Page 1 :

TURNER, NSQF LEVEL - 5, , 4th Semester, TRADE THEORY, SECTOR: Production & Manufacturing, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, , Copyright @ NIMI Not(i)to be Republished

Page 2 : Sector, , : Turner, , Duration : 2 - Years, Trade, , : Turner 4th Semester - Trade Theory - NSQF level 5, , Copyright© 2018 National Instructional Media Institute, Chennai, First Edition :, , December 2018, , Copies : 1,000, , Rs.230/-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical,, including photocopy, recording or any information storage and retrieval system, without permission in writing from the, National Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone : 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected],

[email protected], Website: www.nimi.gov.in, , Copyright @ NIMI(ii)Not to be Republished

Page 3 :

FOREWORD, The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of, every four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy., Industrial Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled, manpower. Keeping this in mind, and for providing the current industry relevant skill training to Trainees,, ITI syllabus has been recently updated with the help of Mentor Councils comprising various stakeholder's, viz. Industries, Entrepreneurs, Academicians and representatives from ITIs., The National Instructional Media Institute (NIMI), Chennai has now come up with instructional material to, suit the revised curriculum for Turner 4th Semester Trade Theory NSQF Level - 5 in Production &, Manufacturing Sector under Semester Pattern. The NSQF Level - 5 Trade Theory will help the trainees, to get an international equivalency standard where their skill proficiency and competency will be duly, recognized across the globe and this will also increase the scope of recognition of prior learning. NSQF, Level - 5 trainees will also get the opportunities to promote life long learning and skill development. I have, no doubt that with NSQF Level - 5 the trainers and trainees of ITIs, and all stakeholders will derive, maximum benefits from these IMPs and that NIMI's effort will go a long way in improving the quality of, Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve, appreciation for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, , Director General/ Addl.Secretary, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , Copyright @ NIMI Not(iii)to be Republished

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Employment and Training (D.G.E & T), Ministry of Labour and Employment, (now under Directorate, General of Training, Ministry of Skill Development and Entrepreneurship) Government of India, with technical, assistance from the Govt. of the Federal Republic of Germany. The prime objective of this institute is to, develop and provide instructional materials for various trades as per the prescribed syllabi under the Craftsman, and Apprenticeship Training Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials, are generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book,, Practical book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and, Transparencies) and other support materials., The trade practical book consists of series of exercises to be completed by the trainees in the workshop., These exercises are designed to ensure that all the skills in the prescribed syllabus are covered. The, trade theory book provides related theoretical knowledge required to enable the trainee to do a job. The, test and assignments will enable the instructor to give assignments for the evaluation of the performance, of a trainee. The wall charts and transparencies are unique, as they not only help the instructor to effectively, present a topic but also help him to assess the trainee's understanding. The instructor guide enables the, instructor to plan his schedule of instruction, plan the raw material requirements, day to day lessons and, demonstrations., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the, Media Development Committees specially drawn from Public and Private sector industries, various training, institutes under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment & Training, of various State Governments, Training Departments of Industries both in the Public and Private sectors,, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators, but, for whose active support NIMI would not have been able to bring out this materials., , Chennai - 600 032, , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Copyright @ NIMI(iv)Not to be Republished

Page 6 :

INTRODUCTION, TRADE THEORY, The manual of trade theory consists of theoritical information for the Fourth Semester couse of the Turner, Trade. The contents are sequenced according to the practical exercise contained in the manual on Trade, practical. Attempt has been made to relate the theoritical aspects with the skill covered in each exercise to, the extent possible. This co-relation is maintained to help the trainees to develop the perceptional capabilities, for performing the skills., The manual is divided into six modules. The distribution of time for the practicals in the six modules are given, below., Module 1, , Introduction to CNC, , 25 Hrs, , Module 2, , CNC Turning, , 75 Hrs, , Module 3, , Tool setting and data input, , 75 Hrs, , Module 4, , Programme and Simulation, , 75 Hrs, , Module 5, , CNC Turning operations, , 75 Hrs, , Module 6, , Advance Turning, , 200Hrs, , Total, , 525 Hrs, , The Trade Theory has to be taught and learnt along with the corresponding exercise contained in the manual, on trade practical. The indication about the corresponding practical exercise are given in every sheet of this, manual., It will be preferable to teach/learn the trade theory connected to each exercise atleast one class before, performing the related skills in the shop floor. The trade theory is to be treated as an integral part of each, exercise., The material is not the purpose of self learning and should be considered as supplementary to class room, instruction., TRADE PRACTICAL, The trade practical manual is intended to be used in workshop . It consists of a series of practical exercies to, be completed by the trainees during the Fouth Semester course of the Turner trade supplemented and, supported by instructions/ informations to assist in performing the exercises. These exercises are designed, to ensure that all the skills in the prescribed syllabus are covered., The skill training in the computer lab is planned through a series of practical exercises centered around some, practical project. However, there are few instance where the individual exercise does not form a part of project., While developing the practical manual a sincere effort was made to prepare each exercise which will be easy, to understand and carry out even by below average trainee. However the development team accept that there, is scope for further improvement. NIMI, looks forward to the suggestions from the experienced training faculty, for improving the manual., , Copyright @ NIMI(vi)Not to be Republished

Page 7 :

CONTENTS, Lesson No., , Title of the Lesson, , Page No., , Module 1: Introduction to CNC, 4.1.111, , CNC Technology basics, , 1, , 4.1.112, , Machine model, control system and specification, , 6, , 4.1.113, , Axis convention of CNC machine, , 18, , 4.1.114, , Importance of feedback system and Concept of co-ordinate geometry, , 23, , 4.1.115, , Coordinate Geometry & Machine Axis, , 25, , Module 2: CNC Turning, 4.2.116 -117, , Preparation of part programming, , 30, , 4.2.118, , Operational modes, , 44, , 4.2.119, , Types of offsets, , 48, , 4.2.120, , Tool path study of machining operation (Straight turning), , 52, , 4.2.121 -122, , Cutting parameters, cutting speed and feed, depth of cut,CSM,, tool wear, tool life, , 60, , Module 3: Tool setting and Data Input, 4.3.123-124, , Cutting tool materials for Turning, , 68, , 4.3.125, , Tool Geometry, Insert Type, Nomenclature of Inserts, , 74, , 4.3.126, , Describe tooling system for turning, , 77, , 4.3.127, , Setting work and tool offset, , 79, , 4.3.128, , Describe tooling system for CNC Turning centres, , 80, , 4.3.129, , Cutting tool material for CNC turning, , 81, , 4.3.130, , ISO Nomenclature for Turning tool holder, boring tool holder, indexable insert, , 82, , 4.3.131, , Tool holders and inserts for radial grooving, face grooving,, threading and drilling, , 85, , Module 4: Programme and Simulation, 4.4.132, , Preparation of Part programming as per drawing, , 87, , 4.4.133, , Checking using CNC Simulator, , 93, , 4.4.134, , Process and tool selection (CNC), , 94, , 4.4.135, , Part programme for Grooving, , 95, , 4.4.136, , Part progarmme for drilling, , 96, , 4.4.137, , Part progarmme for boring, , 97, , 4.4.138, , Part progarmme for threading, , 99, , Copyright @ NIMI Not(vii)to be Republished

Page 8 :

Lesson No., , Title of the Lesson, , Page No., , Module 5: CNC Turning Operations, 4.5.139, , Programming on CNC Tapping, , 101, , 4.5.140, , CNC Programme for Grooving (OD/ID), , 103, , 4.5.141, , CNC Programming for threading, , 105, , 4.5.142, , Trouble shooting in CNC machines, , 107, , 4.5.143, , Factors affecting quality & productivity, , 114, , 4.5.144, , Parting off Operation in a CNC, , 119, , 4.5.145, , Bar Feeding System through Bar Feeder, , 117, , 4.5.146, , Input and Output of data, , 118, , 4.5.147, , DNC system, , 123, , 4.5.148, , Use of CAM Programme, , 124, , Module 6 : Advance Turning, 4.6.149, , Setting of tool for taper threads, calculation of taper setting and thread depth, , 126, , 4.6.150, , Interchangeability meaning, procedure for adoption, quality control, procedure for quality production, , 135, , 4.6.151-152, , Importance of Technical term used in Industry, , 158, , 4.6.153, , Terms used in part drawings and Geometrical tolerances, and symbols, , 175, , 4.6.154-156, , Automatic lathe - types - parts, toolholders, theory of calculation, , 184, , Copyright @ NIMI(viii), Not to be Republished

Page 9 :

LEARNING / ASSESSABLE OUTCOME, On completion of this book you shall be able to, • Set (Both job and tool) CNC turning centre and produce components, as per drawing by preparing part programme., • Manufacture and assemble components to produce utility items, by performing different operations and observing principle of, interchangability and check functionality item (screw jack, vice, spindle, box nut, marking block, drill chuck, collet chuck etc, by, different operation)., • Threading (Square thread) BSW, ACME, Metric, thread on taper,, different boring operations., • Make a process plan to produce components by performing, special operations on lathe and check for accuracy., • Perform special operation in CNC lathe worm shaft cutting, boring,, threading etc.,., , Copyright @ NIMI Not(ix)to be Republished

Page 10 :

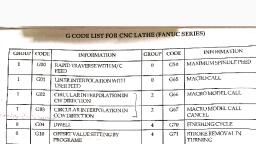

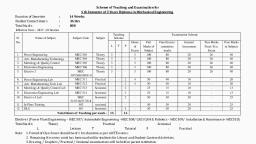

SYLLABUS, Fourth Semester, Week, No., 79, , 80-82, , Duration: Six Month, , Ref. Learning, Outcome, •, , Set (both job and, tool) CNC turn, centre and produce, components as per, drawing by, preparing part, programme., , -do-, , Professional Skills, (Trade Practical), with Indicative hours, 111. Personal and CNC machine, Safety: Safe handling of tools,, equipment and CNC, machine. (2 hrs.), 112. Identify CNC machine, CNC, console. (5 hrs.), 113. Demonstration of CNC lathe, machine and its parts - bed,, spindle motor and drive,, chuck, tailstock, turret, axes, motor and ball screws, guide, ways, LM guides, console,, control switches,coolant, system, hydraulic system,, chip conveyor, steady rest., (7 hrs.), 114. Working of parts explained, using Multimedia based, simulator for CNC parts, shown on machine. (6 hrs.), 115. Identify machine over travel, limits and emergency stop., (1 hrs.), , 116. Conduct a preliminary check, of the readiness of the CNC, turning centre viz., cleanliness, of machine, referencing – zero, return, functioning of, lubrication, coolant level,, correct working of sub-system., (2 hrs.), 117. Identification of safety, switches and interlocking of, DIH modes. (1 hrs.), 118. Machine starting & operating, in Reference Point, JOG and, Incremental Modes. (12 hrs.), 119. Check CNC part programming, with simple exercises and, using various programming, codes and words. (12 hrs.), 120. Check the programme, simulation on machine OR, practice in simulation software, in respective control system., (12 hrs.), , Professional Knowledge, (Trade Theory), CNC technology basics:, Difference between CNC and, conventional lathes., Advantages and disadvantages of, CNC machines over conventional, machines., Machine model, control system, and specification., Axes convention of CNC machine, - Machine axes identification for, CNC turn, centre., Importance of feedback devices, for CNC control., Concept of Co-ordinate geometry,, concept of machine axis., , Programming – sequence, formats,, different codes and words., Co-ordinate system points and, simulations., Work-piece zero points and ISO/, DIN G and M codes for CNC., Different types of programming, techniques of CNC machine., Describe the stock removal cycle in, CNC turning for OD / ID operation., L/H and R/H tool relation on speed., Describe CNC interpolation, open, and close loop control systems. Coordinate systems and Points., Program execution in different, modes like manual, single block, and auto., Absolute and incremental, programming., Canned cycles., Cutting parameters- cutting speed,, feed rate , depth of cut, constant, surface speed, limiting spindle, speed, tool wear,, tool life, relative effect of each, cutting parameter on tool life., , Copyright @ NIMI(x)Not to be Republished

Page 11 :

83-85, , -do-, , 86-88, , -do-, , 121. Absolute and incremental, programming assignments, and simulations. (12 hrs.), 122. Linear interpolation, and, Circular interpolation, assignments and, simulations on soft ware. (24hrs.), , Selection of cutting parameters from, a tool manufacturer’s catalog for, various operations., Process planning & sequencing,, tool layout & selection and cutting, parameters selection., Tool path study of machining, operations., Prepare various programs as per, drawing., , 123. Perform Work and tool setting:, - Job zero/work coordinate, system and tool setup and live, tool setup. (12 hrs.), 124. Carryout jaw adjustment, according to Diameter and, tooling setup on Turret., (12hrs.), 125. CNC turning centre operation in, various modes: JOG, EDIT,, MDI, SINGLE BLOCK, AUTO., (12 hrs.), 126. Program entry. (2 hrs.), 127. Set the tool offsets, entry of, tool nose radius and, orientation. (12 hrs.), 128. Conduct work off set, measurement, Tool off set, measurement and entry in, CNC Control. (8 hrs.), 129. Make Tool nose radius and, tool, orientation entry in CNC control., (6 hrs.), 130. Jaw removal and mounting on, CNC Lathe. (4 hrs.), 131. Manual Data Input (MDI) and, MPG mode operations and, checking of zero offsets and, tool offsets. (9 hrs.), , Tool Nose Radius Compensation, (G41/42) and its importance, (TNRC)., Cutting tool materials, cutting tool, geometry – insert types, holder, types, insert cutting edge, geometry., - Describe Tooling system for, turning, - Setting work and tool offsets., - Describe the tooling systems, for CNC TURNING Centers., - Cutting tool materials for CNC, Turning and its applications, - ISO nomenclature for turning tool, holders, boring tool, holders, indexable inserts., - Tool holders and inserts for, radial grooving, face grooving,, threading, drilling., , 132. Program checking in dry run,, single block modes. (6 hrs.), 133. Checking finish size by over, sizing through tool offsets., (9 hrs.), 134. Part program preparation,, Simulation & Automatic Mode, Execution for the exercise on, Simple turning & Facing (step, turning) (10 hrs.), 135. Part program preparation,, Simulation & Automatic Mode, Execution for the exercise on, Turning with Radius / chamfer, with TNRC. (10 hrs.), , Prepare various part programs as per, drawing & check using CNC simulator., Processes and Tool selection related to, grooving, drilling, boring & threading, , Copyright @ NIMI Not(xi)to be Republished

Page 12 :

136. Part program preparation,, Simulation & Automatic Mode, Execution of CNC Machine for, the exercise on Blue print, programming contours with, TNRC. (10 hrs.), 137. Machining parts on CNC lathe, with parallel, taper, step, radius, turning, grooving & threading., (15 hrs.), 138. Carryout Drilling /Boring cycles, in CNC Turning. (15 hrs.), (First 60 % of the practice is on, CNC machine simulator,, followed by 40 % on machine.), 89-91, , -do-, , 139. Geometry Wear Correction., Geometry and wear offset, correction. (10 hrs.), 140. Produce components on CNC, Machine involving different, turning operations viz.,, • h Stock removal cycle OD, • h Drilling / boring cycles, • h Stock removal cycle ID, • h Carryout threading in different, pitches. (18 hrs.), 141. Produce components by involving, turning operation and part, programme exercises of, C N C, turning viz.,, • h Grooving and thread cutting, OD, • h Grooving and thread cutting, ID, • h Threading cycle OD, • h Sub programs with repetition, • h Using Sub Programs &, Cycles in the Main Program., (18 hrs.), 142. Part off: Part Prog. (4 hrs.), 143. Produce job involving profile, turning, threading on taper,, boring, etc. operations. (22, hrs.), 144. Demo on M/C on bar feeding, system. (simulation/ video), (1 hrs.), 145. DNC system setup., (Optional), 146. Run the machine on DNC, mode.(Optional), 147.CAM programme, execution.(Optional), 148. Data Input-Output on, CNCmachine. (2 hrs.), , - Describe Tapping on CNC, turning., - Programming for, Grooving/Threading on OD/, ID in CNC Turning., - Trouble shooting in CNC, lathe machine, - Identify Factors affecting, turned part quality/, productivity., - Parting off operation, explanation., - Bar feeding system, through bar feeder., - Input and Output of Data., - DNC system. Interlacing, with PC., - Use of CAM Programme., (Optional), , Copyright @ NIMI(xii)Not to be Republished

Page 13 :

92 - 93, , 94-95, , 96, , 97, , Manufacture and, assemble components, to produce utility items, by performing different, operations & observing, principle of, interchangeability and, check functionality., [Utility item: - screw, jack/ vice spindle/, Box nut, Marking, block, drill chuck,, collet chuck etc.;, different operations:, - threading (Square,, BSW, ACME,, Metric), Thread on, taper, different, boring (Plain,, stepped)], -do-, , -do-, , Make a process, plan to produce, components by, performing special, operations on lathe, and check for, accuracy. [Accuracy, - ±0.02mm or proof, machining &, ±0.05mm bore;, Special operation Worm shaft cutting, (shaft) boring,, threading etc.], , 149. Theard on taper, surface(Vee form), (50 hrs.), , Setting of tool for taper, threadscalculation of taper, setting and thread depth., Heat treatment – meaning &, procedure hardening,, tempering, carbonizing etc., Different types of metal used, inengineering application., , 150.Manufacturing&, Assembly of Screw, jack/vice/Box nut by, performing different lathe, operation.(To use earlier, produce screw jack)., (50 hrs.), , Interchangeability meaning,, procedure for adoption, quality, control procedure for quality, production., , 151. Prepare different types, of documentation as, per industrial need by, different methods of, recording information., (4 hrs.), 152. Turn Bevel gear blank., (21 hrs.), , Importance of Technical English, terms, used in industry –(in simple, definition, only)Technical forms, process, charts,, activity logs in required formats of, industry, estimation, cycle time,, productivity reports, job cards., , 153. Read a part drawing,, makeaprocess plan, , Terms used in part drawings and, interpretation of drawings –, tolerances,, geometrical symbols - cylindricity,, parallelism. etc., , Copyright @ NIMI Not(xiii)to be Republished

Page 14 :

98, , -do-, , 154. Practice of special operations, on lathes - worm gear cutting., (Shaft) (25 hrs.), , 99, , -do-, , 155. Boring on lathe using soft jaws, to make bush with collar, (standard) on non ferrous metal, and check with dial bore gauge, to accuracy of +/- 0.05 mm., (15 hrs.), 156. Make Arbor support bush., (Proof Machining) (10 hrs.), , 100 -101, , Automatic lathe-its main parts,, types diff. Tools used-circular, tool etc, , Related theory and, calculation., , In-plant training/ Project work (Any Project to be done onCNC machine), 1. Taper Sunk, 2. Socket With Split Collet, 3. Screw Jack, 4. Spindle With Hub, 5. Morse Taper Eccentric, 6. Crank Shaft With Taper Sleeve, , 102-103, , Revision, , 104, , Examination, , Copyright @ NIMI(xiv), Not to be Republished

Page 15 :

Production & Manufacturing, Turner - Introduction to CNC, , Related Theory for Exercise 4.1.111, , CNC Technology basics, Objectives: At the end of this lesson you shall be able to, • describe the fundamentals of NC controls, • state the present status of CNC technology, • state the different between conventional lathe and CNC lathe, • state the specification of CNC lathe, • state the advantages and disadvantages of CNC., When the computer was invented, the inventor himself, must not have dreamt of the use of computers in various, fields of life which is drastically changing the entire, scenario of the Universe. It is now an integral part of our, day to day life. There is lot of research going on with the, help of computers in the field of factory automation. The, declining cost of computers coupled with the invention of, Multi task high speed micro processors, really made an, industrial revolution and there seems to be no end for, this. A distinct trend can be observed in industries which, include an increase in the use of Computer controlled, Machine tools, the application of new manufacturing, systems, such as laser beam machines and appearance, of new generation of industrial robots in the production, line, the manufacturing management through MRP I, MRP, II & MRP III etc.(Material Resource Planning), , -, , The next logical extension is a fully automated factory, which employs a flexible manufacturing system (FMS), and Computer Aided Design/Computer Aided, Manufacturing (CAD/CAM) techniques., , -, , The latest of the above is Computer Integrated, Manufacturing (CIM) which includes battery of CNC, machines, with flexible modules for manufacturing tool, head changers, automatic material handling system, like AGV's (Automated Guided Vehicle) etc with, minimum number of operating personnels., , Fundamentals of NC controls, , Evolution of automation, , NC equipment has been defined by Electronics Industries, Association (EIA) as "A system in which actions are, controlled by the direct insertion of numerical data at some, point. The system must automatically interpret at some, portion of the data"., , Automatically controlled factory is nothing more than the, latest development in the industrial revolution that began, in Europe two centuries ago and progressed through the, following stages:, , In a typical NC system the part program is prepared on a, punched tape. The part programme is arranged in blocks, of information needed for processing a segment of work, piece, the segment of length, speed, etc., , -, , Mechanisation started in 1870 at the beginning of, industrial revolution with simple production machines., , Advantage of NC machine are, , -, , In 18th Century fixed automatic mechanism and, transfer lines came into existence for faster output, and shorter production time., , -, , Simple automatic control machines and copying, machines were invented in the later part of the 18th, century. After 1950 the industrial automation was, started. In this second phase of the industrial, automation/revolution, workers, instead of physically, performing all the task are placed in the control of the, machines., , Progressive change after 1950 is as follows, -, , The introduction of numerical control (NC) in 1952, opened a new era in automation., , -, , The extension of NC was Computerised Numerical, Control (CNC) machine tools in which computer (Micro, Processor) is included as an integral part of the control, system., , -, , Commercial Industrial robot was manufactured in, 1961 along with CNC systems. The use of these, robots, are well utilised only after 1970's., , -, , Complex shapes can be machined easily, , -, , Accuracy and repeatability is achieved., , -, , High production rate, , -, , Reduced component rejection, , -, , Less operator skill and involvement, , There are many disadvantages of NC system:, -, , If tape is spoiled the entire programme of, manufacturing will be affected, , -, , Editing of the program in tape is not very easy., , -, , Manual loading of tape is a laborious job., , -, , Instruction are read, block by block and carried out, which is slow when compared to CNC machine tools:, , -, , If the punch reader is not reading the program properly, then the entire production is lost., , Computer numerical control, A dedicated micro processor or mini computer on the, machine control makes the computer numerical control., CNC machines are very popular coupled with lots of other, advantages:, , Copyright @ NIMI Not to be Republished, , 1

Page 16 :

Advantages, , 4 Changing of cutting :, conditions, , Step less Speed, feed etc are, changed easily through, programming instruction., , 5 In process control, , Self diagnosing and gauging, through measuring probes, the parts and tools are, available as an in-process, control., , -, , Accuracy and repeatability is very high, , -, , Reduced scrap and rework, , -, , Reduced inspection time, , -, , Ease of inter changeability of machined parts, , -, , Reduced space, , -, , Reduced, material handling, -, , B Keeping machining time to minimum, , -, , Less paper work, , Higher metal removal rate through, , -, , Less lead time, , -, , Proper cutting tools, , -, , Less inventory, , -, , Rigid machine spindle, , -, , Easy editing of programme, , -, , Higher spindle power, , -, , Complicated shapes and contours are easily, manufactured with quality assurance and better, production management., , -, , Higher feed power, , -, , Rigid structure, , -, , Multi spindle, , -, , Multi turrets etc., , :, , -, , Better utilisation of machines., , -, , Reduced tooling, , -, , Reduced operator skill, , Higher quality is achieved, , -, , Jig not used but with minimum fixtures, , -, , Servo mechanism, , -, , -, , Reduced floor space, , For correction of feed, through motors, , -, , Higher level of integration such as DNC, FMS, CAD/, CAM, CIM etc.,, , -, , Curvic coupling, , -, , For quick indexing, , -, , Linear motion guides -, , For heavy load movement, of slides., , -, , Linear ball screw, , -, , For accurate friction free, backlash free movement, , -, , Encoders and tacho, generator, , -, , For accurate positioning, and velocity error correction, etc., , Disadvantages of CNC machines, -, , High cost of machine, , -, , High cost of training needs, , -, , High Maintenance cost, , Major advantages of CNC machines are, -, , Higher production, , -, , High quality production, , These are achieved through:, Higher production, , In automobile, aircraft and general engineering industry,, CNC machines are common sight now a days. CNC is, used to control almost all types of machines and some of, the commonly used machines are listed below:, -, , CNC lathes, , A., , Keeping idle time as minimum as possible, , -, , CNC Milling/drilling machine, , B., , Keeping machining time to a minimum, , -, , CNC turning centres., , -, , CNC Turn mill centre, , -, , CNC Machine centre, Multi machining centre, , -, , CNC Tool and cutter grinding., , -, , CNC Grinding machine, surface, cylindrical etc., , Kept as minimum by ATC,, quick change tool turret etc., (max.time is less than 8, sec.), , -, , CNC boring and jig boring machines etc., , -, , CNC EDM, Wire cut EDM etc., , -, , CNC Gear hobbing, gear shaping, gear grinding etc., , Rapid movement is easily, achieved through best servo, feedback motors, , -, , CNC Electron beam welding, , -, , CNC Laser/plasma/arc welding machine etc, , A Keeping idle time as minimum, 1 Loading/unloading, , 2 Tool Change time, , 3 Movement of slide, , 2, , Applications of CNC, , :, , :, , :, , Through quick work holding, and work handling system, like pallets, robots etc., , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.111

Page 17 :

-, , CNC Co-ordinate measuring machines, , -, , CNC Nibbling press, press brakes, turret, , Present status CNC technology, Now a days, CNC controllers with system like Sinumeric,, Fanuc, Friera, Allen Brandly, Mazak etc come with graphic, , Some latest controls are having "DOS" front end with, CAD/CAM facility in which one can design a component, and get the computer assisted part programmes (CAPP), and proving the component on the machine control itself, without wasting much time and money. Modern machine, tools have multi spindle with a spindle speed of 75000, , display of tool, paths, along with other software's have, considerably reduce the manual part programming of, three dimensional jobs., User defined parametric programming, Standard Cycles, like stock removal, drilling milling pattern etc are now a, day's standard component of the Systems., , rpm; Cutting feed rate of 5000 mm/min, and rapid traverse, of 20000 mm/min. Use of multi various sensing elements, with adaptive controls, remote diagnostics system makes, the machine more versatile and free from accidents., , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.111, , 3

Page 18 :

The silent and salient use of computers in factory, automation and in factory management will boost the, quality and quantity in production, which in turn will, definitely change the lifestyle of the people in future., Advantages of CNC machines over conventional, lathes, , -, , Production rate is more., , -, , Profitability is high., , -, , Repeatability is very high compared to conventional, lathe., , -, , One operator can operate more than one machine., , -, , Lesser production cost., , -, , Reduced part inventory., , -, , Less manual work., , -, , Semi skilled operator can operate the machine., , -, , Reduced floor space requirements., , -, , Greater accuracy., , -, , Improved manufacturing control., , -, , More flexibility., , -, , Complicated parts shape can be easily machined., , -, , Alteration in dimension is easier through programme., , -, , More number of tools are made available, , -, , Simulation is possible with that we can verify the, dimensions of the component., , Disadvantages of CNC machines, , Difference between conventional and CNC lathes, Conventional lathe, 1, , Involves more manual, work, , Less manual work, , 2, , Skilled labour needed, , Basic Skill is enough, , 3, , Less accuracy, , More accuracy, , 4, , Less flexible, , More flexible, , 5, , No part programming, , Part programming, required, , 6, , Any alteration is, difficult, , Re-programming for, dimensional changes, made easier manually, Once the programme is, done, the computer, takes care, , 7 For every component, machining is done, with great care., , 4, , CNC, , 8, , Simulation or trial, run not possible, , Simulation or trial run, possible and correction, may be done if required., , 9, , Less production rate, , More production rate, , 10 Repeatability is not, possible, , Rate of repeatability, is high, , 11 Individual operator, required for each, machine, , One operator can, operate more than, one machine, , -, , Higher investment cost., , -, , Higher maintenance cost., , -, , Training of CNC operator involves more cost., , -, , Semi skilled or unskilled operator cannot do, programming in CNC., , -, , Cost of spare parts and tool cost are high., , -, , Suitable for mass production only., , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.111

Page 19 :

SPECIFICATIONS OF C.N.C LATHE, 1, , No. of controlled axis, , 2, , 2, , Interpolation, , Linear/circular/parabolic, , 3, , Maximum swing over bed, , 320 mm, , 4, , Maximum machining length, , 245 mm, , 5, , Collet, , ID = 56 mm OD = 48 mm, , 6, , Spindle taper hole, , ∅52 mm, , 7, , Maximum bar dia, , ∅38 mm, , 8, , Spindle head type, , A2 - 5, , 9, , Spindle speed range, , 60 to 5000 R.P.M, , 10, , Main motor, , 3.70 KW, , 11, , Chuck size, , ∅200 mm, , 12, , Chuck type, , Hydraulic, solid, , 13, , Rapid transfer speed on x axis, , 18 metre/min, , 14, , Rapid transfer speed on z axis, , 18 metre/min, , 15, , X axis travel, , 200 mm, , 16, , Z axis travel, , 320 mm, , 17, , Guideway type, , Linear guideway, , 18, , Turret type, , Gang type, , 19, , Turret tool, , Boring bar size 20/20 mm ∅20 mm, , 20, , Weight, , 1700 Kg, , 21, , Dimensions, , 1600x1250x1650 mm, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.111, , 5

Page 20 :

Production & Manufacturing, Turner - Introduction to CNC, , Related Theory for Exercise 4.1.112, , Machine model, control system and specification, Objectives : At the end of this lesson you shall be able to, • explain the control panel, • list the control keys and learn technical specification of CNC machine, • list the address keys., , 6, , Copyright @ NIMI Not to be Republished

Page 21 :

Introduction, The CNC control system of a machine tool includes mainly, control unit and the motion control system. The motion, control system includes servo motor, drives, axis, postioning devices. The control systems are classified, , as contouring system, point to point system, closed loop/, open loop system and based on number of axis of the, machine.The details of the control unit and the control, systems are shown in the following pages., , 1 Power consumption main motor (relative display), 2 Chuck open/closed, 3 Sleeve forwards, 4 Sleeve backwards, 5, 6 Central lubrication manual with display, 7 Tool turret, manual operation, 8 Coolant On/Off with display, 9 Single item for bar feed with display, 10, 11 Drives On, 12 Drives off, 13 Control On, 14 Feed rate override switch 0-120%, 15 Emergency-off button, , EMCO CONTROL PANEL, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 7

Page 22 :

Keys and display field, , Display field, , Alarm (red), The display is bright whenever an alarm occurs. The alarm number is displayed on the, screen. The alarms are explained in the, alarm list., Position not yet reached (green), The display is bright until the set position, has been reached., Feed stop (red), The display is bright if the feed is stopped, while the program is running., Program running (green), The display is bright until the program has, been completed. Even if the machine is not, moving., Key assignment display (yellow), If the "key assignment display is bright, the, lower-case function (the bottom function) of, a dual-function key is displayed in the input, line when the dual function key is depressed., If the "key assignment." Display is not bright,, the upper function is entered. Switchover is, executed automatically by the controller after a word has been entered in the parts, cases, switchover can be executed by, means of key in the address keypad., , 8, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112

Page 23 :

Address keys/numeric keys, x), Start of program, , x), Skip block, , x), Address block number, , x), Address path condition, , SINUMERIC 810 T, , Alternate changeover to top and, bottom functions. The display is then, either bright or dark., Number 7, Address Position data, , Number 8, Address Position data, Number 9, Address Position data, , x), Address Position data, x), Address Position data, , SINUMERIC 810 M, Address keys, numeric keys and symbol keys, , Number 4, Address Interpolation parameter, Number 6, Address Interpolation parameter, Number 5, Address Interpolation parameter, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 9

Page 24 :

Number 6, , Space character, , Address Interpolation parameter, , Address Auxiliary function, , x), , Additional, , Address Radius B, , unassigned x), Address Radius U, , Mulitiplication, Address Angle A, Number 1, , End of block, , x), In the input line characters appear which are not normally permitted for normal programming., The characters a,b,c,d,e,f are required to enter or modify, commands in CLB00 machine code.(@----)., Input and correction, , Address Feed, Number 2, Address tool correction, Number 3, Address Subroutine, , x), Address No. of passes, Subtractio n, Address Additiona l function, Sign input line, Address Additiona l function, , Number 0, Address Spindle speed, Decimal point, , Delete input, The input line is deleted character-bycharacter. If the key remains depressed, the characters entered are deleted in, sequence until the input line is empty., Delete word/block, The word identified by the correction, pointer is deleted in the parts program, memory if the respective address is in, the input line. A complete block is, deleted if the respective block number, is in the input line., Modifying a word, The word identified with the correction, pointer is replaced by the word in the, input line. The addresses of both words, must be identical., Entering a word, The word in the input line is transferred, to the parts program memory, or into, list displays or input forms., , Address Tool number, , 10, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112

Page 25 :

Control keys, Channel selection switch, The CRT display is switched to the channel, selected. Selection is by repeated depressing of the channel selection switch., Acknowledging alarms, , Correction pointer left/right, The correction pointer is moved to the left, or right word-by-word. The correction pointer, jumps from the beginning of the block to the, end of the previous block or from the end of, the block to the beginning of the following, block. If the key remains depressed, the, correction pointer goes to the beginning or, end of the program., , Alarm form alarm No. 3000 onwards, e.g., "General programming error" alarm can be, acknowledged with this key. "Rest alarm is, not acknowledged!, Actual value display selection with, double-height characters, If the key is depressed again, the previous, display reappears., Diagnostics and start up, , Correction pointer backwards/forwards, , Selection of machine data and switching to, start-up state after entering pass word., , The correction pointer is moved backwards, or forwards block-by-block., , Search key, , If the key remains depressed, the correct, pointer goes to the beginning or end of the, program., Paging backwards/forwards, The CRT display is paged up or down one, page at a time., , Searching for a particular address or word, in the parts program memory. The expression appearing in the input line when the, search key is depressed is looked for. After, the search key has been depressed, the correction pointer marks the next expression, found., Integrated machine control panel, , Integrated machine control panel, , SINUMERIC 810 T, , SINUMERIC 810 M, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 11

Page 26 :

Reset, , Operating mode selection key, , The running program is aborted Alarms, are deleted (up to alarm No. 2999). The, controller is brought to the basic state!, , The following modes can be selected via a, soft key:, , Single block, The parts program is processed blockby-block. Start is by means of "Program, START"., Program STOP, The running program is interrupted The, program can be resumed with "Program, START"., Program START, A parts program is started. The functions, stored are transferred to the PLC in automatic mode., Spindle STOP/START, Feed STOP/START, , Direction keys, When the direction keys are actuated,, the axes are traversed in jog mode., , PRESET, MDI AUTOMATIC, JOG INC 1 TO INC 10,000, (manual encoder), REPOS, AUTOMATIC, REFPOINT, Spindle speed slower/faster, The programmed spindle speed can be, modified in increments of 5 % in the range, of 50 % to 120 % . If the key is depressed, constantly, the final position is approached, in increment of 5 %. The percentage value, set is shown in the basic display., Feed slower/faster, The programmed feed is modified in the following increments from 0% to 120 % 0%, 1% 2% 4% 6% 8% 10% 20% 30% 40% 50%, 60% 70% 75% 80% 85% 90% 95% 100%, 105% 110% 115% 120%., If the key is depressed constantly the end, position is approached. The percentage, value set is displayed in the basic display., In rapid traverse mode the 100% value is, not exceed., , Rapid traverse override key, , Universal interface port, , If this key is depressed simultaneously, with the direction keys the axes are traversed in rapid traverse mode., , 12, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112

Page 27 :

CALL PROGRAM FORM MEMORY FOR EXECUTION, , Switch control to reset, , Main program or subroutine, , Enter program number, , Store, , Program control, if desired (see next page), Single block, if desired, Cycle start, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 13

Page 28 :

PROCEDURE FOR BLOCK SEARCHING:, , 9 Press > (etc key) to bring Over Store., , 1 Select the AUTOMATIC pressing MODE button., , 10 Enter necessary Tool number, Spindle speed, "T",, "D","S","M" code., , 2 Close the feed rate completely., 3 Press (Etc key) and bring the BLOCK SEARCH menu., 4 Enter the necessary block number/sub program block, number., 5 Press START., 6 Confirm whether the required block reached on the, Monitor at N, 7 Press MODE button for bringing the REPOS mode,, and select REPOS., , 11 Press CYCLE START key., 12 Bring Automatic mode by pressing MODE key., 13 Press ACTUAL BLOCK (Look at the Cursor and the, block search complete)., 14 Continue to Run the program by pressing Cycle Start, key and watch Distance to go Actual position and the, Actual values. ('G' codes, M,F,S,T,D, etc.), , 8 Bring the offset values to Zero by Pressing the necessary (+) or (-) direction keys X,Y,Z and feed rate control switch at > 0%, , BLOCK SEARCHING AND RUNNING PROGRAMME, AUTOMATIC, , 14, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112

Page 29 :

Machine models, CNC machines are generally grouped under 2 axis and, 3 axis or multi axis system. Horizontal 2 axis (x and z), are termed as CNC lathe and the vertical CNC machines, are called as machining centre., The machine models are also based on the spindle drives, namely., -, , Separately excited DC shut motor, , -, , 3 Phase AC induction motor, , The CNC machine models are also based feed drives, are, -, , AC servometer, , -, , DC servometer, , -, , Brushless DC servometer, , -, , Stepper motor or liner motor, , Technical Specification of CNC machines, 1, , 2, , Traverse, , Pallet, , x’ - 600 mm, , (Saddle movement), , y’ - 450 mm, , (Head movement), , z’ - 420 mm, , (Column movement), , Pallet size - 500x500mm, Max load - 500 Kgf, indexing position - 360 degree, , 3, , 4, , Spindle, , 11.Kw continuous 14.2 (intermitent), , Type of motor, and drive, , AC, , Bearing dia, , 100 mm, , Spindle taper, , ISO 40, , Spindle speeds, Spindle range, , 40 - 4000 Rpm or, 60 - 6000 Rpm (optional), , 5, , 6, , Constant range, , 40- 4000 Rpm or, 60 - 1500 Rpm (Optional), , Constant power, range, , 1000-4000 Rpm or, 1500-6000 Rpm (Optional), , Feeds, Rapid traverse, , 20 M/min, , x,y,z Axis cutting, feed rate, , 1 to 10000 mm/min, , Feed Motor, Torque X and, , 18.5 Nm, , Y axes z - Axis, , 29 Nm, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 15

Page 30 :

7, , Thrust Capacity, X - Axis, Y - Axis, Z - Axis, , 8, , 600 Kgf, 600 Kgf, 1000Kgf, , Ball Screw, Pitch, Dia, , 9, , 12 mm, 50 mm, , Auto Tool changer, No of tools, Max. Tool Dia, Max. Tool Weight, Max.Tool length, Tool changing time, , 10, , Twin pallet changer, No of pockets, Pallet changing Time, , 11, , 2 Nos, 25 Sec, , Hydraulic, Motor power, Tank Capacity, , 12, , 24 Nos, 10 mm, 15 Kgf, 350 mm, 6 to 12 seconds based on tools, , 3.7 Kw, 90 litres Indian Oil servo 32 or equivalent, , Machining capacity, Milling capacity (steel, 55 - 65 Kg/mm square), , 100 cc/min, , Drilling capacity (Steel, 55-65 Kg/mm square), , 30 mm diameter, Tapping Capacity (Steel, 55 -65 Kg/mm square), , 13, , Machining capacity, Machining capacity, , 10000Kg, , Floor space requirement, Basic machine, , 5900mm (w) x, 5550mm (L), x 3100 (H), , 15, , Air requirement, , 16 Ipm at 5 kg/ Sq.cm, , 16, , Electrical supply, , 50 KVA, , 14, , M 24 x 1.5 mm, , Control System, In CNC machines there are mainly two types of control, system,namely, , control also. These system are not good where extremely, accurate positioning is required., , 1 Open loop control system (Fig 1), 2 Closed loop control system (Fig 2), Open lop control system (Fig 1), In an open loop control system (Fig 1) in which there is no, arrangement for detecting or comparing the actual position, of the cutting tool on the job with the command studies., , Closed loop control system (Fig 2), , Therefore, this system is not providing any check to see, that the commanded position has actually been, achieved.There is no feed back of information to the, , Closed loop control (Fig 2) is a term which is used very, often when we talk about CNC machines. This term, signifies, that the control system has provisions to ensure, , 16, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112

Page 31 :

tha the tool reaches the desired position, at the correct, feed rate, even if some errors creep in due to unforeseen, reasons., For instance in the previous example 60,000 pulses sent, in 2minutes by the control should cause a tool travel of, 60 mm at 30 mm/min, but even if the control sends these, pulses it cannot be ensured that the tool has really, travelled exactly 60 mm., A closed loop control has a device called encoder and this, can continuously ascertain the distance actually travelled, by the tool and then monitor the same, in the form of, feedback signals to the control. The control studies this, feedbacck information and takes corrective action in case, any error is detected in the tool position/feed rate., , Another control system is based on 5 axis & above, •, , Motion type CNC control system, , •, , Loop control system, , •, , Number of axis type CNC control, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.112, , 17

Page 32 :

Production & Manufacturing, Turner - Introduction to CNC, , Related Theory for Exercise 4.1.113, , Axis convention of CNC machine, Objectives: At the end of this lesson you shall be able to, • identify CNC machine by number of axes, • identify CNC machines by orientation of axes, • understand NC coordinate and learn X and Y axis movement., Types of CNC milling machines, , CNC vertical machining centre, , - VMC, , Milling machines can divided into three categories, , CNC horizontal machining centre, , - HMC, , 1 by the no of axes, , CNC horizontal boring mill, , (two, three or more), , Vertical Machining Centres (Fig 1), , 2 by the orientation of axes, (vertical or horizontal), 3 by the presence or absence of a tool changer., The spindle motion is up and down in vertical milling/, machining centre., The spindle motion is in and out in horizontal milling/, machining centre., These machines are capable to perform the following, operations:, Drilling, Reaming, boring, tapping, profiling, thread cutting, and many other operations., ATC: Automatic Tool changer., APC: Automatic pallet changer, CNC: Computer Numerical Control, With the above advanced features built in milling, machines become the new breed of machine tools called, machining centres., Machine axes, The machining centres are provided with minimum three, axes of ‘X’,’Y’&’Z’ axis and fourth axis machines become, more flexible i.e the fourth axis ‘A’ for vertical model and, ‘B’ of horizontal model. The machine with five or more, axes is of higher level of capacity., In aircraft industry 5 axes profile milling machine is used, for complex shapes and to reach cavities and various, angles., Meaning of half / full axis in NC language (what is half /, full axis machine), A full axis vertical machine has X,Y,Z as primary axes, and indexing table designated as ‘A’ axis which can, position but cannot rotate simultnesously is called 3 1/2, axes machine. If the machine is equipped with full rotating, table, simultaneously then it is called four axis machine, tool., In the milling systems, three most common machine tools, are, 18, , VMC is for flat type of work where the machining is done, on only one face of the part in single set up., An optional fourth axis can be provided by mounting rotary, table to the main table either vertically or horizontally, depending on the desired results and the model type., In the combination with a tailstock (usually supplied) the, fourth axis in the vertical configuration can be used for, machining long parts,which need support at both ends., For programming two types of systems are followed. In, one type programming always takes place form the view, point of the spindle, not the operators eye, view as if, looking straight down at 90o towards the machine, for, development of the tool motion., In the second type, various markers located some where, in the machine itself, show the positive and negative, motion of the machine axes. For programming,these, markers should be ignored. The programming directions, are exactly opposite to the markers on the machine tool., Horizontal machining centers (Fig 2), Horizontal CNC machining centres are also categorized, as multi - tool and versatile machines, and are used for, , Copyright @ NIMI Not to be Republished

Page 33 :

cubical parts, where the majority of machining has to be, done on more than one face in a single setup., , define the positive direction of the coordinate axes as, per the Fig 4., , Z - axis (Fig 5), , There are many applications in this area. Common, examples are large parts, such as pump housings, gear, cases, manifolds, engine blocks and so on. Horizontal, machining centres always include a special indexing table, and are typically equipped with a pallet changer and other, features., , The axis of the main (i.e. principle) machine spindle,, whether it be the axis of the tool spindle or the axis about, which the work piece rotates, is denoted as the Z axis., On machine tools, which do not possess principle spindle, (e.g. planning machines) the Z - axis is perpendicular to, the work holding surface., , Axis - nomenclature, The basic designation of the axis (i.e.), in Fig 3 which is, X, Y, Z, is decided by the right hand thumb rule and the, main spindle axis. The thumb indicates X - axis, fore finger, indicates Y - axis and the middle finger indicates Z - axis., , X - axis, The X - axis is always horizontal, parallel to the work, holding surface and perpendicular to the z - axis., Auxillary axes on NC machine, Apart from each side movement axes on the machine,, some other auxillary axes can exist. E.g. Rotary table., This rotary table axis is designed as A axis if it is parallel, to X direction. Similarly B and C axes for Y and Z, respectively., Right hand rule, , Y - axis, The Y - axis is perpendicular to both Z and X axis., Milling tool coordinate system (Fig 6), Classification of machines., CNC machines can be classified by various ways,, a) According to number of axis, , CNC machine can be classified as, The rotary movements about X, Y and Z are designated, • 2 axis machine, as A, B and C respectively. The right hand rule is used to, Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.113, , Copyright @ NIMI Not to be Republished, , 19

Page 34 :

• 3 axis machine, , Straight cut control, , • 4 axis machine, , The system provides feed motion in two axes (but not, simultaneously) and hence their capability is limited to, performing milling either along X axis or along Y axis., (Fig 8), , It should be noted that each axis has it own drive motor., b) According to CNC system, There are three types of CNC systems based on their, capability in providing feed in different axes., , • 1 Point -to- point control, , Contouring control, This can provide feed control in 3 axes. They are also, capable of providing simultaneous feed in 2 or 3 axis., Milling machine with contouring control can mill contours, made up of straight lines and arc/circular elements.., Depending on the number of axes that can be, simultaneously fed, contouring controls are further, classified as 2D control, 2 1/2D control and 3D control., i) 2D control, Machines with 2D control can be simultaneous feed only, in two of the 3 axes. They can mill only contours with, constant depth that too in just one plane ( X-Y) (Fig 9, & 10), •, , 2 Straight cut control, , ii) 2 1/2D control, , •, , 3 Contouring control, , Machines with 2 1/2D control can have simultaneous, feed of any of the two axis X-Y, X-Z,Y,Z and, hence they, can mill contours (of constant depth) in any one of the 3, planes. (Figs 11 & 12), , Point-to-point control, Machines with point-to-point control provide only one feed, axis while the other two axes can perform only rapid, motion. Machines with point-to-points control are suited, only for drilling operations. (Fig 7 ), , 20, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.113

Page 35 :

Part programming for turning centers, Diameter programming, The dimensioning of a turned component is generally, specified by its diameters. However, in turning operation,, the tool should approach the work piece in radial direction, for matching. Hence, for the sake of simplicity, most of, the turning centers are provided with diameter, programming facility., This means that all the movements of the tool along, X-axis should be doubled to represent the diametral rather, than radial movement. The selection of radius or diameter, programming depends upon the system variable set, during the integration of controller with the machine tool., , Axis system(Fig 2), In turning centers, the spindle axis is designated as Z., The radial axis perpendicular to the z-axis and away, toward the principle tool post is termed as x-axis .The, machine datum or home position may be the intersection, of spindle axis and clamping plane. At the start, the, controller display will show the axis position with respect, to home The work piece datum is fixed by the programmer, on the work piece for the convenience of part, programming. The difference between the tool tip position, and the turret datum is termed as offset., , Machine axis identification, NC coordinates system (Fig 1), All the NC machine toolmaker’s use of Cartesian, coordinate system for the sake of simplicity. The guiding, coordinate system followed for designating the axes is, the well known as right hand coordinate system., Designation of axes, First axes to be identified is the z axis .This is then followed, by x and y axes respectively., , Z-axis, The z-axis motion is along the spindle axis or parallel to, the spindle axis. In the case of machine without a spindle, such as shapers and planers, the z-axis is perpendicular, to the work holding surface., For machines such as milling, drilling and lathe, the cutting, tools move in the negative z direction to move a tool into, the work piece. The positive z motion increases the, clearance between the tool holder and work piece surface., When there are several spindles and slide ways, the, spindle perpendicular to the work holding surface may, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.113, , 21

Page 36 :

be chosen as the principle spindle. The primary Z motion, is then related to the primary spindle. The tool motions of, other spindles or slides, designated as U, V, W and P, Q,, R respectively.(Fig 3), X-axis, The principle motion direction of cutting tool on the work, piece is designated as x-axis .It is perpendicular to the, z-axis and should be horizontal and parallel to the work, holding surface whenever possible., , 22, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.113

Page 37 :

Production & Manufacturing, Turner - Introduction to CNC, , Related Theory for Exercise 4.1.114, , Imporatance of feedback system and Concept of co-ordinate geometry, Objectives: At the end of this lesson you shall be able to, • understand feedback system, • understand the cartesian coordinate system, • understand the four quadrants, • explain the difference between polar and rectangular coordinates., Importance of feed, Feed Back System:, •, , The feedback system is also referred to as the, measuring system., , •, , It uses position and speed transducers to continously, and monitor the position at which the cutting tool is, located at any particular instant., , •, , The MCU uses the difference between reference, signals and feedback signals to generate the control, signals for correcting position and speed errors.(Fig 1), The centre of the coordinate system (where the lines, intersect) is called the origin. The axes intersect where, both x and y are zero and is taken as origin The, coordinates of the origin are (0,0)., , A Cartesian coordinate system is coordinate system, that specifies each point uniquely in a plane by a pair of, numerical coordinates, which are the signed distance, to the point from two fixed perpendicular directed lines,, measured in the same unit of length. Each reference line, is called a coordinate axis of the system, and the point, where they meet is its orgin, at ordered pair (0,0). The, coordinates can also be defined as the positions of the, perpendicular projections of the point on to the two axes,, expressed as signed distances from the origin., One can use the same principle to specify the position of, any point in three-dimensional space by three cartesian, coordinates, its signed distances to three mutally, perpendicular planes (or, equivalently, by its perpendicular, projection onto three mutually perpendicular lines). In, general, n-cartesian coordinates (an element of real nspace) specify the point in an n-dimensioanl Euclidean, space for any dimension n. These coordinates are equal,, up to sign, to distances from the point to n mutually, perpendicular hyper planes., , An ordered pair contains the coordinates of one point in, the coordinate system. A point is named by its ordered, pair in the form of (x,y). The first number corresponds to, the X-coordinate and the second to the Y-coordinate., To graph a point, you draw a dot at the coordinates that, corresponds to the ordered pair. It’s always a good idea, to start at the orgin. The x-coordinate tells you how many, steps you have a take to the right (positive) or left, (negative) on the x-axis. And the y-coordinate tells you, how many steps to move up (positive) or down (negative), on the y-axis., The ordered pair (3,4) if found in the coordinate system, when you move 3 steps to the right on the x-axis and 4, upwards on the y-axis.(Fig 3), The ordered pair (-7, 1) is found in the coordinate system, when you mave 7 steps to the left on the x-axis and 1, step upwards on the y-axis.(Fig 3), , Coordinate system and ordered pairs, A coordinate system is a two-dimensional number line,, for example, two perpendicular number lines or axes., This is a typical coordinate system:, The horizontal axis is called the x-axis and the vertical, axis is called the y-axis., , Copyright @ NIMI Not to be Republished, , 23

Page 38 :

To find out the coordinates of a point in the coordinate, sysem you do the opposite. Begin at the point and follow, a vertical line either up or down to the x-axis. There is, your x-coordinate. And then do the same but following a, horizontal line to find the y-coordinate., Absolute coordinates, Absolute coordinates are based on the orgin (0,0), which, is the intersection of the X and Y axes. Use absolute, coordinates when you know the precise X and Y values, of the point., , To point: #0,3, To point: #-5,-3, Polar coordinate system, Points in the polar coordinate system with pole O and, polar axis L. The point with radial coordinate 3 and angular, coordinate 60 degrees or (3, 60°). and the point (4, 210°), represents polar coordinates., , With dynamic input, you specify absolute coordinates with, the # prefix is not used. For example, entering #3,4, specifies a point 3 units along the X axis and 4 units along, the Y axis from the orgin., The following example draws a line beginning at an X, value of -2, Y value of 1, and an endpoint at 3,4. Enter, the following in the tooltip., Command: line, From point: #-2,1, To point: #3,4, The line is located as follows:(Fig 4), , Relative coordinates or incremental coordinate, Relative coordinates are based on the last point entered., Use relative coordinates when you know the location of a, point in relation to the previous point., To specify relative coordinates, precede the coordinate, values with an @ sign. For example, entering @3,4, specifies a point 3 units along the X axis and 4 units along, the Y axis from the last point specified., The following example draws the sides of a triangle. The, first side is a line starting at the absolute coordinates -2,1, and ending at a point 5 units in the X direction and 0 units, in the Y direction. The second side is a line starting at the, endpoint of the first line and ending at a point 0 units in, the X direction and 3 units in the Y direction. The final line, segment uses relative coordinates to return to the starting, point., Command: line, , In mathematics, the polar coordinate system is a twodimensional coordinate system in which each point on a, plane is determined by a distance from a reference point, and an angle from a reference direction., The reference point (analogous to the orgin of a Cartesian, coordinate system) is called the pole, and the ray from, the pole in the reference direction is the polar axis. The, distance from the pole is called the radial coordinate or, radius, and the angle is called the angular coordinate,, polar angle., Uniqueness of polar coordinate & conversion to, cartesian coordinate., Adding any number full turns (360°) to the angular, coordinate does not change the corresponding direction., Similarly any polar coordinate is identical to the coordinate, with the negative radial component and in the opposite, direction. The polar co-ordinates ‘r’ and ø can be, converted into the cartesian coordinate (x,y) by using the, trignometric functions sine & cosine., x = r cos ø, , From point: #-2,1, , y = r sin ø, , To point: #5,0, , r=, , 24, , x2+y2 r = length of line, ø= its angle with axis, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.114

Page 39 :

Production & Manufacturing, Turner - Introduction to CNC, , Related Theory for Exercise 4.1.115, , Coordinate Geometry & Machine Axis, Objectives: At the end of this lesson you shall be able to, • understand the machine coordinate system, • state real number line, • understand cartesion coordinates system, • understand the cartesian coordinates of three-dimensional space., Machine coordinate system, Most of the CNC machinery have a default coordinate, assumed during power up of machine coordinate system., The origin of the system is called machine origin are home, zero location. Home zero is usually located at the tool, change position., In the manufacturing industry, with regard to numerically, controlled machine tools, the phrase machine coordinate, system refers to the physical limits of the motion of the, machine in each of its axes, and to the numerical coordinate, which is assigned (by the machine tool builder) to each of, these limits. CNC Machinery refers to machines and, devices that are controlled by the using programmed, commands which are encoded on to a storage medium,, and NC refers to the automation of machine tools that are, operated by abstract commands programmed and, encoded onto a storage medium., The cartesian coordinate system, Cartesian coordinates allow one to specify the location of, a point in the plane, or in three dimensional space. the, cartesian coordinates or rectangular coordinates system, of a point are a pair of numbers (in two dimensions) or a, triplet of numbers (in three - dimensions) that specified, signed distances from the coordinate axis. First we must, understand a coordinate system to define our directions, and relative positions (axis) and a reference position, (origin). A coordinate system can be rectangular or polar,, Just as points on the line can be placed in one to one, correspondence with the real number line, so points in, plane can be placed in one to one correspondence with, pairs of real number line by using two coordinate lines. To, do this, we construct two perpendicular coordinate line, that intersect at their origins, for convenience. Assign a, set of equally space graduations to the x and y axes, starting at the origin and going in both directions, left and, right (x axis) and up and down (y axis) point along each, axis may be established.We make one of the number, lines vertical with its positive direction upward and, negative direction downward. The other number lines, horizontal with its positive direction upward to the right and, negative direction to the left. The two number lines are, called coordinate axes; the horizontal line is the x axis, the, vertical line is the y axis, and the coordinate axes together, form the cartesian coordinate system or a rectangular, coordinate system. The point of intersection of the, coordinate axes is denoted by O and is the origin of the, coordinate system. See Fig 1., , It is basically, Two Real Number lines Put Together, one, going left - right, and the other going up- down. The, horizontal line is called x-axis and the vertical line is called, y-axis., The origin, The point (0,0) is given the special name “The Origin” ,, and is given the letter “O”., Rral number line, The basis of this system is the real number line marked at, equal intervals. The axis is labeled (X,Y or Z). One point, on the line is designated as the Origin. Numbers on one, side of the line are marked as positive and those to the, other side marked negative. See Fig 2., , Cartesian coordiantes of the plane, A plane in which a rectangular coordinate system has, been introduced is a coordinate plane or an x-y-plane. We, will now show how to establish a one to one, correspondence between points in a coordinate plane, and pairs of real number. If A is a point coordinate plane,, then we draw two lines through A, one perpendicular to, the x-axis and one perpendicular to the y-axis. If the first, line intersects the x-axis at the point with coordinate x and, the second line intersects the y-axis at the point with, coordinate y, then we associate the pair (x,y) with the A, (See Fig 2). The number a is the x-coordinate or abcissa, of P and the number b is the y-coordinate or ordinate of p;, we say that A is the point with coordinate (x,y) and denote, , Copyright @ NIMI Not to be Republished, , 25

Page 40 :

the point by A (x,y). The point (0,0) is given the special, name “The Origin” , and is sometimes given the letter “O”., Abscissa and Ordinate, The words “Abscissa” and “Ordinate” ... they are just the, x and y values:, •, , Abscissa: the horizontal (“x”) value in a pair of, coordinates: how far along the point is., , •, , Ordinate: the vertical (“y”) value in a pair of coordinates:, how far up or down the point is., , X and Y Axis, The horizontal line is called x-axis and vertical line is, called y-axis; both line runs through zero origin,(0,0) put, them together on a graph ... See Fig 6., It is basically, a set of two real Number lines., , Negative Values of X and Y, The Real Number Line, you can also have negative, values., Neagative: start at zero and head in the opposite direction;, See Fig 4, , Axis: The reference line from which distances are, measured., Example:, Point (6,4) is, Go along the x direction 6 units then go up 4 units up in the, y direction then “plot the dot”., And you can remember which axis is which by:, • the horizontal distance first,, • then the vertical distance., , So, for a negative number:, •, , go left for x, , •, , go down for y, , Ordered pair, , For example (-3,-5) means :, go left along the x axis 3 then go up 5 in the y-axis., (Quadrant II x is negative , y is positive), , The number are separated by a comma, and parentheses, are put around the whole thing like this: (7,4), Example: (7,4) means 7 units to the right (x-axis), and 4, units up(y-axis), , And (-3,-5) means :, go left along the axis 3 then go down 5 in the yaxis.(Quadrant III x is negative ,y is negative), Using Cartesian Coordinates, mark a point on a graph by, how far along and how far up it is; See Fig 5. The point, (12,5) is 12 units along the x-axis, and 5 units up on the yaxis., 26, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.115

Page 41 :

Cartesian coordinates of three dimensional space, In three-dimensional space (xyz space), oriented at right, angles to the xy-plane. The z axis, passes through the, origin of the xy-plane. Coordinates are determined, according to the east-west for x-axis north-south for yaxis, and up -down for the z-axis displacements from the, origin. The Cartesian coordinarte system is based on, three mutually perpendicular coordinate axes: the x-axis,, the y-axis, and the z-axis, See Fig 6 below. The three axes, intersect at the point called the origin. You can imagine, the origin being the point where the walls in the corner of, a room meet the floor. The x-axis is the horizontal line, along which the wall to your left and the floor intersect., The y-axis is the vertical line along which the wall to your, right and the floor intersect. the z-axis is the vertical line, alongwhich the walls intersect. the parts of the lines that, you see while standing in the room are the positive portion, of each of the axes. The negative part of these axes would, be the continuations of the lines outside of the room., Three-dimensional cartesian coordinate axes. A, representation of the three- dimensional cartesian, coordinate system. The positive x-axis , y-axis, and, positive z-axis are the sides labeled by x,y,z. The origin is, the intersection of all the axes. The branch of each axis, on the opposite side of the origin (the unlabeled side) os, the negative part., When dealing with 3-dimensional motion, is to set up a, suitable coordinate system. The most stright-forward, type of coordinate system is called a Cartesian system. A, Cartesian coordinate system consists of three mutually, perpendicular axes, the X, Y, and Z-axes. By convention,, the orientation of these axes is such that when the index, finger, the middle finger, and the thumb of the right -hand, are configured so as to be mutually perpendicular, the, index finger, the middle finger, and the thumb can be, aligned along the X,Y,Z-axes respectively. Such a, coordinate system is termed right-handed. See Fig 7. The, point of intersection of the three coordinate axes is, termed the origin of the coordinate system., , to the coordinate axis and opposite corners at the origin, and the given point., The points may now be defined in a three dimensional, volume or space. This permits to define points in three, dimensions from the origin. The Cartesian coordinates, (x,y,z) of a point in three-dimensions specify the signed, distance from the origin along the x,y, and z-axes,, respectively. Z-axis points become the third entry when, defining coordinate locations., Given the above corner-of-room analogy, we could form, the Cartesian coordinates of the point at the top of your, head,as follows. Imagine that you are five meters tall the, z-axis, and that you walk two meters from the origin along, the x-axis, then turn left and walk parallel to the y-axis four, meters into the room. the Cartesian coordinates of the, point at the top of your head would be (2,4,5)., For example, a notation of (2,4,5) corresponds to the, value of X2, Y4, and Z5. See Fig 9., , 3 DIMENSIONS, Cartesian coordinates can be used for locating points in 3, dimensions as in this example:, Figure 10. The point (2,4,5) is shown in three-dimensional, Cartesian coordinates., , The Cartesian coordinates of a point in three dimensions, are a triplet of numbers (x,y,z). The three numbers, or, coordinates, specify the signed distance from the origin, along the x,y, and z- coordinate axis respectively. They, can be visualized by forming the box with edges parallel, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.115, , 27

Page 42 :

(They are numbered in a counter clockwise direction), , QUADRANTS, The coordinate axes divide the plane into four parts,, called quadrants (See Fig 11). The quadrants are number, counter clockwise,starting from the upper right,labeled, I,II,III,IV with axes designations as shown in illustrations, below., , In Quadrant I : both x and y are positive, In Quadrant II : x is negative (y is still positive), In Quadrant III : both x and y are negative, In Quadrant IV : x is positive again, while y is negative., , When we include negative values, the x and y divide the, space up into 4 pieces:, , Quadrant, , X(Horizontal), , Y(Vertical), , Example, , l, , Positive, , Positive, , (3,2), , ll, , Negative, , Positive, , (-5,2), , lll, , Negative, , Negative, , (-2,-1), , lV, , Positive, , Negative, , (2,-5), , 28, , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.115

Page 43 :

Example: the point “A” (3,2) is 3 units along the x-axis,, and 2 units up the y-axis., Both x and y are positive, so that point is i “Quadrant I”, Example: The point “C” (-2,-1) is 2 units along the axis in, the negative direction, and 1 unit down the y-axis in the, negative direction., Both x and y are negative, so that point is in “Quadrant III, DIMENSIONS: 1,2,3 AND MORE..., 1 The Real Number Line can only go:, •, , Left-right, , •, , So any position needs just one number., , 2 Cartesian coordinates can go:, •, , Left-right, and, , •, , Up-down, , •, , So any position needs two numbers, , 3 3 Dimensions, • Left-right,, •, , Up-down, and, , •, , Forward-backward, , •, , So any point can be located with (x,y,z) coordinates., , Copyright @ NIMI Not to be Republished, , Production & Manufacturing : Turner (NSQF Level-5) - RT for Ex - 4.1.115, , 29

Page 44 :