Page 1 :

Subject Name: Physical Pharmaceutics –II Module -IV, Subject Code: BP 403T, , Objectives of the course, , , , Understand various physicochemical properties of drug molecules in the designing the dosage, forms, , Learning outcomes, Students learnt about the properties, nature and general characteristics of particles and, powder.

Page 2 :

Structure of Module –IV BP 403T, Learning Material, , MicromereticsParticle size and distribution, mean particle size, number and weight distribution, particle number,, methods for determining particle size by different methods, counting and separation method, particle, shape, specific surface, methods for determining surface area, permeability, adsorption, derived, properties of powders, porosity, packing arrangement, densities, bulkiness and flow properties.

Page 3 :

1

Page 4 :

Micromeritics & Powder Technology:, Preformulation & formulation aspects, , , , , , , , Syllabus, Basics of micromeritics- Fundamental and derived, properties of powders and their measurementparticle shape & size, surface area, densities, flow, properties, packing properties, fluidization of, powders., Large scale manufacturing aspects- Unit operations, and equipment used: Size reduction, size separation,, powder mixing, segregation of mixed powders;, packaging & Q.C. of powders., Brief coverage of following powders- Dusting, powders,, Oral rehydration powders, Dry syrup, 2

Page 5 :

What is Micromeritics?, The Science and Technology of small, particles is known as Micromeritics., It is the study of various characteristics like, Particle size and size distribution, Particle shape and surface area, Porosity, Density, Flow property etc…, , 3

Page 6 :

Need/ Importance/ Application of, Micromeritics, , , Knowledge and control of the size and the size, range of particle is of profound importance in, pharmacy, Size and surface area can be related to the, physical, chemical and pharmacological, properties of a drug., 1. Drug release and dissolution: Particle size affects, drug release from dosage forms that are, administered orally, parenterally, rectally and, topically., Higher, surface, area, brings, about, intimate, 4

Page 7 :

Need/ Importance/ Application of, Micromeritics, 2. Absorption and drug action: Particle size and, surface area influence the drug absorption and, subsequently the therapeutic action. Higher the, dissolution faster the absorption. Hence quicker, the drug action, 3. Physical stability : Particle size influences the, physical stability of suspensions and emulsions., Smaller the size better is the physical stability (as it, would take more time for particles to agglomerate), 5

Page 8 :

4. Dose uniformity: Particle size and shape, also governs flow properties of powders and, granules in tabletting., Any interference in the flowability of, powders or granules may alter the weight of, the powder blend and thus amount of drug, incorporated into the tablet or capsules and, thereby reduce the uniformity of the dose., , 6

Page 9 :

Examples…, Reduction of particles size improves surface area, and can help in improving solubility of certain, drugs. e.g. The solubility of Griseofulvin can be, greatly increased by particle size reduction., Reduction, , of particles size can increase the rate of, absorption of and consequently bioavailability of, many drugs e.g. tetracycline, aspirin and, sulphonamides, nitrofurantoin etc.., 7

Page 10 :

Properties of Powders, 1., , Fundamental properties :-These, properties relate to the individual particle., , 2., , Derived properties :- They are dependent, on fundamental properties & define the, factors relating to their measurement., , 8

Page 11 :

Fundamental properties:1., Particle size and size distribution, 2., Particle shape, 3., Particle surface area, 4., Particle weight, 5., Particle number, Derived properties:, 1., Density of powders (a) bulk density (b)tapped, density (c) granular density (d)true density, 2., Flow properties of powders, 3., Porosity, 4., Bulkiness, 9

Page 12 :

Fundamental properties of, powders, , 10

Page 13 :

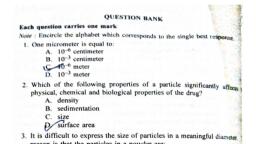

I. Particle size, , , Denoted in micrometers, (formerly called as microns), One micrometer is equal to 10-3 mm or 10-6 m, One millimicrometer is called one nanometer (nm), One nanometer = 10-9 m or 10-6 mm or 10-3 µm, , 1 m = 1000 mm, 1 mm = 1000 µm, 1 µm = 1000 nm, 11

Page 14 :

Particle size determination (PSD) -Methods, 1., , 2., 3., 4., , 12, , Optical Microscopy, Sieving Method, Sedimentation Method, Conductivity Method

Page 15 :

1. Optical Microscopy, , , , , , , , Particle size in the range of 0.2 – 100 µm can be, measured., This method gives number distribution which can be, converted to weight distribution, Optical microscope lens has limited resolving power, Advanced microscopes have better resolving power and, can measure size in nano range: Ultramicroscope,, Electron microscope- Scanning Electron microscope, (SEM), Transmission Electron microscope (TEM)., Application: Particle size analysis in suspensions,, 13, aerosols,, globule size analysis in emulsion

Page 16 :

Procedure:, 1. Eye piece of the microscope is fitted with a, micrometer., 2. This eye-piece micrometer is calibrated using a, standard stage micrometer., 3. The powder sample is dispersed in a suitable, vehicle in which it does not dissolve and its, properties are not altered. (eg. water, paraffin oil.), 4. This sample is mounted on a slide and placed on, the stage under the objective of microscope., 5. Around 625 particles are visualized. their, diameter, is noted and mean is computed., 14

Page 17 :

15

Page 18 :

16

Page 19 :

17

Page 20 :

18

Page 21 :

Advantages, , , One can view particles, Any aggregates detected, Contamination of particles detected, Use of cover slip for arresting motion of particles, Easy and simple, Disadvantages, , , Length and breadth can be detected but depth or, thickness of particles cannot be measured, Slow- time consuming , tedious, inaccurate, Number of particles to be measured is more, 19, Large sample required

Page 22 :

2. Sieving Method, Sieving method is an ordinary and simple, method., It is widely used as a method for the particle, size analysis, Sieve analysis is usually carried out using dry, powders. Although, for powders in liquid, suspension or which agglomerate during dry, sieving, a process of wet sieving can be used., , , 20

Page 23 :

Sieving, , method directly gives weight, distribution., It find application in dosage form, development of tablets and capsules., Normally, 15% of fine powder should be, present in granulated material to get, proper flow of material and achieve good, compaction., Thus percent of coarse, moderate, fine, powder is estimated by this method., 21

Page 24 :

Method:, , Sieve analysis utilizes a wire mesh made of, brass, bronze or stainless steel with known, aperture (hole) diameters which form a, physical barrier to particles., The standard sieve sizes are as per the, pharmacopoeia, Most sieve analyses utilize a series, stack, (layer) of sieves which have the coarser, mesh at the top of the series and smallest, mesh at the bottom above a collector tray, (The, mesh size goes on decreasing from top, 22,

Page 25 :

Method:, A sieve stack usually comprises 6-8 sieves., Powder is loaded on to the coarsest sieve of the, stack and then it is subjected to mechanical, vibration for specified time, eg 20 minutes., After this time, the powder retained on each, sieve is weighed, The particles are considered to be retained on, the sieve mesh with an aperture corresponding, to the sieve diameter., The size is estimated as per the standards, given in pharmacopoeia, 23

Page 26 :

24

Page 27 :

25

Page 28 :

26

Page 29 :

27

Page 30 :

, , Care should be taken to get reproducible results., The type of motion, time of operation, speed,, weight of powder should be fixed and standardized., AdvantagesInexpensive, Simple, Rapid,, Reproducible results (if parameters are, standardized), Disadvantages- lower limit is 50 microns, Powder if moist, can cause clogging of apertures, Attrition between particles during the process may, cause, size reduction giving inaccurate results., 28

Page 31 :

3. Sedimentation Method, In this method particle size can be determined, by examining the powder as it sediments out., Sample preparation: Powder is dispersed in, a suitable solvent, If the powder is hydrophobic, it may be, necessary to add dispersing agent to aid, wetting of the powder., In case where the powder is soluble in water it, will be necessary to use non- aqueous liquids, or carry out the analysis in a gas., , , 29

Page 32 :

Principle of Measurement, Particle size analysis by sedimentation method, can be divided into two main categories, according to the method of measurement, used., One of the type is based on measurement of, particle in a retention zone., Another type uses a non-retention, measurement zone., An example of a non-retention zone, measurement is known as the pipette method., 30

Page 33 :

Andreasen pipette method:, One, , of the most popular of the pipette, methods was that developed by, Andreasen and Lundberg and commonly, called the Andreasen pipette., In this method , known volumes of, suspension are drawn off and the, concentration differences are measured, with respect to time., It involves measuring the % of solids that, settle with time in a graduated vessel., 31

Page 34 :

Construction:, The Andreasen fixed-position pipette, consists of a 200 mm graduated cylinder, which can hold about 500 ml of suspension, fluid., A pipette is located centrally in the cylinder, and is held in position by a ground glass, stopper so that its tip coincides with the, zero level., A three way tap allows fluid to be drawn, into a 10 ml reservoir which can then be, emptied, into a beaker or centrifuge tube., 32

Page 35 :

Method:, A 1% suspension of the powder in a suitable, liquid medium is placed in the pipette., At a given intervals of time, samples are, withdrawn from a specified depth without, disturbing the suspension., The amount of powder can be determined by, weight following drying or centrifuging;, alternatively, chemical analysis of the, particles can be carried out., 33

Page 36 :

, , The particle size is determined in terms of stokes’, diameter (the diameter of a particle measured during, sedimentation at constant rate) using modified, Stokes' equation., , , , dst: stokes’ diameter, n: viscosity of medium, h: sedimentation height, ps- pf: difference in density of particle and fluid, Fg: force of gravity, t: sedimentation time, , , , , , , , 34

Page 37 :

A pipette is located centrally in the cylinder, and is held in position by a ground glass, stopper so that its tip coincides with the zero, level., A three way tap allows fluid to be drawn into, a 10 ml reservoir which can then be emptied, into a beaker or centrifuge tube., The amount of powder can be determined by, weight following drying or centrifuging., The data of cumulative weight is used for the, determination of particle weight distribution,, 35, number, distribution etc..,

Page 38 :

36

Page 39 :

The, , second type of sedimentation size, analysis, using retention zone methods,, also uses Stokes' law to quantify particle, size., One of the most common retention zone, methods uses a sedimentation, balance., In this method the amount of, sedimented particles falling on to a, balance pan suspended in the fluid is, recorded., 37

Page 40 :

4. Conductivity methods, There are various subtypes. Two popular methods are Electrical stream sensing zone method, (Coulter counter), Laser light scattering methods, It is based on the principle of change in light, intensity. The measurement of this change in, light intensity gives estimate of particle size., , 38

Page 41 :

Electrical stream sensing zone method(Coulter, counter), Sample Preparation:, Powder samples are dispersed in an electrolyte, to form a very dilute suspension., The suspension is usually subjected to, ultrasonic agitation to break up any particle, agglomerates., A dispersant may also be added to aid particle, deagglomeration., 39

Page 42 :

Electrical stream sensing zone method(Coulter, counter), Method, The particle suspension is drawn through an, aperture accurately drilled through a sapphire, crystal set into the wall of a hollow glass tube., Electrodes, situated on either side of the, aperture are surrounded by an electrolyte, solution., These electrodes monitor the change in, electrical signal which occurs when a particle, momentarily occupies the orifice and displaces, 40, its own volume of electrolyte.

Page 43 :

Electrical stream sensing zone method(Coulter, counter), Method, The, , volume of electrolyte fluid which is, displaced in the orifice by the presence of, a particle causes a change in electrical, resistance between the electrodes which, is proportional to the volume of the, particle., , 41

Page 44 :

Advantage:, Particle size ranging from 0.5 – 500 microns, Gives number distribution, Particle volume measured, and can be converted to diameter., Accurate, sensitive, fast technique., 4000 particles per second can be counted., Disadvantage, Expensive, , 42

Page 45 :

43

Page 46 :

44

Page 47 :

II. Particle Shape Determination, Particle shape also has influence on surface area,, flow properties, packing and compaction of the, particles., Spherical particles have minimum surface area, and better flow properties., Shape can also have influence on rate of, dissolution of drugs., Techniques of determination are:, Microscopy (refer in particle size determination), 45, Light scattering

Page 48 :

46

Page 49 :

III. Surface Area Determination, 1. Adsorption method:, Surface area is most commonly determined based on, Brunauer-Emmett-Teller (BET) theory of adsorption., Most substances adsorb a monomolecular layer of gas, under certain conditions of partial pressure of gas and, temperature., The adsorption process is carried out at liquid nitrogen, temperatures -196˚C., Once surface adsorption has reached equilibrium, the, sample is heated at RT and Nitrogen gas is desorbed. Its, volume is measured., As each N2 mol. occupies fixed area, one can compute, surface area of pre-weighed sample., 47

Page 50 :

Surface Area Determination, 2. Air Permeability method:, , , Powder is packed in sample holder, Packing appears as series of capillaries, Air is allowed to pass through the capillaries at, constant pressure, Resistance is created as air passes through, capillaries thus causing pressure drop., Greater the surface area greater the resistance, Air permeability is inversely proportional to, the surface area, 48

Page 51 :

Manometer, , 49

Page 52 :

, , Surface area of a powder can be calculated using, particle size data obtained from any suitable method., Specific surface area i.e. surface area per unit weight, (Sw) or unit volume (Sv) can be estimated as follows:, Sv = surface area of particles, volume of particles, Sv = no. of particles x surface area of each particle, no. of particles x volume of each particle, Surface area is an important parameter as the, bioavailability of certain drugs is dependant on surface, area. eg. Bephenium (anthelminitic), Griseofulvin (antifungal)- if the surface area is less than specified, the, absorption decreases., 50

Page 53 :

Derived properties of, powders, , 51

Page 54 :

Derived properties of powders, Size, , or diameter is a fundamental, property of a particle., Volume, density, porosity etc. are the, properties derived from fundamental, properties., e.g. Volume can be calculated from the, diameter of the particle (4/3 πr3)., However, derived properties can also, be calculated without the use of, fundamental properties., 52

Page 55 :

DENSITY, , , Apparent bulk density- is determined by, pouring presieved (40#) bulk drug into a, graduated cylinder via a funnel and note the, volume as is (g/ml) without subjecting to any, external force., , , , Tapped density: The cylinder is subjected to, fixed no. of taps on a mechanical tapper, apparatus (approx. 100) until the powder bed, has reached minimum., (useful for determining the appropriate size for, capsule formulation), 53

Page 56 :

Bulk Density Apparatus, Bulk density, , = Mass of the powder, Bulk volume, , Tapped bulk density, = Mass of the powder, , Tapped Bulk volume, , 54

Page 57 :

Applications, , , Decides the size of the capsule based on bulk, and tapped volume of a given sample, , , Higher the bulk volume, lower the bulk density, , and bigger the size of the capsule, , , Helps to decide proper size of a container or, packing material, , 55

Page 58 :

, , , , Light powders, , , When particles packed loosely, , , , Lots of gaps between particles, , , , Bulk volume increases, , Light powders have high bulk volume, , , 56, , hence low density

Page 59 :

DENSITY, , , True density: Volume occupied by voids (interparticle spaces) and intraparticle pores are not, included in this measurement., , , , Calculated by suspending drug in solvents of, various densities & in which the compound is, insoluble., , , , After vigorous agitation, samples are, centrifuged briefly, and then left to stand, undisturbed till settling/ flotation has reached, equilibrium. The sample that remains, suspended corresponds to the true density of, the material. Calculated with a pycnometer., 57

Page 60 :

TRUE DENSITY DETERMINATION, , , Helium displacement method (for porous, powders), , , , Liquid displacement method (for non porous, powders), , 58

Page 62 :

Helium displacement Method, Helium gas is selected as it does, not adsorb on solid sample., It enters the pores., very useful for estimating the true, density of porous solids, , 60

Page 63 :

, , Helium Pycnometer, , , , , , 61, , Sample holder (A), Valve (B), Pressure detector (C), Piston (D)

Page 64 :

Sample holder, Sealed after placing the sample, Valve, Connected to sample holder, Has provisions for removing air from the, sample holder and introducing helium, gas, Pressure detector, Maintains preset constant pressure, Piston, Reads the corresponding pressure, It is also related to the volume of the, 62,

Page 65 :

Working:, Air in the sample holder removed by vacuum, Helium gas introduced through valve, Pressure adjusted and set at particular value, with the help of piston, At this position, the reading on the scale, denotes U1, U1 = volume of empty sample holder, , 63

Page 66 :

, , , , , , , Place standard known true volume Vstd of stainless, steel spheres, Air removed and helium gas introduced through, valve, Pressure adjusted to preset value with the help of, piston, At this position, the reading on the scale denotes, U2, The difference between U1 and U2 gives the, volume occupied by the standard., The last step involves determination of volume of, sample. The standard is replaced with sample and, the, reading is noted, Us., 64

Page 68 :

Powder flow properties, , , P’ceutical powders may be broadly classified, as free-flowing or cohesive., , , , Most flow properties are significantly affected, by changes in particle size, density,, electrostatic charges, adsorbed moisture., , , , Good flow property is required for easy and, uniform flow from hopper to die cavity, ensuring accurate weight and dose., 66

Page 69 :

Angle of repose is calculated for estimating flow, properties., , It is defined as the maximum angle possible, between the surface of a pile of the powder, and the horizontal plane, , 67

Page 70 :

68

Page 71 :

Powder flow properties estimation, , , , , , Simple flow rate apparatus consisting of a metal tube from which, drug flows through an orifice onto an electronic balance, which is, connected to a recorder., Angle of repose determination using reposograph, Another method is % compressibility (Carr’s index), = (bulk volume- tapped volume) x 100, bulk volume, , Hausner’s, , ratio = tapped density/ Bulk density, Or, Bulk volume/ tapped volume, 69

Page 72 :

Compres, sibility, Flow, Index, Characte, (%), r, 10, , Excellent, , Hausner, Ratio, , Flow Property, Excellent, , Angle of, Repose, (degrees), 25–30, , 1.00–1.11, Good, , 31–35, , Fair—aid not, needed, , 36–40, , 11–15, , Good, , 1.12–, 1.18, , 16–20, , Fair, , 1.19–, 1.25, , 21–25, , Passable, , 1.26–, 1.34, , Passable—may, hang up, , 41–45, , 26–31, , Poor, , 1.35–, 1.45, , Poor—must agitate,, vibrate, , 46–55, , 32–37, , Very poor, , 1.46–, 1.59, , Very poor, , 56–65, , >38, , Very, very, poor, , >1.60, Very, very poor, 70, , >66

Page 73 :

Packing properties (Porosity), , , Porosity definition: It is the ratio of the volume, of voids between particles, plus the volume of, pores, to the total volume occupied by, the powder, including voids and pores., , , , A set of particles can be filled into a volume of space in, different ways., This is because by slight vibration, particles can be, mobilized and can occupy a different spatial volume, than before., This changes the bulk volume because of, rearrangement of the packing geometry of the, particles., 71, In general, such geometric rearrangements, result in a, , , , , ,

Page 74 :

Packing properties (Porosity), , , , , , , , , Example: : A set of monosized spherical particles can be, arranged in many different geometric configurations., In Fig.a, when the spheres form a cubic arrangement, the, particles are most loosely packed and have a porosity of, 48%, In Fig.b, when the spheres form a rhombohedral, arrangement, they are most densely packed and have a, porosity of only 26%, The porosity used to characterize packing geometry is linked, to the bulk density of the powder., ., 72

Page 75 :

73

Page 76 :

Packing properties (Porosity), , , , , , Thus bulk density, is a characteristic of a powder rather than, individual particles and can be variable., The bulk density of a powder is always less than the, true density of its component particles because the, powder contains interparticle voids., Thus, powder can possess a single true density, but can have many different bulk densities,, depending on the way in which the particles are, packed and the bed porosity., , 74

Page 77 :

Powder fluidization, Fluidization can be a highly effective method for, handling a fine bulk material in an aerated or liquidlike condition. Air or another gas can be used for, powder fluidization either in a fully fluidized state or, only in a localized manner with small amounts of gas, flow., Typical bulk solids suitable for fluidization have a fine, particle size, a low permeability, and low cohesive, strength., Advantages:, Elimination or reduction of poor flow problems of, powder, Increased discharge rate from hopper, 75, Reduction in mixture segregation,

Page 78 :

Large Scale Equipment, , 76

Page 79 :

I. Particle-size reduction, The need of size reduction can be to improve, solubility thus improve its bioavialability. In, case of disperse systems, it helps in improving, stability (discussed earlier)., The function of size reduction may also be to, aid efficient processing of solid particles by, facilitating better powder mixing., There are also some special functions of size, reduction, such as reducing the bulk volume of, a material to improve transportation efficiency., , , 77

Page 80 :

Size Reduction methods, 1. Cutting method: Cutter mill, 2., , Compression method: Endrunner and edge, runner mill, , 3., , Impact method:, , Hammer mill, vibration, , mill, 4., , Attrition method: Roller mill, , 5., , Combined impact and attrition: ball mill,, Fluid energy mill, , 78

Page 81 :

Size Reduction methods, 1. Cutting method- Cutter mill, , A cutter mill consists of a series of rotating, knives attached to a horizontal rotor which act, against a series of stationary knives, attached to the mill casing., During milling, size reduction occurs by, fracture of particles between the two sets of, knives, which have a clearance of a few, millimetres., A screen is fitted in the base of the mill casing, and, acts to retain material in the mill until a, 79,

Page 82 :

The high shear rates, present in cutter mills, are useful in producing, a coarse degree of, size reduction of dried, granulations prior to, tableting., Used for fibrous crude, drugs such as roots,, peels or barks prior to, extraction., , , 80

Page 83 :

Cutter mill, , 81

Page 84 :

II. Compression method, , , , , , , , Size reduction by compression can be carried out on, a small scale using a mortar and pestle., End-runner and edge-runner mills are mechanized, forms of mortar and pestle., In the end-runner mill a heavy pestle is turned by, the friction of material passing beneath it as the, mortar rotates under power., The edge-runner mill has the pestles mounted, horizontally. It rotates against a bed of powder, so, that size reduction occurs by attrition as well as, compression., Scrapers are employed in scraping the material, constantly, from the bottom of the vessel. Such, 82

Page 85 :

83

Page 86 :

III. Impact method, Size reduction by impact is carried out using a, hammer mill., Hammer mills consist of a series of four or, more hammers, hinged on a central shaft, which is enclosed within a rigid metal case., During milling the hammers swing out radially, from the rotating central shaft., The velocity of the hammer is so high that, most particles undergo brittle fracture., , , 84

Page 87 :

Impact method, Hammer mills tend to produce powders with, narrow size distributions., Particles are retained within the mill by a, screen, which allows only adequately, comminuted particles to pass through., According to the purpose of the operation, the, hammers may be square-faced, tapered to a, cutting edge or have a stepped form., , , 85

Page 88 :

Hammer mill, , 86

Page 89 :

Vibration mill, •Vibration mills, are filled with, porcelain or, steel balls., •During milling, the whole body, of the mill is, vibrated, , 87, , •Size reduction, occurs by, repeated

Page 90 :

IV. Attrition method, Roller mills use the principle of attrition to, produce size reduction of solids in, suspensions, pastes or ointments., Two or three porcelain or metal rolls are, mounted horizontally with an adjustable gap,, which can be as small as 20 µm., The rollers rotate at different speeds in, counter-clockwise manner so that the material, is sheared as it passes through the gap and is, transferred from the slower to the faster roll,, from which it is removed by means of a, 88, scraper.,

Page 91 :

89

Page 92 :

V. Combined impact and attrition methods, A ball mill is an example of a comminution, method which produces size reduction by both, impact and attrition of particles., Ball mills consist of a hollow cylinder mounted, such that it can be rotated on its horizontal, longitudinal axis., Mills usually contain balls with many different, diameters owing to self-attrition, and this helps, to improve the product as the large balls tend to, break down the coarse feed materials and the, smaller balls help to form the fine product by, 90, reducing, void spaces between balls.,

Page 93 :

91

Page 94 :

V. Combined impact and attrition methods, The amount of material in a mill is of, considerable importance: too much feed, produces a cushioning effect and too little, causes loss of efficiency and abrasive wear of, the mill parts., The factor of greatest importance in the, operation of the ball mill is the speed of, rotation., At low velocities- balls move with drum and, very little relative movement of balls is, achieved, so the size reduction is minimal., 92,

Page 95 :

V. Combined impact and attrition methods, At high angular velocities the balls are thrown, out on to the mill wall by centrifugal force and, no size reduction occurs., At about two-thirds of the critical angular, velocity where centrifuging occurs, a, cascading action is produced., By this means, the maximum size reduction, occurs by impact of the particles with the balls, and by attrition., , , 93

Page 96 :

low velocity, , 94, , high velocity, , moderate velocity

Page 97 :

V. Combined impact and attrition methods, Fluid energy milling is another form of sizereduction method which acts by particle, impaction and attrition., This type of mill or 'micronizer‘ consists of a, hollow toroid (structure with a hole; like a, doughnut) which has a diameter of 20-200 mm,, depending on the height of the loop, which, may be up to 2 m., A fluid, usually air, is injected as a highpressure jet through nozzles at the bottom., 95, The, high velocity of the air gives rise to zones,

Page 98 :

V. Combined impact and attrition methods, The high kinetic energy of the air causes the, particles to impact -with other particles, with sufficient momentum for fracture to occur., Turbulence ensures that the level of particleparticle collisions is high enough to produce, substantial size reduction by impact and, some attrition., A particle size classifier is incorporated in, the system so that particles are retained in the, toroid until sufficiently fine and remain, entrained, in the air stream that is exhausted, 96,

Page 99 :

97

Page 100 :

98

Page 101 :

Particle-size separation, , 99

Page 102 :

II. Particle-size separation, Size separation is a process by which powder, particles are classified into separate particle, size ranges., SIZE-SEPARATION METHODS, 1. Size separation by sieving, 2. Size separation by fluid classification, , , , , , , Sedimentation method, Elutriation method, Cyclone methods, 100

Page 103 :

Size separation by sieving, Principle and construction:, Same as described in size reduction, 1., , The use of sieving in size separation usually, requires processing of larger volumes of, powder than are commonly found in size, analysis operations., For this reason, the sieves used for size, separation are often larger in area than, those used for size analysis., , , 101

Page 104 :

Size separation by sieving, There are several techniques for separating, particles into their appropriate size fractions, efficiently., 1. Agitation methods- Size separation is achieved, 1., , by electrically induced oscillation or, mechanically induced vibration of the sieve, meshes, or alternatively by gyration, in which, sieves are fitted to a flexible mounting which is, connected to an flywheel., The rotation of the flywheel imparts a rotary, movement of high intensity to the sieve and, causes, the particles to spin, thereby continuously, 102

Page 105 :

103

Page 106 :

1., , , Size separation by sieving, Brushing methods- A brush is used to re-, , orientate particles on the surface of a, sieve and prevent apertures becoming, blocked., A single brush can be rotated about, the midpoint of a circular sieve or, for, large-scale processing, a horizontal, cylindrical sieve, is employed, with a, spiral brush rotating about its, longitudinal axis., 104

Page 107 :

105

Page 108 :

1., , , Size separation by sieving, Centrifugal methods - Particles are thrown, , outwards on to a vertical cylindrical sieve, under the action of a high-speed rotor, inside the cylinder., The current of air created by the rotor, movement also assists in sieving,, especially where very fine powders are, being processed., , 106

Page 109 :

II. Size separation by fluid classification, 1. Sedimentation method, Size separation by sedimentation utilizes the, differences in settling velocities of particles, with different diameters, and these can be, related according to Stokes‘ equations, eg. use of Andreasen pipette:, Disadvantages of this method is that they it is, a batch processes and discrete particle, fractions cannot be collected, as samples do, not contain specific size ranges., 107

Page 110 :

Sedimentation method, An alternative technique is to use a, continuous settling chamber so that, particles in suspension enter a shallow, container, in a streamline flow., Particles entering at the top of the chamber, are acted upon by a driving force which can, be divided into two components:, A horizontal component equal to the, suspension fluid velocity, and a, A vertical component which corresponds to, Stokes' settling velocity and is different for, 108, each particle size, 1.

Page 111 :

1., , Sedimentation method, , The, , coarsest particles will have the, steepest settling paths and will sediment, closest to the inlet, whereas the finest, particles with low Stokes velocity, component will have the shallowest, settling paths and will sediment, furthest from the fluid suspension, feed stream, Particles separated into the different, hopper-type discharge points can be, removed continuously., 109

Page 112 :

110

Page 113 :

II. Elutriation method, Principle:, In sedimentation methods the fluid is stationary, and the separation of particles of various sizes, depends solely on particle velocity., Therefore, the division of particles into size, fractions depends on the time of, sedimentation., Elutriation is a technique in which the fluid, flows in an opposite direction to the, sedimentation movement, so that in, gravitational elutriators particles move, 111, vertically downwards while the fluid travels

Page 114 :

II. Elutriation method, Principle:, If the upward velocity of the fluid is less, than the settling velocity of the particle,, sedimentation occurs and the particle, moves downwards against the flow of fluid., Conversely, if the settling velocity of the, particle is less than the upward fluid velocity,, the particle moves upwards with the fluid flow., Therefore, in the case of elutriation,, particles are divided into different size, fractions, depending on the velocity of the, 112

Page 115 :

II. Elutriation method, Air may be used as the counter-flow fluid in, place of water for elutriation of soluble particles, into different size ranges., There are several types of air elutriator, which, differ according to the airflow patterns used., Particles are held on a supporting mesh through, which air is drawn., The desired particle size fraction can be, separated by selecting the appropriate, airflow rate and rotor speed., , , 113

Page 117 :

III. Cyclone methods, Cyclone separation can take the form of a, centrifugal elutriation process or a centrifugal, sedimentation process in which particles, sediment out of a helical gas or liquid, stream., The most common type of cyclone used to, separate particles from fluid streams is the, reverse-flow cyclone., In this system, particles in air or liquid, suspension are often introduced tangentially, into the cylindrical upper section of the cyclone,, 115, where, the relatively high fluid velocity produces

Page 118 :

II. Cyclone methods, Coarser, , particles separate from the fluid, stream and fall out of the cyclone through, the particle outlet, whereas finer particles, remain entrained in the fluid stream and, leave the cyclone through the vortex, finder., A series of cyclones having different flow, rates or different dimensions could be, used to separate a powder into different, particle-size ranges., 116

Page 119 :

Reverse-flow cyclone separator, , 117

Page 120 :

III. Powder Mixing and Demixing, , 118

Page 121 :

Powder Mixing, The importance of mixing, Pharmaceutical products contain several, ingredients to formulate required dosage form, eg. Tablets contain variety of excipients likediluents, binders, disintegrants and lubricants, Whenever a product contains more than one, component a mixing or blending stage is, required to ensure an even distribution of the, active component for uniform drug, distribution and release at a desired rate, for, even appearance, etc, 119

Page 122 :

Mixing, Pharmaceutical mixing may be defined as a unit, operation that aims to bring each component as, near as possible to each unit of the other, components., If this is achieved it produces a theoretical 'ideal‘, situation, i.e. a perfect mix., , 120

Page 123 :

Powder segregation (demixing), Segregation is the opposite effect to mixing, i.e., components tend to separate out., Care must be taken to avoid segregation during, handling after powders have been mixed, e.g., during transfer to filling machines, or in the, hopper of a tablet/capsule/sachet-filling, machine., Segregation will cause an increase in content, variation , weight variation in samples causing, a batch to fail a uniformity of content test., 121

Page 124 :

Reasons for Powder segregation (demixing), Segregation arises because powder mixtures, are not composed of mono-sized spherical, particles, but contain particles that differ in, size, shape and density., These variations mean that particles will tend to, behave differently when forced to move and, hence, tend to separate., Segregation is more likely to occur, if the, powder bed is subjected to vibration., Reasons are – particle size effects, density, effects, shape effects.., 122

Page 125 :

Particle-size effects, A difference in the particle sizes of components, of a formulation is the main cause of, segregation in powder mixes in practice., Smaller particles tend to fall through the voids, between larger ones and so move to the bottom, of the mass., This is known as percolation segregation. eg, in cereal packets or jars of coffee, where the, smaller 'particles' settle towards the bottom of, the container, 123

Page 126 :

Particle-size effects, During mixing, larger particles will tend to have, greater kinetic energy imparted to them (owing, to their larger mass) and therefore move greater, distances than smaller particles before they, come to rest., This may result in the separation of particles of, different size, an effect referred to as trajectory, segregation., , 124

Page 127 :

Particle-size effects, During mixing, or when a material is discharged, from a container, very small particles ('dust'), tends to be 'blown' upwards by turbulent air, currents, and remains suspended in the air., When the mixer is stopped or material, discharge is complete, these particles will, sediment and subsequently form a layer on top, of the coarser particles., This is called elutriation segregation and is, also referred to as 'dusting out'., 125

Page 128 :

Particle-density effects, If components are of different density, the more, dense material will have a tendency to move, downwards even if the particle sizes are similar., Particle-shape effects, Spherical particles exhibit the greatest, flowability and are therefore more easily mixed,, but they also segregate more easily than nonspherical particles., Irregularly or needle-shaped particles may, become interlocked, reducing the tendency to, 126, segregate, once mixing has occurred.

Page 129 :

Approaches to reduce/ prevent segregation, Selection of particular size fractions (e.g. by, sieving to remove fines or lumps) to achieve, drug and excipients of the same narrow particle, size range;, Size reduction (Milling of components) to, reduce the particle size (excessive size, reduction should be avoided), Controlled crystallization during production of, the drug/excipients to give components of a, particular crystal shape or size range., 127

Page 130 :

Selection of excipients which have a density, similar to the active component (s), Granulation of the powder mixture (size, enlargement) so that large numbers of different, particles are evenly distributed in each granule., Reduce the extent to which the powder mass is, subjected to vibration or movement after mixing;, Use equipment where several operations can, be carried out without transferring the mix, e.g., a fluidized-bed drier or a high-speed mixer, , , 128

Page 131 :

Powder mixing equipment, 1., 2., 3., 4., , Tumbling mixers/blenders, High-speed mixer-granulators, Fluidized-bed mixers, Agitator mixers, , 129

Page 132 :

Tumbling mixers/blenders, Tumbling mixers are commonly used for the, mixing/blending of granules or free-flowing, powders., There are many different designs of tumbling, mixer, e.g. double-cone mixers, twin-shell, mixers, cube mixers, Y-cone mixers and, drum mixers etc (see diagram), Mixing containers are generally mounted so that, they can be rotated about an axis., When operated at the correct speed, the, desired tumbling action is achieved., 1., , 130

Page 133 :

Tumbling mixers/blenders, Too high a rotation speed will cause the material, to be held on the mixer walls by centrifugal, force, and too low a speed will generate little, shear mixing., The addition of 'prongs', baffles or rotating, bars also helps in good mixing., Tumbling mixers are available from approx 50 g,, e.g. for laboratory-scale development work, to, over 100 kg at a production scale., The rate of mixing depends on mixer design., The material typically occupies about a half to, 131, 2/3rd of the mixer volume., 1.

Page 134 :

Tumbling mixers/blenders, Tumbling mixers are good for free-flowing, powders/granules but poor for cohesive/poorly, flowing powders., A common use of tumbling mixers is in the, blending of lubricants, glidants or external, disintegrants with granules prior to tableting., 1., , 132

Page 135 :

133

Page 136 :

2., , , , , , , , High-speed mixer-granulators, In pharmaceutical product manufacture it is often, preferable to use one piece of equipment to carry, out more than one function., An example of this is the use of a rapid mixergranulator (RMG), As the name suggests, it can both mix and, granulate a product, thereby removing the need to, transfer the product between pieces of equipment, and so reducing the opportunity for segregation to, occur., The centrally mounted impeller blade at the bottom, of 134, the mixer rotates at high speed, throwing the, material towards the wall by centrifugal force.

Page 137 :

High-speed mixer-granulators, The particulate movement within the bowl tends, to mix the components quickly owing to high, shear forces (arising from the high velocity), Once mixed, granulating agent can be added, and granules formed in situ using a slower, impeller speed and the action of the sidemounted chopper blade., Because of the high-speed movement care, must be taken to prevent material fracture., e.g. Diosna® mixer-granulator, 2., , 135

Page 138 :

Diagrammatic representation of a high-speed, mixer-granulator., 136

Page 139 :

3. Fluidized-bed mixers, (construction and diagram: fluid energy mill), The main use of fluidized-bed equipment is in, the drying of granules or the coating of multiparticulates, Fluidized-bed equipment can, however, be used, to mix powders prior to granulation in the same, bowl., Fluidization is achieved by the introduction of, pressurized fluid (can be air, gas or suitable, solvent) through the particulate medium., This results in suspension of particles in fluid,, 137, which can be mixed, separated, or pumped

Page 140 :

4. Agitator mixers, This type of mixer depends on the motion of a, blade or paddle through the product, and hence, the main mixing mechanism is convection., Examples include the ribbon mixer, Nautamixer.,, Planetary mixer., In the ribbon mixer, mixing is achieved by the, rotation of helical blades in a hemispherical, trough. (similar to screw conveyor), The Dead spots' are difficult to eliminate in this, type of mixer and the shearing action caused by, the movement of the blades may be insufficient, to138break up drug aggregates.

Page 141 :

The ribbon mixer, however, mix poorly flowing, material and is less likely to cause segregation, than a tumbling mixer., The Nautamixer consists of a conical vessel, fitted at the base with a rotating screw, which is, fastened to the end of a rotating arm at the, upper end., The screw conveys the material to near the top,, where it cascades back into the mass., The mixer thus combines convective mixing (as, the material is raised by the helical conveyor), and shear and diffusive mixing (as the material, 139, cascades, downwards).,

Page 142 :

Ribbon agitator powder mixer, 140

Page 144 :

QC of Powders, , 142

Page 145 :

QC of Powders (elaborate as per marks), 1., , 2., 3., 4., 5., 6., 7., , Particle size and shape determination, (Methods: Sieving, Sedimentation, Microscopy,, light Scattering etc…), Surface area (BET, air permeability), Density - Bulk density , tapped density, true, density, Granule density, strength and friability, Flow properties- Angle of Repose,, Compressibility Index, Hausner’s ratio, Moisture content, Percentage fines, 143

Page 146 :

QC of Powders, Granule density, strength and friabilityGranule density = Granule weight/ Granule volume, , Granule volume is determined by mercury, displacement method. Mercury is used as it, enters voids but does not enter the pores of, the particles., Mercury also has non wetting characteristics., Method similar to true density determination, Strength – using hardness tester, , , Friability: using friabilator (Roche ® friabilator), 144

Page 148 :

QC of Powders, MOISTURE CONTENT, The amount of moisture present in the granule is, called moisture content., Generally granules contain 2% moisture., It is required for the binding of the powder or, granules during compression in die cavity., Percentage of moisture is calculated by using, moisture balance or IR balance., IR balance consist of simple balance containing, IR bulb which produces heat inside the chamber., 146

Page 149 :

QC of Powders, MOISTURE CONTENT, , , , , , A small amount of sample is placed in IR, balance and weight is recorded (Initial reading), IR balance is operated at specified time and, temperature., Sample is reweighed (Final reading), Moisture content = [(Initial weight – Final, weight )/ Initial weight] * 100, , 147

Page 150 :

148

Page 151 :

QC of Powders, PERCENTAGE FINES, Fines indicate particles of very minute size., Fine powder is necessary for the tablet, compression because if 100% granules are, used then it is difficult to maintain hardness of, tablet as they have (voids) free space in the, die cavity and after compression tablet will, crack due to these void spaces., % fines can be calculated by using sieve, method., 149, % fine should not be more than 15%

Page 152 :

Dusting powders,, Oral rehydration powders,, Dry syrup formulations, , 150

Page 153 :

1. Powders, Advantages, Useful for Bulky drug, large dose (e.g., Antacids), Swallowing easy. Tablets are difficult to, swallow for children, elderly., Faster dispersal and absorption of, medicaments, Insoluble drugs which cannot be formulated, as solutions can be given in powder form, Drugs which are unstable in liquid form can, 151 given as powders, be,

Page 154 :

Disadvantages of Powders, Dose accuracy is not there in bulk powders, (1 tsp, 1 tbsp need to be taken)., Difficult to carry/administer, chances of, spillage while opening paper packets, Not suitable for deliquescent (tendency to, absorb moisture), volatile, oxygen sensitive, drugs, Time consuming to manufacture, Cannot completely mask bitter taste, , , 152

Page 155 :

Powders classification, , 1. Bulk, , Divided, (single dose), , 2., , 153, , For Internal use, For External use, (Dusting powder), Simple, Compound

Page 156 :

1. Dusting powders, Dusting powders contain ingredients used for, therapeutic, prophylactic or lubricant purposes, and are intended for external use.., Two types:, 1. Medical dusting powders, 2. Surgical dusting powders, Medical dusting powders, Used for superficial skin conditions, not on, wounds, abraded/ broken skin, Thus sterility not required but it should be free, 154, from, pathogens.,

Page 157 :

Some mineral ingredients like kaolin, talc may be, contaminated with spores of tetanus, gangrene,, anthrax and should be sterilized before use., e.g. Zinc undecenoate dusting powder BPC, (contains light kaolin, starch, zinc, undecenoate… It is antifungal preparation), Surgical dusting powders, , , , , , , Used in body cavities, wounds, burns, umbilical, cord of infants. Thus it should be sterile., Contains antibacterial agent, Diluent used may be sterilisable maize starch, e.g. Chlorhexidine and hexachlorophene dusting, 155

Page 158 :

Dusting powders are normally dispensed in, glass or metal containers with a perforated lid., The powder must flow well from such a, container, so that they can be dusted over the, affected area. The active ingredients must, therefore be diluted with materials having, reasonably good flow properties, e.g. purified, talc or maize starch., Proprietary dusting powders are available,, mostly as antifungal, antibacterial and skin, disinfectants., e.g., Candid Dusting powder, 156,

Page 159 :

Insufflations:, , , , , , , , , It is also a type of dusting powder (for external, use), Insufflation (Latin: insufflare for "to blow into") is, the act of blowing something (such as a gas,, powder, or vapor) into a body cavity, It is used to produce local effect e.g. In treatment, of ear, nose, throat infections or systemic effect, (eg. pituitary insufflation BPC), Diluents used are Lactose, sterilizable maize, starch used, Sterility is required if preparation is for open, 157, wounds or raw surfaces

Page 160 :

Used with an, insufflator., Insufflator blockage, can be a problem, because of, clumping of particles, thus should be, stored in dry place, lack of uniform, dosage is also a, drawback., 158

Page 161 :

ORAL REHYDRATION SALTS, Also knows as Oral rehydration powders/, therapy (ORS/ORT) is a type of fluid, replacement used to prevent and, treat dehydration, especially that due, to diarrhea, It involves drinking water with modest, amounts of sugar and salts, specifically sodium and potassium., Oral rehydration therapy can also be given by, a nasogastric tube in severe, bedridden, 159, patients.,

Page 162 :

ORAL REHYDRATION SALTS, In, , diarrhea, sodium-rich intestinal, secretions are lost before they can be, reabsorbed., This can lead to life, threatening dehydration or electrolyte, imbalances within hours when fluid loss, is severe., The objective of therapy is the, replenishment of sodium and water, losses by ORT or intravenous infusion., 160

Page 163 :

ORAL REHYDRATION SALTS, Oral Rehydration Salts are dry,, homogeneously mixed powders containing, Dextrose, Sodium Chloride, Potassium, Chloride and either Sodium Bicarbonate or, Sodium Citrate for use in oral rehydration, therapy after being dissolved in the requisite, amount of water., They may contain suitable flavouring agents, and, where necessary, suitable flow promoting, agents in the minimum quantity required to, 161, achieve, a satisfactory product.,

Page 164 :

ORAL REHYDRATION SALTS, They should not contain artificial sweetening, agents like mono/ polysaccharides., If saccharin/saccharin sodium or aspartame is, used in preparations meant for paediatric use,, the concentration of saccharin should be such, that its daily intake is not more than 5 mg/kg of, body weight and that of aspartame should be, such that its daily intake is not more than 40, mg/kg of body weight., Refer Journal for formula and role of, 162, ingredients,

Page 165 :

163

Page 166 :

Dry syrup formulations, For patients who have difficulty taking capsules, and tablets, e.g. young children or elderly, a, liquid preparation of a drug offers a suitable, alternative., However, many drugs, e.g. antibiotics, are, physically or chemically unstable when, formulated as a solution or suspension., The method used to overcome this instability, problem is to manufacture the dry ingredients of, the liquid preparation in a suitable container in, the form of a powder or granules., , , 164

Page 167 :

Dry syrup formulations, While consuming the product, stated quantity of, water (given on product label) is added to, reconstitute the solution or suspension., This enables product to remain stable without, degradation., Once it is reconstituted, the preparation should, be used within a few days., Shelf-life of the reconstituted syrup depends on, the stability of API (in general, it can be 1-2, weeks), Examples are Erythroped Suspension and, 165,

Page 168 :

166

Page 169 :

167