Page 1 :

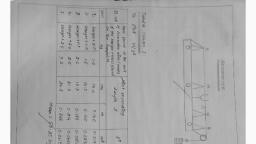

Scanned with CamScanner, Date 19lo7(2018, Expt. No.., 1., Page No. 1, SONOMETER., SONOMETER, M, AIM:, To find the frequency of the given tuning fork using, Sonometer., APPARATUS, REQUIRED:, Sonometer, Screw Gauge , turůng fork , hammer, weighd, hanger set and, rider., papur, Tabul ar Column I:, FORMULA:, To, find, The frequency of the turing fork, n = !, IM, g Hz, Mass placed at the end, of Sonometer wire (mass, of the hanger t mass placed, on the hanger) M, kg, st resonating, SI NO, l ength I, where,, m2 kgm-2, UNIT, cm, M= total mass, at, the end of the Sonameter wire., Hanger + o-5, Hanger + 1.0, 1., 0.0196 51. 02, ire. Mass of the weight hanger + Mass placed an t., 9= accelexation, m= linear density of the wire, i.e., l first, 1.0, 14.0, 0.140, due sto gravi ty, 2., 1.5, 16.5, 0.165, 0-0872 55-14, Hanger +f.5, 18.8, 2.0, 0.188, 0.0353 56.65, Hanger +2-0, Hanger + 2.5, mass per unit dength of the uire., resonating Xength., linean density of the wire, me J ip, 4., 2.5, 21.4, 0.214, 0.0457 SH 70, 5., 3.0, 24.8, 0.248, 0.0615 48 78, The, Mean = 3.25 kgm-2, whene,, Pe density of the, Y= radius of the, material of the wire, Sonameter wire, Teacher's signature:

Page 2 :

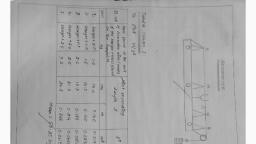

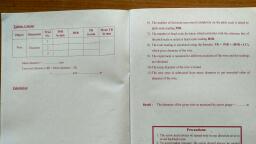

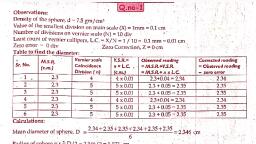

Scanned with CamScanner, Date 19loz/2018, Expt. No., 1., Observations:, Page No., -2, 9.8 ms, Acceleration due to gravity g, DESCRIPTION:, -3, - 8600 kgm, consists of a, Density of the material of the wire,P, A Sanometen, holloco wadden box about, MIA, metre with, bridges A and B fisced at two ends on, the top Surface. A unifor m wire is stretched ovey the, end of the uwire being fixed to the, at one end of the box. The other end passes, one, Distance moved in, pitch Sale, Pitch of the Screw =, No. of rotations given to H, two bridges, one, Pitch /No. of HSD, 100, nåil, Ci) Least count =, ww, KESMISED:, 20TAA9A, Smoath pulley and catries, be placed., weight hanger OD, Mand N are fwo, over, a, Number of HSD = 100 div, which weights, bridges in, and B. By changing, vibrating segment of the, can, LC = 0•01 m m., ZE= 2X0.0, moveable, the feced bridges A, and, Zero Correction:, between, Ci) Zero Error, their position, the length of the, こ008, wire, can be alteed, Tabular Colemn- II, PROCEDURE, load say, two moveable bridges M and N, To find, the diametor the wire, Suitable, 0-5 kg placed, on the, hanger. The, are placed, ider i placed, LC = 0.01 mm;, ZE. = 0.02mm ;, Z.C= - 0.02 mm, clase, to each other A light paper, centre of the segment, at the, wire The given turing fork i., s pressed, ibrating segment, moving, flutters vfolently and fall down., length l latawseen M and N, metre, SI-NO, PSR, HSC, HSR=HSC XLC, OR = PSR + HSR, CR=ORt ZC, MN of the, exci ted and 9ts stem, Sonometer, UNIT, div, mm, mm, mm, Sonometen box. The lenglh of the, MN is gradually åncreased by, bridge M or N, ll, 1., 43, O•H3, 0.43, on the, 2., 46, O H6, 0.46, O 44, the, the paper rider., The first resonating, is measured us ing the, る。, 44, O.44, O.44, Q. 42, 4マ, O.47, O.47, O AS, 5., O.40, 0-38, fixed on the, 1kg i:5 kg, 2kg, 2.5kg, 3kg etc, the resonating length is, is, scale, Sonometer bx. The load, & changed to, and un each, and M/1R, The, average diameter, of, the wire =, O H2mm, determired, Case, Radius of the wire, r= d/g, 0.21 mm, calculated., R= 0 21 X (0 m, Teacher's signature :

Page 3 :

Scanned with CamScanner, Date 19loz/2018, CALCULATION., Expt. No., 1., Page No. 5, per unit length of the wire, m= JTrf., diameter d, The mass, The, of the wire is found using a, of the wire r ůs calculated., per urit length of the wire ů m=JIY*P, material of the wire., frequency of Phe given turůng furk s, values of M/o and, m= 3.14 (0.21X10-3)x 8600, Screco, gouige., The, radius, The, mass, 9., = 3.14 XO.OH4.X10 x8600, Here P is the, density of the, The, m = 1196.87 x 10-6, calculated by substituling, the formula, The, The frequenay of the tuning fork, n=, M., Hz, 53.25x9.8, /190-8子x10, 53.25 x8229, 438194, z x 66/, bong, = 330 Hz, bir, R一, RESULT:, The frequency of the given, tuning fürk (n) _330, Hz, 18, Teacher's signature :

Page 4 :

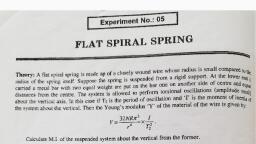

Scanned with CamScanner, Date 02loal2018, Expt. No., 3., Page No., 13, MICROMETER (SCREW GAUGE)., MICROMETER (SCREW GAUGE), Pitch scale, Ra tchet, AIM:, To, of the gi ven 9regula r, the thickness, glass plake, using a, glass plate using, the volume of the glass plate., A, measure, micrometer., To measure, area, Head scale, of Hhe, a graph sheat and to calaulate, > Frame, APPARATUS REQUIRED:, Screw gauge + graph sheat and given glass plate., FORMULA:, Volume of glass plate = Thickness x area of the glass, OBSERVATIONS:, plate m3, Thickness of glass plate = Observed Reading + Zero Correcton., {PSR +(HSC X LC)} +zc, scale Reading, scale co încidence, %3D, ti Least count =, Pitch of the Screw, %3D, %3D, 190, No. of Head Scale division., where,, PSR =, Pitch, HSC =, Head, Distance moved in, the pitch Srale, Ditch of the Screw=, LC =, Least, count, No. of rotation s given to H-S., ZC =, Zero Correction., Head Scale Reading (HSR) = Head Sale coinidencex Lcast Count, Observed Reading (OR) = Pitch Scale Reading +Headl Scale Reading, Correct Reading (CR) = Obserred Reading +zero Correction., Number of head Scale divisions =100 div, .Least co unt (L-C) =, Pitch, 01, mm, No of HSD, 100, LC. =, 0.01 /mm, Teacher's signature :

Page 5 :

Scanned with CamScanner, Date 02lo8/2018, Expt. No., 3., eiror and correction:, Page No.., Three possible înitial, DESCRIPTION:, HS, The, Screw Gauge Consists of a screw workeng in, T0, MIA, a hollow cylindrical nut, G. On the, This, a fired stud A at the One end of the frame and, exactly opposite to A, the Screu . The other, attached to one, end of a frame, AL-, 1-L, E90, hollow cylinder ä scale marked in mm., 95, scale called the pitch Scale (PS). There is, Negati ve error, Posi fi ve corechiaD, Positive error, No error, a moveable, end of thi, ups, there uů, stud B of, No correction, Negatire, head H. To the, On the tapering, marked. This scale us, Screw gauge, avoid oven- eworking of the, Screw has a, altached., or 100 divisions, the Head Scale (HS)., ratchet arrangamant,, head, a, of Ahe sleeve so, hollow sleeve is, elg, and, correction, for the given Screw, called, zero, are, (it) zero, erroy, The, head ui, having a, gauge:, to, Screw., HSC= 98 div (Negativ e error -> Positive corsection)., PROCEDURE:, ZE = - (100 - HSC) XLC, i) To find the least count (1C):, -(roo-98)xo-01 mm, count s the műnimum measurement that can, Least, be made with the given 9nstrument, First, the pitch scale of the, = -2 x 0. O1 mm, screw s determned;, known number of rotahions to head, dötace advanced in pitch, the number of diisions un the, by giving, Z.E. = - 0. 02mm, a, Scale and, Scale in, head Scale also, The pitch and least count are determined using the, formulae., noting, the, Z.C=, + o.6 a mm., mm. Then, 100., noted., Teacher's signature :