Page 1 :

MECHANIC DIESEL, NSQF LEVEL - 4, , 2nd Semester, TRADE THEORY, SECTOR: Automobile, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright @ NIMI Not to be Republished

Page 2 : Sector, , : Automobile, , Duration : 1 - Years, Trades, , : Mechanic Diesel 2nd Semester - Trade Theory - NSQF LEVEL 4, , Copyright © 2018 National Instructional Media Institute, Chennai, First Edition:, , November 2018, , Copies: 1,000, , Rs. 180/-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical,, including photocopy, recording or any information storage and retrieval system, without permission in writing from the, National Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone: 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected] ,

[email protected], Website: www.nimi.gov.in, (ii), , Copyright @ NIMI Not to be Republished

Page 3 :

FOREWORD, The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of every, four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy. Industrial, Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled manpower., Keeping this in mind, and for providing the current industry relevant skill training to Trainees, ITI syllabus, has been recently updated with the help of Mentor Councils comprising various stakeholders viz. Industries,, Entrepreneurs, Academicians and representatives from ITIs., The National Instructional Media Institute (NIMI), Chennai, has now come up with instructional material to, suit the revised curriculum for Mechanic Diesel, 2nd Semester Trade Theory NSQF Level - 4 in, Automobile Sector under Semester Pattern. The NSQF Level - 4 will help the trainees to get an international, equivalency standard where their skill proficiency and competency will be duly recognized across the globe, and this will also increase the scope of recognition of prior learning. NSQF Level - 4 trainees will also get, the opportunities to promote life long learning and skill development. I have no doubt that with NSQF Level, - 4 the trainers and trainees of ITIs, and all stakeholders will derive maximum benefits from these Instructional, Media Packages IMPs and that NIMI's effort will go a long way in improving the quality of Vocational training, in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, Director General/ Addl.Secretary, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright @ NIMI Not to be Republished

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Employment and Training (D.G.E & T), Ministry of Labour and Employment, (now under Directorate, General of Training, Ministry of Skill Development and Entrepreneurship) Government of India, with technical, assistance from the Govt. of Federal Republic of Germany. The prime objective of this Institute is to develop, and provide instructional materials for various trades as per the prescribed syllabus under the Craftsman, and Apprenticeship Training Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials are, generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book, Practical, book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and Transparencies) and, other support materials., The trade practical book consists of series of exercises to be completed by the trainees in the workshop., These exercises are designed to ensure that all the skills in the prescribed syllabus are covered. The trade, theory book provides related theoretical knowledge required to enable the trainee to do a job. The test and, assignments will enable the instructor to give assignments for the evaluation of the performance of a trainee., The wall charts and video clips are unique, as they not only help the instructor to effectively present a topic, but also help him to assess the trainee's understanding. The instructor guide enables the instructor to plan, his schedule of instruction, plan the raw material requirements, day to day lessons and demonstrations., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the Media, Development Committees specially drawn from Public and Private sector industries, various training institutes, under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment & Training, of various State Governments, Training Departments of Industries both in the Public and Private sectors,, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators, but for, whose active support NIMI would not have been able to bring out this materials., , R. P. DHINGRA, Chennai - 600 032, , EXECUTIVE DIRECTOR, , (iv), , Copyright @ NIMI Not to be Republished

Page 6 :

INTRODUCTION, TRADE THEORY, The manual of trade theory consists of theoretical information for the Second Semester course of the Mechanic, Diesel Trade. The contents are sequenced according to the practical exercise contained in the manual on Trade, practical. Attempt has been made to relate the theortical aspects with the skill covered in each exercise to, the extent possible. This co-relation is maintained to help the trainees to develop the perceptional capabilities, for performing the skills., The Trade theory has to be taught and learnt along with the corresponding exercise contained in the manual, on trade practical. The indicating about the corresponding practical exercise are given in every sheet of this, manual., It will be preferable to teach/learn the trade theory connected to each exercise atleast one class before, performing the related skills in the shop floor. The trade theory is to be treated as an integrated part of each, exercise., , Module 1, , Diesel engine over view, , 50 Hrs, , Module 2, , Diesel engine components, , Module 3, , Cooling & lubricating system, , 75 Hrs, , Module 4, , Intake and exhaust system, , 25 Hrs, , Module 5, , Diesel fuel system, , 75 Hrs, , Module 6, , Marine & stationary engine, , 25 Hrs, , Module 7, , Emission control system, , 25 Hrs, , Module 8, , Charging and Starting system, , 25 Hrs, , Module 9, , Trouble shooting, , 50 Hrs, , 175 Hrs, , Total, , 525 Hrs, , The material is not the purpose of self learning and should be considered as supplementary to class room, instruction, TRADE PRACTICAL, The trade practical manual is intented to be used in workshop . It consists of a series of practical exercises, to be completed by the trainees during the Second Semester course of the Mechanic Diesel trade, supplemented and supported by instructions/ informations to assist in performing the exercises. These, exercises are designed to ensure that all the skills in compliance with NSQF LEVEL - 4, The manual is divided into Nine modules. The distribution of time for the practical in the Eight modules are given, below., The skill training in the shop floor is planned through a series of practical exercises centred around some, practical project. However, there are few instances where the individual exercise does not form a part of project., While developing the practical manual a sincere effort was made to prepare each exercise which will be easy, to understand and carry out even by below average trainee. However the development team accept that there, is a scope for further improvement. NIMI, looks forward to the suggestions from the experienced training faculty, for improving the manual., (vi), , Copyright @ NIMI Not to be Republished

Page 7 :

CONTENTS, Exercise No., , Title of the Exercise, , Page No., , Module 1 : Diesel engine over view, 2.1.62, , 2.1.63, , 2.1.64, , 2.1.65, , Internal and external combustion engine, , 1, , Classification of engine, , 2, , Function of Diesel engine, , 4, , Function of spark ignition, , 6, , Main parts of Internal Combustion engine, , 10, , Direct and indirect fuel injection system, , 11, , Dashboard gauges, meters and warnings lights, , 16, , Gauges used in automobiles, , 18, , Starting and stopping methods of engine, , 20, , Procedure for dismantling of diesel engine from the vehicle, , 22, , Module 2 : Diesel engine components, 2.2.66, , Description and constructional feature of cylinder head, , 23, , 2.2.67, , Effect on size of intake and exhaust passages, , 26, , 2.2.68 & 2.2.70, , Valves, , 27, , valve operating mechanism, , 28, , Valve contructional features and valve timining, , 31, , Camshaft, , 35, , Camshaft drive mechanisms, , 35, , Piston and piston rings, , 38, , Piston ring, , 43, , Description & function of connecting rod, , 46, , Locking methods of piston pin, , 47, , 2.2.71, , 2.2.72 & 2.2.76, , 2.2.77, , (vii), , Copyright @ NIMI Not to be Republished

Page 8 :

Exercise No., , 2.2.78 & 2.2.82, , Title of the Exercise, , Page No., , Description and function of crankshaft, , 48, , Bearings, , 50, , Application bearing, failure of its causes and care of maintenance, , 52, , Crankshaft balancing, firing order of the engine, , 54, , Flywheel, , 56, , Vibration damper, , 56, , 2.2.85, , Timing gear drive, , 58, , 2.2.86, , Clutch, , 59, , 2.2.87 & 2.2.91, , cylinder block, , 62, , 2.2.92 & 2.2.94, , Engine assembling special tools, , 64, , Gas turbine, , 65, , 2.2.83 & 2.2.84, , Module 3 : Cooling & Lubricating system, 2.3.95 & 102, , Cooling and lubricating system, , 66, , Components of water cooling system, , 68, , Engine Lubricating system, , 72, , Oil pump & Filter, , 75, , Lubricant, , 77, , Module 4 : Intake and exhaust systen, 2.4.103 & 104, , 2.4.105 & 107, , Description of diesel induction and exhaust system, , 79, , Aircompressor, exhauster and turbo charger, , 79, , Turbocharger, , 81, , Air cleaner and air cooler, , 83, , Manifolds and silencer, , 84, , Mufflers, , 85, , (viii), , Copyright @ NIMI Not to be Republished

Page 9 :

Exercise No., , Title of the Exercise, , Page No., , Module 5 : Diesel fuel system, 2.5.108, , 2.5.109, 2.5.110 & 2.2.113, , 2.5.114, , Fuel and feed system, , 87, , Fuel feed pump and filter, , 88, , Carburettor systems, , 90, , Diesel fuel, , 94, , Fuel tank and fuel pipes, , 96, , Fuel filter, , 96, , Fuel feed pump, , 98, , Fuel injection pump, , 99, , Nozzles, , 101, , Electronic diesel control (EDC) system, , 105, , ECM Electronic control module (or) system, , 107, , Common rail diesel injection CRDI, , 108, , HEUI Hydraulically actuated electronically controlled unit injector, , 109, , Module 6 : Marine & stationary engine, 2.6.115 & 2.6.117, , Electro magnetic coupling different of starting on marine engine, , 115, , Auxiliary Engine Automation System, , 118, , Common rail system of marine engines, , 121, , Module 7 : Emission control system, 2.7.118 & 2.7.119, , 2.7.120, , Sources of Emission, , 125, , Vehicle emissions standards- Euro and Bharat, , 125, , Combustion chamber design, , 131, , Combustion process, , 132, , Characteristics and Effect of Hydrocarbons, , 133, , Hydrocarbons in exhaust gases, , 133, , Diesel particulate filters (DPF), , 133, , (ix), , Copyright @ NIMI Not to be Republished

Page 10 :

Exercise No., , Title of the Exercise, , Page No., , Source of Pollutants, , 135, , Crankcase emission control, , 136, , Exhaust gas recirculation (EGR) valve, , 137, , Evaporation emission control, , 139, , Catalytic converter, , 140, , Selective catalytic reduction(SCR), , 141, , EGR Vs SCR, , 142, , Module 8 : Charging and starting system, 2.8.121, , 2.8.122, , Alternator, , 143, , Differences Between Alternator And Dynamo, , 146, , Common troubles and remedies in alternator, , 147, , Starting motor circuit and constructional details, , 148, , Module 9 : Trouble shooting, 2.9.123, , Trouble shooting (causes and remedies), , (x), , Copyright @ NIMI Not to be Republished, , 152

Page 11 :

LEARNING / ASSESSABLE OUTCOME, On completion of this book you shall be able to, • Understand basics of engine types construction, working., • Dismantle & assemble of Diesel Engine from vehicle (LMV/HMV), along with other accessories (torqueing methods, handling parts.), • Overhaul, service and testing Diesel Engine, its parts and check, functionality., • Trace, Test & Repair cooling and Lubrication System of engine, (types of coolants and oils relevant to the engines)., • Trace & Test Intake and Exhaust system of engine. (cleaning egr, valves, exhaust inlet valves, ports and manifolds), • Service Diesel Fuel System and check proper functionality (calibration of mechanical and electronic pumps, checking injectors,, filters), • Plan & overhaul the stationary engine and Governor and check, functionality., • Monitor emission of vehicle and execute different operation to, obtain optimum pollution as per emission norms., • Carryout overhauling of Alternator and Starter Motor., • Diagnose & rectify the defects in LMV/HMV to ensure functionality, of vehicle, • Checking the condition of hoses, mounts, radiators and fans., • Electronic control diagnostics of CR engines., , (xi), , Copyright @ NIMI Not to be Republished

Page 12 :

SECONED SEMESTER, , Week, No., , 27-28, , 20-30, , SYLLABUS FOR MECHANIC DIESEL TRADE, , LearningOutcome, Reference, , Professional Skills, (Trade Practical), with Indicative hrs., , Duration: 06 Months, , Professional Knowledge, (Trade Practical), , Dismantle & assemble of, Diesel Engine from vehicle, (LMV/HMV) along with other, accessories., , 62. Identify the different parts of IC, Engine(10 hrs), 63. Identify the different parts in a, diesel engine of LMV/ HMV (10, hrs), 64. Perform practice on starting and, stopping of diesel engines., Observe and report the reading, of Tachometer, Odometer,, temp and Fuel gauge under, ideal and on load condition. (10, hrs), , Introduction to Engine:, - Description of internal & external, combustion, engines,, Classification of IC engines,, Principle & working of 2&4stroke, diesel, engine, (Compression ignition Engine, (C.I)),, - Principle of Spark Ignition, Engine(SI), differentiate between, 2-stroke and 4 stroke, C.I engine, and S.I Engine,, - Main Parts of IC Engine, - Direct injection and indirect, injection, Technical terms used, in engine, Engine specification., - Study of various gauges/, instrument on a dash board of a, vehicleSpeedometer,, Tachometer, Odometer and Fuel, gauge, and Indicators such as, gearshift position, Seat belt, warning light, Parking-brakeengagement warning light and an, Enginemalfunction light., - Different type of starting and, stopping method of Diesel, Engine, - Procedure for dismantling of, diesel engine from a vehicle., , Overhaul & service Diesel, Engine, its parts and check, functionality., , 65. Practice on dismantling Diesel, engine of LMV/HMV as per, procedure. (20 hrs), 66. Perform Overhauling of cylinder, head assembly, Use of service, manual for clearance and other, parameters,(10 hrs), 67. Perform practice on removing, rocker arm assembly manifolds., (07 hrs), 68. Perform practice on removing the, valves and its parts from the, cylinder head, cleaning. (07 hrs), 69. Inspection of cylinder head and, manifold surfaces for warping,, cracks and flatness. Checking, valve seats & valve guide –, Replacing the valve if necessary., (07 hrs), , Diesel Engine Components:, - Description and Constructional, feature of Cylinder head,, Importance of Cylinder head, design,, - Type of Diesel combustion, chambers,, - Effect on size of Intake &, exhaust passages, Head, gaskets., - Importance of Turbulence, Valves & Valve Actuating, Mechanism - Description and Function of, Engine Valves, different types,, materials,, - Type of valve operating, mechanism, Importance of Valve, seats, Valve seats inserts in, cylinder heads,, , (xii), , Copyright @ NIMI Not to be Republished

Page 13 :

31, , 32, , -do-, , -do-, , 70.Check leaks of valve seats for, leakage – Dismantle rocker, shaft assembly -clean & check, rocker shaft-and levers, for wear, and cracks and reassemble. (07, hrs), 71. Check valve springs, tappets,, push rods, tappet screws and, valve stem cap. Reassembling, valve parts in sequence, refit, cylinder head and manifold &, rocker, arm, assembly,, adjustable valve clearances,, starting, engine, after, adjustments. (12 hrs), , - importance of Valve rotation,, Valve stem oil seals, size of, Intake valves, Valve trains, Valvetiming diagram, concept of, Variable valve timing., - Description of Camshafts &, drives ,, - Description of Overhead, camshaft (SOHC and DOHC),, importance of Cam lobes,, Timing belts & chains, Timing, belts & tensioners., , 72. Perform Overhauling piston and, connecting rod assembly. Use of, service manual for clearance and, other parameters (05 hrs), 73. Perform Practice on removing oil, sump and oil pump – clean the, sump., 74. Perform removing the big end, bearing, connecting rod with the, piston. (05 hrs), 75. Perform removing the piston rings;, Dismantle the piston and, connecting rod. Check the side, clearance of piston rings in the, piston groove & lands for wear., Check piston skirt and crown for, damage and scuffing, clean oil, holes. (05 hrs), 76. Measure -the piston ring close gap, in the cylinder, clearance between, the piston and the liner, clearance, between crank pin and the, connecting rod big end bearing., (05 hrs), 77. Check connecting rod for bend and, twist. Assemble the piston and, connecting rod assembly. (05 hrs), , - Description & functions of, different types of pistons, piston, rings and piston pins and, materials., - Used, recommended, clearances for the rings and its, necessity precautions while, fitting rings, common troubles, and remedy., - Compression ratio., - Description & function of, connecting rod, - importance, of big- end split obliquely, - Materials used for connecting, rods big end & main bearings., Shells piston pins and locking, methods of piston pins., , 78. Perform Overhauling of crankshaft,, Use of service manual for, clearance and other parameters, (05 hrs), 79. Perform removing damper pulley,, timing gear/timing chain, flywheel,, main bearing caps, bearing shells, and crankshaft from engine(05 hrs), 80. Inspect oil retainer and thrust, surfaces for wear. (05 hrs), 81. Measure crank shaft journal for, wear, taper and ovality. (05 hrs), , (xiii), , -, , Description and function of Crank, shaft, camshaft,, - Engine bearings- classification, and location – materials used &, composition of bearing materialsShell bearing and their, advantages- special bearings, material for diesel engine, - Application bearing failure & its, causes-care & maintenance., - Crank-shaft balancing, firing, order of the engine., , Copyright @ NIMI Not to be Republished

Page 14 :

82. Demonstrate crankshaft for, fillet radii, bend & twist. (05, hrs), , 33, , 34, , 35, , 36-38, , -, , Description and function of the, fly wheel and vibration damper., - Crank case & oil pump, gears, timing mark, Chain sprockets,, chain tensioner etc., - Function of clutch & coupling, units attached to flywheel., , 83. Inspect flywheel and mounting flanges,, spigot and bearing.(05 hrs), 84. Check vibration damper for defect. (02, hrs), 85. Perform removing cam shaft from, engine block, Check for bend & twist, of camshaft. Inspection of cam lobe,, camshaft journals and bearings and, measure cam lobe lift. (07 hrs), 86. Fixing bearing inserts in cylinder, block & cap check nip and spread, clearance & oil holes & locating lugs, fix crank shaft on block-torque bolts, - check end play remove shaft - check, seating, repeat similarly for, connecting rod and Check seating, and refit. (11 hrs), , -do-, , -do-, , -do-, , Trace, Test &, Repair Cooling and, Lubrication System, of engine., , 87. Perform cleaning and checking of, cylinder blocks. (04 hrs), 88. Surface for any crack, flatness measure, cylinder bore for taper & ovality, clean, oil gallery passage and oil pipe line., (05 hrs), 89. Perform bore - descale water passages, and examine. (05 hrs), 90. Removing cylinder liners from scrap, cylinder block. (04 hrs), 91. Perform practice in measuring and, refitting new liners as per maker’s, recommendations precautions while, fitting new liners. (07 hrs), , - Description of Cylinder block,, - Cylinder block construction,, - Different type of Cylinder sleeves, (liner)., , 92. Perform reassembling all parts of, engine in correct sequence and torque, all bolts and nuts as per workshop, manual of the engine. (12 hrs), 93. Perform testing cylinder compression,, Check idle speed. (08 hrs), 94. Perform removing & replacing a cam, belt, and adjusting an engine drive belt,, replacing an engine drive belt. (05 hrs), , -, , 95. Perform practice on checking &top up, coolant, draining & refilling coolant,, checking / replacing a coolant hose. (10, hrs) 96. Perform test cooling system, pressure. (05 hrs), 97. Execute on removing & replacing, radiator/ thermostat check the radiator, pressure cap. (10 hrs), 98. Test of thermostat. (5 hrs), 99. Perform cleaning & reverse flushing. (10, hrs), , Need for Cooling systems, - Heat transfer method, Boiling, point & pressure,, - Centrifugal force,, - Vehicle coolant properties and, recommended change of, interval,, - Different type of cooling, systems,, , (xiv), , Engine assembly procedure, with aid of special tools and, gauges used for engine, assembling., - Introduction to Gas Turbine,, Comparison of single and two, stage turbine engine,, - Different between gas turbine, and Diesel Engine., , Copyright @ NIMI Not to be Republished

Page 15 :

Basiccoolingsystem, 100.Perform overhauling water pump and, components, refitting. (10 hrs), - Radiator, Coolant hoses, 101.Perform checking engine oil, draining, - Water pump,, engine oil, replacing oil filter, & refilling, - Cooling, system, engine oil (10 hrs), thermostat, Cooling fans,, 102. Execute overhauling of oil pump, oil, - Temperature indicators,, coolers, air cleaners and air filters and, - Radiator pressure cap,, adjust oil pressure relief valves, repairs to, Recovery, system,, oil flow pipe lines and unions if necessary., Thermoswitch., (15 hrs), Need for lubrication, system,, - Functions of oil, Viscosity, and its grade as per SAE ,, - Oil additives, Synthetic, oils, The lubrication, system, Splash system,, - Pressure system, - Corrosion/noise reduction, in the lubrication system., - Lubrication, system, components, - Description and function of, Sump, Oil collection pan,, Oil tank, Pickup tube,, - different type of Oil pump, & Oil filters Oil pressure, relief valve, Spurt holes &, galleries, Oil indicators, Oil, cooler., , 39, , Trace & Test Intake 103. Execute dismantling air compressor and, exhauster and cleaning all parts and Exhaust system, measuring wear in the cylinder,, of engine., reassembling all parts and fitting them in, the engine. (6 hrs), 104. Execute dismantling & assembling of, turbocharger, check for axial clearance as, per service manual. (05 hrs), 105.Examine exhaust system for rubber, mounting for damage, deterioration and out, of position; for leakage, loose connection,, dent and damage; (05 hrs), 106. Perform practice on exhaust manifold, removal and installation, practice on, Catalytic converter removal and installation., (05 hrs), 107.Check Exhaust system for rubber mounting, for damage, deterioration and out of position;, for leakage, loose connection, dent and, damage. (04 hrs), , (xv), , Intake & exhaust systems–, - Description of Diesel, induction & Exhaust, systems. Description &, function, of, air, compressor, exhauster,, Supercharger,, Intercoolers,, turbo, charger, variable turbo, charger mechanism., Intake system components- Description and function, of Air cleaners, Different, type, air, cleaner,, Description of Intake, manifolds and material,, Exhaustsystem components- Description and function, of Exhaust manifold,, Exhaustpipe, Extractors,, Mufflers-Reactive,, absorptive, Combination, of Catalyticconverters,, Flexible connections,, Ceramic coatings, Backpressure,, - Electronic mufflers., , Copyright @ NIMI Not to be Republished

Page 16 :

40-42, , Service Diesel Fuel, System and check, proper functionality., , 108. Perform work on removing, &cleaning fuel, t a n k s ,, checking leaks in the fuel lines. (10, hrs), 109. Perform soldering & repairing pipe, lines and Unions, brazing nipples to, high pressure line studying the fuel, feed system in diesel engines,, draining of water separators. (10 hrs), 110.Execute overhauling of Feed Pumps, (Mechanical & Electrical). (10 hrs), 111.Perform bleeding of air from the fuel, lines, servicing primary & secondary, filters. (10 hrs), 112. Execute removing a fuel injection, pump from an engine-refit the pump, to the engine re- set timing - fill, lubricating-oil start and adjust slow, speed of the engine. (15 hrs), 113.Execute overhauling of injectors and, testing of injector. (10 hrs), 114. General maintenance of Fuel, Injection, Pumps (FIP). (10 hrs), , Fuel Feed System in IC, Engine(Petrol & Diesel), - Gravity feed system, Forced, feed system, main parts,, Fuel Pumps- Mechanical &, Electrical Feed Pumps., - Knowledge about function,, working & types of, Carburettor., Diesel Fuel Systems, - Description and function of, Diesel fuel injection, fuel, characteristics, concept of, Quiet diesel technology, &Clean diesel technology., Diesel fuel system, components, - Description and function of, Diesel tanks & lines, Diesel, fuel filters, water separator,, Lift pump, Plunger pump,, Priming pump,, - Inline injection pump,, Distributor-type injection, pump, Diesel injectors, Glow, plugs, Cummins & Detroit, Diesel injection., Electronic Diesel control- Electronic Diesel control, systems, Common Rail, Diesel Injection (CRDI), system,, hydraulically, actuated electronically, controlled unit injector, (HEUI) diesel injection, system. Sensors, actuators, and ECU (Electronic Control, Unit) used in Diesel Engines., , 43, , Plan & overhaul the, stationary engine and, Governor and check, functionality., , 115. Execute Start engine adjust idling, speed and damping device in, pneumatic governor and venture, control unit checking. (06 hrs), 116. Verify performance of engine with, off load adjusting timings. Start, engine- adjusting idle speed of the, engine fitted with mechanical, governor checking- high speed, operation of the engine. (07 hrs), 117. Check performance for missing, cylinder by isolating defective, injectors and test- dismantle and, replace defective parts and, reassemble and refit back to the, engine. (12 hrs), , Marine & Stationary Engine:Types,, - double acting engines,, opposed piston engines,, starting systems, cooling, systems,, lubricating, systems, supplying fuel oil,, hydraulic coupling,, - Reduction gear drive,, electromagnetic coupling,, - Electrical drive, generators, and motors, supercharging., , (xvi), , Copyright @ NIMI Not to be Republished

Page 17 :

44, , 21.. Monitor emission of, vehicle and execute, different operation to obtain, optimum pollution as per, emission norms., , 118. Monitor emissions procedures by, use of Engine gas analyser or, Diesel smoke meter. (10 hrs), 119.Checking & cleaning a Positive, crank case ventilation (PCV) valve., Obtaining & interpreting scan tool, data. Inspection of EVAP canister, purges system by use of scan Tool., (10 hrs), 120. EGR /SCR Valve Remove and, installation for inspection. (05 hrs), , Emission Control:- Vehicle, emissions, - Standards- Euro and Bharat, II, III, IV, V Sources of, emission, Combustion,, Combustion chamber design., Types of emissions:, - Characteristics and Effect of, Hydrocarbons, Hydrocarbons, in exhaust gases, Oxides of, nitrogen, Particulates, Carbon, monoxide, Carbon dioxide,, Sulphur content in fuels, Description of Evaporation, emission control, Catalytic, conversion, Closed loop,, Crankcase emission control,, - Exhaust gas recirculation, (EGR) valve, controlling airfuel ratios, Charcoal storage, devices, Diesel particulate, filter (DPF). Selective, Catalytic, Reduction (SCR),, EGR VS SCR, , 45, , Carryout overhauling of, Alternator and Starter Motor, , 121. Perform removing alternator from Basic Knowledge about DC, Generator & AC Generator., vehicle dismantling, cleaning, Constructional details of, checking for defects, assembling, Alternator, and testing for motoring action of, alternator & fitting to vehicles. (15 - Description of charging circuit, operation of alternators,, hrs), regulator unit, ignition warning, 122. Practice on removing starter motor, lamp- troubles and remedy in, Vehicle and overhauling the starter, charging system., motor, testing of starter motor (10, Description, of starter motor, hrs), circuit,, - Constructional details of, starter motor solenoid, switches, common troubles, and remedy in starter circuit., , 46-47, , 23. Diagnose & rectify the, defects in LMV/HMV to, ensure functionality of, vehicle., , 123. Execute troubleshooting in LMV/, HMV for Engine Not starting –, Mechanical & Electrical causes,, High fuel consumption, Engine, overheating,, Low, Power, Generation, Excessive oil, consumption, Low/High Engine Oil, Pressure, Engine Noise. (50 hrs), , (xvii), , Troubleshooting :, Causes and remedy for, - Engine, Not, starting, Mechanical & Electrical, causes,, - High fuel consumption,, Engine overheating,, - Low Power Generation, Excessive oil consumption,, - Low/High Engine Oil, Pressure, Engine Noise., , Copyright @ NIMI Not to be Republished

Page 18 :

49-50, , In-plant training / Project work Projects viz., a. Overhauling of Pressure Lubrication system, b. Maintenance of cooling system., c. Overhauling of FIP., d. Cleaning & Testing of Injectors., e. Overhauling of Alternator, f. Overhauling of Starter Motor, g. Study on Diagnosis Tool/Scanner Tool for ECU of CRDI engine, , 51, , Revision, , 52, , Examination, , (xviii), , Copyright @ NIMI Not to be Republished

Page 19 :

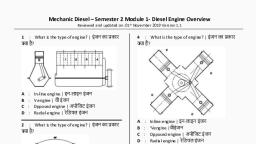

Automobile, Related Theory for Exercise 2.1.62, Mechanic Diesel - Diesel engine over view, Internal and external combustion engine, Objectives : At the end of this lesson you shall be able to, • type of heat engine, • state the internal and external combusion engine, • difference between an internal and external combusion engine., Types of heat engines, 1 External combusion engine, Steam engine, 2 Internal combusion engine, , Rotary, , Piston type, , Reciprocating, piston engine, , Rotary piston, engine, (Experimental), , Free piston engine, (At preliminary, stage), , Diesel engine, , Petrol engine, , Two, Stroke, , Gas Turbine, , Four, Stroke, , Two, Stroke, , Four, Stroke, , As indicated above, modern automobile engines are:, With regard to their construction and operation:, i, , Piston type, , ii Rotary, iii Turbine, Internal combusion engine, , External combusion engine, , Internal combusion engine means, that combusion takes, place inside the cylinder, this definition including the two, stroke and four stroke engine, spark ignition and, compression ignition engine, wrankle, austine and jet, engines are also i.e engine., , External combusion engine is that type of engine in which, combusion takes place outside the engine cylinder. ex:, steam engine., , Copyright @ NIMI Not to be Republished, , 1

Page 20 :

., , Difference between internal and external combusion engine, Sl.No, , Internal combusion engine, , External combusion engine, , 1, , Occupies less space., , Occupies more space., , 2, , Lighter in weight., , Heavier in weight., , 3, , High speed engine., , Slow speed engine., , 4, , Combusion of fuel takes palce inside the, engine., , Combusion of fuel takes palce inside the engine., , 5, , Fuels used in when engine is not running., , Soild or liquid fuels used to form steam., , 6, , No loss of fuel when engine is not running., , Fuel has to burn even when the engine is not, running for small halts., , 7, , Could be started or stopped at will., , Cannot be started unless steam is prepared, which takes much time., , 8, , Temperature produced inside the cylinder, is too high., , Works at comparatively low temperature., , 9, , Cooling arrangement necessary., , No cooling of the cylinders required. Rather, it is steam jacketed., , 10, , Single acting., , Mostly double acting., , 11, , Exhause gas temperature as high as 300°C., , The temperature of exhaust steam is quite low., , 12, , Thermal efficiency of diesel engine up to 40%., , Thermal efficiency up to 24% as that of petrol engine., , 13, , No needs boiler, furnace or condenser., , Boilder, furnace and condenser are must., , Classification of engine, Objective: At the end of this lesson you shall be able to, • state the classification of engines., Engines are classified according to the following factors., Number of cylinders, Single cylinder, Multi cylinder, Arrangements of cylinders, In this type, the cylinders are arranged in one line. The, length of the crankshaft is longer than that of the other, types of engines, and hence a limited number of cylinders, are used. Better balancing and more uniform torque is, obtained in this type., , In-line engine (Fig 1), `V' shape engine (Fig 2), Opposed engine (Fig 3), Horizontal engine, , V engines, , Radial engine (Fig 4), Vertical engine, Types of engines as per cylinder arrangement, In-line engines, , 2, , In this type, the cylinders are arranged in V shape at an, angle, of usually 60°. This engine is more economical and, compact. For multi-cylinder engines, the length of the, crankshaft is much shorter than that of the in- line engine., In this type, the engine height is also lower than it is in the, in-line engine., , Automobile: Mechanic Diesel (NSQF Level-5) - R.T. for Exercise 2.1.62, , Copyright @ NIMI Not to be Republished

Page 21 :

Types of engine as per number of cylinders, Single cylinder engines, An engine which has only one cylinder is called a single, cylinder engine. Since it is a single cylinder engine it, cannot develop more power. It is normally used only in two, wheelers like scooters and motor cycles., Multi cylinder engines, These engines have more than one cylinder. Two-cylinder, engines are usually used in tractors. Three or four cylinder, engines are used in cars, jeeps and other vehicles. In, heavy vehicles six-cylinder engines are used. A greater, number of cylinders gives smoother engine operation., Opposed engines, , Types of fuel used, , In this type the cylinders are arranged horizontally opposite, to each other. This provides better mechanical balance., This type of engine can run smoothly even at a much higher, speed. It also gives higher output. The length of the engine, is too much, and therefore engine has to be placed in the, transverse direction in the vehicle., , Petrol, Diesel, Types of valve arrangements, `I' head engine, `F' head engine, `L' head engine, `H' head engine, `T' head engine, , Radial engines, , Application of engine, Constant speed engine, Variable speed engine, Cooling system, Air cooled engine, Water cooled engine, Strokes of engine, Four-stroke engine, Two-stroke engine, Rotary engine, , In this type, the cylinders are arranged radially. This type, of engine is shorter, lighter and more rigid. Since it is rigid,, a higher engine speed is possible and a higher combustion, pressure can be obtained. This leads to high fuel efficiency., The radial type engines are used mostly in aeroplanes., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.62, , Copyright @ NIMI Not to be Republished, , 3

Page 22 :

Function of Diesel engine, Objectives : At the end of this lesson you shall be able to, • describe the function of a two-stroke diesel engine, • describe the function of a four-stroke diesel engine., Two strke diesel engine:, , Four-stroke engine, , To produce power in a two stroke engine the following, operation take place in the sequence given., , To produce power in a four-stroke engine the following, operations take place in the sequence given., , First stroke: Piston at BDC the scavenging port and outlet valve open (Fig 1). A root blower sucks in pure air and, presses it through the scavenging port into the cylinder., The tangential layout of the scavenging port brings the air, into a turbulent motion. The cylinder is completely flushed, out in the direct current and filled with fresh air. The exhaust gases flow out towards the outlet valve., , Suction stroke, , As the piston moves up from BDC the scavenging port, and outlet valve closed. The piston compresses the fresh, air to the compression chamber. The air temperature increases intensively., Second stroke: Piston at TDC (Fig 2) scavenging port, and outlet valve closed. The fuel is directly injected into, the cylinder with the help of a fuel injection pump and an, injector fitted in the cylinder head. The fuel gets vaporised, into an ignitable fuel air mixture by the hot air. After attaining the ignition temperature the mixture gets automatically ignited and burns. The heat increases the pressure, in the combustion chamber. The gases get expanded and, push the piston to the bottom dead centre., , 4, , The piston moves from TDC to BDC (Fig 3). A vacuum is, created inside the cylinder. The inlet valve opens while the, exhaust valve remains closed. The charge (air/air-fuel, mixture) enters the cylinder., , Compression stroke, The inlet valve closes. The exhaust valve remains closed., The piston moves from BDC to TDC (Fig 4). The charge (air/, air-fuel mixture) is compressed.The pressure and, temperature rise., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.62, , Copyright @ NIMI Not to be Republished

Page 23 :

Power stroke, , Exhaust stroke, , At the end of compression stroke diesel fuel is injected into, the hot compressed air in the combusion chamber; result, in instances burning of diesel with an explosion the gas, expand for is the piston down and power is produced and, pressure develops inside the cylinder. The gas expands, and the piston is forced down from TDC to BDC (Fig 5). Both, the valves remain closed. Power is supplied to the flywheel., , The inlet valve remains in the closed position. The exhaust, valve opens, the piston moves from BDC to TDC (Fig 6) due, to the energy stored in the flywheel. The burnt gases inside, the cylinder go out through the exhaust valves. At the end, of the stroke the exhaust valve closes., The cycle of suction, compression power and exhaust are, repeated. In this type of engines one power stroke is, obtained in two revolutions of the crankshaft., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.62, , Copyright @ NIMI Not to be Republished, , 5

Page 24 :

Automobile, Related Theory for Exercise 2.1.63, Mechanic Diesel - Diesel engine over view, Function of spark ignition, Objectives : At the end of this lesson you shall be able to, • describe the function of a two-stroke engine, • describe the function of a four-stroke engine, • differentiate between a four-stroke and a two-stroke engine, • explain an OTTO cycle, • explain a diesel cycle., Two-Stroke spark ignition engines, To produce power in two stroke engine the following, operations take place in the sequence given., First stroke (Suction and compression), , As the piston moves up from BDC,(Fig 1) it closes the inlet, port (1), the exhaust port (3) and the transfer port (2)., Further upward movement of the piston results in, compressing the mixture in the cylinder and opening of the, inlet port (1). The upward motion of the piston creates a, partial vacuum inside the crank-case below the piston, and, the air/fuel mixture is drawn into the crank-case through the, inlet port (I). The exhaust and transfer ports remain closed, during the operation of the upward stroke and the charge, which reached above the piston during the previous stroke, is compressed., , Second stroke (power and exhaust), The piston is forced downward from the TDC (Fig 2). During, this stroke the exhaust port opens and burnt gases escape, into the atmosphere., , Further downward movement of the piston opens the, transfer port and allows the partially compressed mixture,, received during the previous stroke, to reach the combustion, chamber from the crankcase., The piston head has a special shape. It deflects a fresh, change of fuel mixture up into the cylinder. The mixture, flows down and pushes the burnt gas out. Through the, exhaust port. This process is called scavenging. Once the, flywheel has completed one revolution, the cycle is repeated., In this engine one power stroke is obtained in each, revolution of the crankshaft., , At the end of this stroke the mixture is ignited by an electric, spark (4). This causes the pressure to rise., , 6, , Copyright @ NIMI Not to be Republished

Page 25 :

Spark ignition (Fig 3), , Power stroke, , In a spark ignition (SI) engine, petrol is used as fuel. During, the suction stroke the air and fuel mixture is sucked into the, cylinder. The quantity of the mixture is metered by the, carburettor according to the load and speed. The ratio of, air/fuel mixture is also metered by the carburettor. During, the compression stroke, this air/fuel mixture is ignited by, the spark and the mixture is burnt. It raises the pressure of, the gas above the piston. The piston is forced down and, this power is supplied to the flywheel. During the exhaust, stroke burnt gases escape through the exhaust port/valve., , The charge is ignited and pressure develops inside the, cylinder. The gas expands and the piston is forced down, from TDC to BDC (Fig 6). Both the valves remain closed., Power is supplied to the flywheel., , In this type of engine the compression ratio is low., , Exhaust stroke, The inlet valve remains in the closed position. The exhaust, valve opens, the piston moves from BDC to TDC (Fig 7) due, to the energy stored in the flywheel. The burnt gases inside, the cylinder go out through the exhaust valves. At the end, of the stroke the exhaust valve closes., , Four-stroke spark ignition engine, , The cycle of suction, compression power and exhaust are, repeated. In this type of engines one power stroke is, obtained in two revolutions of the crankshaft., , To produce power in a four-stroke engine the following, operations take place in the sequence given., Suction stroke, The piston moves from TDC to BDC (Fig 4). A vacuum is, created inside the cylinder. The inlet valve opens while the, exhaust valve remains closed. The charge (air/air-fuel, mixture) enters the cylinder., Compression stroke, The inlet valve closes. The exhaust valve remains closed., The piston moves from BDC to TDC (Fig 5). The charge (air/, air-fuel mixture) is compressed. The pressure and, temperature rise., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished, , 7

Page 26 :

Comparison between four-stroke engine and two-stroke engine, Four-stroke engine, , 8, , Two-stroke engine, , Four operations (suction, compression, power and, exhaust) take place in the four strokes of the piston., , The four operations take place in two strokes of the piston., , It gives one power stroke in the four strokes, i.e in two, revolutions of the crankshaft. As such three strokes are, idle strokes., , The power stroke takes place in every two strokes i.e., one power stroke for one revolution of the crankshaft., , Due to more idle strokes and non-uniform load on the, crankshaft, a heavier flywheel is required., , The engine has more uniform load as every time the, piston comes down it is the power stroke. As such a, lighter flywheel is used., , The engine has more parts such as valves and its, operating mechanism. Therefore, the engine is heavier., , The engine has no valves and valve-operating mechanism, therefore it is lighter in weight., , The engine is costlier as it has more parts., , The engine is less expensive as it has a lesser number, of parts., , The engine efficiency is more as the charge gets, completely burnt out. Consequently the fuel efficiency, is more., , The engine efficiency is less. A portion of the chargescapes, through the exhaust port, and because of this, the fuel, efficiency is less., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished

Page 27 :

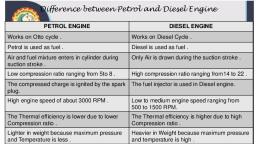

Comparison between S.I and C.I. Engine, SI engine, , CI engine, , Petrol is used as fuel., , Diesel is used as fuel., , During the suction stroke air and fuel mixture is, sucked in., , During the suction stroke air alone is sucked in., , Compression ratio is low. (Max. 10:1), , Compression ratio is high. (Max. 24:1), , Compression pressure is low. (90 to 150 PSI), , Compression pressure is high. (400 to 550 PSI), , Compression temperature is low., , Compression temperature is high., , It operates under constant volume cycle (otto cycle)., , It operates under constant pressure cycle (diesel cycle)., , Fuel is ignited by means of an electric spark., , Fuel is ignited due to the heat of the highly compressed, air. Combustion takes place at constant pressure., , A carburettor is used to atomize, vaporize and meter, the correct amount of fuel according to the requirement., , Fuel injection pumps and atomizers are used to inject, metered quantities of fuel at high pressure according to, the requirement., , Less vibration, and hence, smooth running., , More vibration, and hence, rough running and more noisy., , Engine weight is less., , Engine weight is more., , It emits carbon monoxide. (CO), , It emits carbon dioxide. (CO2), , Otto Cycle, , The gas expands during the power stroke (4-5), reducing, both pressure and temperature., Heat is rejected at constant volume. (5-2), Burnt gases exhaust when piston moves from BDC to TDC., (2-1), Diesel Cycle, , 1-2, 2-3, 3-4, 4-5, 5-2-1, , -, , Suction, Compression, Heat addition, Power, Exhaust, , In otto cycle engine,(Fig 8) combustion takes place at, constant volume., Suction takes place at a pressure below atmospheric, pressure when piston moves from TDC to BDC. (1-2), Compression takes place when piston moves from BDC to, TDC. (2-3), Fuel mixture is ignited by introducing a spark at constant, volume. (3-4), , 1-2, 2-3, 3-4, 4-5, , -, , Suction, Compression, Heat addition, Power, , Suction takes place at (Fig 9) pressure below atmospheric, pressure when piston moves from TDC to BDC. (1-2), Compression takes place when piston moves BDC to TDC., (2-3) (Both the valves closed)., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished, , 9

Page 28 :

Fuel is sprayed at high pressure and ignited by hot, compressed air (3-4), and this process takes place at, constant pressure., , Heat is rejected at constant volume. (5-2), Burnt gases exhaust when piston moves from BDC to, TDC. (2-1), , Fuel ignites, pressure of burnt gas increases, gas expands, and piston is forced from TDC to BDC. (4-5), , Main parts of Internal Combustion engine, Objectives : At the end of this lesson you shall be able to, • location of an engine parts fitting., Internal combustion engine parts, Internal combustion engine’s function is accomated with, the different types of components and it is connected in, outer JPG & inside of the engine., , 27 Connecting rod, 28 Crank shaft, , Name of the components (Fig 1, 2 & 3), , 29 Remove the timing gear and chain (22). (Notedown timing marks.), , 1 Air compressor, , 30 Remove the cam shaft, , 2 F.I.P, , 31 Remove the oil sump (23), , 3 Injector, , 32 Disconnect the oil pipes from the oil pump., , 4 Air cleaner, , 33 Remove the oil pump and strainer (24), , 5 High pressure fuel, , 34 Remove the oil filter, , 6 Fly wheel, , 35 Remove the connecting rod caps. (Note down Nos. on, the caps), , 7 Oil filter, , 36 Remove the piston (21) and connecting rod (27) from, engine. (Note down the marks/Nos. on the piston), , 8 Fuel filter, 9 Fan belt, , 37 Remove the main bearing caps. (Note down them No., on the caps), , 10 Alternator, 11 Self starter, 12 Water pump, 13 Cam shaft, 14 Inlet manifold, 15 Exhaust manifold, 16 Valve door (cover), 17 Rocker assembly, 18 Push rod, 19 Tappets, 20 Cylinder head, 21 Piston, 22 Turning chain, 23 Oil sump, 24 Strainer, 25 Fly wheel housing, 26 Dip stick, 10, , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished

Page 29 :

Direct and indirect fuel injection system, Objectives : At the end of this lesson you shall be able to, • state the function of direct fuel injection, • state the function of indirect fuel injection., Direct Fuel Injection Works (Fig 1), Gasoline engines work by sucking a mixture of gasoline, and air into a cylinder, compressing it with a piston, and, igniting it with a spark. The resulting explosion drives the, piston downwards, producing power. Traditional indirect, fuel injection systems pre-mix the gasoline and air in a, chamber just outside the cylinder called the intake manifold., In a direct injection system, the air and gasoline are not premixed. Rather, air comes in via the intake manifold, while, the gasoline is injected directly into the cylinder., , spray pattern that breaks the gasoline up into smaller, droplets. The result is a more complete combustion - in, other words, more of the gasoline is burned, which translates, to more power and less pollution from each drop of, gasoline., Disadvantages of Direct Fuel Injection, The primary disadvantages of direct injection engines are, complexity and cost. Direct injection systems are more, expensive to build because their components must be, more rugged. They handle fuel at significantly higher, pressures than indirect injection systems and the injectors, themselves must be able to withstand the heat and, pressure of combustion inside the cylinder., Indirect injection (Fig 2), , Advantages of Direct Fuel Injection, Combined with ultra-precise computer management, direct, injection allows more accurate control over fuel metering,, which is the amount of fuel injected and injection timing, the, exact point when the fuel is introduced into the cylinder., The location of the injector also allows for a more optimal, , Indirect injection in an internal combustion engine is fuel, injection where fuel is not directly injected into the, combustion chamber. In the last decade, gasoline engines, equipped with indirect injection systems, wherein a fuel, injector delivers the fuel at some point before the intake, valve, have mostly fallen out of favor to direct injection., However, certain manufacturers such as Volkswagen and, Toyota have developed a 'dual injection' system, combining, direct injectors with port (indirect) injectors, combining the, benefits of both types of fuel injection. Direct injection, allows the fuel to be precisely metered into the combustion, chamber under high pressure which can lead to greater, power, fuel efficiency. The issue with direct injection is that, it typically leads to greater amounts of particulate matter, and with the fuel no longer contacting the intake valves,, carbon can accumulate on the intake valves over time., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished, , 11

Page 30 :

Adding indirect injection keeps fuel spraying on the intake, valves, reducing or eliminating the carbon accumulation on, intake valves and in low load conditions, indirect injection, allows for better fuel-air mixing. This system is mainly used, in higher cost models due to the added expense and, complexity., Port injection refers to the spraying of the fuel onto the back, of the intake port, which speeds up its evaporation., An indirect injection diesel engine delivers fuel into a, chamber off the combustion chamber, called a prechamber,, where combustion begins and then spreads into the main, combustion chamber. The prechamber is carefully designed, to ensure adequate mixing of the atomized fuel with the, compression-heated air., , Advantages of indirect injection combustion chambers, •, , Smaller diesels can be produced., , •, , The injection pressure required is low, so the injector is, cheaper to produce., , •, , The injection direction is of less importance., , •, , Indirect injection is much simpler to design and, manufacture; less injector development is required and, the injection pressures are low (1500 psi/100 bar versus, 5000 psi/345 bar and higher for direct injection), , •, , The lower stresses that indirect injection imposes on, internal components mean that it is possible to produce, petrol and indirect injection diesel versions of the same, basic engine. At best such types differ only in the, cylinder head and the need to fit a distributor and spark, plugs in the petrol version whilst fitting an injection, pump and injectors to the diesel. Examples include the, BMC A-Series and B-Series engines and the Land, Rover 2.25/2.5-litre 4-cylinder types. Such designs, allow petrol and diesel versions of the same vehicle to, be built with minimal design changes between them., , •, , Higher engine speeds can be reached, since burning, continues in the prechamber., , Disadvantages, •, , Fuel efficiency is lower than with direct injection because, of heat loss due to large exposed areas and pressure, loss due to air motion through the throats. This is, somewhat offset due to indirect injection having a much, higher compression ratio and typically having no, emissions equipment., , •, , Glow plugs are needed for a cold engine start on diesel, engines., , •, , Because the heat and pressure of combustion is, applied to one specific point on the piston as it exits the, precombustion chamber or swirl chamber, such engines, are less suited to high specific power outputs (such as, turbocharging or tuning) than direct injection diesels., The increased temperature and pressure on one part of, the piston crown causes uneven expansion which can, lead to cracking, distortion or other damage due to, improper use; use of " starting fluid" (ether) is not, recommended in glow plug, indirect injection systems,, because explosive knock can occur, causing engine, damage., , Classification of indirect combustion chambers, •, , 3.1Swirl chamber, , •, , 3.2Precombustion chamber, , •, , 3.3Air cell chamber, , Overview, The purpose of the divided combustion chamber is to speed, up the combustion process, in order to increase the power, output by increasing engine speed.[2] The addition of a, prechamber, however, increases heat loss to the cooling, system and thereby lowers engine efficiency. The engine, requires glow plugs for starting. In an indirect injection, system the air moves fast, mixing the fuel and air. This, simplifies injector design and allows the use of smaller, engines and less tightly toleranced designs which are, simpler to manufacture and more reliable. Direct injection,, by contrast, uses slow-moving air and fast-moving fuel;, both the design and manufacture of the injectors is more, difficult. The optimisation of the in-cylinder air flow is much, more difficult than designing a prechamber. There is much, more integration between the design of the injector and the, engine.[3] It is for this reason that car diesel engines were, almost all indirect injection until the ready availability of, powerful CFD simulation systems made the adoption of, direct injection practical., , 12, , Basic technical terms used in relation to engines, T.D.C. (Top dead centre), It is the postion of the piston at the top of a cylinder, where, the piston changes its direction of motion from the top to, the bottom., , Automobile: Mechanic Diesel (NSQF Level - 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished

Page 31 :

B.D.C. (Bottom dead centre), It is the position of the piston at the bottom of the cylinder, where the piston changes its direction of motion from the, bottom to the top., , where N is r.p.m of the crankshaft, and T is the torque, produced., Indicated horsepower (IHP), It is the power developed in the engine cylinder., , Stroke, The distance travelled by the piston from TDC to BDC or, BDC to TDC., Cycle, , Where Pm is the mean effective pressure in kg./cm2., , A set of operations performed in sequence by the motion, of the piston in an engine to produce power., , L is length of stroke in metres, , Swept volume (VS), , A is the area of the piston in cm2, N is the No. of power strokes per minute, , Displacement volume of a piston., Clearance volume (VC), Volume of the space above the piston when it is at TDC., , K is the No. of cylinders., Frictional horsepower, It is the horsepower lost in the engine due to friction., , Compression ratio (CR), Ratio of compression volumes before the stroke and after., , FHP =, , IHP - BHP, , Mechanical efficiency, It is the ratio of power delivered (BHP) and the power, available in the engine (IHP). It is expressed in percentage, , where, , VS = Swept volume, VC = Clearance volume, , Mechanical efficiency =, , VS+VC = Total volume at BDC., , Volumetric efficiency, , Power, Power is the rate at which work is done in a specific time., , It is the ratio between the air drawn in the cylinder during, the suction stroke and the volume of the cylinder., Throw, , Horsepower (HP), It is the measurement of power in SAE. One hp is the power, required to lift a load of 33000 lbs, through one foot in one, minute or 4500 kg through one meter in one minute (in, metric system), , It is the distance between the centre of the crank pin to the, centre of the main journal. The piston stroke is double the, throw., Firing order, , Thermal efficiency, , The firing order is the sequence in which the power stroke, takes place in each cylinder in a multi-cylinder engine., , It is the ratio of work output to the fuel energy burnt in the, engine. This relationship is expressed in percentage., , Technical Specification of an engine, , Brake horsepower (BHP), , Engines are specified as per the following., , It is the power output of an engine, available at the flywheel,, , Automobile: Mechanic Diesel (NSQF Level - 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished, , 13

Page 32 :

Type, , Capcity of cooling system, , 20 litres, , Crankcase oil capacity, , Maximum - 14 litres, Minimum - 10 litres, , Cooling water temperature, , 75°C - 95°C, , Number of cylinders, Bore diameter, , Biasis, , Stroke length, Capacity in cu.cm/cu.inch, , Raidator, Clutch, , Core frontal area..3500 sq.cm approx x551 (sq.in), Single plate dry friction type, Diameter of clutch lining:, Outside : 280 mm (11”), Inside : 165 mm (61/2”), Friction area (both sides), : 798 sq.cm approx, (124 sq.in), , Transmission, , No.of speeds:, Forward, 5, Reverse, 1, Gear Ratio :, 1st, 7.37 :1, 2nd, 4.23 : 1, 3rd, 2.49 : 1, 4th, 1.56 : 1, 5th, 1:1, Reverse, 7.15 : 1, Rear Axle ratio 7.48 - 1 : 6.8.57, , Steering, , Heavy duty re-circulating ball type steering with, universal joint, Gear Ration 34.2 :1, , Maximum engine output at specified r.p.m., Maximum torque, Compression ratio, Firing order, Idling speed, Air cleaner (Type), Oil filter (Type), Fuel filter, Fuel injection pump, Weight of engine, Cooling system (type), Type of fuel, Techincal specifications of vehicles, LPT - 1210 D, Specifications, Engine, Model, , 6692 D.I., , Number of cylinders, , 6, , Bore, , 92 mm, , Stroke, , 120mm, , Capacity, , 4788 cc, , Gross H.P. (S.A.E.), , 125 at 2800 R.P.M., , Taxable H.P., , 31.5, , Maximum Torque, , 30 mkg at 2000 R.P.M, , Compression Ratio, , 17 : 1, , Compression pressure at, 150-200 R.P.M., , Minimum 20 kg/cm2, , Fuel injection begins, , 23° before T.D.C., , Firing order, , 1-5-3-6-2-4, , Opening pressure of the, injection nozzles, , Brakes, , Hand brake : Mehanically operated brake acting on, rear wheel, Foot brake : Hydraulic brakes on front and real, wheels, assisted by single chamber air, pessure booster., Brake drum diameter:, Front : 408 mm (16”), Rear : 408 mm (16”), Total braking area, Front : 1440 sq. cm approx (223 sq.in), Rear : 1440 sq. cm approx (223 sq.in), , Frame, , Side member of channel section, , Depth max : 223 mm, , Width, , : 60 mm, , 200 + 10kg/cm2 Newnozzels, Min. 180 kg/cm2 Used nozzels, Thickness : 7 mm, , Maximum variation permissible, in injectionn: nozzle pressure, , 5 kg/cm2, , Inlect valve clearance, , 0.20 mm, , Exhaust valve clearance, , 0.30 mm, , Air cleaner, , oil bath, , Total bearing area per bearing, , 55 sq.cm, , No.of main bearings, , 7, , Fuel injection pump, , MICO BOSCH, , Weight (Dry), , 382 kg, , 14, , Steering wheel diameter 550 mm, , Springs, , No.of cross members : 8, Type : Semi-elliptical, Composition of steel : silicon -manganese, No.of leaves:, Front, rear, Main, 12, 12, Auxillary, 5, Leaf thickness, , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished

Page 33 :

Dimesions, Main 11 mm, , 13 mm, , Wheel base, , LPT 1210D/36, 3625, , LPT 1210D/42, 4225 mm, , Auxillary ––, Total thickness of spring with bottom plate:, Wheel track :, Front, 132 mm, , 1925 mm, , 1925 mm, , 1755 mm, , 1755 mm, , 233 mm, , Width of spring leaf:, Rear, 60 mm, , 80 mm, , Total weight of spring, 50 kg. (123 lb) 123 kg. (271 lb), Shock Absorbers, Wheels and tyres, , Hydraulic telescopic type on fron and rear axles., No.of wheels : Total 7 : Front 2, Rear 4, spare 1., Rim size : 7.00 x 20, No.of Tyres : Toral 6 : Fron 2, Rear 4, Tyre size : 9.00 x 20 ... 12 ply EHD, , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.63, , Copyright @ NIMI Not to be Republished, , 15

Page 34 :

Automobile, Related Theory for Exercise 2.1.64, Mechanic Diesel - Diesel engine over view, Dashboard gauges, meters and warnings lights, Objectives: At the end of this lesson you shall be able to, • state different type of meters and their uses, • describe the purpose of each warning lights, • specify the purpose of each gauges., Odometer, An odometer (Fig 1) is an instrument that indicate distance, travelled by a vehicle, such as motor cycle and motor, vehicle automobile. The device may be electronic,, mechanical, or a combination of both. It is also called as, trip meter in case of short trips of every ride. The distance, mentioned in the odometer generally in kms., , Speedometer, A speedometer or a speed meter is a gauge that measures, and displays the instantaneous speed of a vehicle. The, unit in which the display shown is in Km/hr. There are, both analog and digital meters are available now a days., Engine RPM meter, An engine rpm meter (Fig 2) is used to display the engine, rotation in revolution per minute., , 3 Traction control indicator : This tells you the traction, control is off. A blinking traction-control light indicates, that the system is preventing wheel spin. In which, case you should either; let off the gas a bit and drive a, little slower; or let off the gas a bit and drive much, slower., 4 Stability control indicator : This indicates that the, stability control has been turned off. There's not much, reason to turn it off on the road, and some cars can be, dangerous in the wet without it. A blinking light indicates, that the stability control system is actively preventing, loss of control. If this happens, pay attention and stop, trying to drive like an idiot., 5 Centre differential lock (or 4Hi/Lo): This indicates, that the center differential on or car with part-time fourwheel drive has been engaged. We can't stress this, enough; Part time all-wheel drive is not meant for onroad use, and running it on dry tarmac can cause, "binding" and other problems. We've heard sob stories, from dealerships where customers had to pay for costly, repairs because the later didn't realize this., 6 Proximity sensor indicator : Some cars have, proximity sensors all around instead of just the rear, bumper. This helps you park your big, cumbersome, vehicle in tight parking spots. It also makes for, incessant buzzing as motorcyclists and pedestrians, filter around you in traffic. Recognizing whether it's on, or off can help prevent a nasty scrape., 7 Econ indicator : This can mean different things on, different cars. Some cars use it to tell you that economy, mode is engaged, which means that the accelerator, and the transmission are in their most relaxed mode., On some cars with cylinder deactivation, this tells you, that the system is turned on (typically when you're, cruising or coasting), and half your cylinders are not, burning gas at the moment. On other cars, this lights, up when you are driving in an "economical" manner,, and it can be used as a training tool for good, efficient, driving. Other cars use color-changing dash lights for, the same purpose. They're educational, helpful and, rather cool., , 1 Bulb indicator : This shows you that you have a dead, bulb. Not all cars have this, but it's a helpful warning., 2 Cruise control indicator : This indicator is used to, display the accelerator opening level to maintain the, set speed. This reminds you that cruise control is on., , 16, , Copyright @ NIMI Not to be Republished

Page 35 :

8 Electric power steering indicator : This indicates a, fault in the EPS system. It could mean temporary, overheating of the assist motor or a major fault in the, system. Electric steering motors are usually compact,, and violent sawing at the wheel can sometimes overtax, them. This can happen when you're doing a 30-point, turn in a tight garage, or when you're banging comes, on a tight autocross. Best let things cool down and, see if the problem goes away; otherwise, it's time for a, checkup., 9 Glow plug indicator : Lacking spark plugs, diesels, rely on pressure and heat to burn their fuel. As there's, little heat in the motor when you first start it in the, morning, glow plugs heat up the fuel coming out of the, injectors to give the motor a better chance of starting., The light should turn on briefly after you switch the, ignition to the 'on' position. Once it's off, the plugs are, hot enough to start the car. A flashing light may indicate, busted plugs, but some cars use the glow plug light as, a catch-all indicator for problems ranging from bad, injectors to exhaust gas recirculation valve issues. Get, it checked as soon as possible., 10 Check engine light : We've saved the most crucial, indicator for last. This is a confusing and often, maddening-warning light. It can signal any number of, issues or faults with the sensors and electronic, equipment on the engine, some of which are serious,, some of which are not. The most common cause is a, busted exhaust oxygen sensor, which is bad for, emissions but won't prevent your car from running., Other common causes include ignition coil and spark, plug problems on gasoline cars, or an issue with any, of the dozen-odd sensors that keep your engine happy., Even if you think it's nothing serious, don't ignore it., Have your car subjected to a diagnostic scan as soon, as possible., Mechanic motor vehicle/mechanic diesel, , 2 Airbag indictor : This signals a malfunction with the, airbags or air bag sensor. This means that they may, not go off in a crash. On some cars, there's also a, passenger. Airbag off light that means the car has, detected a small person in the front seat and has, deactivated the front passenger airbag. This ensures, that the (presumably short) front passenger doesn't, suffocate or suffer a broken neck when the airbag goes, off., 3 Brake indicator : This signals several things (Fig 3), a Your parking brake is engaged, so disengage it;, b The parking brake sensor is out of alignment, so have, it fixed;, c The brake fluid level is low, d The hydraulic pressure between the two braking circuits, are mismatched. The last two are potentially, dangerous, and could mean a possible fluid leak, as, well as reduced or even completely absent braking, performance., Don't wait for the light to go off; check your fluid every, morning before you go out, because sometimes the, warning light comes on too late. Some newer cars, also have a brake pad warning light that goes off if the, pads need to be replaced., 4 ABS indicator : Some cars have a separate ABS, light that signals a problem with the ABS system. If, this goes off, that means that the Antilock Braking, System has malfunctioned and the brakes may lock, up under hard braking. Bring the car in for servicing, immediately., 5 Temperature warning : Some older cars with, temperature gauges merely have a red light, but many, modern cars have this symbol. This indicates that, your engine is overheating or is about to overheat. Best, to pull over immediately to cool down, to avoid, potentially expensive engine repair bills., 6 Oil level/Pressure warning : There's no genie in this, lamp. Just the magic slippery stuff that keeps your, engine lubricated. This typically signals your oil level, is low by about two liters. No lasting damage should, occur if you top off the oil the moment you see this, warning. But if you ignore it, your motor could end up, looking like a frying pen that's been left on the burner, for a few hours. Not a pretty sight and a new engine is, much more expensive than a new frying pan., , 1 Seatbelt indicator : This one is easy. This indicates, that the driver is not wearing the seatbelt. On newer, vehicles, weight sensors in the seat tell the car if, someone is sitting there, and warnings will appear for, passengers, too. If the driver or passengers remain, unbelted, a warning chime will sound. Don't ignore it., Studies show that seatbelt use reduces the chance of, injury in a crash by 50%. Worse yet, being hit by an, air bag with out your seat belt on can be fatal., , 7 Electrical system warning : This one looks like a, battery, which means battery problems. It could also, mean alternator problems, so simply buying a new, battery may not be enough. Thankfully, many shops, can test the alternator's charging capacity when you, go in for a battery replacement., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.64, , Copyright @ NIMI Not to be Republished, , 17

Page 36 :

8 Transmission warning light : This comes in many, different forms, and can indicate a malfunction with the, transmission itself, the gearshift or transmission fluid, overheating. You most often see this on trucks when, you're hauling heavy loads, or in high performance cars, with automatic transmission if you drive them a little, too hard. Needless to say, pulling over to let the, transmission cool down is a good idea., , 10 High beam indicator : While not a warning light per, se, this bright icon represents a big danger to other, motorists, and is one of the most ignored indicators in, the Philippines. Leaving your high beams on will blind, other motorists and can lead to nasty accidents., Remember to turn them off when there's oncoming traffic, or when driving behind another car., , 9 Tire pressure monitoring system : This indicates, either an issue with the TPMS itself or low pressure in, one of your tires. Check immediately, Low pressure, carry increased risk of blowout on the highway due to, tire overheating.Not to mention the danger of, hydroplaning in the rain, as wider tires slide over the, water more easily than narrower ones., , You don't need to see the road 2km ahead when you, can simply follow the other guy ahead of you., You don't need to be a "car whisperer" to know something's, wrong when your dashboard lights up like a Christmas, tree. But knowing what these lights denote can mean the, difference between a quick fix and a long walk home., , Gauges used in automobiles, Objectives: At the end of this lesson you shall be able to, • explain the location of various gauges in a vehicle, • explain the purpose of a fuel gauge, • explain the working of a fuel gauge, • explain the purpose of a temperature gauge, • explain the working of a temperature gauge, • explain the purpose of an oil pressure gauge, • explain the working of an oil pressure gauge., The gauges indicate to the driver the working of the, particular system to which they are connected. These, gauges are located on the dashboard of the vehicle., Some of the electrically operated gauges are the following., •, , Fuel gauge (Balancing coil type), , •, , Temperature gauge (Balancing coil type), , •, , Oil pressure gauge (Balancing coil type), , Fuel gauge, Purpose, It is used to know the quantity of fuel available in the fuel, tank., Tank unit, , Gauge unit (Dash unit), , It consists of a tank unit and the indicator unit (Fig 1). The, two units are connected in series by a single wire to the, battery through the Ignition switch. When the ignition, switch is turned on, current passes through both the units., The tank unit is fitted on the fuel tank and the indicator unit, on the dashboard. The tank unit consists of a hinged arm, with a float fitted at one end and a sliding contact at the, other end and also a variable resistance. The sliding, contact moves along the resistance. The float arm moves, up and down as the level of fuel in the tank changes. The, movement of the float arm changes the electrical resistance, in the circuit., 18, , It is fitted on the panel board., Two terminals (8) & (9) are connected to the tank unit's, terminal (4) and ignition switch (10) respectively., It consists of two coils (11) & (12) and a pointer (13) with, the magnet (14) attached to it., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.64, , Copyright @ NIMI Not to be Republished

Page 37 :

•, , The dash unit consists of a dial (3) pointer (4), a magnet, (5) and coil (6) and (7). (Fig 4), , •, , The two terminals of gauge are connected to the ignition, switch (8) and the engine unit (1). The operating current, is supplied from the battery through the ignition switch., , Working, When the ignition switch (10) (Fig 2) is on, current from the, battery flows to the coils and a magnetic field is produced., When the tank (7) is full, the float (1) raises above and, moves the sliding contact (5) to the high resistance, position on the resistance coil (3). The current flowing, through the coil (12) also flows through the coil (11). The, magnetism of the coil (12) becomes weaker. The, magnetism of the coil (11) thus becomes stronger and pulls, the armature (14) and the pointer (13) to the full side of the, dial. When the fuel level (6) comes down the float in the, tank falls down and resistance also becomes less, thereby, strengthening the magnetic field around coil (12) and, forcing the armature and pointer towards the empty side of, the dial., Temperature gauge, Purpose, It is used to know the temperature of water in the cooling, system of engine at all times. It cautions the driver against, overheating of the engine., •, , It consists of an engine unit (1) immersed in the engine, coolant in the cylinder head or cylinder block in the form, of a pellet. (Fig 3), , Working, When the coolant temperature rises, the engine unit, becomes hot. When the engine unit temperature is high, the resistance is less and more current passes to the right, coil of the indicating units., The difference in the strength of the magnetic field between, the two coils increases and the armature and pointer move, towards the right to indicate a high temperature., When the engine coolant temperature falls down, the, resistance becomes high. This results in less current, flowing through the left coil, and the magnetic field becomes, less and causes the armature and pointer to move towards, the left to indicate lower temperature., Oil pressure gauge, Purpose, This device is used to know the pressure of lubricating oil, during the working of the engine and serves as a warning, signal to the driver against any sudden failure of the, lubrication system., Types, •, , Bourdon tube type gauge (non-electric), , •, , Balancing coil type (electric), , The Bourdon tube gauge is not widely used nowadays, as, it has certain drawbacks i.e. the connecting tube leaks at, joints., •, , It is made of special material whose electrical resistance, increases when temperature is lowered and it reduces, when the temperature is increased., , •, , The resistance unit is provided with the dash unit (2) and, it is fitted on the panel board., , In modern vehicles balancing coil type (electric) oil pressure, gauges are used., , Automobile: Mechanic Diesel (NSQF Level- 4) - R.T. for Exercise 2.1.64, , Copyright @ NIMI Not to be Republished, , 19

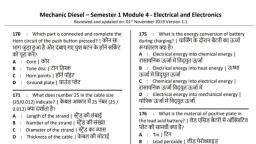

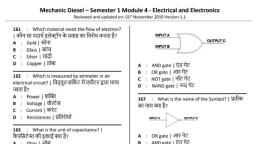

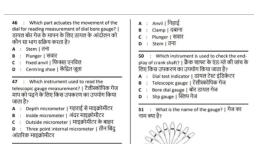

Page 38 :