Page 1 :

Angular Measurement, • No absolute standard is required for angular, measurement., • Units of measurement, – Degrees (°): defined as 1/360 of a circle, – Radians (rad): defined as 1/(2π) of a circle., , • 1 radian = 57.29578°

Page 2 :

Angular Measurement, Common Instruments Used:, • Protractors, • Sine Bars & Sine Centers, • Angle Gauges, • Spirit Level, • Autocollimator, • Angle Dekkor

Page 3 :

Universal Bevel Protractor, • Construction: It consists of, – Main scale is graduated in degrees, & rotates with the rotation of the, adjustable blade., – Vernier scale is divided into twelve, equal parts on each side of zero., – Acute angle attachment, , • Accuracy: Upto 5 minutes., Least count on Main scale = 10, 24 div of VS = 46 div on MS, or 1/12th of 230, LC of bevel protractor, = 2- (23/12) = 1/12

Page 4 :

Optical Bevel Protractor, • It has a glass circle fitted, inside the main body, • Glass circle is divided into, 10’ throughout its 3600., • Provision for, magnification is available., • By approximation, it may, read upto 2’.

Page 5 :

Sine Bars, • Hardened and precision ground tools used for:, – Measuring known angles or locating any work to a, given angle., – Checking of unknown angles., , • Used in conjunction with slip gauges and dial, indicator., • Depending on the accuracy they may be, – Grade A: 0.01 mm/m of length, – Grade B: 0.02 mm/m of length

Page 6 :

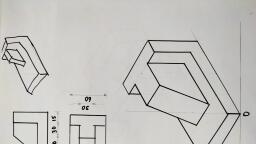

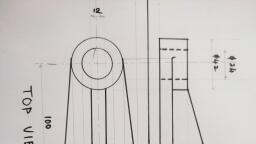

Sine Bar: Construction, • Made of high carbon, high chromium corrosion resistant, steel hardened ground and stabilized, • Two accurately lapped rollers of the same diameter are, located a fixed distance apart., • Surface of sine bar is parallel to the center lines of the, plug/rollers., • Sine bars sizes: of 100, 200,, 250, 300 mm, • Holes are drilled in the body, for easy handling and, reduced weight

Page 7 :

Sine Bar: Principle, • If sine bar is the, hypotenuse of right, angled triangle and h, the height of slip, gauges as shown in, Figure, h = Height in mm, L = Center distance in mm, Sinθ = Opp / Hyp = (h/ L)

Page 8 :

Use of Sine Bar

Page 9 :

Sine Bar: Types

Page 10 :

Sine Bar Error, • Accuracy of an angle set by a sine bar depends on:, – Error in spacing of roller centers (dL), – error in or errors in combination of slip gauges (dh), , • The height of slip gauge combination (h) required to, set angle (ϴ) is given by:, h = L sin ϴ, , Partial differentiation of the above equation yields:, or, or, , dh/dϴ = (sin ϴ) (dL /dϴ) + L cos ϴ, dh = (sin ϴ) dL + (L cos ϴ) dϴ, dϴ = tan ϴ ((dh/h) - (dL /L)), , • As the angle increases, the error (dϴ) in the angular, measurement increases. Above 45 °, the graph for dϴ, vs. ϴ rises sharply, so a sine bar is never used beyond, 45°.

Page 11 :

Limitation of Sine Bar, • Sine bars are not used beyond 450 because:, – It is difficult to handle & position on slip gauges., – Large angular error may result due to slight error, in length., – Long gauge stacks are not as accurate as short, ones, – Different deformation is observed at the two, rollers because at large angles, weight load gets, shifted towards the fulcrum roller

Page 12 :

Sine Centers, • Useful for testing of, conical work up to 60°., • Centers ensure correct, alignment of the work, piece.

Page 13 :

Sine Plate, • Allow angles to be, measured and set in, each of two orthogonal, planes., • A work piece is secured, to the top plate and the, bottom plate is secured, to a machine tool table, using clamps or a, magnetic chuck.

Page 15 :

Sine Bar: Advantages& Disadvantages, Advantages, • Used for accurate &, precise angular, measurement., • It is cheap., , Disadvantages, • Application is limited for, a fixed center distance, between two plugs or, rollers., • It is fairly reliable till, about 150. But, inaccuracies increase, with increase in angles.

Page 16 :

Angle Gauges, Wedge shaped block used as standards for, angle measurement., Large number of combinations by adding or, subtracting gauges are possible, Nominal angles of combination angle gauges, Degrees, Minutes, Seconds, , 1, 1, 3, , 3, 3, 6, , 9, 9, 18, , • Square block is also available, , 27, 27, 30, , 41

Page 17 :

Angle Gauges

Page 18 :

Spirit Level, • Used for measuring small angle or inclinations and also enable the, position of a surface to be determined with respect to the horizontal., • It consists of a sealed glass tube that is:, – Nearly filled with ether & contains a bubble of ether vapors, – Ground on its inside surface to a convex form with a large radius of, curvature R, – A scale is engraved on the glass at the top of the tube., , • The glass tube is set in the base and adjusted in such a way that when, the base is horizontal the bubble rests at the center of the scale which is, engraved on the glass.

Page 19 :

Spirit Level, • Principle: When the base of the level, is moved out of the horizontal, the, bubble moves along the scale. Thus,, l = Rα = Rh/L, (For small values of α), , • Thus sensitivity of the level increases, as, – Radius of curvature (R)increases, – Length of the base (L) decreases, , • Scale division values:, – For precise measurements: 4 to 10, – For ordinary purposes: 10 to 40, , • Very sensitive to variation in, surroundings temperature

Page 20 :

Types of Spirit Level (Contd.), According to BS 1958, three types of spirit levels are recommended., • Type 1.:, –, –, –, , •, , Type 2, –, –, –, , •, , It has an unrelieved flat base of steel, hardened and lapped., The base length of spirit level varies between 100 to 200 mm., Effective length of the level can be varied by wringing two gauge, blocks on the base at the desired distance apart., It is mounted in cast iron or steel body, having a base formed with, feet bearing surfaces at the two ends (middle portion being, relieved)., Base length 250-500 mm, The bearing surface may be plain or contain a longitudinal 120° Vgroove for use on cylindrical surfaces., , Type 3:, –, –, , It is a square block level about 200 mm square and made of cast, iron., The four bearing surfaces are flat and may have the middle portion, relieved. Alternatively, the base and one adjacent-surface may, contain a longitudinal 120° vee groove for use on cylindrical, surfaces in which case a short cross-level is provided.

Page 21 :

Reading level, , Figure : Readings a spirit level

Page 22 :

Clinometer, • A special case of the application of, spirit level., • Uses:, – Checking angular faces, and relief, angles on large cutting tools and milling, cutter inserts., – For setting inclinable table on jig boring;, machines and angular work on grinding, machines etc., , • In some clinometers, a graduated, circle is supported on accurate ball, bearings such that when released, it, always takes up the position relative, to the true vertical. The reading is, taken against the circle to an, accuracy of 1 second with the aid of, Vernier., • Reading up-to 1′ is possible

Page 24 :

Autocollimator, An optical instrument used for the, measurement of small angular differences., It is essentially an infinity telescope and a, collimator combined into one instrument.

Page 25 :

Principle, • When light from a point source, (placed at the principal focus) passes, through a collimating lens, it emerges, as a parallel beam of light., • If this beam strikes a plane reflector, normal to the optical axis, it will be, reflected back along its own path and, focussed at the same point O., • However, if the reflector is tilted by, an angle θ, then the reflected rays, makes an angle 2*θ and converges at, point O’., OO’ = (2* θ)*(f), where f is focal length

Page 27 :

Autocollimator (Cond.), • Sensitivity and angular measuring range, depend on focal length and the effective, aperture., • A large separation might cause the reflected, rays to completely miss the lens and no image, will be formed.

Page 28 :

• A cross line target graticule is positioned at the focal plane of telescope, objective., • Rays of light reach the objective via beam splitter and are projected from, objective as parallel., • A proportion of the returned light passes straight through the beam, splitter and the return image of the target crossline is therefore visible, through the eyepiece., • The linear displacement of the graticule image is measured by an, eyepiece graticule , optical micrometer or electronic detector system ,, scaled directly in angular units.

Page 29 :

• Visual Autocollimator, – Reflected image of a pinhole light source gives the displacement., – Resolution: 3-5” over a distance of 1.5m, , • Digital Autocollimator, – An electronic photo-detector detects the reflected light., – Output may be transferred to a data acquisition system, – Resolution up-to 0.01 arc-second, , • Laser Auto-collimator, –, –, –, –, , Ideal for measuring angles of small objects (1mm diameter), Long measuring range (15m or more), Better accuracy, Can be used for non- mirror finish surface.

Page 30 :

• Measurement of straightness and flatness., • Precise angular indexing in conjuction with, polygons., • Comparative measurement using master, angles., • Assessment of squareness and parallelism of, components., • Measurement of small linear dimensions.

Page 31 :

Angle Dekkor, • Used as a comparator, • Working, – Image of an illuminated scale in the focal, plane of the collimating lens is projected as a, parallel beam by the collimating lens after, striking a reflector., – In the field of view of microscope, another, datum scale is fixed across the center of, screen., – Changes in angular position of the reflector in, two planes are indicated by changes in the, point of intersection of the two scales., , • Accuracy: up-to 1’., • It is used in combination with angle, gauges to., – Measure angle of a component, – For precise angular setting for machining, operations., – Checking the sloping angle of a V-block