Page 1 :

GOVERNMENT OF INDIA, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, DIRECTORATE GENERAL OF TRAINING, , COMPETENCY BASED CURRICULUM, , WELDER, (Duration: One Year), , CRAFTSMEN TRAINING SCHEME (CTS), NSQF LEVEL- 4, , SECTOR – CAPITAL GOODS AND MANUFACTURING

Page 2 :

WELDER, (Engineering Trade), , (Revised in 2019), Version: 1.2, , CRAFTSMEN TRAINING SCHEME (CTS), NSQF LEVEL - 4, , Developed By, Ministry of Skill Development and Entrepreneurship, Directorate General of Training, , CENTRAL STAFF TRAINING AND RESEARCH INSTITUTE, EN-81, Sector-V, Salt Lake City,, Kolkata – 700 091, www.cstaricalcutta.gov.in

Page 3 :

CONTENTS, , S No., , Topics, , Page No., , 1., , Course Information, , 1, , 2., , Training System, , 3, , 3., , Job Role, , 7, , 4., , General Information, , 10, , 5., , Learning Outcome, , 12, , 6., , Assessment Criteria, , 14, , 7., , Trade Syllabus, , 19, , Annexure I (List of Trade Tools & Equipment), , 33, , Annexure II (List of Trade experts), , 37

Page 4 :

WELDER, , 1. COURSE INFORMATION, During the one year duration a candidate is trained on subjects Professional Skill,, Professional Knowledge, Engineering Drawing, Workshop Science & Calculation and, Employability Skills related to job role. In addition to this a candidate is entrusted to undertake, project work and extracurricular activities to build up confidence. The broad components, covered under Professional Skill subject are as below:, The practical skills are imparted in simple to complex manner & simultaneously theory, subject is taught in the same fashion to apply cognitive knowledge while executing task. The, safety aspects covers components like OSH & E, PPE, Fire extinguisher, First Aid and in addition, 5S being taught. The practical part starts with edge preparation by hacksawing, filing and fitting, followed by Oxy Acetylene Welding & Brazing, Oxy Acetylene Cutting, Shielded Metal Arc, Welding, Gas Metal Arc Welding, Gas Tungsten Arc Welding and Spot Welding, Plasma Cutting, and Arc Gouging. These processes are widely used in Industries., During the practice on Welding / Brazing process, the trainees will learn to read the job, drawing, select the required base metal and filler metals, cut the metals by appropriate, process, carry out edge preparation, setup the plant and do welding/Brazing on M.S, SS,, Aluminium and Copper in different positions. On completion of each job the trainees will also, evaluate their jobs by visual inspection, and identify the defects for further, correction/improvement. They learn to adapt precautionary measures such as preheating;, maintaining inter-pass temperature and post weld heat treatment for Welding Alloy steel, Cast, Iron etc. The Work Shop calculation taught will help them to plan and cut the required jobs, economically without wasting the material and also used in estimating the Electrodes, filler, metals etc. The Workshop Science taught will help them to understand the materials and, properties, effect of alloying elements etc. Engineering Drawing taught will be applied while, reading the job drawings and will be useful in understanding the location, type and size of weld, to be carried out., The professional knowledge taught will be useful in understanding the principles of Welding,, Brazing and Cutting process, use of jigs and Fixtures, distortion and methods of control,, selection of consumables and to take precautionary measures for storage and handling and, apply the same for executing the Cutting, Welding and Brazing., The knowledge and practice imparted on Destructive and Non-destructive testing will be use in, understanding the standard quality of welds and to carry out shop floor Inspection and test in, laboratories., , 1

Page 5 :

WELDER, One project need to be completed by the candidates in a group. In addition to above, components the core skills components viz., Workshop calculation & science, Engineering, drawing, employability skills are also covered. These core skills are essential skills which are, necessary to perform the job in any given situation., , 2

Page 6 :

WELDER, , 2. TRAINING SYSTEM, 2.1 GENERAL, The Directorate General of Training (DGT) under Ministry of Skill Development &, Entrepreneurship offers a range of vocational training courses catering to the need of different, sectors of economy/ Labour market. The vocational training programmes are delivered under, the aegis of Directorate General of Training (DGT). Craftsman Training Scheme (CTS) with, variants and Apprenticeship Training Scheme (ATS) are two pioneer schemes of DGT for, strengthening vocational training., Welder trade under CTS is one of the most popular courses delivered nationwide through, a network of ITIs. The course is of one-year duration. It mainly consists of Domain area and Core, area. In the Domain area (Trade Theory & Practical) imparts professional skills and knowledge,, while the core area (Workshop calculation & Science, Engg. Drawing and Employability Skill), imparts requisite core skills, knowledge, and life skills. After passing out the training program,, the trainee is awarded National Trade Certificate (NTC) by DGT which is recognized worldwide., , Trainee broadly needs to demonstrate that they are able to:, , , , , , , Read & interpret technical parameters/documentation, plan and organize work, processes, identify necessary materials and tools;, Perform tasks with due consideration to safety rules, accident prevention regulations and, environmental protection stipulations;, Apply professional knowledge, core skills & employability skills while performing the job,, and repair & maintenance work., Check the job/ assembly as per drawing for functioning identify and rectify errors in job/, assembly., Document the technical parameters in tabulation sheet related to the task undertaken., , 2.2 PROGRESSION PATHWAYS, , , , , , Can join industry as Technician and will progress further as Senior Technician, Supervisor, and can rise up to the level of Manager., Can become Entrepreneur in the related field., Can join Apprenticeship programme in different types of industries leading to National, Apprenticeship certificate (NAC)., Can join Crafts Instructor Training Scheme (CITS) in the trade for becoming instructor in, ITIs., 3

Page 7 :

WELDER, , , Can join Advanced Diploma (Vocational) courses under DGT as applicable., , 2.3 COURSE STRUCTURE:, Table below depicts the distribution of training hours across various course elements, during a period of one year: S No., 1, 2, 3, 4, 5, , Course Element, Professional Skill (Trade Practical), Professional Knowledge (Trade Theory), Workshop Calculation & Science, Engineering Drawing, Employability Skills, Total, , Notional Training, Hours, 1000, 280, 80, 80, 160, 1600, , 2.4 ASSESSMENT &CERTIFICATION, The trainee will be tested for his skill, knowledge and attitude during the period of course, through formative assessment and at the end of the training programme through summative, assessment as notified by the DGT from time to time., a) The Continuous Assessment (Internal) during the period of training will be done by Formative, assessment method by testing for assessment criteria listed against learning outcomes. The, training institute have to maintain individual trainee portfolio as detailed in assessment, guideline. The marks of internal assessment will be as per the formative assessment template, provided on www.bharatskills.gov.in, b) The final assessment will be in the form of summative assessment. The All India Trade Test for, awarding NTC will be conducted by Controller of examinations, DGT as per the guidelines. The, pattern and marking structure is being notified by DGT from time to time. The learning outcome, and assessment criteria will be basis for setting question papers for final assessment. The, examiner during final examination will also check individual trainee’s profile as detailed in, assessment guideline before giving marks for practical examination., , 2.4.1 PASS REGULATION, For the purposes of determining the overall result, weightage of 100% is applied for six, months and one year duration courses and 50% weightage is applied to each examination for, 4

Page 8 :

WELDER, two years courses. The minimum pass percent for Trade Practical and Formative assessment is, 60% & for all other subjects is 33%. There will be no Grace marks., , 2.4.2 ASSESSMENT GUIDELINE, Appropriate arrangements should be made to ensure that there will be no artificial, barriers to assessment. The nature of special needs should be taken into account while, undertaking assessment. Due consideration should be given while assessing for team work,, avoidance/reduction of scrap/wastage and disposal of scarp/wastage as per procedure,, behavioral attitude, sensitivity to environment and regularity in training. The sensitivity towards, OSHE and self-learning attitude are to be considered while assessing competency., Assessment will be evidence based comprising the following:, , , , , , , , , , Job carried out in labs/workshop, Record book/ daily diary, Answer sheet of assessment, Viva-voce, Progress chart, Attendance and punctuality, Assignment, Project work, , Evidences and records of internal (Formative) assessments are to be preserved until, forthcoming examination for audit and verification by examination body. The following marking, pattern to be adopted while assessing:, , 5

Page 9 :

WELDER, , Performance Level, , Evidence, , (a) Weightage in the range of 60 -75% to be allotted during assessment, Demonstration of good skill in the use of, hand tools, machine tools and workshop, equipment, 60-70%, accuracy, achieved, while, undertaking different work with those, demanded by the component/job/set, standards., A fairly good level of neatness and, consistency in the finish, Occasional support in completing the, project/job., , For performance in this grade, the candidate, should produce work which demonstrates, attainment of an acceptable standard of, craftsmanship with occasional guidance, and, due regard for safety procedures and, practices., , (b)Weightage in the range of above75% - 90% to be allotted during assessment, Good skill levels in the use of hand tools,, machine tools and workshop equipment, 70-80%, accuracy, achieved, while, undertaking different work with those, demanded by the component/job., A good level of neatness and consistency, in the finish, Little support in completing the, project/job, (c) Weightage in the range of above 90% to be allotted during assessment, , For this grade, a candidate should produce, work which demonstrates attainment of a, reasonable standard of craftsmanship, with, little guidance, and regard for safety, procedures and practices., , High skill levels in the use of hand tools,, machine tools and workshop equipment, Above 80% accuracy achieved while, undertaking different work with those, demanded by the component/job/set, standards., A high level of neatness and consistency in, the finish., Minimal or no support in completing the, project., , For performance in this grade, the, candidate, with minimal or no support in, organization and execution and with due, regard for safety procedures and practices,, has produced work which demonstrates, attainment of a high standard of, craftsmanship., , 6

Page 10 :

WELDER, , 3. JOB ROLE, Welder, Gas; fuses metal parts together using welding rod and oxygen acetylene flame., Examines parts to be welded, cleans portion to be joined, holds them together by some suitable, device and if necessary, makes narrow groove to direct flow of molten metal to strengthen, joint. Selects correct type and size of welding rod, nozzle etc. and tests welding, torch. Wears, dark glasses and other protective devices while welding. Releases and regulates valves of, oxygen and acetylene cylinders to control their flow into torch. Ignites torch and regulates, flame gradually. Guides flame along joint and heat it to melting point, simultaneously melting, welding rod and spreading molten metal along joint shape, size etc. and rectifies defects if any., Welder, Electric; fuses metals using arc-welding power source and electrodes. Examines parts, to be welded, cleans them and sets joints together with clamps or any other suitable device., Starts welding power source and regulates current according to material and thickness of, welding. Connect one lead to part to be welded, selects required type of electrode and clamps, other lead to electrode holder. May join parts first at various points for holding at specified, angles, shape, form and dimension by tack welding. Establish arc between electrode and joint, and maintain it throughout the length of the joint., Welder, Resistance; sets up and operates resistance welding machine to join metal parts,, according to blueprints, work orders, or oral instructions. Turns machine dials to set air and, hydraulic pressure, amperage, and joining time, according to specified type of metal, weld, and, assembly. May select, install, and adjust electrodes. Aligns work pieces, using square and rule., May hold pieces together manually, fasten into jigs, or secure with clamps to align in specified, assembly position. Holds part between electrodes or positions on machine worktable., Depresses pedal or pulls trigger to close electrodes and form weld at point of contact. Releases, pedal or trigger after specified welding time. Cleans electrodes, using file, tip dresser, emery, cloth. May operate machine which automatically releases electrodes from metal after welding, cycle. May devise and build fixtures to hold pieces. May inspect finished work. May operate, machine equipped with two or more electrodes which weld at several points simultaneously., Important variations include types of joints welded (seam, spot, butt) and types of materials, welded (aluminium, steel)., Gas Cutting; cuts metal to require shape and size by gas flame either manually or by machine., Examines material to be cut and marks it according to instruction of specification. Makes, necessary connections and fits required size of nozzle in welding torch. Releases and regulates, flow of gas in nozzle, ignites and adjusts flame. Guides flame by hand or machine along cutting, line at required speed and cuts metal to required size., 7

Page 11 :

WELDER, Brazer; joints metal parts by heating using flux and filler rods. Cleans and fastens parts to be, joined face to face by wire brush. Apply flux on the joint and heats by torch to melt filler rods, into joint. Allows it to cool down. Clean and examines the joint., Tungsten Inert Gas (TIG) welder; reads fabrication drawing, examines parts to be welded,, cleans them and sets joints with clamps or any other suitable device. Selects suitable tungsten, electrode, grinds the edges and fit in to the GTA welding torch. Selects gas nozzle and fit in to, the GTA welding torch. Selects suitable filler rods and cleans them. Connects work piece with, earth cable, Connects the machine with Inert gas Cylinder, regulator and flow meter. Starts the, Constant current GTA welding machine, sets suitable welding current & polarity and inert gas, flow. Establish arc through across a column of highly ionized inert gas between work piece and, Tungsten electrode. Melts the metal and deposit weld beads on metal surfaces by passing the, suitable filler rod in to the weld puddle. Joins metal pieces such as Steel, Stainless steel and, Aluminium metals., Gas Metal Arc Welder/ Metal Inert Gas/ Metal Active Gas/ Gas Metal Welder, (MIG/MAG/GMAW); reads fabrication drawing, examines parts to be welded, cleans them and sets, joints with clamps or any other suitable device. Connects work piece with earth cable. Connects the, machine with suitable gas Cylinder, regulator and flow meter. Connects pre-heater when CO2 is used as, shielding gas. Selects suitable wire electrode, feed it to welding GMA Welding torch through wire feeder., Selects contact tip gas nozzle and fit in to the GMA welding torch. Preheats joints as required. Starts the, Constant Voltage GMA welding machine, sets suitable welding voltage & wire feed speed and shielding, gas flow, produces arc between work piece and continuously fed wire electrode. Melts the metal and, deposit weld beads on the surface of metals or joins metal pieces such as Steel, and Stainless-steel, metals., , Iron and Steel Plasma Cutter- Manual; cuts different materials (mild carbon steel, stainless, steel, aluminium, high tensile and special steels, and other materials) in various profiles. This, involve setting-up and preparing operations interpreting the right information from the, specification documents, obtaining the right consumables and other materials, etc., Plan and organize assigned work and detect & resolve issues during execution in his own, work area within defined limit. Demonstrate possible solutions and agree tasks within the team., Communicate with required clarity and understand technical English. Sensitive to environment,, self-learning and productivity., Reference NCO 2015:, (i) 7212.0100 – Welder, Gas, (ii) 7212.0200 – Welder, Electric, (iii) 7212.0700 – Welder, Resistance, 8

Page 12 :

WELDER, (iv), (v), (vi), (vii), (viii), (ix), (x), , 7212.0400 – Gas Cutter, 7212.0500 – Brazer, 7212.0105 – Tungsten Inert Gas Welder, 7212.0303 – Gas Metal Arc Welder/ Metal Inert Gas/ Metal Active Gas/ Gas, Metal Welder (MIG/MAG/GMAW), 7212.0111- Repair Welder, 7212.0402- Plasma Cutter – Manual, , 9

Page 13 :

WELDER, , 4. GENERAL INFORMATION, Name of the Trade, Trade Code, NCO - 2015, , Welder, DGT/1004, 7212.0100,, 7212.0200,, 7212.0700,7212.0400,, 7212.0105, 7212.0303, 7212.0111, 7212.0402, , NSQF Level, , Level – 4, , Duration of Craftsmen, Training, Entry Qualification, Minimum Age, , 7212.0500,, , One year (1600 Hours), Passed 8th class examination, 14 years as on first day of academic session., , Eligibility for PwD, LD, LC, DW, AA, DEAF, HH, Unit Strength (No. Of, 20 (There is no separate provision of supernumerary seats), Student), Space Norms, 80 Sq. m, Power Norms, 16 KW, Instructors Qualification for, 1. Welder Trade, B.Voc/Degree in Mechanical/ Metallurgy/ Production Engineering/, Mechatronics from AICTE /UGC recognized university/ college with, one year experience in relevant field., OR, 03 years Diploma in Mechanical and allied from AICTE/ recognized, technical board of education or relevant Advanced Diploma, (Vocational) from DGT with two years experience in relevant field., OR, NTC/NAC passed in the Trade of “Welder” with three years’, experience in the relevant field., Essential Qualification:, Relevant National Craft Instructor Certificate (NCIC) in any of the, variants under DGT., , 2. Workshop, Calculation & Science, , Note: Out of two Instructors required for the unit of 2(1+1), one, must have Degree/Diploma and other must have NTC/NAC, qualifications. However, both of them must possess NCIC in any of, its variants., B.Voc/Degree in Engineering from AICTE/UGC recognized, Engineering College/ university with one-year experience in the, relevant field., OR, 03 years Diploma in Engineering from AICTE/ recognized board of, 10

Page 14 :

WELDER, technical education or relevant Advanced Diploma (Vocational) from, DGT with two years’ experience in the relevant field., OR, NTC/ NAC in any one of the engineering trades with three years’, experience., Essential Qualification:, , 3. Engineering, Drawing, , 4. Employability Skill, , National Craft Instructor Certificate (NCIC) in relevant trade., OR, NCIC in RoDA or any of its variants under DGT., B.Voc/Degree in Engineering from AICTE/UGC recognized, Engineering College/ university with one-year experience in the, relevant field., OR, 03 years Diploma in Engineering from AICTE/ recognized board of, technical education or relevant Advanced Diploma (Vocational) from, DGT with two years’ experience in the relevant field., OR, NTC/ NAC in any one of the Engineering trades with three years, experience., Essential Qualification:, National Craft Instructor Certificate (NCIC) in relevant trade, OR, NCIC in RoDA / D’man (Mech /civil) or any of its variants under DGT., MBA/ BBA / Any Graduate/ Diploma in any discipline with Two, years’ experience with short term ToT Course in Employability Skills, from DGT institutes., (Must have studied English/ Communication Skills and Basic, Computer at 12th / Diploma level and above), OR, Existing Social Studies Instructors in ITIs with short term ToT Course, in Employability Skills from DGT institutes., 21 Years, , 5. Minimum Age for, Instructor, List of Tools and, As per Annexure – I, Equipment, Distribution of training on Hourly basis: (Indicative only), Total Hrs, Trade, Trade, Workshop, /week, Practical, Theory, Cal. & Sc., 40 Hours, 25 Hours, 7 Hours, 2 Hours, , 11, , Engg. Drawing, 2 Hours, , Employability, Skills, 4 Hours

Page 15 :

WELDER, , 5. LEARNING OUTCOME, , Learning outcomes are a reflection of total competencies of a trainee and assessment will, be carried out as per the assessment criteria., , 5.1 LEARNING OUTCOMES (TRADE SPECIFIC), 1., 2., , 3., 4., 5., , 6., , 7., 8., , 9., , 10., , 11., 12., 13., 14., , Set the gas welding plant and join MS sheet in different position following safety, precautions. [Different position: - 1F, 2F, 3F, 1G, 2G, 3G.], Set the SMAW machine and perform different type of joints on MS in different position, observing standard procedure. [different types of joints- Fillet ( T-joint, lap & Corner),, Butt (Square & V); different position - 1F, 2F, 3F,4F, 1G, 2G, 3G, 4G], Set the oxy- acetylene cutting plant and perform different cutting operations on MS, plate. [Different cutting operation – Straight, Bevel, circular], Perform welding in different types of MS pipe joints by Gas welding (OAW). [Different, types of MS pipe joints – Butt, Elbow, T-joint, angle (45) joint, flange joint], Set the SMAW machine and perform welding in different types of MS pipe joints by, SMAW. [Different types of MS pipe joints – Butt, Elbow, T-joint, angle (45) joint, flange, joint], Choose appropriate welding process and perform joining of different types of metals, and check its correctness. [appropriate welding process – OAW, SMAW; Different metal, – SS, CI, Brass, Aluminium], Demonstrate arc gouging operation to rectify the weld joints., Test welded joints by different methods of testing. [different methods of testing- Dye, penetration test, Magnetic particle test, Nick break test, Free band test, Fillet fracture, test], Set GMAW machine and perform welding in different types of joints on MS sheet/plate, by GMAW in various positions by dip mode of metal transfer. [different types of jointsFillet ( T-joint, lap, Corner), Butt (Square & V); various positions- 1F, 2F, 3F,4F, 1G, 2G,, 3G], Set the GTAW machine and perform welding by GTAW in different types of joints on, different metals in different position and check correctness of the weld. [different types, of joints- Fillet ( T-joint, lap, Corner), Butt (Square & V) ; different metals- Aluminium,, Stainless Steel; different position- 1F & 1G], Perform Aluminium & MS pipe joint by GTAW in flat position., Set the Plasma Arc cutting machine and cut ferrous & non-ferrous metals., Set the resistance spot welding machine and join MS& SS sheet., Perform joining of different similar and dissimilar metals by brazing operation as per, standard procedure. [different similar and dissimilar metals- Copper, MS, SS], 12

Page 16 :

WELDER, 15. Repair Cast Iron machine parts by selecting appropriate welding process. [Appropriate, welding process- OAW, SMAW], 16. Hard facing of alloy steel components/ MS rod by using hard facing electrode., , 13

Page 17 :

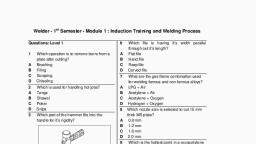

WELDER, , 6. ASSESSMENT CRITERIA, , LEARNING OUTCOMES, , ASSESSMENT CRITERIA, , 1. Set the gas welding plant, and join MS sheet in, different position following, safety, precautions., [Different position: - 1F, 2F,, 3F, 1G, 2G, 3G.], , Plan and select the nozzle size, working pressure, type of, flame, filler rod as per requirement., Prepare, set and tack the pieces as per drawing., Set up the tacked joint in specific position., Deposit the weld following proper welding technique and, safety aspect., Carry out visual inspection to ascertain quality weld joint., , 2. Set the SMAW machine and, perform different type of, joints on MS in different, position observing standard, procedure. [different types, of joints- Fillet ( T-joint, lap, & Corner), Butt (Square &, V); different position - 1F,, 2F, 3F,4F, 1G, 2G, 3G, 4G], , Plan and select the type & size of electrode, welding, current., Prepare edge as per requirement, Prepare, set SMAW machine and tack the pieces as per, drawing., Set up the tacked pieces in specific position., Deposit the weld maintaining appropriate arc length,, electrode angle, welding speed, weaving technique and, safety aspects., Clean the welded joint thoroughly., Carry out visual inspection for appropriate weld joint &, check by gauges., , 3. Set the oxy- acetylene, cutting plant and perform, different cutting operations, on MS plate. [Different, cutting operation – Straight,, Bevel, circular], , Plan and mark on MS plate surface for, straight/bevel/circular cutting., Select the nozzle size and working pressure of gases as per, requirement., Set the marked plate properly on cutting table., Set the cutting plant & perform the cutting operation, maintaining proper techniques and all safety aspects., Clean the cutting burrs and inspect the cut surface for, soundness of cutting., , 4. Perform welding in different Plan and prepare the development for a specific type of, types of MS pipe joints by pipe joint., Gas, welding, (OAW). Mark and cut the MS pipe as per development., 14

Page 18 :

WELDER, [Different types of MS pipe, joints – Butt, Elbow, T-joint,, angle (45) joint, flange, joint], , Select the size of filler rod, size of nozzle, working, pressure etc., Set and tack the pieces as per drawing., Deposit the weld bead maintaining proper technique and, safety aspects., Inspect the welded joint visually for poor penetration,, uniformity of bead and surface defects., , 5. Set the SMAW machine and, perform welding in different, types of MS pipe joints by, SMAW. [Different types of, MS pipe joints – Butt,, Elbow, T-joint, angle (45), joint, flange joint], , Plan and prepare the development for a specific type of, pipe joint., Mark and cut the MS pipe as per development., Select the electrode size and welding current for welding., Set and tack the pieces as per drawing., Deposit the weld bead maintaining proper technique and, safety aspects., Insect the welded joint visually for root penetration,, uniformity of bead and surface defects., , 6. Choose appropriate welding, process and perform joining, of different types of metals, and check its correctness., [appropriate, welding, process – OAW, SMAW;, Different metal – SS, CI,, Brass, Aluminium], , Plan and prepare the pieces for welding., Select the type and size of filler rod and flux/electrode,, size of nozzle and gas pressure/welding current,, preheating method and temperature as per requirement., Set and tack metals as per drawing., Deposit the weld maintaining appropriate technique and, safety aspects., Cool the welded joint by observing appropriate cooling, method. Use post heating, peening etc. as per, requirement., Clean the joint and inspect the weld for its uniformity and, different types of surface defects., , 7. Demonstrate arc gouging Plan and select the size of electrode for Arc gouging., operation to rectify the Select the polarity and current as per requirement., weld joints., Perform gouging adapting proper gouging technique., Clean and check to ascertain the required stock removed., 8. Test, , welded joints by Plan and select the job and clean the surface thoroughly., 15

Page 19 :

WELDER, different, methods, of, testing. [different methods, of testing- Dye penetration, test, Magnetic particle test,, Nick break test, Free band, test, Fillet fracture test], , Select the appropriate testing methods., Perform testing of welded joints adapting standard, operating procedure., Record the test result & compare with standard, parameter/ result value., Accept/reject the job based on test result., , 9. Set GMAW machine and, perform welding in different, types of joints on MS, sheet/plate by GMAW in, various positions by dip, mode of metal transfer., [different types of jointsFillet ( T-joint, lap, Corner),, Butt (Square & V); various, positions- 1F, 2F, 3F,4F, 1G,, 2G, 3G], , Select size of electrode wire, welding voltage, gas flow, rate, wire feed rate as per requirement., Prepare, set (machine & Job) and tack the pieces as per, drawing and type of joints., Set up the tacked joint in specific position., Deposit the weld adapting proper welding technique and, safety aspects., Carry out visual inspection to ensure quality of welded, joint., Inspect the weld using Dye-penetration Test, (DPT)/Magnetic particle Test (MPT)., , 10. Set the GTAW machine and, perform welding by GTAW, in different types of joints, on different metals in, different position and check, correctness of the weld., [different types of jointsFillet ( T-joint, lap, Corner),, Butt (Square & V) ; different, metalsAluminium,, Stainless Steel; different, position- 1F & 1G], , Select power source as per material, size and type of, Tungsten electrode, welding current, gas nozzle size, gas, flow rate and filler rod size as per requirement., Prepare, set (machine & Job) and tack the pieces as per, drawing and type of joints., Set up the tacked joint in specific position., Deposit the weld by adapting proper welding technique, and safety aspects., Carry out visual inspection to ensure quality of welded, joint., Inspect the weld using Dye-penetration Test, (DPT)/Magnetic particle Test (MPT)., , 11. Perform Aluminium & MS Plan and prepare development or edge preparation for, pipe joint by GTAW in flat specific type of pipe joint., position., Mark and cut the MS pipe as per development., Select the type of welding current, size and type of, tungsten electrode, size of nozzle, gas flow rate and, 16

Page 20 :

WELDER, welding current as per requirement., Set and tack the piece as per drawing., Deposit the weld bead maintaining proper technique and, safety aspects., Inspect the welded joint visually for root penetration,, bead uniformity and surface defects., 12. Set the Plasma Arc cutting Plan and mark on Ferrous/Non ferrous metal plates, machine and cut ferrous surface for plasma cutting., &non-ferrous metals., Select the torch/nozzle size, current and working pressure, of gas as per requirement., Set the marked plate properly on cutting table., Set the plasma cutting machine and perform the cutting, operation by adapting proper techniques and safety, aspects., Clean and inspect the cut surface for quality of cutting., 13. Set the resistance spot Plan and select the material and clean the surface, welding machine and join thoroughly., MS & SS sheet., Set the spot welding parameters on machine., Spot weld the joint adapting appropriate techniques and, safety., Inspect the joint for soundness of weld., 14. Perform joining of different, similar and dissimilar metals, by brazing operation as per, standard, procedure., [different, similar, and, dissimilar metals- Copper,, MS, SS], , Plan and select the nozzle size, working pressure type of, flame, filler rod and flux as per requirement., Prepare, set and tack the pieces as per drawing., Braze the joint adapting proper brazing technique and, safety aspect., Carry out visual inspection to ascertain quality weld joint., , 15. Repair Cast Iron machine, parts, by, selecting, appropriate, welding, process., [Appropriate, welding process- OAW,, , Plan and prepare the job as per requirement., Select the type & size of electrode, power source, polarity,, welding current as per requirement., Set the part properly., Deposit the weld adapting appropriate welding technique, and safety aspects., 17

Page 21 :

WELDER, SMAW], , Clean the welded joint thoroughly., Carry out visual inspection to ascertain quality of weld, joint., , 16. Hard facing of alloy steel Plan and prepare the component by cleaning the surface, components / MS rod by thoroughly., using hard facing electrode. Select the type & size of electrode, power source, welding, current as per requirement., Deposit the weld observing standard practice and safety., Clean the welded surface thoroughly., Carryout visual inspection to ascertain quality of weld., , 18

Page 22 :

WELDER, , 7. TRADE SYLLABUS, SYLLABUS - WELDER, DURATION: ONE YEAR, Duration, Professional, Skill 50 Hrs;, Professional, Knowledge, 14 Hrs, , Reference Learning, Outcome, , Process, code, , Set the gas welding, plant and join MS, sheet in different, position, following, safety, precautions., [Different position: 1F, 2F, 3F, 1G, 2G,, 3G.], , 1., , Set, the, SMAW, machine and perform, different type of joints, on MS in different, position, observing, standard procedure., [different types of, joints- Fillet (T-joint,, lap & Corner), Butt, (Square & V); different, position - 1F, 2F,, 3F,4F, 1G, 2G, 3G, 4G], , 4., , 2., , 3., , Professional Skills, (Trade Practical), With Indicative Hrs., Demonstration, of, Machinery used in the, trade. (6 hrs.), Identification to safety, equipment and their, use etc. (4 hrs.), Hack sawing, filing, square to dimensions., (7 hrs.), Marking out on MS, plate and punching. (8, hrs.), , 5. Setting of oxy-acetylene, OAW-01, welding, equipment,, Lighting and setting of, flame. (5 hrs.), 6. Perform fusion run, SMAW-01, without filler rod on MS, sheet 2mm thick in flat, position. (5 hrs.), 7. Setting up of Arc, welding machine &, accessories and striking, an arc. (5 hrs.), 8. Deposit straight line, bead on MS plate in flat, position. (10 hrs.), , 19, , Professional Knowledge, (Trade Theory), - Importance, of, trade, Training., - General discipline in the, Institute, - Elementary First Aid., - Importance of Welding in, Industry, - Safety, precautions, in, Shielded, Metal, Arc, Welding,, and, OxyAcetylene Welding and, Cutting., (07 hrs), - Introduction and definition, of welding., - Arc and Gas Welding, Equipments, tools and, accessories., - Various Welding Processes, and its applications., - Arc and Gas Welding terms, and definitions., (07 hrs)

Page 23 :

WELDER, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Set the gas welding, plant and join MS, sheet in different, position, following, safety, precautions., [Different position: 1F, 2F, 3F, 1G, 2G,, 3G.], , Set the SMAW, machine and perform, different type of joints, on MS in different, position observing, standard procedure., [different types of, joints- Fillet ( T-joint,, lap & Corner), Butt, (Square & V); different, position - 1F, 2F,, 3F,4F, 1G, 2G, 3G, 4G], Set the oxy- acetylene, cutting plant and, perform different, cutting operations on, MS plate. [Different, cutting operation –, Straight, Bevel,, , OAW-02 9. Depositing bead with - Different process of metal, filler rod on M.S. sheet, joining methods: Bolting,, 2 mm thick in flat, riveting, soldering, brazing,, position. (10 hrs.), seaming etc., - Types of welding joints and, OAW-03 10. Edge joint on MS sheet, its, applications., Edge, 2 mm thick in flat, preparation and fit up for, position without filler, different thickness., rod. (15 hrs.), - Surface Cleaning, (07 hrs), SMAW-02 11. Straight line beads on - Basic electricity applicable, M.S. plate 10 mm thick, to arc welding and related, in flat position. (10 hrs.), electrical, terms, &definitions., SMAW-03 12. Weaved bead on M. S - Heat and temperature and, plate 10mm thick in flat, its terms related to, position. (15 hrs.), welding, - Principle of arc welding., And characteristics of arc., (07 hrs), , OAGC-01 13. Setting up of oxy- - Common gases used for, acetylene and make, welding & cutting, flame, straight cuts (freehand), temperatures and uses., (2 hrs.), - Chemistry of oxy-acetylene, OAGC-02 14. Perform marking and, flame., straight line cutting of - Types of oxy-acetylene, MS plate 10 mm thick, flames and uses., 20

Page 24 :

WELDER, circular], OAGC-03, , OAGC-04, , OAGC-05, , OAGC-06, , Professional, Skill 150 Hrs;, Professional, Knowledge, 42 Hrs, , Set the gas welding, plant and join MS, sheet in different, position, following, safety, precautions., [Different position: 1F, 2F, 3F, 1G, 2G,, 3G.], , OAW-04, , SMAW-04, , OAW-05, Set, the, SMAW, machine and perform, different type of joints, on MS in different, position, observing, , SMAW-05, , OAW-06, , by gas. Accuracy within, ±2mm., (4 hrs.), 15. Beveling of MS plates, 10 mm thick, cutting, regular, geometrical, shapes and irregular, shapes,, cutting, chamfers by gas cutting., (7 hrs.), 16. Circular gas cutting on, MS plate 10 mm thick, by, profile, cutting, machine.(7 hrs.), 17. Marking and perform, radial cuts, cutting out, holes, using, oxyacetylene gas cutting.(3, hrs.), 18. Identify cutting defects, viz., distortion, grooved,, fluted or ragged cuts;, poor draglines; rounded, edges; tightly adhering, slag.(2 hrs.), 19. Square butt joint on, M.S. sheet 2 mm thick, in flat Position. (1G)(9, hrs.), 20. Fillet “T” joint on M.S., Plate 10 mm thick in flat, position. (1F)(7 hrs.), 21. Open corner joint on, MS sheet 2 mm thick in, flat Position (1F)(9 hrs.), 22. Fillet lap joint on M.S., plate 10 mm thick in flat, position. (1F)(7 hrs.), 23. Fillet “T” joint on MS, 21, , - Oxy-Acetylene, Equipment, parameters, application., (07 hrs), , Cutting, principle,, and, , - Arc, welding, power, sources:, Transformer,, Motor Generator set,, Rectifier and Inverter type, welding machines and its, care & maintenance.., - Advantages, and, disadvantages of A.C. and, D.C. welding machines, (06 hrs), - Welding positions as per, EN &ASME: flat, horizontal,, vertical and over head, position.

Page 25 :

WELDER, standard procedure., [different types of, joints- Fillet ( T-joint,, lap & Corner), Butt, (Square & V); different, position - 1F, 2F,, 3F,4F, 1G, 2G, 3G, 4G], , SMAW-06, , OAW-07, , SMAW-07, , I&T-01, , OAW-08, , SMAW-08, , SMAW-09, , OAW-09, , SMAW-10, , sheet 2 mm thick in flat, position. (1F)(7 hrs.), 24. Open Corner joint on, MS plate 10 mm thick in, flat position. (1F)(8 hrs.), 25. Fillet Lap joint on MS, sheet 2 mm thick in flat, position. (1F)(08 hrs.), 26. Single “V” Butt joint on, MS plate 12 mm thick in, flat position (1G). (11, hrs.), 27. Testing of weld joints by, visual inspection. (1 hr.), 28. Inspection of welds by, using weld gauges. (1, hr.), 29. Square Butt joint on, M.S. sheet. 2 mm thick, in Horizontal position., (2G)(8 hrs.), 30. Straight line beads and, multi layer practice on, M.S. Plate 10 mm thick, in Horizontal position., (4 hrs.), 31. Fillet “T” joint on M.S., plate 10 mm thick in, Horizontal, position., (2F)(7 hrs.), 32. Fillet Lap joint on M.S., sheet 2 mm thick in, horizontal, position, (2F)(10 hrs.), 33. Fillet Lap joint on M.S., plate 10 mm thick in, horizontal position. (11, hrs.) (2F), 22, , - Weld slope and rotation., - Welding symbols as per BIS, & AWS. (06 hrs), , - Arc length – types – effects, of arc length., - Polarity:, Types, and, applications., - Weld quality inspection,, common welding mistakes, and appearance of good, and defective welds, - Weld gauges & its uses., (06 hrs), , - Calcium carbide properties, and uses., - Acetylene gas properties, and generating methods., - Acetylene gas Purifier,, Hydraulic back pressure, valve and Flash back, arrestor., (06hrs), , - Oxygen gas and its, properties, - Production of oxygen by, Air liquefaction., - Charging process of oxygen, and acetylene gases, - Oxygen and Dissolved, Acetylene gas cylinders

Page 26 :

WELDER, , OAW-10, , OAW-11, , SMAW-11, , SMAW- 12, , OAW-12, , SMAW-13, , Professional, Skill 100 Hrs;, Professional, Knowledge, 28 Hrs, , Set, the, SMAW, machine and perform, different type of joints, on MS in different, position, observing, standard procedure., [different types of, joints- Fillet ( T-joint,, lap & Corner), Butt, (Square & V); different, , OAW-13, , SMAW-14, , and Color coding for, different gas cylinders., - Gas regulators, types and, uses., (06 hrs), 34. Fusion run with filler - Oxy acetylene gas welding, rod in vertical position, Systems (Low pressure and, on 2mm thick M.S, High pressure)., sheet. (7 hrs.), Difference between gas, 35. Square Butt joint on, welding blow pipe(LP &HP), M.S. sheet. 2 mm thick, and gas cutting blow pipe, in vertical position - Gas welding techniques., (3G)(7 hrs.), Rightward and Leftward, 36. Single Vee Butt joint on, techniques., M.S. plate 12 mm thick, (06 hrs), in horizontal position, (2G). (8hrs.), 37. Weaved bead on M.S - Arc blow – causes and, Plate 10mm in vertical, methods of controlling., position.(7 hrs.), - Distortion in arc & gas, 38. Fillet “T” joint on M.S, welding and methods, sheet 2 mm thick in, employed to minimize, vertical position. (3F)(7, distortion, hrs.), - Arc, Welding, defects,, 39. Fillet “T” joint on M.S., causes and Remedies., plate 10 mm thick in, (06 hrs), vertical position. (3F)(8, hrs.), 40. Structural pipe welding - Specification of pipes,, butt joint on MS pipe Ø, various types of pipe, 50 and 3mm WT in 1G, joints, pipe welding all, position. (15 hrs.), positions, and procedure., 41. Fillet Lap joint on M.S. - Difference between pipe, Plate 10 mm in vertical, welding and plate welding., position. (3G)(10 hrs.), (07 hrs), , SMAW-15 42. Open Corner joint on - Pipe development for, MS plate 10 mm thick in, Elbow joint, “T” joint, Y, 23

Page 27 :

WELDER, position - 1F, 2F,, 3F,4F, 1G, 2G, 3G, 4G], , Perform welding in, different types of MS, pipe joints by Gas, welding, (OAW)., [Different types of MS, pipe joints – Butt,, Elbow, T-joint, angle, (45) joint, flange, joint], , Professional, Skill 75 Hrs;, Professional, Knowledge, 21 Hrs, , Set, the, SMAW, machine and perform, different type of joints, on MS in different, position, observing, standard procedure., [different types of, joints- Fillet ( T-joint,, lap & Corner), Butt, (Square & V); different, position - 1F, 2F,, , vertical position. (2F)(10, joint and branch joint, hrs.), - Manifold system, OAW-14 43. Pipe welding - Elbow, (07 hrs), joint on MS pipe Ø 50, and 3mm WT. (1G)(15, hrs.), OAW-15 44. Pipe welding “T” joint - Gas welding filler rods,, on MS pipe Ø 50 and, specifications and sizes., 3mm WT. (1G)(10 hrs.) - Gas welding fluxes – types, and functions., SMAW-16 45. Single “V” Butt joint on - Gas Brazing & Soldering :, MS plate12 mm thick in, principles, types fluxes &, vertical position (3G)., uses, (15 hrs.), - Gas, welding, defects,, causes and remedies, (07 hrs), OAW-16 46. Pipe welding 45 ° angle - Electrode : types, functions, joint on MS pipe Ø 50, of flux, coating factor, sizes, and 3mm WT. (1G)(15, of electrode Coding of, hrs.), electrode as per BIS, AWS,, - Effects of moisture pick up., SMAW-17 47. Straight line beads on - Storage and baking of, M.S. plate 10mm thick, electrodes., in over head position. - Special purpose electrodes, (10 hrs.), and their applications., (07 hrs), SMAW-18 48. Pipe Flange joint on - Weldability of metals,, M.S plate with MS pipe, importance of pre heating,, Ø 50 mm X 3mm WT, post heating, and, (1F)(15 hrs.), maintenance of inter pass, temperature., SMAW-19 49. Fillet “T” joint on M.S., (07 hrs), plate 10 mm thick in, over head position., (4F)(10 hrs.), SMAW-20 50. Pipe welding butt joint - Classification of steel., on MS pipe Ø 50 and 5 - Welding of low, medium, mm WT. in 1G position., and high carbon steel and, 24

Page 28 :

WELDER, 3F,4F, 1G, 2G, 3G, 4G], , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Set, the, SMAW, machine and perform, welding in different, types of MS pipe, joints by SMAW., [Different types of MS, pipe joints – Butt,, Elbow, T-joint, angle, (45) joint, flange, joint], Choose appropriate, welding process and, perform joining of, different types of, metals and check its, correctness., [appropriate welding, process, –, OAW,, SMAW;, Different, metal – SS, CI, Brass,, Aluminium], Choose appropriate, welding process and, perform joining of, different types of, metals and check its, correctness., [appropriate welding, process, –, OAW,, SMAW;, Different, metal – SS, CI, Brass,, Aluminium], , (15 hrs.), alloy steels., SMAW-21 51. Fillet Lap joint on M.S., (07 hrs), plate 10 mm thick in, over head position., (4G). (10 hrs.), SMAW-22 52. Single “V” Butt joint on - Effects, of, alloying, MS plate 10mm thick in, elements on steel, over head position(4G) - Stainless steel types- weld, (15 hrs.), decay and weldability., SMAW-23 53. Pipe butt joint on M. S., (07 hrs), pipe Ø 50mm WT 6mm, (1G Rolled).(10 hrs.), OAW-17 54. Square Butt joint on, S.S. sheet. 2 mm thick, in flat position. (1G)(8, hrs.), SMAW -24 55. Square Butt joint on S.S., Sheet 2 mm thick in flat, position. (1G)(8 hrs.), OAW-18 56. Square Butt joint on, Brass sheet 2 mm thick, in flat position. (1G)(9, hrs.), OAW-19 57. Square Butt & Lap joint, on M.S. sheet 2 mm, thick by brazing in flat, SMAW-25, position. (11 hrs.), 58. Single “V” butt joint C.I., plate 6mm thick in flat, AG-01, position. (1G)(11 hrs.), 59. Arc gouging on MS plate, 10 mm thick. (3 hrs.), , Demonstrate, arc, gauging operation to, 25, , - Brass – types – properties, and welding methods., - Copper, –, types, –, properties and welding, methods., (07 hrs), , - Aluminium and its alloys,, properties and weldability,, Welding methods, - Arc cutting & gouging,, (07 hrs)

Page 29 :

WELDER, rectify the weld joints., , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 200 Hrs;, Professional, Knowledge, 56 Hrs, , Choose appropriate, OAW-20 60. Square Butt joint on, welding process and, Aluminium sheet., 3, perform joining of, mm thick in flat, different types of, position. (12 hrs.), metals and check its, 61. Bronze welding of cast, correctness., OAW-21, iron (Single “V” butt, [appropriate welding, joint) 6mm thick plate, process, –, OAW,, (1G).(13 hrs.), SMAW;, Different, metal – SS, CI, Brass,, Aluminium], Test welded joints by, I&T-02 62. Dye penetrant test. (5, different methods of, hrs.), testing. [different, I&T-03 63. Magnetic particle test., methods of testing(5 hrs.), Dye penetration test,, I&T-04 64. Nick- break test. (5, Magnetic particle test,, hrs.), Nick break test, Free, I&T-05 65. Free bend test. (5 hrs.), band test, Fillet, I&T-06 66. Fillet fracture test. (5, fracture test], hrs.), Set GMAW machine, 67. Introduction to safety, and perform welding GMAW- 01, equipment and their, in different types of, use etc. (2 hrs.), joints, on, MS, 68. Setting up of GMAW, sheet/plate by GMAW, welding machine &, in various positions by, accessories, and, dip mode of metal GMAW - 02, striking an arc. (4 hrs.), transfer., [different, 69. Depositing, straight, types of joints- Fillet, line beads on M.S, (T-joint, lap, Corner),, Plate. (10 hrs.), Butt (Square & V);, 70. Fillet weld – “T” joint, various positions- 1F,, on M.S plate 10mm, 2F, 3F,4F, 1G, 2G, 3G], thick in flat position by, 26, , - Cast iron and its properties, types., - Welding methods of cast, iron., (07 hrs), , - Types, of, Inspection, methods, - Classification, of, destructive, and, NDT, methods, - Welding economics and, Cost estimation., (07 hrs), - Safety precautions in Gas, Metal Arc Welding and Gas, Tungsten Arc welding., - Introduction to GMAW equipment – accessories., - Various other names of the, process. (MIG/MAG/CO2, welding.), (05 hrs)

Page 30 :

WELDER, , GMAW -03 71., , GMAW -04 72., , GMAW -05 73., , GMAW -06 74., , GMAW -07 75., , GMAW -08 76., , GMAW -09 77., , 27, , Dip transfer. (1F) (4, hrs.), Fillet weld – Lap joint - Advantages of GMAW, on M.S. sheet 3mm, welding over SMAW ,, thick in flat position by, limitations, and, Dip transfer. (1F) (5, applications, hrs.), - Process, variables, of, Fillet weld – “T” joint, GMAW., on M.S. sheet 3mm - Modes of metal transfer –, thick in flat position by, dip or short circuiting, Dip transfer. (1F), transfer, spray transfer, (5hrs.), (free flight transfer) and, Fillet weld – corner, globular, transfer, joint on M.S. sheet, (intermittent transfer) and, 3mm thick in flat, Pulsed metal transfer., position, by, Dip, (05 hrs), transfer. (1F)(5 hrs.), Butt weld – Square - Wire feed system – types –, butt joint on M.S, care and maintenance., sheet 3mm thick in - Welding wires used in, flat position (1G) (07, GMAW,, standard, hrs.), diameter and codification, Butt weld – Single “V”, as per AWS., butt joint on M.S plate (05 hrs), 10 mm thick by Dip, transfer, in flat, position. (1G), (8, hrs.), Fillet weld – “T” joint - Types of shielding gases, on M.S plate 10mm, and gas mixtures used in, thick, in Horizontal, GMAW, and, its, position, by, Dip, applications., transfer. (2F), (10 - Flux cored arc welding –, hrs.), description,, advantage,, Fillet weld – corner, welding wires, coding as, joint on M.S plate, per AWS., 10mm, thick, in (06 hrs), Horizontal position by

Page 31 :

WELDER, , GMAW -10 78., , GMAW -11 79., , GMAW -12 80., , GMAW -13 81., , GMAW -14 82., , GMAW -15 83., , 28, , Dip transfer. (2F) (15, hrs.), Fillet weld –, “T” - Edge, preparation, of, joint on M.S. sheet, various thicknesses of, 3mm, thick, in, metals for GMAW., Horizontal position by - GMAW defects, causes and, Dip transfer. (2F), remedies, (10 hrs.), (07 hrs), Fillet weld – corner, joint on M.S. sheet, 3mm, thick, in, Horizontal position by, Dip transfer. (2F) (15, hrs.), Fillet weld – “T” joint - Heat input and techniques, on M.S plate 10mm, of controlling heat input, thick, in vertical, during welding., position, by, Dip - Heat distribution and, transfer. (3F), (10, effect of faster cooling, hrs.), (07 hrs), Fillet weld – corner, joint on M.S plate, 10mm thick in vertical, position, by, dip, transfer. (3F), (15, hrs.), Fillet weld – Lap joint - Pre heating & Post Weld, on M.S. sheet 3mm, Heat Treatment, thick, in, vertical - Use, of, temperature, position, by, Dip, indicating crayons., transfer. (3F), (10, (07 hrs), hrs.), Fillet weld – corner, joint on M.S. sheet, 3mm thick in vertical, position, by, Dip, transfer. (3F), (15, hrs.)

Page 32 :

WELDER, GMAW -16 84. Fillet weld – Lap and, “T” joint on M.S sheet, 3mm thick inover, head position by Dip, transfer. (4F), (15, GMAW -17, hrs.), 85. Tee Joints on MS Pipe, Ø 60 mm OD x 3 mm, WT 1G position – Arc, constant (Rolling) (10, hrs.), GMAW -18 86. Depositing bead on, S.S sheet in flat, position. (10 hrs.), GMAW -19 87. Butt joint on Stainless, steel 2 mm thick sheet, in flat position by Dip, transfer. (15 hrs.), Professional, Skill 100 Hrs;, Professional, Knowledge, 28 Hrs, , Set the GTAW, machine and perform, welding by GTAW in, different types of, joints on different, metals in different, position and check, correctness of the, weld. [different types, of joints- Fillet ( Tjoint, lap, Corner),, Butt (Square & V) ;, different metalsAluminium, Stainless, Steel; different, position- 1F & 1G], , GTAW -01, , GTAW -02, , GTAW -03, , GTAW -04, , 88. Depositing bead on, Aluminium sheet 2, mm thick in flat, position. (10 hrs.), 89. Square butt joint on, Aluminium, sheet, 1.6mm thick in flat, position. (15 hrs.), , 90. Fillet weld – “T” joint, on Aluminium sheet, 1.6 mm thick in flat, position. (1F) (10 hrs.), 91. Fillet weld – Outside, corner, joint, on, Aluminium sheet 2, mm thick in flat, position. (1F) (15 hrs.), 29, , - Submerged arc welding, process, –principles,, equipment,, advantages, and limitations, - Electro slag and Electro gas, welding, processes–, principles,, equipments,, advantages, and, limitations., (07 hrs), - Thermit welding processtypes,, principles,, equipments,, Thermit, mixture, types, and, applications., - Use of backing strips and, backing bars, (07 hrs), - GTAW process - brief, description., Difference, between AC and DC, welding,, equipments,, polarities and applications., - Various other names of, the process (TIG, Argonarc), - Power sources for GTAW AC &DC, (07 hrs), - Tungsten electrodes –, types & uses, sizes and, preparation, - GTAW, Torches- types,, parts and their functions, - GTAW filler rods and, selection criteria., (07 hrs)

Page 33 :

WELDER, GTAW -05, , GTAW -06, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Professional, , Perform Aluminium &, MS pipe joint by, GTAW in flat position., , GTAW -07, , Perform Aluminium &, MS pipe joint by, GTAW in flat position., , GTAW -08, , Set the Plasma Arc, cutting machine and, cut ferrous & nonferrous metals., Set the resistance spot, welding machine and, join MS & SS sheet., , PAC-01, , RW-01, , RW-02, , Perform joining of, different similar and, , OAW-01, , 92. Butt weld - Square - Edge preparation and fit, butt joint on Stainless, up., steel sheet 1.6 mm - GTAW parameters for, thick in flat position, welding, of, different, with purging gas (1G), thickness of metals, (25 hrs.), - Pulsed TIG welding - brief, description,, pulse, parameters slope up and, slope down., (07 hrs), 93. Fillet weld – “T” joint - Argon / Helium gas, on Stainless steel, properties – uses., sheet 1.6 mm thick in - GTAW Defects, causes and, flat position. (1F) (25, remedy., hrs.), (07 hrs), 94. Pipe butt joint on - Friction welding processAluminium pipe Ø 50, equipment and application, mm x 3 mm WT in Flat - Laser, beam, welding, position. (1G) (25 hrs.), (LBW)and Electron beam, welding(EBW), (07 hrs), 95. “T” Joints on MS Pipe - Plasma Arc Welding (PAW), Ø 50 mm OD x 3 mm, and cutting (PAC) process, WT, position – Flat, –, equipments, and, (1F) (15 hrs.), principles of operation., 96. Straight cutting on - Types of Plasma arc,, ferrous, and, non, advantages, and, ferrous (10 hrs.), applications., (07 hrs), 97. Lap joint on Stainless - Resistance welding process, steel, sheet, by, -types, principles, power, Resistance, Spot, sources, and, welding, welding. (10 hrs.), parameters., 98. MS sheets joining by - Applications, and, Resistance, Spot, limitations., welding (15 hrs.), (07 hrs), 99. Square butt joint on - Metalizing – types of, Copper sheet 2mm, metalizing, principles,, 30

Page 34 :

WELDER, Skill 50 Hrs;, Professional, Knowledge, 14 Hrs, , dissimilar metals by, brazing operation as, per, standard, procedure. [different, similar and dissimilar, metals- Copper, MS,, SS], , OAW-02, , OAW-03, , OAW-04, , Professional, Skill 25 Hrs;, Professional, Knowledge, 07 Hrs, , Repair, Cast, Iron, machine parts by, selecting appropriate, welding, process., [Appropriate welding, processOAW,, SMAW], Hard facing of alloy, steel components /, MS rod by using hard, facing electrode., , OAW - 05, , SMAW-01, , SMAW-02, , thick in flat position., (1G) (15 hrs.), 100. “T” joint on Copper to, MS sheet, 2mm thick, in flat, position by, Brazing (1F) (10 hrs.), 101. Silver brazing on S.S, Sheet with copper, sheet “T” joint. (10, hrs.), 102. Silver, brazing, on, copper tube to tube., (15 hrs.), , 103. Repair welding of, broken C.I. machine, parts by oxy-acetylene, welding with C.I and, bronze filler rod. (10, hrs.), 104. Repair welding of, broken C.I machine, parts by C.I. electrode., (8 hrs.), 105. Hard, surfacing, practice on M.S round, rod Ø 25 mm by using, Hard facing electrode, in flat position. (7 hrs.), , In-plant training / Project work, Broad area:, a) Universal welding manipulator, b) Metal rack, c) Cylinder trolley with chain provision for locking, d) Welding fixture for TIG- butt/ corner joint with purging facility, , 31, , equipments, advantages, and applications, - Manual Oxy – acetylene, powder coating processprinciples of operation and, applications, (07 hrs), - Welding, codes, and, standards, - Reading of, assembly, drawing, - Welding, Procedure, Specification (WPS) and, Procedure, Qualification, Record ( PQR), (07 hrs), - Hard facing/ surfacing, necessity,, surface, preparation, various hard, facing, alloys, and, advantages of hard facing., (06 hrs)

Page 35 :

WELDER, , SYLLABUS FOR CORE SKILLS, 1. Workshop Calculation & Science ( Common for one year trades) (80 hrs), 2. Engineering Drawing (80 hrs), 3. Employability Skills ( Common for all CTS trades) (160 hrs), , Learning outcomes, assessment criteria, syllabus and Tool List of Core Skills subjects which is, common for a group of trades, provided separately in www.bharatskills.gov.in., , 32

Page 36 :

WELDER, , ANNEXURE-I, LIST OF TOOLS AND EQUIPMENT, WELDER (For batch of 20 Candidates), S No., , Name of the Tools& Equipment, , Specification, , Quantity, , A. TRAINEES TOOL KIT ( For each additional unit trainees tool kit Sl. 1-15 is required, additionally), 1., Welding helmet fiber, 20+1 Nos., 2., Welding hand shield fiber, 20+1 Nos., with metal handle 250, 20+1 Nos., 3., Chipping hammer, Grams, 4., Chisel cold, flat 19 mm x 150 mm, 20+1 Nos., 5., Centre punch, 9 mm x 127 mm, 20+1 Nos., 6., Dividers, 200 mm, 20+1 Nos., 7., Stainless steel rule, 300mm, 20+1 Nos., 8., Scriber, 150 mm double point, 20+1 Nos., 9., Flat Tongs, 350mm long, 20+1 Nos., 10., Hack saw frame, fixed 300 mm, 20+1 Nos., 11., File half round, bastard 300 mm, 20+1 Nos., 12., File flat, 350 mm bastard, 20+1 Nos., 13., Hammer ball pane, 1 kg with handle, 20+1 Nos., 14., Tip Cleaner, 20+1 Nos., 15., Try square, 6”, 20+1 Nos., B. INSTRUMENTS AND GENERAL SHOP OUTFIT - For 2 (1+1) units no additional items are, required, TOOLS & EQUIPMENT, 16., Spindle key, 4 Nos., 300mm blade and 250, 1 each, 17., Screw Driver, mm blade, 18., Number punch, 6 mm, 2 set, 19., Letter punch, 6 mm, 2 set, 20., Magnifying glass, 100 mm dia., 2 Nos., 21., Universal Weld measuring gauge, 2 Nos., 22., Earth clamp, 600A, 6 Nos., 23., Spanner D.E., 6 mm to 32mm, 2 sets, 24., C-Clamps, 10 cm and 15 cm, 2 each, 25., Hammer sledge, double faced 4 kg, 1 No., 26., S.S tape, 5 meters flexible in case, 1 No., 27., Electrode holder, 600 amps, 6 Nos., 28., H.P. Welding torch, with 5 nozzles, 2 sets, 33

Page 37 :

WELDER, 29., 30., 31., 32., 33., 34., 35., 36., 37., 38., , Oxygen Gas Pressure, Acetylene Gas Pressure, CO2 Gas pressure regulator, Argon Gas pressure regulator, Metal rack, First Aid box, Steel lockers, Steel almirah / cupboard, Black board and easel with stand, Flash back arrester (torch mounted), Flash back arrester (cylinder, 39., mounted), GENERAL SHOP OUTFIT, 40., , Welding Transformer, , 41., , Welding Transformer (or) Inverter, based welding machine, , 42., , D.C Arc welding rectifiers set with all, accessories, , 43., , GMAW welding machine, , 44., , AC/DC GTAW welding machine, , 45., , Air Plasma cutting equipment, , 47., , Air compressor suitable for above air, plasma cutting system., Auto Darkening Welding Helmet, , 48., , Spot welding machine, , 49., , Portable gas cutting machine, , 50., , Pedestal grinder fitted with coarse, , 46., , regulator double stage, regulator double stage, with flow meter, with flow meter, 182 cm x 152 cm x 45 cm, with 8 Pigeon holes, , 2 Nos., 2 Nos., 2 set, 2 set, 1 No., 1 No., 2 Nos., 2 Nos., 1 No., 4 pairs, 4 pairs, , with all accessories, (400A, OCV 60–100 V,, 60% duty cycle), with all accessories, (300A, OCV 60 – 100 V,, 60% duty cycle), (400 A. OCV 60 – 100 V,, 60% duty cycle ), 400A capacity with air, cooled torch, Regulator,, Gas pre-heater, Gas hose, and Standard accessories, with water cooled torch, 300 A, Argon regulator,, Gas hose, water, circulating system and, standard accessories., with all accessories,, capacity to cut 12 mm, clear cut, , 1 set, , 1 set, , 1 sets, 1 set, , 1 set, , 1 set, , 1 No., 2 Nos., 15 KVA with all, accessories, capable of cutting Straight, & Circular with all, accessories, 300 mm dia., 34, , 1 set, 1 set, , 1 No.

Page 38 :

WELDER, , 52., 53., 54., 55., , and medium grain size grinding, wheels, Bench grinder fitted with fine grain, size silicon carbide green grinding, wheel, AG 4 Grinder, Suitable gas welding table, Suitable Arc welding table, Trolley for cylinder (H.P. Unit), , 56., , Hand shearing machine capacity, , 57., 58., 59., , Power saw machine, Portable drilling machine, Oven, electrode drying, , 60., , Work bench, , 61., 62., 63., 64., , Oxy Acetylene Gas cutting blow pipe, Oxygen, Acetylene Cylinders **, CO2 cylinder **, Argon gas cylinder **, Anvil 12 sq. inches working area with, stand, Swage block, Die penetrant testing kit, Magnetic particle testing Kit #, Fire extinguishers (foam type and CO2, type), Fire buckets with stand, Portable abrasive cut-off machine, Suitable Gas cutting table, Welding Simulators for, SMAW/GTAW/GMAW, , 51., , 65., 66., 67., 68., 69., 70., 71., 72., 73., , 1 No., 150 mm dia., , with fire bricks, with positioner, cut 6 mm sheets and, flats, 14’’, (Cap. 6 mm), 0 to 350°C, 10 kg capacity, 340x120x75 cm with 4, bench vices of 150 mm, jaw opening, , 2 Nos., 2 Nos., 6 Nos., 2 Nos., 1 No., 1 No., 1 No., 1 No., 4 sets, 2 sets, 2 each, 2 Nos., 2 Nos., 1 No., 1 No., 1 set, 1 set, 1. No., 4 Nos., 1 No., 1 No., 1 each, (Optional), , C. CONSUMABLE, 74., 75., 76., 77., 78., 79., 80., 81., , Leather Hand Gloves, Cotton hand Gloves, Leather Apron leather, S.S Wire brush, Leather hand sleeves, Safety boots for welders, Leg guards leather, Rubber hose clips, , 14”, 8”, 5 rows and 3 rows, 16”, , ½", 35, , 20 pairs, 20 pairs, 20 Nos., 20 Nos. each, 20 pairs, 20 pairs, 20 pairs, 20 Nos.

Page 39 :

WELDER, 82., 83., 84., 85., 86., 87., , Rubber hose oxygen, Rubber hose acetylene, Arc welding cables multi cored, copper, Arc welding single coloured glasses, Arc welding plain glass, Gas welding Goggles, , 8 mm dia X 10 Mtr. long, as per BIS, 8 mm dia X 10 Mtr. long, as per BIS, 400/ 600 amp as per BIS, 108 mm x 82 mm x 3 mm., DIN 11A &12 A, 108 mm x 82 mm x 3 mm., with Colour glass 3 or 4A, DIN, , 2 Nos., 2 Nos., 45 mts. each, 34 Nos., 68 Nos., 34 Nos., , 88., Safety goggles plain, 34 Nos., 89., Spark lighter, 6 Nos., 90., AG 4 Grinding wheels, 10 Nos., D. CLASS ROOM FURNITURE FOR TRADE THEORY, 91., Instructor’s table and Chair (Steel), 1 set, 92., Students chairs with writing pads, 20 Nos., 93., White board, size 1200mm X 900 mm, 1 No., Instructor’s laptop with latest, configuration pre-loaded with, 94., 1 No., operating system and MS Office, package., 95., LCD projector with screen., 1 No., Welding Process, Inspection & codes, 1 set each, 96., DVD/ CDs., (optional), Note:, 1., ** Optionally Gas cylinders can also be hired as and when required., 2., # One machine per institute irrespective of number of units of welding trade is, necessary., , 36

Page 44 :

WELDER, , 41