Page 1 :

Physical Pharmacy M02 (BP403T), Objectives of the course, Understand various physicochemical properties of drug molecules in the designing the dosage forms, , Learning outcomes, 1), , Students learnt about the behavior of liquid and solid their deformation flow of liquids, determination of, , viscosity of liquids by various viscometers., 2), , Students learnt about the knowledge about terms thixotropy, antithixotropy in various substances which follow, , non Newtonian systems, , Structure of Module -2 Learning Material, Rheology, , , Newtonian systems, law of flow, kinematic viscosity, effect of temperature, , , , Non- Newtonian systems, pseudoplastic, dilatant, plastic, , , , Thixotropy, thixotropy in formulation,, , , , Determination of viscosity, capillary, falling Sphere, rotational viscometers., , Deformation of Solids, , , Plastic and elastic deformation, , , , Heckel equation, Stress, Strain, , , , Elastic Modulus.

Page 4 :

Viscous Fluid

Page 5 :

Viscosity, Viscosity is the resistance of, liquidto flow under stress, Types, , •, •, , Absolute (Dynamic)Viscosity, Kinematic Viscosity

Page 6 :

Viscosity, • Viscosity is the measure of the internal friction, of a fluid., • This friction becomes apparent when a layer of, fluid is made to move in relation to another, layer., • The greater the friction, the greater the, amount of force required to cause this, movement, which is called sheer., • Shearing occurs whenever the fluid is, physically moved or distributed, as in, pouring, spreading, spraying, mixing, etc., • Highly viscous fluids, therefore, require more, force to move than less viscous materials.

Page 7 :

RHEOLOGY, • Science describing the flow, , and deformation of matter under, stress., • Rheo = the flow

Page 8 :

Importance of Rheology, – Formulation of medicinal preparations, – Fluidity (syringebility) of solutions for injection., – Mixing, – Packaging into containers,, – Their removal prior to use, whether by, pouring from a bottle, extrusion from a, tube, –Patient acceptability (compliance),, – Physical stability, and even bio-availability.

Page 9 :

RHEOLOGY, • Rheology describes the deformation of a, body under the influence of stresses., • Ideal fluids such as liquids and gases, deform irreversibly -- they flow, • Ideal solids deform elastically., • The energy required for the, deformation is fully recovered when the, stresses are removed.

Page 10 :

Block of material subjected to, shear, stresses, , Fig. 1

Page 11 :

Terminologies, • Shear: is the movement of, material relative to parallel layer., • Shear stress (F) is the force applied per unit, Area to make liquid flow (Force/Area), • Shear rate (G) difference in velocity, dv, between two planes of liquids, separated by distance dr (i.e. dv/dr), , dv, G, dr

Page 12 :

Newton’s law offlow, • Rate of shear is directly, proportional to shear stress., • In other words, twice the force, would move the fluid twice as fast., Example- Castor oil

Page 13 :

Shear, , Viscosi, , Newtonian, , Shear, stress, , Shear, rate

Page 14 :

FLOW, , NEWTONIAN, , NON-NEWTONIAN

Page 15 :

Newton’s law offlow, • Isaac Newton was the first to express the, basic law of viscometry describing the flow, behavior of an ideal liquid:, , F G, shear stress = viscosity × shear rate

Page 16 :

Absolute (dynamic) viscosity, Viscosity() , , F, G, , • The fundamental unit of, viscosity measurement is the, poise., • Shear force required to produce a, velocity of 1 cm/sec between two, parallel planes of liquid each 1cm2 in, area and separated by 1cm, • Fluidity; it is the reciprocal of viscosity Ø = 1/

Page 17 :

η, its unit is inverse poise.

Page 18 :

Kinematic Viscosity, It is the absolute viscosity divided by the, density of liquid at a specified temperature, , , Kinematic Viscosity , , Where ρ is the density of the, liquid The unit is Stock (s) or, centistock (cs)

Page 20 :

NON-NEWTONIAN SYSTEMS, • A non-Newtonian fluids are those fluids for, which the relationship between F and G is, not a constant for there flow., • The viscosity of such fluids will therefore, change as the shear rate is varied., •, Examples; colloids, emulsions, liquid, suspensions and ointments.

Page 21 :

NON-NEWTONIAN SYSTEMS, THREE CLASSES:, – Dilatant flow, – Pseudoplastic flow, – Plastic flow

Page 22 :

Rheogram, Rheogram is a plot of shear rate,G, as a, function of shear stress, F, Rheogram is also known as consistency, curve of flow curve.

Page 24 :

PLASTIC FLOW, • Associated with flocculated particles or, concentrated suspension., • A Bingham body does not begin to flow until a, shearing stress corresponding to the yield, value is exceeded., • Yield value (f); is an indication of the force that, must be applied to a system to convert it to a, Newtonian System., • Examples; suspension of ZnO in, mineral oil, certain paints, ointments

Page 25 :

Plastic flow Contd…

Page 26 :

Shear, , Plastic Flow, , Shear stress, , Fig. 3

Page 27 :

Contd…., • The slope of the rheogram is termed, Mobility, analogous to fluidity in, Newtonian system, and its reciprocal is, known as, Plastic viscosity, U, , F– f, U, G, • Where f is the yield value

Page 28 :

Pseudoplastic Flow, (shear-thinning), • The curve begins at the origin (or approach it), and there is no yield value., • Occurs in for polymers in solution (e.g., syenthetic or natural gum, cellulose, derivatives), • As the shearing molecules orient, themselves to the direction of flow., • This orientation reduces internal friction and

Page 30 :

Shear, , Pseudo plastic systems, (shear-thinning), , Shear stress, , Fig. 5

Page 31 :

DIALATANT Flow, (shear-thickening), • Certain suspensions with a high, percentage (upto 50%) of deflocculated, solids exhibit an increase in resistance to, flow with increasing rate of shear., • Such systems actually increase in volume, when sheared and hence termed dilatant, and phenomenon as rheopexy, • When stress is removed, a dilatent, system returns to its original state of, fluidity., • E.g. corn starch in water.

Page 33 :

Reasons for Dilatency, • Particles are closely packed with amount of, vehicle is enough., • Increase shear stress, the bulk of the system, expand (dilate), and the particles take an, open form of packing., • The vehicle becomes insufficient, • Particles are no longer completely lubricated, by the vehicle., • Finally, the suspension will set up as a firm, paste.

Page 34 :

Dilatant Systems, , Shear stress, , Fig. 7

Page 35 :

Significance of dilatency, • Such behaviour suggests that appropriate, precautions should be used during, processing of dilatent materials., • Mixing (powder+granulating liquid) is, usually conducted in high speed mixers,, dilatent materials may solidify under, these conditions thereby damage the, equipments.

Page 36 :

THIXOTROPY, • Non-Newtonian, • Time Dependent behaviour, • Downcurve displace left to upcurve for, shear thinning system, • It is the decrease in viscosity as a function, of time upon shearing, then recovery of, original viscosity as a function of time, without shearing.

Page 38 :

THIXOTROPY, • Loose network through sample., • At rest, its Rigidity is like Gel, • As shear applied, the structure begin to, break and the material undergo Gel-toSol transformation., • Finally, at rest the structure is restored, again (Sol-to Gel), • e.g. Procaine penicilline G (40-70%, w/v in water)

Page 39 :

Measurement of thixotropy, • Hysteresis loop formed by upcurve and, down curve… Measurement of area of, hysteresis loop, • For Bingham plastic two approaches are, used to estimate degree of thixotropy

Page 40 :

Approach 1, • Structural breakdown with time at constant, ‘shear rate’ (Fig 9)., • B= thixotropic coefficient (rate of, breakdown at with time at constant rate, of shear)

Page 42 :

Approach 2, • Determine structural breakdown due to, increasing shear rate (Fig. 10). Two, hysteresis loop are obtaind having, different maximum, ‘shear rate’, • M= loss in shearing stress per unit increase, in, ‘shear rate’

Page 44 :

Bulge, 3-Dimentional structure result, bulge formation., Crystalline plates of bentonite, ‘house of card’structure, E.g. 10-15% bentonite magma., , Crystalline plate, , `House of Cards`

Page 45 :

Spur, Sharp point of Structural, breakdown at low shear, E.g. Procain Penicillin

Page 46 :

Antithixotrophy, Increase in, consistency, (resistance to flow), on down, curve with, increase, in time of shear., , Example,, Magnesia Magma

Page 48 :

• Increase in consistency (resistance to, flow) on down curve with increase in, time of shear., • Reason for antithixotropy is, Increased collision frequency of, particles and bonding with time., Example,, Magnesia Magma

Page 49 :

Antithixotropy vs Dilatency, Antithixotropy, (Negative, thixotropy), • Occur in, flocculated system, with low solid, content (1-10%), • Solid form gel more, readily in resting, state than sheared, state, , • Sol is equilibrium form

Page 50 :

Dilatency, (Rheopexy), • Occur in, deflocculated, system with, high solid, content (50% by, volume), • Solid form gel, more readily, when sheared, rather than, resting, , condition, • Gel is equilibrium form

Page 51 :

Thixotropy vs Antithixotropy, THIXOTRO, PY, decrease in viscosity as, a function of time upon, shearing, then, recovery, of, original viscosity as a, function, of, time, without shearing, e.g. Procaine penicilline, G, (40-70% w/v in water), , ANTITHIXOTRO, PY, Increase in consistency, (resistance to flow) on, down curve with, increase in time of, shear Increased, collision frequency of, particles, E.g. Magnesia magma

Page 53 :

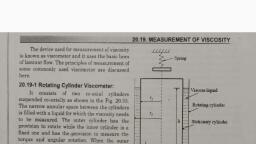

CHOICE OF VISCOMETER, Instruments used for measurement of, viscosity are known as viscometers, • Newtonian fluids: (Because shear rate, is directly proportional to shear stress), instruments that operate at single, rate of shear can be used., • Non- Newtonian fluids: Instrument, which could operate at (multiple), variable rate of shears are required.

Page 54 :

Measurement of Viscosity, • Capillary viscometers (single rate of shear), • Falling sphere viscometers (single rate of, shear), • Rotation viscometers (variable rate of shear)

Page 55 :

Oswald Viscometer, (Capillary viscometer), • It follow Poiseuille’s Law for flow of, liquid through capillary, • The apparatus consists of a glass U-tube, • viscometer made of clear borosilicate, glass and constructed in accordance, with the dimensions given in official, books.

Page 57 :

Method, • Clean viscometer using chromic acid, • Fill the viscometer with the liquid, being examined through left arm of, tube to slightly above, the, bubble using a pipette, • Suck the liquid till start mark then, allow it to flow till stop mark., • Note the time of flow for liquid, from start to stop mark., • Determine the viscosity using, formula where viscosity of water 𝜂1, =0.9 cP, • 𝜂2= (𝝔2t2/ 𝝔1t1) 𝜂1

Page 59 :

Hoeppler Falling ball Viscometer, • It follows Stoke’s law, • Glass or steel ball roll down almost, vertical tube containing the test liquid, • Rate (speed) at which ball with, particular density and diameter falls, is inversely proportional to viscosity, of liquid, • Sample and ball are placed in inner tube, and allowed to equilibrate at temperature, (jacket), • Tube and jacket inverted and time, required for ball to fall between two

Page 60 :

marks is noted and it is repeated, several times.

Page 61 :

Hoeppler Falling ball Viscometer, Viscosity is calculated using the formula, 𝜂= t(Sb-Sf)B, t, = time interval in seconds, Sb-Sf = specific gravities of ball and fluid, B, = constant for ball supplied by instrument, manufacturer

Page 62 :

Rotational Viscometers, • Cup and Bob (Disadvantage: Plug flow), Couette type Cup rotate e.g., MacMichael, Searle type Bob rotate , e.g. Stromer(Plug flow can be minimized by, reducing gap between bob and cup), , • Cone and Plate (Advantage: No plug flow), Ferranti Shirley, Brookfield

Page 63 :

Cup and Bob, viscometer, • Sample is sheared in, space between outer, wall of bob and inner, wall of cup, • Viscous drag on bob, due to sample causes it, to turn, • Resultant torque is, proportional to viscosity, of sample, • MacMichael, viscometer: Rotating, cup and stationary, bob, • Searle

Page 64 :

viscometer:, Rotating, bob, and stationary, cup

Page 66 :

Cone and Plate viscometer, , T= torque, V= speed of rotation of, cone f= yield value, Cf = instrumental constant

Page 69 :

Brookfield viscometer, •, , The rotational viscometer basically, consists of two parts - a head unit with a, motor and a spindle that is driven by the, motor., , •, , The viscosity is determined by, measuring the resistance of a spindle, rotating in the sample.

Page 72 :

Viscoelasticity, Continuous shear (rotational viscometer), dose not allow material to be in ‘ground state’, but in deformation state, Analysis of viscoelastic materials (Cream,, lotion, suppositories etc.) is designed not to, destroy ground state of material, Viscoelastic measurement depend, upon mechanical properties of, material

Page 73 :

Viscoelasticity, • Semisolids exhibit properties of both, states…, elasticity of solid and viscosity of fluids., • Viscosity of Newtonian fluids is expressed, by, • F/ G, • Elasticity of solids is expressed, by Hook’ s law, • E= F/ , •, , E= e l astic modulus, = S t rain

Page 74 :

Maxwell unit

Page 75 :

Maxwell unit, • When a constant stress is applied on, Maxwell unit there is a strain on material, which corresponds to displacement of, spring, • Applied stress displacement of, pistonindashpot due to viscous flow, • When stress is removed spring, return tooriginal position but viscous flow, show no recovery

Page 77 :

Voigt Unit, • Drag of viscous fluid in dashpot, simultaneously influences extension, and compression of spring, • Strain is expressed as, deformation or compliance , J, (strain per unit stress), • J= J∞(1-e-t/𝜏), • 𝜏= viscosity per unit modulus, • J∞ = compliance at infinite time

Page 78 :

Creep viscometer (creep curve), Maxwell element can be combined with, Vogit unit to make creep viscometer, Creep curve is used to measure, viscoelasticity of non-Newtonian, pharmaceutical systems

Page 80 :

Creep Curve for viscoelastic materials, AB= Elastic movement .. Top spring, BC= viscoelastic flow …. Two Voigt unit, CD= Viscous flow… Movement of piston at, bottom of Maxwell unit, When stress is removed there is instant, elastic recovery DE (equivalent to AB), followed by EF (figure on previous slide)

Page 82 :

Reference, • ‘Martin’s Physical Pharmacy and, Pharmaceutical Sciences’ Fifth edition,, Lippincott Williams and Wilkins, Indian Edition, distributed by B.I.Publications Pvt Ltd, 2006.