the second gear, and the second gear is obtained. Similarly the movement of the right dog clutch to the left, results in low gear and towards right in reverse gear position.

Page 14 :

SYNCHROMESH GEAR BOX:, , This type of gear box is similar to the constant mesh type in that all the gears on the, main shaft are in constant mesh with the corresponding gears on the lay shaft. The gears on, the lay shaft are fixed to it while those on the main shaft are free to rotate on the same. Its, working is also similar to the constant mesh type, but in the former there is one definite, improvement over the latter. This is the provision of synchromesh device which avoids the

Page 15 :

necessity of double declutching. The parts which ultimately are to be engaged are first, brought into frictional contact which equalizes their speed, after which these may be engaged, smoothly., Figure shows the construction and working of a synchromesh gear box. In most of the, cars, however the synchromesh devices are not fitted to all the gears as is shown in this, figure. They are fitted only on the high gears and on the low and reverse gears ordinary dog, clutches are only provided. This is done to reduce the cost., In the above figure the engine shaft, gears B, C, D, E are free on the main shaft and, are always in mesh with corresponding gears in the lay shaft. Thus all the gears on the main, shaft as well as on the lay shaft continue to rotate so long as shaft A is rotating. Menders F1, and F2 are free to slide on splines on the main shaft. G1 and G2 are ring shaped members, having internal teeth fit onto the external teeth members F1 and F2 respectively. K1 and K2, are dog teeth on B and D respectively and these also fit onto the teeth of G1 and G2. S1and, S2 are the forks. T1and T2 are the ball supported by springs. These tend to prevent the sliding, of members G1 (G2) on F1 (F2). However, when force is applied in G1 (G2) through fork S1, (S2) exceeds a certain value, the balls are overcome and member G1 (G2) slides over F1, (F2). There are usually six of these balls symmetrically placed circumferentially in one, synchromesh device. M1, M2, N1, N2, P1, P2, R1, R2 are the frictional surfaces., The working of the gear box is as follows- For direct gear, member G1 and hence, member F1 (through spring-loaded balls) is slid towards left till M1 and M2 rub and friction, makes their speed equal. Further pushing the member G1 to left causes it to override the balls, and get engaged with dogs K1. Now the drive to the main shaft is direct from B via F1 and, the splines. We have to give sufficient time for synchronization of speeds; otherwise clash, may be the result., For the second gear the members F1 and G1 are slide to the right so that finally the, internal teeth on G1 are engaged with L1. Then the drive to main shaft will be from B via U1,, U2, C, F1 and splines. For first gear, G2 and F2 are moved towards right. In this case the, drive will be from B via U1, U3, D, F2 and splines to the main shaft. For reverse, G2 and F2, are slide towards right. In this case the drive will be from B via, U1, U4, U5, D, F2 and, splines to the main shaft., SELECTOR MECHANISMS: (SHIFT MECHANISMS), There are many mechanisms used for selecting the desired gear. Broadly speaking, these can be divided into two categories, the mechanism where the gear shift lever is mounted, on the top of transmission case and the other where the gear shifting lever is mounted on the, steering column. However, in these two types most of the mechanism is similar and only the, external linkage is different., Figure shows a typical selector mechanism for a 4 forward speeds and one reverse, gear box. The gear lever is ball mounted in the gear box cover. This facilitates its movement, in any direction. The lower end of the gear lever fits into a slot in the selector sleeve. There, are forks mounted on the sleeves on three separate selector rods which are supported in the, gear box casing. Each selector sleeve can slide on its rod. When a particular gear is to be, engaged the corresponding selector rod is moved in the desired direction. To avoid unwanted, engagement of gears, slots are made on the selector rods and the sleeves are provided with

Page 16 :

spring loaded balls. These balls resist the movements of the forks until some force is applied, to the gear lever to overcome their resistance., , OVERRUNNING CLUTCH DRIVE:, The overrunning clutch, which is employed in this type of drive, is shown in the, figure. It consists of a shell and a pinion collar connected in such a way that when the shell is, rotating at a speed greater than that of the pinion collar, the former will drive the later., However, whenever the speed of the collar becomes more than the speed of the shell, there is, no more connection between the two. Such a connection is provided by the spring loaded, rollers, the shell is connected with the armature shaft through splines, whereas the collar is, attached to the pinion., A starting drive employing the overrunning clutch is shown in the figure. The shift, lever is attached to solenoid switch. When the driver turns ignition switch the shift lever, moves about its pivot, thereby pushing the switch of starting motor and moving the, overrunning clutch and the pinion assembly through the spring simultaneously. This causes, the pinion to get engaged with the teeth on the flywheel and also get the armature shaft and, thereby the pinion rotates, which starts the engine. However, as soon as the engine gets, started, the flywheel and the pinion rotate at much faster a speed, causing the overrunning, clutch to disconnect the pinion side from the motor side. Further the motor also stops as soon, as the engine starts. The driver leaves the starting pedal or key which causes the shift lever to

Page 17 :

come back to its previous position, leaving the motor switch open and disengaging the pinion, from the flywheel., , FLUID FLYWHEEL, An automotive fluid coupling consists of a split housing which is rotated by the, engine crankshaft. Inside the housing is a driven member called the runner and the driven, member is connected by a shaft to the gear box. The driving member is mounted on the, crankshaft and it is called impeller., The driving (input) and driven (output) members are very close with their ends facing, each other and enclosed in housing, so that they can be turned without touching each other., The liquid or oil is filled in the housing. The fly wheel housing is divided into a number of, cells by means of radial vanes. These cells correspond to similar openings in the driven, member. When the crankshaft turns, the driving member or impeller also rotates. The fluid, flows outwards due to centrifugal force and circulates from the flywheel to the driven, member. The fluid tends to rotate the driven member because the fluid is also carried out

Page 18 :

round by the driving member. Thus the torque is transmitted from the crankshaft to the gear, box shaft., Liquid coupling is not suited for use with an ordinary gear box. It is generally used in, conjunction with epicyclical gears to provide a semi or fully automatic gear box., , TORQUE CONVERTER:, A single stage torque converter is shown in the figure. It consists of three main parts,, viz., (i) The impeller (pump) or driving member which is connected to the engine,, (ii) The turbine or driven member which is connected to the road wheels through, transmission and, (iii) The stator fixed to the frame through a free wheel. In addition there is a transmission oil, pump which keeps the converter full of oil under pressure., As soon as the flywheel of engine starts rotating, the torque converter housing as well, as the pump also starts rotating in the same speed and direction. Because of the profile of the, pump blades, the fluids inside the torque converter are pushed out centrifugally. As pressure, is built up by the pump, the fluids are forced into the blades of the turbine and this makes it, rotate in the same direction as the pump. The fluids enter the outer periphery of the turbine, and leave from the inner periphery and reaches to the stator blades there. The function of the, stator is to guide the incoming fluid from the turbine to reach at a specific angle to the pump.

Page 19 :

If the turbine is rotating at a speed lower than that of the pump (i.e., when the vehicle, is accelerating) then the fluids from the turbine hits the front sides of the stator blades and the, one way clutch prevents it from rotating. In this condition the fluids leaving the stator hits the, pump at a "helping" angle to increase the torque (or multiply the torque) and thus increase the, speed of the turbine., When the vehicle achieves its constant speed, then the angle at which the fluids leave, the stator change and no more torque multiplications happens., While retarding, the speed of the turbine increases than that of the pump and the fluid, from the turbine hits the back sides of the stator blades and make the stator rotate at the same, direction as the pump and turbine and the fluid from the stator hits the pump in such angles, that the torque reduces.

Page 20 :

PROPELLER SHAFT:, This is the shaft which transmits the drive from the transmission to the bevel pinion or Worm, of drive in front engine, rear drive vehicles and from the transfer box to the front and rear, axles in all-wheel drive vehicle. It is also called drive shaft. It consists mainly of three parts:, , (a) Shaft - As this has to withstand mainly torsional loads, it is usually made of tubular crosssection it also has to be well balanced to avoid whirling at high speeds. Shafts are made of, steel, aluminium or composite materials., (b) One or two universal joints - Depends upon the type of rear axle drive used. The universal, joint account for the up and down movements of the rear axle when the vehicle is running., Modern vehicles use, however, high-speed constant velocity joints, rubber couplings., (c) Slip joint - Depending upon the type of drive, one slip joint may be there in shaft. This, serves to adjust the length of the propeller shaft when demanded by the rear axle movements., Fig. 6.1 shows a propeller shaft, with two universal joints at the ends and a slip or sliding, joint. Slip joint is formed by the internal splines on the sleeve attached to the left universal, joint and external splines on the propeller shaft.

Page 21 :

In some designs, slip arrangement is slightly different. In these a universal joint and, splined slip yoke are located at the transmission end of the shaft where these are held in, alignment by a bushing in the transmission rear extension. This spline is lubricated internally, by transmission lubrication or grease. Sometimes a rubber element is incorporated in-between, the two sliding tubes to make the relative movement smooth and noiseless., UNIVERSAL JOINT:, Hooke's Joint:, , A universal joint is a particular type of connection between two shafts, whose axes are, inclined to each other. The simplest type of universal joint is the Hooke's joint which is most, widely used as it is simple and compact in construction and reasonably efficient at small, angles of up and down propeller shaft movement, say up to 180. The axes of shafts A and B, are intersecting. Each of these shafts contains a yoke. The cross C has four arms. The two, opposite arms of the cross are supported in bushes in the yoke of shaft A, while the other two, arms of the cross are supported in the yoke of shaft B. Thus shaft A can have angular rotation, about axis XX and the shaft B, about the axis YY. It is thus seen that it will be possible with, the Hooke's joint for the shafts A and B to have positive drive while allowing angular, movement between them. An improved form of the Hooke's joint uses needle roller bearing, to support the cross in the yoke and this results in the increase of joint efficiency., Rzeppa Joint (Constant Velocity joint), The first real constant velocity joint, still in use, is the Rzeppa joint. In this six spherical balls are held in a precise geometric position midway between the two shafts, bisecting the, angle between them.

Page 22 :

As shown in the figure, the joint consists of an outer race, inner race, cage and six balls. The, joint can also slide in the axial direction on account of the balls sliding in the axial grooves of, the outer race. Thus the drive shafts can accommodate the changes in their lengths., Types of Axles:, Following are the three different types of axles, Rear Axles, Front Axle, Stub Axle, Rear Axles:, In between the differential and the driving wheels is the rear axle to transmit power from the, differential to the driving wheels. It is clear from the construction of the differential, that the, rear axle is not a single piece, but it is in two halves connected by the differential, one part is, known as the half shaft., The inner end of the half shaft is connected to the sun gear of the differential. And the outer, end of the driving wheel. In rear-wheel-drive vehicles, the rear wheels are the driving wheels., Whereas, in front-wheel drive vehicles, the front wheels are the driving wheels. Almost all, rear axles on modern passenger cars are live axles, that is, they revolve with the wheels., Dead axles simply remain stationary; do not move with the wheels. Housing completely, encloses the rear axles and the differential, protecting them from water, dust and injury, in, addition to mounting their inner bearings and providing a container of the lubricant.

Page 23 :

Types of Rear axles:, Depending upon the methods of supporting the rear axles and mounting the rear wheels,, the three types of rear axles are as follows:, 1. Semi-floating axle, 2. Full-floating axle, 3. Three quarter floating axle, Semi-Floating Axle, A semi-floating axle has a bearing located on the axle and inside the axle casing. It has to, support all the loads as listed above. Therefore, it needs to be of a larger size, for the same, torque output, than any other type. The inner end of the axle is supported by the differential, side gear., , It is thus relieved of the job of carrying the weight of the car by the axle housing. The outer, end has to support the weight of the car and take end thrust. The inner end of the axle is, splined to the differential side gear., The outer end is flanged so that the wheel can be bolted directly to it. In some design, the hub, of the wheel is keyed to the outer end of the axle. The vehicle load is transmitted to the axle, through the casing and the bearing, which causes the bending or shearing of the axle. The, semi-floating axle is the simplest and cheapest of all other types and widely used on cars., Full-Floating Axle:

Page 24 :

A full floating axle has two deep groove ball or taper roller bearings, located between the, axle casing and wheel hub. The outer of an axle is made flanged to which the wheel hub is, bolted. The axle is not supported by bearing at either end, and its position is maintained by, the way that it is supported at both ends., , Thus the axle is relieved of all strain caused by the weight of the vehicle on the end thrust. It, transmits only the driving torque. For this reason, it is called full floating. The axle may be, removed from the housing without distributing the wheel by removing the nuts., An additional advantage of this design is the ability to the vehicle even if it has a broken axle., This type of axle is more, expensive and heavier than the other axle. It is usually fitted on, commercial vehicles., Three-Quarter Floating Axle:, This type of axle has a bearing placed between the hub and the axle casing. Thus, the weight, of the vehicle is transferred to the axle casing, and only the side thrust and driving torque are, taken by the axle.

Page 25 :

The axle is keyed rigidly to the hub, thus proving the driving connection and maintaining the, alignment of the wheel. The inner end of this axle has the same construction as that of the, semi-floating axle. Although the three-quarter floating axle is more reliable it is not as simple, as the semi-floating axle., Front Axle:, The front axle is used to carry the weight of the front part of the vehicle as well as to, facilitate steering and absorb shocks due to road surface variations. It must be right and, robust in construction., The front axle is usually a steel drop forging having 0.4% carbon steel or 1-3% nickel, steel. It is made of I-section in the centre portion, while the ends are made either circular or, elliptical., With this construction, it takes bending loads due to the load of the vehicle. Also, the, torque centre portion is given a downward sweep. The different components of the front axle, are the beam, stub axle, swivel pin and track rod.

Page 26 :

Types of Front Axles:, Usually, there are two main types of the front axle:, 1. Live front axle., 2. Dead front axle., The front axles are usually dead axles because they do not rotate, in contrast to the live axles, that they are used in the rear axle to transmit power to the rear wheels. A live front axle, as, compared to the dead axle, has the additional function of transmitting the driving power taken, from a transfer gearbox to the front wheels having a different swiveling mechanism., The live front axles although resembling the gear axles have some difference at the axle half, shafts end where the wheels are mounted. A dead front axle has enough rigidity and strength, to carry the weight of the vehicle from the springs to the front wheels., The ends of the axle beam are formed suitably to assemble the stub axle. In order to, accommodate a swivel pin connecting the sub axle portion of the assembly, the ends of the, beam are usually shaped either as a yoke or plain surface with drilled hole.

Page 27 :

The figure shows front axle components with the steering linkage. The wheels are fixed on, the stub axles which are usually pivoted. From the stub axle, the inclined steering arms are, connected to the track rod ends, and a third steering arm is attached to the drag link., Some vehicles have the drag link placed transversely instead of in the fore and at the position, in order to allow a more compact vehicle design. It is often used in independent wheel, suspension systems. The drag link connects the steering linkage to the drop arm of the, steering box., Stub Axle:, The front wheels are mounted on the stub axles, which are connected to the front axle by, means of kingpins. The stub axles are the forging of 3% nickel steel and alloy steels, containing chromium and molybdenum.

Page 28 :

The stub axle turns on the pink pin which is a light drive fit in the axle beam eye placed and, locked by a taper cotter pin. Phosphor bronze bushes are fitted into the forked ends of the, axle to provide a bearing surface for the kingpin., Vertical load are taken by a steel washer or a thrust bearing located either on the top fork of, the stub axle or between the lower fork and the underside of the axle beam., Types of Stub Axle:, Following are the four types of the stub axle:, 1. Elliot., 2. Reverse Elliot., 3. Lamoine., 4. Reversed Lamoine., The Elliot stub axle is attached to the front axle by placing in the yoke end with a kingpin and, cotter to join the two together.

Page 29 :

In Reversed Elliot type stub axle, the arrangement is reversed. In Lamoine type stub axle,, instead of yoke type hinge, an L-shaped spindle is used as shown in the figure., DIFFERENTIAL:, Differentials are a variety of gearbox, almost always used in one of two ways. In one, of these, it receives one input and provides two outputs; this is found in every automobile., In automobile and other wheeled vehicles, the differential allows each of the driving wheels, to rotate at different speeds, while supplying equal torque to each of them. In the other, less, commonly encountered, it combines two inputs to create an output that is the sum (or, difference) of the inputs. In automotive applications, the differential and its housing are, sometimes collectively called a "pumpkin" (because the housing resembles a pumpkin)., Purpose:The differential gear box has following functions:, drawing, a curve., a single rigid rear axle, and provides a coupling between two rear axles.

Page 30 :

The following description of a differential applies to a "traditional" rear- or frontwheel-drive car or truck: Power is supplied from the engine, via the transmission or gearbox,, to a drive shaft termed as propeller shaft, which runs to the differential. A spiral bevel pinion, gear at the end of the propeller shaft is encased within the differential itself, and it meshes, with the large spiral bevel ring gear termed as crown wheel. The ring and pinion may mesh in, hypoid orientation. The ring gear is attached to a carrier, which holds what is sometimes, called a spider, a cluster of four bevel gears in a rectangle, so each bevel gear meshes with, two neighbors and rotates counter to the third that it faces and does not mesh with. Two of, these spider gears are aligned on the same axis as the ring gear and drive the half shafts, connected to the vehicle's driven wheels., These are called the side gears. The other two spider gears are aligned on a, perpendicular axis which changes orientation with the ring gear's rotation. These two gears, are just called pinion gears, not to be confused with the main pinion gear. (Other spider, designs employ different numbers of pinion gears depending on durability requirements.), As the carrier rotates, the changing axis orientation of the pinion gears imparts the, motion of the ring gear to the motion of the side gears by pushing on them rather than turning, against them (that is, the same teeth stay in contact), but because the spider gears are not, restricted from turning against each other, within that motion the side gears can counter-rotate, relative to the ring gear and to each other under the same force (in which case the same teeth, do not stay in contact)., Thus, for example, if the car is making a turn to the right, the main ring gear may, make 10 full rotations. During that time, the left wheel will make more rotations because it, has further to travel, and the right wheel will make fewer rotations as it has less distance to, travel. The side gears will rotate in opposite directions relative to the ring gear by, say, 2 full, turns each (4 full turns relative to each other), resulting in the left wheel making 12 rotations,, and the right wheel making 8 rotations., The rotation of the ring gear is always the average of the rotations of the side gears., This is why if the wheels are lifted off the ground with the engine off, and the drive shaft is

Page 31 :

held (preventing the ring gear from turning inside the differential), manually rotating one, wheel causes the other to rotate in the opposite direction by the same amount., When the vehicle is traveling in a straight line, there will be no differential movement, of the planetary system of gears other than the minute movements necessary to compensate, for slight differences in wheel diameter, undulations in the road (which make for a longer or, shorter wheel path), etc., , When the car is taking a turn, the outer wheel will have to travel greater distance as, compared to the inner wheels. If the car has a solid rear axle only, there will be tendency for, the wheels to skid. Hence if skidding of the wheel is to be avoided, some mechanism must be, incorporated in the rear axle, which would reduce the speed of the inner wheels and increase, the speed of the outer wheels while taking turns. It should at the same time keep the speeds of, all the wheels the same when going straight ahead. Such a device which serves the above, functions is called a differential., The crown wheel of the final drive is attached on a cage which carries a 'cross pin. Two sun, gears mesh with the two planet pinions. Axle half-shafts are splined to each of these sun, gears. The crown wheel is free to rotate on the half-shaft as shown., When the vehicle is going straight the cage and the inner gears rotate as a single unit and the, two half shafts revolve at the same speed. In this situation, there is no relative movement, among the various differential gears. To understand what happens when the vehicle is taking, a turn, assume that the cage is stationary. Then turning one sun gear will cause the other to, rotate in the opposite direction. That means if left sun gear rotates 'n' times in a particular, time, the right sun gear will also rotate n times in the same period but, of course, in the, opposite direction. This rotation is super-imposed on the normal wheel speed when the, vehicle is taking a turn. Thus the outer wheel rotates at higher speed than the inner wheel, while taking a turn.

Page 32 :

Types of Differentials in Cars and Trucks, Open Differential, This type of diff is the most basic and only allows for variations of individual wheel speed or, slip but that’s it. In optimal road conditions, it allows the outside wheel to rotate faster than, the inside wheel. The problem is when road conditions are not ideal such as on wet pavement,, ice, snow, or gravel., With an open diff, the engine torque still transfers even if the wheel has zero traction so that, slipping tire will simply spin and not go anywhere., Open differentials are found in most vehicles on the road today so generally speaking,, the cost to repair the differential is less that other diff types (if same axle)., , Limited-Slip Differential, Under ideal road conditions, a limited-slip diff acts just like an open diff and transfers torque, independently to each wheel.

Page 33 :

But, under hard cornering or heavy acceleration where an open diff would generally cause a, tire to slip, a limited-slip diff prevents the normal amount of torque to go to the slipping tire, (the one with least resistance)., It does so through the use of clutches and plates within the differential. This enables the, vehicle to power through corners a vehicle with an open diff would struggle with. Race cars, and other performance vehicles (as well as some off-road vehicles) use limited-slip, differentials., , Locking Differential, Found on many off-road vehicles and some performance cars, locking differentials use, clutches and springs to activate a lock which sends an equal amount of power to each wheel, no matter the traction situation. This essentially creates a fixed axle., The benefit is the locked diff’s ability to gain a greater amount of traction since the full, amount of torque is always available to a wheel and not limited by the lower traction of one, wheel., At higher speeds this is a negative but when off-roading or rock climbing, it’s a big, advantage.

Page 34 :

Torque-Vectoring Differential:, The most complicated and advanced type of differential, a torque-vectoring diff uses a, collection of sensors and electronics to obtain data from various things (road surface, throttle, position, steering system, etc.) to activate electronically actuated clutches and a controller., Also known as active differentials, they work in the most efficient way which results in a, truly dynamic, high performance driving experience. Torque-vectoring differentials can be, found in some high performance rear-wheel drive and all-wheel drive vehicles., , How a Differential Works:, All vehicles have either a front differential or rear differential as part of the axle assembly. A, front-wheel drive car will have a front differential while a rear-wheel drive car has a rear, differential., If the vehicle has 4-wheel drive then it could have both front and rear differentials., A differential can be defined as a gearbox that has 3 common elements: Side Gear, Ring Gear, and Pinion Gear. It’s job is to drive a pair of wheels on an axle but allowing them to rotate at, different speeds.

Page 35 :

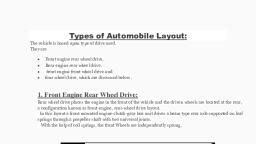

This is necessary when your car is turning on the road. As you go around a turn, the outside, wheel needs to cover a longer distance than the inside wheel so the outside wheel needs to, spin faster. The differential allows this to happen., Front Engine / Rear-Wheel Drive (FR) Type, , Engine → Transmission → Drive Shaft → Rear Differential → Axle Shaft → Rear Wheels, Front Engine / Front-Wheel Drive (FF) Type, , Engine → Transaxle & Built-in Front Differential → Front Wheels, 4-Wheel Drive Type:, , Engine → Transmission → Transfer Case → Front & Rear Drive Shaft → Front & Rear, Differential → Front Drive Shaft & Rear Axle Shaft → Front and Rear wheels

Page 36 :

Based on information above, the Front Engine / Front-Wheel Drive setup uses a front, differential that’s built-in together with the transmission/transaxle. This means that the cost to, repair this setup is often more expensive than others., Four Wheel Drive:, , TERMINOLOGY Four-wheel drive (4WD) is often designated as “4 × 4” and refers to a, vehicle that has four driven wheels., ■ The first 4 indicates that the vehicle has four wheels., ■ The second 4 indicates that all four wheels are driven., A vehicle will have more pulling power and traction if all of its wheels are driven. This, requires a drive axle at each end of the vehicle, another driveshaft, and a transfer case or, power transfer unit to drive the additional driveshaft and drive axle. The transfer case is, normally attached to the rear of the transmission. It has a single input shaft from the, transmission and two output shafts, one to the front drive axle and one to the rear drive axle., Some transfer cases are two-speed and include a set of reduction gears for lower-speed,, higher-torque operation., Four-wheel drive can be built into, ■ A front-engine rear-wheel drive, ■ A front-engine front-wheel drive, ■ A rear-engine rear-wheel drive

Page 37 :

Fig. Three major 4WD configurations. The traditional form (a) uses a transfer case to split the, torque for the front and rear drive axles. Both (b) and (c) are typical AWD configurations., ALL-WHEEL DRIVE:, All-wheel-drive (AWD), also called full-time four-wheel drive, vehicles are four-wheel-drive, vehicles equipped with a center (inner-axle) differential so they can be operated on pavement, in four-wheel drive. Full-time four-wheel drive is another name for all-wheel drive. Allwheel drive vehicles are designed for improved on-road handling., There will be one differential in each drive axle assembly plus a differential between the two, drive axles. The inter-axle differential allows the front-to-rear wheel speed differential., Because all wheels are driven, these vehicles are excellent for use in rain and snow where, added control is needed., Four-Wheel Drive Advantages, The main benefits of 4WD are traction and power. Have you ever seen those commercials, where the Jeep is climbing over boulders and rocks? That’s 4WD in action., If you are climbing a steep hill or are off-roading, you will want increased power in order to, get over obstacles and climb steep hills. While 2WD will get you over even the steepest hills, of San Francisco, if you are off-roading you will probably want the extra power that comes, with 4WD., 4WD improves traction in dangerous driving conditions, such as snow, ice, rocks, and, other scenarios that can make control difficult. By engaging both sets of wheels,, traction and control improves., Additional weight contributes to better grip on the road., 4WD is great for those who like off-roading.

Page 38 :

If you frequently drive in conditions where there is low traction, or if you enjoy off-roading,, you will greatly benefit from four-wheel drive., Four-Wheel Drive Disadvantages, In most cases, 4WD is not necessary. It uses more fuel and can also lead to overconfidence,, leading to more situations where you can get stuck. Save money and fuel by only using 4WD, when you need it., The main disadvantage of 4WD is added cost for purchase, maintenance, and fuel., The extra equipment (differentials, transfer case, etc.) adds complexity and weight to, the vehicle, increasing initial market value, tire wear, and the cost of repairs and, maintenance., The added power and weight of 4WD and AWD systems require more fuel, making, them less efficient than their 2WD counterparts., Added weight improves traction and control, but it also increases the braking distance, required to make a complete stop. Lighter vehicles can avoid collision easier than, heavier vehicles., 4WD and AWD can cause overconfidence in drivers, ironically leading to more, situations where you can become stuck., Although 4WD improves traction, slow down and use extreme caution on icy, snowy,, and slick roads. Overconfidence can lead to dangerous accidents.