Page 1 :

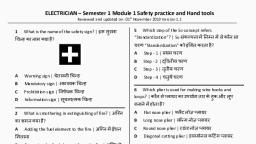

MECHANIC DIESEL, NSQF LEVEL - 4, , 1st Semester, TRADE THEORY, SECTOR: Automobile, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright @ NIMI Not to be Republished

Page 2 : Sector, , : Automobile, , Duration : 1 - Year, Trade, , : Mechanic Diesel 1st Semester - Trade Theory, , Copyright@2018 National Instructional Media Institute, Chennai, First Edition : November 2018, , Copies : 1,000, , Rs. 285 /-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical, including, photocopy, recording or any information storage and retrieval system, without permission in writing from the National, Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone : 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected] ,

[email protected], Website: www.nimi.gov.in, (ii), , Copyright @ NIMI Not to be Republished

Page 3 :

FOREWORD, , The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of every, four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy. Industrial, Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled manpower., Keeping this in mind, and for providing the current industry relevant skill training to Trainees, ITI syllabus, has been recently updated with the help of Mentor Councils comprising various stakeholder's viz. Industries,, Entrepreneurs, Academicians and representatives from ITIs., The National Instructional Media Institute (NIMI), Chennai, an autonomous body under Ministry of Skill, Development & Entrepreneurship is entrusted with developing producing and disseminating Instructional, Media Packages (IMPs) required for ITIs and other related institutions., The institute has now come up with instructional material to suit the revised curriculum for Mechanic, Diesel 1st semester Trade Theory NSQF Level - 4 in Automobile Sector under Semester Pattern., The NSQF Level - 4 Trade Theory will help the trainees to get an international equivalency standard where, their skill proficiency and competency will be duly recognized across the globe and this will also increase, the scope of recognition of prior learning. NSQF Level - 4 trainees will also get the opportunities to promote, life long learning and skill development. I have no doubt that with NSQF Level - 4 the trainers and trainees, of ITIs, and all stakeholders will derive maximum benefits from these IMPs and that NIMI's effort will go a, long way in improving the quality of Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, Director General/ Addl.Secretary, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright @ NIMI Not to be Republished

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Employment and Training (D.G.E & T), Ministry of Labour and Employment, (now under Ministry, of Skill Development and Entrepreneurship) Government of India, with technical assistance from the Govt., of the Federal Republic of Germany. The prime objective of this institute is to develop and provide instructional, materials for various trades as per the prescribed syllabi under the Craftsman and Apprenticeship Training, Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials are, generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book, Practical, book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and Transparencies) and, other support materials., The trade practical book consists of series of exercises to be completed by the trainees in the workshop., These exercises are designed to ensure that all the skills in the prescribed syllabus are covered. The trade, theory book provides related theoretical knowledge required to enable the trainee to do a job. The test and, assignments will enable the instructor to give assignments for the evaluation of the performance of a trainee., The wall charts and transparencies are unique, as they not only help the instructor to effectively present a, topic but also help him to assess the trainee's understanding. The instructor guide enables the instructor to, plan his schedule of instruction, plan the raw material requirements, day to day lessons and demonstrations., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the Media, Development Committees specially drawn from Public and Private sector industries, various training institutes, under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment & Training, of various State Governments, Training Departments of Industries both in the Public and Private sectors,, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators, but for, whose active support NIMI would not have been able to bring out this materials., , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Chennai - 600 032, , (iv), , Copyright @ NIMI Not to be Republished

Page 6 :

INTRODUCTION, TRADE THEORY, This manual of trade theory consists of theoretical information for theFirst Semester Course of the Mechanic Diesel., The contents are sequenced according to the practical exercise contained in NSQF LEVEL - 4 syllabus on Trade, Practical. Attempt has been made to relate the theoretical aspects with the skill covered in each exercise to, the extent possible. This correlation is maintained to help the trainees to develop the perceptional capabilities, for performing the skills., , The trade theory has to be taught and learnt along with the corresponding exercise contained in the manual on, trade practical. The indications about the corresponding practical exercises are given in every sheet of this, manual., It will be preferable to teach/learn trade theory connected to each exercise at least one class before performing, the related skills in the shop floor. The trade theory is to be treated as an integrated part of each exercise., The material is not for the purpose of self-learning and should be considered as supplementary to class room, instruction., TRADE PRACTICAL, The trade practical manual is intended to be used in practical workshop. It consists of a series of practical, exercises to be completed by the trainees during the First Semester Course of Mechanical Diesel supplemented and, , supported by instructions / informations to assist in performing the exercises. These exercises are designed, to ensure that all the skills in compliance with NSQF LEVEL - 4 syllabus are covered., The manual is divided into six modules. The distribution of time for the practical in the six modules are given below:, Module 1, , Safety workshop practice, , 25 Hrs, , Module 2, , Measuring, marking & workshop tools, , 100 Hrs, , Module 3, , Fastening and fitting, , 125 Hrs, , Module 4, , Electrical and electronics, , 100 Hrs, , Module 5, , Arc & Gas welding, , 75 Hrs, , Module 6, , Hydraulics and pneumatics, , 50 Hrs, , Module 7, , Specification and service equipments, , 25 Hrs, , Total, , 525 Hrs, , The skill training in the shop floor is planned through a series of practical exercises centered around some, practical project. However, there are few instances where the individual exercise does not form a part of project., While developing the practical manual, a sincere effort was made to prepare each exercise which will be easy to, understand and carry out even by below average trainee. However the development team accept that there is a, scope for further improvement. NIMI looks forward to the suggestions from the experienced training faculty for, improving the manual., , (vi), , Copyright @ NIMI Not to be Republished

Page 7 :

CONTENTS, Lesson No., , Title of the Lesson, , Page No., , Module 1 : Safety workshop practices, 1.1.01, , Organization of ITI’s and scope of the mechanic diesel trade, , 1, , Scope of the mechanic diesel trade, , 2, , 1.1.02, , Knowledge of personal safety and safety precautions in handling diesel machines., , 3, , 1.1.03, , Concept of house keeping & 5S method, , 7, , 1.1.04, , Safe handling and periodic testing of lifting equipments, , 9, , Safety disposal of used engine oil, , 9, , Safe handling of fuel spillage, , 10, , Safe disposal of toxic dust, , 10, , Elementary first-aid, , 12, , Occupational health and safety, , 13, , Safety practice - fire extinguishers, , 15, , Electrical safety tips, , 17, , 1.1.07, , Used for different types of fire extinguishers, , 19, , 1.1.08, , Energy conservation process, , 21, , 1.1.05, , 1.1.06, , Module 2 : Measuring, marking & workshop tools, 1.2.09, , Marking material, , 22, , Cleaning tools, , 22, , Scrapper, , 24, , Surface plates, , 25, , Try Square, , 26, , Types of calipers, , 27, , Jenny calipers, , 28, , Dividers, , 29, , Surface Gauges, , 29, , Scriber, , 31, , 1.2.10, , Wheelbase, wheeltrack and measuring tape, , 32, , 1.2.11, , Length measurement, , 33, , Engineer’s steel rule, , 33, , 1.2.12, , Air impact wrench, air ratchet, , 34, , 1.2.13, , Hand tools, , 35, , Chisel, , 37, , Angles of chisels, , 38, , Hammers, , 39, , Wooden mallet, , 41, , Screwdrivers, , 42, (vii), , Copyright @ NIMI Not to be Republished

Page 8 :

Lesson No., , Title of the Lesson, , Page No., , Allen keys, , 46, , Bench vice, , 47, , Types of vices, , 47, , C - Clamps and toolmaker’s clamps, , 48, , Spanners and their uses, , 49, , Pliers, , 54, , SNIPS (Straight & Bent), , 56, , Wrenches, , 57, , Flaring, flare fittings and testing the joints, , 59, , Puller, , 61, , Least count calculation, care and use of micrometer, , 64, , Precision measuring instruments - Outside metric micrometer, , 67, , 1.2.15, , Depth micrometer, , 69, , 1.2.16, , Description least count, calculation, care and use of vernier caliper, , 71, , The universal vernier caliper and its application, , 73, , 1.2.17, , Telescope gauge, , 75, , 1.2.18, , Dial bore gauge, , 76, , 1.2.19, , Dial test indicators, , 78, , 1.2.20, , Straight edges, , 80, , 1.2.21, , Feeler gauge & uses, , 81, , 1.2.22, , Vacuum gauge, , 82, , 1.2.23, , Tyre pressure gauge, , 83, , 1.2.14, , Module 3 : Fastening and fitting, 1.3.25, , Rivets - types & uses, , 84, , Rivet proportions, , 84, , Riveted joints, , 86, , Tools for hand riveting, , 87, , Spacing of rivets in joints, , 88, , Defects in riveted joints, , 89, , Caulking and fullering, , 89, , Special sheet metal rivets and their applications, , 91, , Bolts, studs and nuts, , 92, , Locking Devices, , 93, , Keys and splines, , 98, , Circlips, , 100, , Washers - Types and uses, , 101, , Different types of screws, nuts, studs and bolts, , 103, , Thumb screws, , 105, , Types of Nuts, , 106, (viii), , Copyright @ NIMI Not to be Republished

Page 9 :

Lesson No., 1.3.26, , 1.3.27 - 1.3.28, , 1.3.29, , 1.3.30, , 1.3.31, , 1.3.32, , 1.3.33, , 1.3.34, , Title of the Lesson, , Page No., , Methods of removing broken studs, , 109, , Screw pitch gauge, , 110, , Hacksaw frame and blade, , 111, , Elements of a file, , 112, , Cut of files, , 113, , File specifications and grades, , 114, , File - Applications, , 115, , Shapes of files, , 115, , Off - hand grinding with bench and pedestal grinders, , 116, , Safe working on off - hand grinders, , 118, , Indian standard system of limits & fits - terminology, , 118, , Fits and their classification as per the indian standard, , 122, , Soldering, , 125, , Brazing, , 127, , Gasket, , 128, , Oil seal, , 128, , Drilling machine (portable type), , 130, , Drilling machines (Bench and pillar type), , 131, , Cutting speed and RPM, , 133, , Work - holding devices, , 133, , Drill - holding devices, , 134, , Drill bits, , 136, , Drill Angles, , 137, , Hand taps and dies, , 140, , Tap drill size, , 141, , Die and die stock, , 143, , Hand Reamers, , 145, , Hole size for reaming, , 146, , Lapping, , 147, , Lap materials and lapping compounds, , 148, , Types of sheet metals and their application, , 149, , Properties of an auto body sheet metal, , 149, , Notches in sheet metal, , 150, , Edge stiffening, , 151, , Sheet metal joints, , 152, , Folding and joining allowances, , 153, , Groovers, , 154, , Standard wire gauge, , 155, , Sheet metal shearing, drawing, squeezing, , 156, , (ix), , Copyright @ NIMI Not to be Republished

Page 10 :

Lesson No., , 1.3.35, , 1.3.36, , Title of the Lesson, , Page No., , Bending sheet metal, , 158, , Manual bending, , 159, , Bending metals to an angle, , 161, , Pipe bending machines, , 163, , Pipes and pipe fittings, , 164, , Blow lamp, , 167, , Brazing techniques, , 168, , Module 4 : Electrical and electronics, 1.4.37, , Electricity principles, , 171, , Earthing and its importance, , 173, , 1.4.38, , Ohm’s Law, , 174, , 1.4.39, , Basic types of electrical meters, , 177, , Multimeter, , 179, , 1.4.40, , Fuse, , 181, , 1.4.41, , Cable colour codes and size, , 183, , Law of Resistances, , 185, , Resistors and capacitots, , 186, , Capacitors, , 188, , Grouping of capacitors, , 189, , DC series - parallel - series and parallel combination circuits, , 191, , Potential difference and polarity of IR voltage drops, , 193, , DC parallel circuit, , 195, , Series parallel combination, , 197, , Battery, , 200, , Electricity effects, , 204, , Electromagetic induction, self-induced emf - inductors, , 206, , Tracing auto electrical components in circuit - solenoid & relay, , 207, , Primary and secondary winding, transformers, stator and rotor coil, , 208, , Diodes, , 210, , Transistors and classification, , 212, , Uni -junction transistor (UJT), , 215, , Field effect Transistors, , 215, , Metal oxide field effect transistor (MOSFET), , 217, , Basic logic gates, , 219, , 1.4.42 - 1.4.43, , 1.4.44 - 1.4.47, , 1.4.48, , 1.4.49 - 1.4.50, , 1.4.51, , Module 5 : Arc & Gas Welding, 1.5.52, , Principles of arc welding brief description classification and applications, , 221, , Arc -welding machines, , 223, , A.C. Arc - welding machine, , 224, , D.C. Arc - welding machine, , 225, (x), , Copyright @ NIMI Not to be Republished

Page 11 :

Lesson No., , 1.5.53, , Title of the Lesson, , Page No., , Edge preparation, , 226, , Tools and equipment used in oxy - acetylene gas welding, , 227, , Systems of oxy - acetylene welding, , 230, , TIG welding process and equipment, , 230, , GMAW equipment and accessories, , 233, , GMAW (MIG/MAG) torches, , 234, , Cutting processes - plasma arc cutting, , 237, , Heat Treatment, , 240, , Module 6 : Hydraulics and pneumatics, 1.6.54, , Non - destructive testing methods, , 243, , 1.6.55, , Introduction to the hydraulics and pneumatics, , 245, , Pascal’s law - pressure viscosity, , 246, , Hydraulics, , 249, , Hydraulic actuators and valves, , 251, , Pneumatic System, , 255, , 1.6.56 - 1.6.57, , Module 7 : Specifications and service equipments, 1.7.58, , Resent trends and developments, , 259, , 1.7.59, , Classification of vehicles, , 261, , 1.7.60, , Ministry of road transport & high ways, , 263, , 1.7.61, , Uses of hoists, jacks and stands, , 265, , LEARNING / ASSESSABLE OUTCOME, On completion of this book you shall be able to, • Check & perform measuring & marking by using various, measuring & marking tools. ( Vernier callipers, micrometre, telescope gauges, dial bore gauges, dial indicators, straightedge,, feeler gauge, thread pitch gauge, vaccum gauge, tire pressure, gauge.), • Plan & perform basic fastening & fitting operation by using correct, hand tools, machine tools & equipment., • Trace and test all electrical & electronic components & circuits and, assemble circuit to ensure functionality of system., • Join components by using Arc & Gas welding., • Trace & test hydraulic and pneumatic components, • Check & interpret vehicle specification data and VIN, select &, opearte various service station equipment., (xi), , Copyright @ NIMI Not to be Republished

Page 12 :

Copyright @ NIMI Not to be Republished

Page 13 :

Automobile, Related Theory for Exercise 1.1.01, Mechanic Diesel - Safety workshop practices, Organization of ITI’s and scope of the mechanic diesel trade, Objectives: At the end of this lesson you shall be able to, • state brief introduction about Industrial Training Institutes (ITI), • state about the organized structure of the Institute., Brief Introduction of Industrial Training Institute (ITIs), Industrial Training Institute plays a vital role in economy of, the country, especially interms of providing skilled, manpower., The Directorate General of Training (DGT) comes under, Ministry of Skill Development and Entrepreneurship, (MSDE) offers a range of vocational training trades in, different sectors based on economy /labour market. The, vocational training programmes are delivered under the, aegis of National Council of Vocational Training, (NCVT). Craftsmen Training scheme (CTS) and, Apprenticeship Training Scheme (ATS) and two pioneer, programmes of NCVT for Propagatory Vocational Training., Total number of ITIs in India as on April 2016 is about, 13105 (Govt. it is 2293 + 10812 Private affiliated ITIs)., They are giving training about 132 trades including, Engineering and Non-engineering trades with the duration, of 1 or 2 years. The minimum eligibility for admission in, ITIs 8th, 10th and 12th pass with respect to the trades, and admission process will be held in every year in July., From 2013, semester pattern was introduced with 6, months/Semester and revised the syllabus for each, semester. Then in 2014, they introduced and implemented, "Sector Mentor council (SMC)" re-revised syllabus under, 11 sectors of about 87 trades., At the end of each semester, All India Trade Test (AITT), will be conducted in every July and January, with OMR, answer sheet pattern and multiple choice type questions., , After passing, National trade certificates (NTC), will be, issued by DGT which is authorized and recognized, internationally. In 2017, for some trades they have, introduced and implemented National Skill Qualification, Frame work (NSQF) with Level 4., After finishing instructional training with 'NTC' certificate,, they have to undergo Apprenticeship training (ATS) for one, or two year with respect to trades under the Apprentice, ACT 1961, in various government and private, establishments with stipend. At the end of the, Apprenticeship training, All India Apprentice Test will be, conducted and apprentice certificate will be issued. They, can get job opportunities in private or government, establishment in India/Abroad or they can start small scale, industries in manufacturing or in service sector with, subsidiary government loan., Organizational Structure of ITIs, The head of the institute is the Principal /DDT/HDT under, him one vice-principal (VP). then Training Officers (TO),, Group Instructors (GI) who are the management and, supervisory staff. Then deputy training officer (DTO), Assistant Training Officers (ATO)/junior training officer (JTO), technical assistants are under Training officers for each, trade and for Workshop calculations, Engineering Drawing,, Employability skills etc. Administrative office staff, superintendent , UDC, LDC, office assistant, employees., Hostel Superintendent (H.S.) physical Education Trainer, (PET), Library incharge, Pharmacist,store keeper etc. will, be under the one umbrellas of the institute., , Scope of the mechanic diesel trade, Objectives: At the end of this lesson you shall be able to, • importance and scope of the diesel mechanic trade training, • general discipline in the institute., Scope of the diesel mechanic trade training : Mechanic diesel trade under craftsmen training scheme (CTS), is one of the most popular trade delivered nation wide, through the network of ITI. This trade one year (2 semester) duration., •, , Identify the various types of tools equipment, raw, materials, spares used in mechanic diesel trade,, , •, , Practice to measuring, fitting, welding, sheet metal, works, mechanical and electrical and hydraulic system, fault diagnosis and rectification, , •, , Practice to indent and repairing various type of diesel, engines,, , Carrier Progress Pathways: Can join the apprenticeship, training in different types of industries and often National, Apprenticeship Certificate (NAC), Can join Craftsman Instructor Training Scheme (CITS) to, become an instructor in ITIs, , Copyright @ NIMI Not to be Republished, , 1

Page 14 :

Job Opportunities, •, , •, , Mechanic diesel can join in central and state, government establishments, like railway, airport,, marine, military, joins as a service technician in dealer, of agricultural machinery minining, trucks, bus, car,, stationary engines, compressors, diesel generators,, construction equipments, etc., employment. opportunities in overseas., , Self-employment opportunities, •, , Service centre in rural and urban areas., , •, , Maintenance contractor, , •, , Manufacturer of sub-assembly, , •, , Dealership/agency for automobile spare parts, , •, , Own repair shop or garrage., , General discipline in the institute : Always be polite,, courteous while in institue, Do not arguments with others, on matters of related to, your training or with the office while seeking clarifications, Do not bring bad name to your institute by your improper, habitude., , Do very attentive and listen to the lecture carefully during, the theory classes and practical demonstration given by, the training staff., Give respect to your trainer and all other training staff,, office staff and co-trainees., Be interested in all the training activities., Do not make noise or be playful while undergoing training., Keep the institute premises neat and clean avoid poluting, the environment., Do not take away any material from the institute which, does not belong to you., Always attend the institute well dressed and good physical, appearance., Be regular to attend the training without fail and avoid absent, from the theory or practical classes for simple reasons., Prepare well before writing a test/examination., Avoid any malpractice during the test/examination., Write your theory and practical records regularly and, submit them on time for correction, Take care of your safety as well as other’s safety while, doing the practicals., , Do not waste your precious time in gossips with your, friends and on activities other than training., Do not be late to the theory practical and other classes., Do not unnecessarily interfere in other’s activities., , 2, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.01, , Copyright @ NIMI Not to be Republished

Page 15 :

Automobile, Related Theory for Exercise 1.1.02, Mechanic Diesel - Safety workshop practices, Knowledge of personal safety and safety precautions in handling diesel, machines., Objectives: At the end of this lesson you shall be able to, • state the is personal protective equipment and its purpose, • name the two categories of personal protective equipment, • list the most common type of personal protective equipment, • list the conditions for selection of personal protective equipment, • state the safety precaution in handling diesel machines., Personal Protective Equipment (PPE), , Categories of PPEs, , Devices, equipment, clothing are used by the employees,, as a last resort, to protect against hazards in the, workplace. The primary approach in any safety effort is, that the hazard to the workmen should be eliminated or, controlled by engineering methods rather than protecting, the workmen through the use of personal protective, equipment (PPE). Engineering methods could include, design change, substitution, ventilation, mechanical, handling, automation, etc. In situations where it is not, possible to introduce any effective engineering methods, for controlling hazards, the workmen shall use appropriate, types of PPE., , Depending upon the nature of hazard, the PPE is broadly, divided into the following two categories:, , As changing times have modernized the workplace,, government and advocacy groups have brought more safety, standards to all sorts of work environments. The Factories, Act, 1948 and several other labour legislations 1996 have, provisions for effective use of appropriate types of PPE., Ways to ensure workplace safety and use personal, protective equipment (PPE) effectively., •, , Workers to get up-to-date safety information from the, regulatory agencies that workplace safety in their, specific area., , •, , To use all available text resources that may be in work, area and for applicable safety information on how to, use PPE best., , •, , When it comes to the most common types of personal, protective equipment, like goggles, gloves or bodysuits,, these items are much less effective if they are not worn, at all times, or whenever a specific danger exists in a, work process. Using PPE consistent will help to avoid, some common kinds of industrial accidents., , •, , Personal protective gear is not always enough to protect, workers against workplace dangers. Knowing more, about the overall context of your work activity can help, to fully protect from anything that might threaten health, and safety on the job., , •, , Inspection of gear thoroughly to make sure that it has, the standard of quality and adequately protect the user, should be continuously carried out., , 1 Non-respiratory: Those used for protection against, injury from outside the body, i.e. for protecting the head,, eye, face, hand, arm, foot, leg and other body parts, 2 Respiratory: Those used for protection from harm due, to inhalation of contaminated air., They are to meet the applicable BIS (Bureau of Indian, Standards) standards for different types of PPE., The guidelines on 'Personal Protective Equipment' is issued, to facilitate the plant management in maintaining an, effective programme with respect to protection of persons, against hazards, which cannot be eliminated or controlled, by engineering methods listed in table1., Table1, No., , Title, , PPE1, , Helmet, , PPE2, , Safety footwear, , PPE3, , Respiratory protective, equipment, , PPE4, , Arms and hands protection, , PPE5, , Eyes and face protection, , PPE6, , Protective clothing and coverall, , PPE7, , Ears protection, , PPE8, , Safety belt and harnesses, , Copyright @ NIMI Not to be Republished, , 3

Page 16 :

Common type of personal protective equipments and their uses and hazards are as follows:, Types of protection, , 4, , Hazards, , PPE to be used, , Head protection (Fig 1), , 1. Falling objects, 2. Striking against objects, 3. Spatter, , Helmets, , Foot protection (Fig 2), , 1. Hot spatter, 2. Falling objects, 3. Working wet area, , Leather leg guards, Safety shoes, Gum boots, , Nose (Fig 3), , 1. Dust particles, 2. Fumes/ gases/ vapours, , Nose mask, , Hand protecion (Fig 4), , 1. Heat burn due to direct contact, 2. Blows sparks moderate heat, 3. Electric shock, , Hand gloves, , Eye protection (Fig 5, Fig 6), , 1. Flying dust particles, 2. UV rays, IR rays heat and, High amount of visible, radiation, , Goggles, Face shield, Hand shield, Head shield, , Face Protection (Fig 6, Fig 7), , 1. Spark generated during, Welding, grinding, 2. Welding spatter striking, 3. Face protection from, UV rays, , Face shield, Head shield with or, without ear muff, Helmets with welders, screen for welders, , Ear protection (Fig 7), , 1. High noise level, , Ear plug, Ear muff, , Body protection (Fig 8, Fig 9), , 1. Hot particles, , Leather aprons, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.02, , Copyright @ NIMI Not to be Republished

Page 17 :

Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.02, , Copyright @ NIMI Not to be Republished, , 5

Page 18 :

Quality of PPE’s, , •, , Keep all flammable material away from the diesel, machine., , •, , Always keep clean hand and tools while work on, machine, , •, , Keep the diesel machines operating area free from any, form of fire., , Selection of PPE’s requires certain conditions, , •, , Safety operation of diesel machine:, , •, , Nature and severity of the hazard, , •, , Don't operate the machine with loose engine mounting, , •, , Type of contaminant, its concentration and location of, contaminated area with respect to the source of, respirable air, , •, , Don't operate the machine without lubricant, , •, , Don't spill diesel during fill in to the fuel tank, , •, , Keep the empty diesel /lubricant can away from the, machine., , •, , Ensure stationary engine exhaust gas outlet should, be far away from work place otherwise it will be harm, full to human health, , •, , Use preheat before start the diesel engine, , •, , Use safe guard around rotating part of the engine, , Proper use of PPEs, , •, , Maintains the coolant and lubricant level in the engine., , Having selected the proper type of PPE, it is essential, that the workmen wears it. Often the workmen avoids using, PPE. The following factors influence the solution to this, problem., , •, , Always keep engine in an upright places for easy, handling and safety., , •, , use specified grade lubricant and coolant in an engine, , •, , safety of rubber hose and pipes:, , PPE must meet the following criteria with regard to its, quality-provide absolute and full protection against possible, hazard and PPE’s be so designed and manufactured out, of materials that it can withstand the hazards against which, it is intended to be used., , •, , Expected activity of workmen and duration of work,, comfort of workmen when using PPE, , •, , Operating characteristics and limitations of PPE, , •, , Easy of maintenance and cleaning and, , •, , Conformity to Indian/ International standards and, availability of test certificate., , The extent to which the workmen understands the, necessity of using PPE, , •, , The ease and comfort with which PPE can be worn, with least interference in normal work procedures, , •, , The available economic, social and disciplinary, sanctions which can be used to influence the attitude, of the workmen, , •, , The best solution to this problem is to make 'wearing, of PPE' mandatory for every employee., , •, , In other places, education and supervision need to be, intensified. When a group of workmen are issued PPE, for the first time., , Safety precaution in handling diesel machine:, •, , •, , Diesel mechanic must know the safety rules first and, then practice to handling diesel machine as well as we, known, when accident starts means safety rules are, not followed during the handling of diesel machine. So, safety precautions are always based on good sense., The following precautions are to be observed to keep a, diesel mechanic/personal accident free., , •, , Inspect the rubber hose periodically and replace the, damaged parts, , •, , Inspect the fuel leaks in fuel system and rectify the, leakages, , •, , Inspect the exhaust gas leaks and rectify the leakages, , •, , Check the engine performance if any air lock in fuel, system, bleed the fuel system., , •, , Safety of engine operation:, , •, , Check the coolant circulation and pressure cap function, , •, , Check the oil pressure, , •, , Check the tappet noise and rectify the noise/adjust, the defective tappet, , •, , Check the abnormal noise in the engine, , •, , Check leakages of lubricant and coolant in the engine, and rectify the leakages., , •, , Ensure free air circulation in engine operating place, , General safety:, •, , 6, , Do not spill the fuel and lubricant on work place, the, spills may cause for the risk of slipping., , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.02, , Copyright @ NIMI Not to be Republished

Page 19 :

Automobile, Related Theory for Exercise 1.1.03, Mechanic Diesel - Safety workshop practices, Concept of house keeping & 5S method, Objectives: At the end of this lesson you shall be able to, • elements of house keeping and cleanliness at work place, • state the concept of 5‘S’ techniques., Concept of house keeping, House keeping is the systematic process of making home/, work place neat and clean. House keeper is responsible for, administering housekeeping maintenance and for assuring, that every thing is in order and he is responsible for, systematic administration of activities that provide, segregation, storage, transfer, processing treatment and, disposal of solid waste (which is collected during cleaning), , in the workplace. Area such as entranceways which, cannot be cleaned continously are to have mats or, some type of anti-slip flooring. It is also important to, replace worn, ripped or damaged flooring that poses a, trip hazard., •, , Lighting: Adequate lighting reduces the potential for, accidents. It is to be ensured that inoperative light, fixtures are repaired and dirty light fixtures are cleaned, regularly so that the light intensity levels are maintained, at the workplace., , •, , Aisles and stairways: Aisles and stairways are to be, kept clear and not to be used for storage. Warning, signs and mirrors can improve sight lines in blind, corners and help prevent accidents. It is also important, to maintain adequate lighting in stairways. Further, stairways need to have railings preferably round railings, for adequate grip., , •, , Spill control: The best method to control spills is to, prevent them from happening. Regular cleaning and, maintenance on machines and equipment is an, essential practice. Also, the use of drip pans where, spills might occur is a good preventative measure. When, spills do occur, it is important to clean them up, immediately. When cleaning a spill, it is required to, use the proper cleaning agents or absorbent materials., It is also to be ensured that the waste products are, disposed of properly., , •, , Waste disposal: The regular collection of the waste, materials contribute to good housekeeping and, cleanliness practices. It also makes it possible to, separate materials that can be recycled from those, going to waste disposal facilities. Allowing material to, build up on the floor wastes time and energy since, additional time is required for cleaning it up. Placing, containers for wastes near the place where the waste, is produced encourages orderly waste disposal and, makes collection easier. All recyclable wastes after, their collection are to be transferred to their designated, places so that the waste materials can be dispatched, to the point of use or sold., , •, , Tools and equipment: Tools and equipment are, required to be inspected prior to their use. Damaged or, worn tools are to be taken out of service immediately., Tools are to be cleaned and returned to their storage, place after use., , Scope of house keeping maintenance, The scope of work hieghly depend on where the house, keeping activity is performed in general, maintains clean, liness and orderliness, Furnishes the room, office,, workplace, house keeping supervisor assisted by an, assistant house keeper., -, , eye appeal, , -, , safety, , -, , maintenance, , Elements of housekeeping and cleanliness at, workplace, The major elements which are normally included in the, housekeeping and cleanliness practices at the workplace, are described below., •, , •, , •, , Dust and dirt removal: Working in dusty and dirty, area is unhygienic as well as unhealthy for the, employees since there can be respiratory type, irritations. Also, If dust and dirt are allowed to, accumulate on surfaces, there is a potential for a slip, hazard. Hence, regular sweeping the workplace for the, removal of dust and dirt is an essential housekeeping, and cleanliness practice. Further, compressed air is, not to be used for removing dust or dirt off employees, or equipment. Compressed air can caused dirt and dust, paticles to be embedded under the skin or in the eye., Employees facilities: Adequate employees facilities, such as drinking water, wash rooms, toilet blocks, and, rest rooms etc. are to be provided for the employees at, the workplace so that employees can use them when, there is a need. Cleanliness at the place of these, facilities is an important aspect of the facilities., Flooring: Floors are to be cleaned regularly and, immediately if liquids or other materials are spilled., Poor floor conditions are a leading cause of accidents, , Copyright @ NIMI Not to be Republished, , 7

Page 20 :

•, , Maintenance: One of the most important elements of, good housekeeping and cleanliness practices is the, maintenance of the equipment and the buildings housing, them. This means keeping buildings, equipment and, machinery in safe and efficient working condition. When, a workplace looks neglected means there are broken, windows, defective plumbing, broken floor surfaces and, dirty walls etc. These conditions can cause accidents, and affect work practices. It is important to have a, replacement program for replacing or fixing broken and, damaged items as quickly as possible., , •, , Storage: Proper storage of materials is essential in a, good housekeeping and cleanliness practice. All, storage areas need to be clearly marked. Flammable,, combustible, toxic and other hazardous materials are, to be stored in approved containers in designated areas, which are appropriate for the different hazards that they, pose. The stored materials are not to be obstruct aisles,, stairs, exits, fire equipment, emergency eyewash, fountains, emergency showers, or first aid stations., Also it is important that all containers be labeled, properly. If materials are being stored correctly, then, the incidents of strain injuries, chemical exposures and, fires get reduced drastically., , •, , Clutter control: Cluttered workplaces typically happen, because of poor housekeeping practices. This type of, workplace can lead to a number of issues which include, ergonomic as well as injuries. It is important to develop, practices where items like tools, chemicals, cords, and, containers are returned to their appropriate storage, location when not in use. Clutter is not only unattractive, but, in a work area, it is also a serious threat to safety., Danger to the employees increases if the established, exit routes and doors are blocked. For this reason, as, well as to prevent slips and trips, assorted waste, materials need to be disposed of promptly in the, appropriate waste containers. Aisles are to be kept, clear of obstructions for obvious reasons., , •, , Individual workspace: Individual workspace need to, be kept neat, cleared of everything not needed for work., Many workplace injuries occur right in the employee’s, workspace. This space is often overlooked when, conducting general housekeeping and cleanliness, inspections. It is necessary to make a checklistwhich, is to be used by the employees to evalute their, workspace., , It can be said that a clean work area demonstrate the, pride employees have with the job and the culture of safety, at the workplace., , The terms (5s) 5 steps are, Step 1: SEIRI (Sorting out), Step 2: SEITON (Systematic arrangement), Step 3: SEISO (Shine cleanliness), Step 4: SEIKTSU (Stanardization), Step 5: SHITSURE (Self discipline), Fig 1 shows the 5s concept wheel., The list describes how to organize a work space for, efficiency and effectiveness by identifying and storing the, items used, maintaining the area and items and sustaining, the new order., , Benefits of 5s, •, , Work place becomes clear and better organised., , •, , Working in working place becomes easier., , •, , Reduction in cost., , •, , People tend to be more disciplined., , •, , Delay is avoided., , •, , Less absenteeism., , •, , Better use of floor space., , •, , Less accidents., , •, , High productivity with quality etc., , 5 Steps (5s) - Concept (Fig 1), 5s is a people-oriented and practice-oriented approach. 5s, expects every one to participate in it. It becomes a basic, for continuous improvement in the organisation., , 8, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.03, , Copyright @ NIMI Not to be Republished

Page 21 :

Automobile, Related Theory for Exercise 1.1.04, Mechanic Diesel - Safety workshop practices, Safe handling and periodic testing of lifting equipments, Objectives: At the end of this lesson you shall be able to, • state the periodic testing of lifting equipments, • state the handling of lifting equipments, Safe and successful lifting operations depends on periodical, testing of lifting equipment, maintenance and handling of, operation, failure of this equipment may result in significant, loss and fatal accident., , •, , Periodic testing of lifting equipment, •, , Visually inspect the component of the lifting equipment, such as lifting chain, slings chain hoist before operating, the equipment., , •, , In Hydraulic function of lift (or) cranes cheek the oil level, and top up the oil level periodically., , •, , The Hydraulic oil used in the lifts or cranes should be, replaced periodically., , •, , The lifting equipment should be over hauled once (or), twice a year., , •, , Cheek the electrical connections of the lifting equipment, periodically., , •, , The calibration of the lifting equipment should be done, once in a year and calibration certificate must to, obtained from the authorized testing center., , Lifts and cranes, Safety precautions for handling of lifts and cranes., •, , Never exceed the safe working load (SWL) of the, equipment you are using., , •, , Always support vehicles with axle stands before working, underneath them., , •, , There is always a danger when loads are lifted or, suspended. Never work under an unsupported,, Suspended or raised load such as a suspended engine., , •, , Always ensure that lifting equipment such as jacks,, hoists, axle stands, slings, etc, are adequate and, suitable for the job, In good condition and regularly, maintained., , Never improvise lifting tackle., , Safety disposal of used engine oil, Objectives: At the end of this lesson you shall be able to, state the purpose of disposal used oil, state the method of safety disposal of used oil, Waste oil, The waste oils, derived from fuels or lubricants, originally, come from petroleum oil, sometimes known as mineral, oils. Many lubricants may also contain synthetic, components., Waste oil is harmful to the environment and some, for, example used engine oils, may cause cancer. so it needs, to be managed carefully. You may need to account for, Health and Safety guidance as well as the environment., , This procedure applies to the disposal of any used oil that, is collected during normal work functions at work place., Used oil may include:, 1 Gasoline. Volatile, flammable, it can be ignited by, sparks and flames even at cold temperatures. Vapors can, migrate to distant ignition sources and in poorly ventilated, spaces, can accumulate to explosive levels. Typical, gasoline contains about 150 different chemicals including, benzence, toluene and xylene., Used Oil Disposal, , Purpose, Oils are defined as greasy, viscous substances from plant,, animal, mineral sources (petroleum), and synthetics that, are not soluble in water, and are usually flammable. These, oils which have been used could be contaminated by, physical or chemical impurities such as dirt, metal scrapings,, and water. Oils that enter storm drains or waterways are a, serious environmental hazard. used oil can pollute fresh, water. The purpose of this procedure is to describe the, proper means for handling and disposing of used oil from, equipment maintenance operations, process procedures,, and any other activities where used oils are generated., , 2 Fuel oils. Fuel oils such as diesel fuel are petroleum, based fluids which are some what volatile and flammable, and can be ignited only when heated above 100°F. Vapors, can travel and flash from ignition sources and can accumlate, to explosive levels in poorly ventilated areas. All fuel oils, consist of complex mixtures of aliphatic and aromatic, hydrocarbons such as kerosene, benzene, and styrene., 3 Lubricating oils. Lubricating oils such as motor oil, and hydraulic fluids are not volatile but are combustible. For, lubricating oil to catch fire some other intense heat source, (i.e., other materials on fire, hot engine manifold, etc.) must, be present. Mineral-based lube oils are refined from, 9, , Copyright @ NIMI Not to be Republished

Page 22 :

petroleum or crude oil and contain additives such as lead, or metal sulphide and other polymers., 4 Transformer oil. Tranformer oil conducts heat away, from and insulates equipment used to convert electricity, from high amperage to low amperage lines. Transformer oil, is a liquid by product of the distillation of petrolem to, produce gasoline., Cooking oils and grease: Cooking oils and grease are, not volatile but they are combustible. With a 400°F flash, point, another heat source must be present for cooking oils, or grease to catch fire. Vegetable oils contain chemical, solvents that are strong enough to dissolve engine seals, and gaskets., Note: for all other waste chemicals, please, refer SOP regarding Used Chemical Disposal., , 1 Wear gloves because oil contains chemicals and, contaminants that are not good for skin contact., 2 Put used oil in a clean plastic or metal container in, good condition and with a tight lid., 3 If the oil is hot, avoid sudden contact with other, substances because mixing may cause ignition or the, receiving container to fracture due to thermal shock., 4 Do not allow used fuel and used oils to mix with any, other substances because unknown and dangerous, chemical reactions may occur., 5 Keep used oils away from gas cylinders and gasoline., 6 Do not fill container to the top but allow a couple inches, below the rim., 7 Label the container with contents,and department., , Procedures, Products saturated with petroleum products require special, handling and disposal by licensed transporters. During the, collection of used oils for disposal, some basic principles, should be followed:, , Safe handling of fuel spillage, Objectives: At the end of this lesson you shall be able to, • state the safe handling of fuel spillage, • state the effect of fuel spillage in workplace., Diesel fuel is a flammable liquid and fuel spillage or leaks, in work place maybe cause for slippage or fire hazard., , 5 Don't spill the fuel during refilling the fuel in fuel tank or, fuel container., , Safe handling of fuel:, , 6 Use funnel during filling the fuel in fuel tank to avoid, fuel spillage, , 1 Improper handling of fuel may cause for fuel spillage, and explosion, so fuel handling should be use, appropriate method., 2 Fuel should not be stored near the working hot engine, 3 Don't refueling, when it is hot, fuel tank vapor may, cause for fire., 4 No smoking is allowed when refueling to the engine., , 7 Use tray during air bleeding from the fuel system to, avoid fuel spillage, 8 Fuel leaks and spills near the engine may cause for, accident so it should be clean and mopped up quickly, as soon as the spillage., 9 Stationary engine fuel tank should be position away, from any source of direct heat to the fuel tank, , Safe disposal of toxic dust, Objectives: At the end of this lesson you shall be able to, • list the waste material in a work shop, • explain the methods of disposal of waste material., Introduction, The Automobiles produces fumes containing unburnt gases, such as carbon-monoxide, nitrogen oxide and other gases, which are harmful to human health. Hence a systematic, and scientifically designed methods are adopted for safe, disposal of such toxic waste., , Brake and clutch components produces dust, when used, compressed air jet to clean them. While cleaning, conforming the PPE to safety regulation & policies. This, includes overall coat, Face mask, safety goggles for eyes, earmuffs & earplug for ear protection, rubber gloves &barrier, cream for hand and valved respirator for breathing., , Dust from vehicle components to be blown into the air,, since such dust floating in air for many hours, may cause, harm to people who breath unknowingly., Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.04, 10, , Copyright @ NIMI Not to be Republished

Page 23 :

Some auto parts having asbestos, is a toxic material, which, cause lung cancer. Airborne dust in workshop leads to, asthma and throat infections. Do not use compressed air, to clean dust from various components & parts of the, Vehicle. Solvent used for cleaning can also form a toxic, waste. Wash work cloths separately from other cloths so, that toxic dust does not get transfer to other clothes. After, cleaning a vehicle, there are certain chemicals present in, this vehicle diet which turns toxic. To eliminate the toxic, waste, create small diet piles and dispose them, spontaneous rather than waiting for big diet pile till the, end of the day. Workshop diet is best cleaned using a, water hose, which does not allow diet to fully. But the, , waste water must be caught in a sledge pit and not into, the storm water drain. Vacuum cleaner is a best device, control toxic waste. Providing high speed exhaust, ventillation can solve toxic diet., Use grease which can not re-used is stored in a separate, container and stored with unique identification. In a similar, manner waste oil is stored in separate container, labeled, ‘Waste oil’ and stored in different location, meant for, disposal used diesel oil and kerosene are also stored in, separate containers and kept at disposal area., , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.04, , Copyright @ NIMI Not to be Republished, , 11

Page 24 :

Automobile, Related Theory for Exercise 1.1.05, Mechanic Diesel - Safety workshop practices, Elementary first-aid, Objectives: At the end of this lesson you shall be able to, • define first aid, • list out the first aid key points, • describe the responsiveness, First aid is defined as the immediate care and support, given to an acutely injured or ill person, primarily to save, life, prevent further deterioration or injury, plan to shift the, victims to safer places, provide best possible comfort and, finally help them to reach the medical centre/ hospital, through all available means. It is an immediate life-saving, procedure using all resources available within reach., Imparting knowledge and skill through institutional teaching, at younger age group in schools, colleges, entry point at, industry level is now given much importance. Inculcating, such habits at early age, helps to build good healthcare, habits among people., First aid procedure often consists of simple and basic life, saving techniques that an individual performs with proper, training and knowledge., The key aims of first aid can be summarized in three, key points:, -, , -, , -, , Preserve life: If the patient was breathing, a first aider, would normally place them in the recovery position,, with the patient leant over on their side, which also, has the effect of clearing the tongue from the pharynx., It also avoids a common cause of death in unconscious, patients, which is choking on regurgitated stomach, contents. The airway can also become blocked through, a foreign object becoming lodged in the pharynx or, larynx, commonly called choking. The first aider will, be taught to deal with this through a combination of, 'back slaps' and 'abdominal thrusts'. Once the airway, has been opened, the first aider would assess to see if, the patient is breathing., Prevent further harm: Also sometimes called prevent, the condition from worsening, or danger of further injury,, this covers both external factors, such as moving a, patient away from any cause of harm, and applying, first aid techniques to prevent worsening of the condition,, such as applying pressure to stop a bleed becoming, dangerous., Promote recovery: First aid also involves trying to, start the recovery process from the illness or injury,, and in some cases might involve completing a, treatment, such as in the case of applying a plaster to, a small wound., , -, , Airway: Attention must first be brought to the airway, to ensure it is clear. Obstruction (choking) is a lifethreatening emergency., , -, , Breathing: Breathing if stops, the victim may die soon., Hence means of providing support for breathing is an, important next steps. There are several methods, practiced in first aid., , -, , Circulation: Blood circulation is vital to keep person, alive. The first aiders now trained to go straight to chest, compressions through CPR methods., , When providing first aid one needs to follow some rule., There are certain basic norms in teaching and training, students in the approach and administration of first aid to, sick and injured., Important guideline for first aiders, Evaluate the situation, Are there things that might put the first aider at risk. When, faced with accidents like fire, toxic smoke, gasses, an, unstable building, live electrical wires or other dangerous, scenario, the first aider should be very careful not to rush, into a situation, which may prove to be fatal., Avoid moving the victim, Avoid moving the victim unless they are immediate danger., Moving a victim will often make injuries worse, especially, in the case of spinal cord injuries., Call emergency services, Call for help or tell someone else to call for help as soon, as possible. If alone at the accident scene, try to establish, breathing before calling for help, and do not leave the victim, alone unattended., Determine responsiveness, If a person is unconscious, try to rouse them by gently, shaking and speaking to them., If the person remains unresponsive, carefully roll, them on the side (recovery position) and open his, airway., -, , Keep head and neck aligned., , -, , Carefully roll them onto their back while holding hishead., , ABC of first aid, ABC stands for airway, breathing and circulation., , 12, , Copyright @ NIMI Not to be Republished

Page 25 :

First aid, -, , Call EMERGENCY number., , -, , Check the person's airway, breathing, and pulse, frequently. If necessary, begin rescue breathing and, CPR., , -, , If the person is breathing and lying on the back and, after ruling out spinal injury, carefully roll the person, onto the side, preferably left side. Bend the top leg so, both hip and knee are at right angles. Gently tilt the, head back to keep the airway open. If breathing or, pulse stops at any time, roll the person on to his back, and begin CPR., , -, , If you see a person fainting, try to prevent a fall. Lay, the person flat on the floor and raise the level of feet, above and support., , -, , If fainting is likely due to low blood sugar, give the person, something sweet to eat or drink when they become, conscious., , DO NOT, -, , Do not give an unconscious person any food or drink., , -, , Do not leave the person alone., , -, , Do not place a pillow under the head of an unconscious, person., , -, , Do not slap an unconscious person's face or splash, water on the face to try to revive him., , Safety, , •, , Improving employees morale, , Safety means freedom or protection from harm, danger,, hazard, risk, accident, injury or damage., , •, , Reducing absenteeism, , •, , Enhancing productivity, , •, , Minimizing potential of work-related injuries and, illnesses, , •, , Increasing the quality of manufactured products and/, or rendered services., , -, , If there is a spinal injury, the victims position may have, to be carefully assessed. If the person vomits, roll the, entire body at one time to the side. Support the neck, and back to keep the head and body in the same, position while you roll., , -, , Keep the person warm until medical help arrives., , Occupational health and safety, Objectives: At the end of this lesson you shall be able to, • define safety, • state the goal of occupational health and safety, • explain need of occupational health and safety, • state what is occupational hygiene?, • list types of occupational hazards., , Occupational health and safety, •, , Occupational health and safety is concerned with, protecting the safety, health and welfare of people, engaged in work or employment., , •, , The goal is to provide a safe work environment and to, prevent hazards., , •, , It may also protect co-workers, family members,, employers, customers, suppliers, nearby communities,, and other members of the public who are impacted by, the workplace environment., , •, , It involves interactions among many related areas,, including occupational medicine, occupational (or, industrial) hygiene, public health, and safety, engineering, chemistry, and health physics., , Need of occupational health and safety, •, , Health and safety of the employees is an important, aspect of a company's smooth and successful, functioning., , •, , It is a decisive factor in organizational effectiveness. It, ensures an accident-free industrial environment., , •, , Proper attention to the safety and welfare of the, employees can yield valuable returns., , Occupational (Industrial) Hygiene, •, , Occupational hygiene is anticipation, recognition,, evaluation and control of work place hazards (or), environmental factors (or) stresses, , •, , This is arising in (or) from the workplace., , •, , Which may cause sickness, impaired health and well, being (or) significant discomfort and inefficiency among, workers., , Anticipation (Identification): Methods of identification, of possible hazards and their effects on health, Recognition (Acceptance): Acceptance of ill-effects of, the identified hazards, Evaluation (Measurement & Assessment): Measuring, or calculating the hazard by Instruments, Air sampling, and Analysis, comparison with standards and taking, judgment whether measured or calculated hazard is more, or less than the permissible standard, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.05, , Copyright @ NIMI Not to be Republished, , 13

Page 26 :

Control of Workplace Hazards: Measures like, Engineering and Administrative controls, medical, examination, use of Personal Protective Equipment (PPE),, education, training and supervision, , 5 Psychological, , Occupational Hazards, "Source or situation with a potential for harm in terms of, injury or ill health, damage to property, damage to the, workplace environment, or a combination of these", , •, , Wrong attitude, , •, , Smoking, , •, , Alcoholism, , •, , Unskilled, , •, , Poor discipline, - absentism, - disobedience, , Types of occupational health hazards, •, , Physical Hazards, , •, , Chemical Hazards, , •, , Biological Hazards, , •, , Physiological Hazards, , •, , Psychological Hazards, , •, , Mechanical Hazards, , •, , Electrical Hazards, , •, , Ergonomic Hazards., , - aggressive behaviours, •, , Accident proneness etc,, , •, , Emotional disturbances, - voilence, - bullying, - sexual harassment, , 6 Mechanical, , 1 Physical Hazards, •, , Noise, , •, , Heat and cold stress, , •, , Vibration, , •, , Radiation (ionising & Nonionising), , •, , Illumination etc.,, , •, , Unguarded machinery, , •, , No fencing, , •, , No safety device, , •, , No control device etc.,, , 7 Electrical, , 2 Chemical Hazards, •, , Inflammable, , •, , Explosive, , •, , Toxic, , •, , Corrosive, , •, , Radioactive, , •, , No earthing, , •, , Short circuit, , •, , Current leakage, , •, , Open wire, , •, , No fuse or cut off device etc,, , 8 Ergonomic, , 3 Biological Hazards, •, , Bacteria, , •, , Virus, , •, , Fungi, , •, , Plant pest, , •, , Infection., , •, , Poor manual handling technique, , •, , Wrong layout of machinery, , •, , Wrong design, , •, , Poor housekeeping, , •, , Awkward position, , •, , Wrong tools etc,, Safety Slogan, A Safety rule breaker , is an accident maker, , 4 Physiological, •, , Old age, , •, , Sex, , •, , Ill health, , •, , Sickness, , •, , Fatigue., , 14, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.05, , Copyright @ NIMI Not to be Republished

Page 27 :

Automobile, Related Theory for Exercise 1.1.06, Mechanic diesel - Safety workshop practices, Safety practice - fire extinguishers, Objectives: At the end of this lesson you shall be able to, • state the effects of a fire break out., • state the causes for fire in a workshop, • state the general precautionary measures to be taken for prevention of fire., • state the types of fire and different extinguishing agent, Fire is the burning of combustible material. A fire in an, unwanted place and on an unwanted occasion and in, uncontrollable quantity can cause damage or destroy, property and materials. It might injure people, and sometimes cause loss of life as well. Hence, every effort must be, made to prevent fire. When a fire outbreak is discovered,, it must be controlled and extinguished by immediate, corrective action., , Preventing fires: The majority of fires begin with small, outbreaks which burn unnoticed until they have a secure, hold. Most fires could be prevented with more care and by, following some simple common sense rules., , Is it possible to prevent fire? Yes, fire can be prevented by, eliminating anyone of the three factors that causes fire., , The cause of fire in electrical equipment is misuse or, neglect. Loose connections, wrongly rated fuses, overloaded, circuits cause overheating which may in turn lead to a fire., Damage to insulation between conductors in cables causes, fire., , The following are the three factors that must be present in, combination for a fire to continue to burn. (Fig 1), , Accumulation of combustible refuse (cotton waste soaked, with oil, scrap wood, paper, etc.) in odd corners are a fire, risk. Refuse should be removed to collection points., , Clothing and anything else which might catch fire should be, kept well away from heaters. Make sure that the heater is, shut off at the end of the working day., Highly flammable liquids and petroleum mixtures (thinner,, adhesive solutions, solvents, kerosene, spirit, LPG gas, etc.) should be stored in the flammable material storage, area., Fuel: Any substance, liquid, solid or gas will burn, if there, is oxygen and high enough temperatures., Heat: Every fuel will begin to burn at a certain temperature., It varies and depends on the fuel. Solids and liquids give off, vapour when heated, and it is this vapour which ignites., Some liquids do not have to be heated as they give off, vapour at normal room temperature say 150C, eg. petrol., Oxygen: Usually exists in sufficient quantity in air to keep, a fire burning., Extinguishing of fire: Isolating or removing any of these, factors from the combination will extinguish the fire. There, are three basic ways of achieving this., – Starving the fire of fuel removes this element., – Smothering - ie. isolate the fire from the supply of, oxygen by blanketing it with foam, sand etc., , Blowlamps and torches must not be left burning when they, are not in use., Extinguishing fires: Fires are classified into four types in, terms of the nature of fuel.(Fig 2,3,4 & 5), Different types of fire have to be dealt with in different ways, and with different extinguishing agents., An extinguishing agent is the material or substance used, to put out the fire, and is usually (but not always) contained, in a fire extinguisher with a release mechanism for spraying, into the fire., It is important to know the right type of agent for extinguishing, a particular type of fire; using a wrong agent can make, things worse.There is no classification for ‘electrical fires’, as such, since these are only fires in materials where, electricity is present., , – Cooling - use water to lower the temperature., Removing any one of these factors will, extinguish the fire., , Copyright @ NIMI Not to be Republished, , 15

Page 28 :

Fuel, , Extinguishing, Most effective ie. cooling with water. Jets of, water should be sprayed on the base of the fire, and then gradually upwards., , Should be smothered. The aim is to cover the, entire surface of the burning liquid. This has the, effect of cutting off the supply of oxygen to the, fire., Water should never be used on burning liquids., Foam, dry powder or CO2 may be used on this, type of fire., , Extreme caution is necessary in dealing with, liquefied gases. There is a risk of explosion and, sudden outbreak of fire in the entire vicinity. If an, appliance fed from a cylinder catches fire - shut, off the supply of gas. The safest course is to, raise an alarm and leave the fire to be dealt with, by trained personnel., Dry powder extinguishers are used on this type, of fire., Special powders have now been developed, which are capable of controlling and/or, extinguishing this type of fire., , The standard range of fire extinguishing agents, is inadequate or dangerous when dealing with, metal fires., Fire on electrical equipment., Halon, Carbon dioxide, dry powder and, vapourising liquid (CTC) extinguishers can be, used to deal with fires in electrical equipment., Foam or liquid (eg. water) extinguishers must, not be used on electrical equipment under any, circumstances., , 16, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.06, , Copyright @ NIMI Not to be Republished

Page 29 :

Electrical safety tips, Objectives: At the end of this lesson you shall be able to, • rescue a person who is in contact with a live wire, • treat a person for electric shock/injury., The severity of an electric shock will depend on the level of, current which passes through the body and the length of, time of contact. Do not delay, act at once. Make sure that, the electric current has been disconnected., If the casualty is still in contact with the supply - break the, contact either by switching off the power, removing the plug, or wrenching the cable free. If not, stand on some insulating, material such as dry wood, rubber or plastic, or using, whatever is at hand to insulate yourself and break the, contact by pushing or pulling the person free. (Figs 1 & 2), , Keep the casualty warm and comfortable. (Fig 4), , Send for help., Do not give an unconscious person anything by, mouth., Do not leave an unconscious person unattended, If the casualty is not breathing - Act at once - don’t wate, time!, Safety practice frist - aid, Electric shock: The severity of an electric shock will, depend on the level of the current which passes through the, body and the length of time of the contact., Other factors that contribute to the severity of shock are:, • age of the person, In bare foot, do not touch the victim with your bare hands, until the circuit is made dead or he is moved away from the, equipment., If the victim is aloft, measures must be taken to prevent him, from falling or atleast make him fall safe., Electric burns on the victim may not cover a big area but, may be deep seated. All you can do is to cover the area with, a clean, sterile dressing and treat for shock. Get expert, help as quickly as possible., If the victim is unconscious but is breathing, loosen the, clothing about the neck, chest and waist and place the, casualty in the recovery position.(Fig 3), , • not wearing insulating footware or wearing wet foot wear, • weather condition, • floor is wet or dry, • mains voltage etc., Effects of electric shock: The effect of current at very low, levels may only be an unpleasant tingling sensation, but, this in itself may be sufficient to cause one to lose his, balance and fall., At higher levels of current, the person receiving the shock, may be throen off his feet and will experience sever pain,, and possibly minor burns at the point of contact., , Keep a constant check on the breathing and pulse rate., , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.06, , Copyright @ NIMI Not to be Republished, , 17

Page 30 :

At an excessive level of current flow, the muscles may, contract and the person unable to release his grip on the, conductor. He becomes conscious and the muscles of the, heart may contract spasmodically (fibrillation). This may, be fatal., , Immediate action: Always in cases of severe bleeding, , Electric shock can also cause burning of the skin at the, point of contact., , • apply pressure to the wound, , • make the patient lie down and rest, • if possible, raise the injured part above the level of the, body (Fig 6), , • summon assistance., , Treatment of electric shock, Prompt treatment is essential., If assistance is close at hand, send for medical aid, then, carry on with emergency treatment., If you are alone, proceed with treatment at once., Switch off the current, if this can be done without undue, delay. Otherwise, remove the victim from contact with the, live conductor, using dry non-conducting materials such as, a wooden bar, rope, a scarf, the victim’s coat-tails, any dry, article of clothing, a belt, rolled-up newspaper, non-metallic, hose, PVC tubing, bakelised paper, tube etc. (Fig 5), , To control severe bleeding: Squeeze together the sides of, the wound. Apply pressure as long as it is necessary to, stop the bleeding. When the bleeding has stopped, put a, dressing over the wound, and cover it with a pad of soft, material. (Fig 7), , For an abdominal stab wound, such as may be caused by, falling on a sharp tool, keep the patient bending over the, wound to stop internal bleeding., Avoid direct contact with the victim. Wrap your hands in dry, material if rubber gloves are not available., Electrical buns: A person receiving an electric shock may, also sustain burns when the current passes through his, body. Do not waste time by applying first aid to the burns, until breathing has been restored and the patient can, breathe normally - unaided., , Large wound: Apply a clean pad (preferably an individual, dressing) and bandage firmly in place. If bleeding is very, severe apply more than one dressing. (Fig 8), , Burns and scalds: Burns are very painful. If a large area of, the body is burnt, give no treatment, except to exclude the, air, eg.by covering with water, clean paper, or a clean shirt., This relieves the pain., Severe bleeding: Any wound which is bleeding profusely,, especially in the wrist, hand or fingers must be considered, serious and must receive professional attention. As an, immediate first aid measure, pressure on the wound itself, is the best means of stopping the bleeding and avoiding, infection., , 18, , Follow the right methods of artificial respiration., , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.06, , Copyright @ NIMI Not to be Republished

Page 31 :

Automobile, Related Theory for Exercise 1.1.07, Mechanic Diesel - Safety workshop practices, Used for different types of fire extinguishers, Objectives: At the end of this lesson you shall be able to, • determine the correct type of fire extinguisher to be used based on the class of fire, Many types of fire extinguishers are available with different, extinguishing ‘agents’ to deal with different classes of, fires. (Fig 1), , Most suitable for, •, , flammable liquid fires, , •, , running liquid fires., , Must not be used on fires where electrical equipment is, involved., , Water-filled extinguishers:There are two methods of, operation. (Fig 2), , Dry powder extinguishers (Fig 4): Extinguishers fitted, with dry powder may be of the gas cartridge or stored, pressure type. Appearance and method of operation is the, same as that of the water-filled one. The main distinguishing, feature is the fork shaped nozzle. Powders have been, developed to deal with class D fires., , Carbon dioxide (CO2): This type is easily distinguished, by the distinctively shaped discharge horn. (Fig 5)., •, , Gas cartridge type, , •, , Stored pressure type, , With both methods of operation the discharge can be, interrupted as required, conserving the contents and, preventing unnecessary water damage., Foam extinguishers (Fig 3):These may be of stored, pressure or gas cartridge types. Always check the, operating instructions on the extinguisher before use., , Suitable for Class B fires. Best suited where contamination, by deposits must be avoided. Not generally effective in, open air., Always check the operating instructions on the container, before use. Available with different gadgets of operation, such as - plunger, lever, trigger etc., , Copyright @ NIMI Not to be Republished, , 19

Page 32 :

Halon extinguishers (Fig 6): These extinguishers may be, filled with carbon-tetrachloride and Bromochlorodifluoro, methene (BCF). They may be either gas cartridge or stored, pressure type., They are more effective in extinguishing small fires involving, pouring liquids. These extinguishers are particularly suitable, and safe to use on electrical equipment as the chemicals, are electrically non-conductive., , The general procedure in the event of a fire:, •, , Raise an alarm., , •, , Turn off all machinery and power (gas and electricity)., , •, , Close the doors and windows, but do not lock or bolt, them. This will limit the oxygen feed to the fire and, prevent its spreading., , •, , Try to deal with the fire if you can do so safely. Do not, risk getting trapped., , •, , Anybody not involved in fighting the fire should leave, calmly using the emergency exits and go to the, designated assembly point. Failure to do this may, mean that some person being unaccounted for and, others may have to put themselves to the trouble of, searching for him or her at risk to themselves., , The fumes given off by these extinguishers are, dangerous, especially in confined space., , 20, , Automobile : Mechanic Diesel (NSQF LEVEL - 4) Related Theory for Exercise 1.1.07, , Copyright @ NIMI Not to be Republished

Page 33 :

Automobile, Related Theory for Exercise 1.1.08, Mechanic diesel - Safety workshop practices, Energy conservation process, Objectives: At the end of this lesson you shall be able to, • define energy conservation, • classify energy conservation opportunities, Energy Conservation, , i) Minor ECOs, , To achieve and maintain optimum energy procurement and, utilization, throughout the organization, , These are simple, easy to implement, and require less, investment implementation time. These may correspond, to stopping of leakage points, avoiding careless waste,, lapses in housekeeping and maintenance etc., , To minimize energy costs / waste without affecting, production, comfort and quality., , ii) Medium ECOs, To reduce environmental pollution per unit of industrial, output - as carbon dioxide, smoke, sulphur dioxide., Definetion of Energy Conservation, Energy conservation is achieved when growth of energy, consumption is reduced, measured in physical terms., Energy conservation can, therefore, be the result of several, processes or developments, such as productivity increase, or technological progress., , These are more complex, and required additional, investment and moderate implementation time. For, example, replacement of existing household appliances, by new energy efficient ones., iii) Major ECOs, These provide significant energy saving. They are complex, and demand major investment and long implementation, periods. For example, replacement or major renovation of, old buildings, machineries etc., , For example, replacing traditional light bulbs with Compact, Fluorescent Lamps (CFL) (which use only 1/4th of the, energy to same light output). Light Emitting Diode (LED), lamps are also used for the same purpose., Energy Conservation Opportunities (ECOs), Opportunities to conserve energy are broadly classified, into three categories:, , Copyright @ NIMI Not to be Republished, , 21

Page 34 :

Automobile, Related Theory for Exercise 1.2.09, Mechanic Diesel - Measuring, marking & workshop tools, Marking material, Objectives: At the end of this lesson you shall be able to, • name the common types of marking material, • select the correct marking material for different applications., Common types of Marking Materials, The common marking materials are Whitewash, Cellulose, Lacquer, Prussian Blue and Copper Sulphate., Whitewash, Whitewash is prepared in many ways., Chalk powder mixed with water, Chalk mixed with methylated spirit, White lead powder mixed with turpentine, Whitewash is applied to rough forgings and castings with, oxidised surfaces. (Fig 1), , Copper Sulphate, The solution is prepared by mixing copper sulphate in, water and a few drops of nitric acid. The copper sulphate, is used on filed or machine-finished surfaces. Copper, sulphate sticks to the finished surfaces well., , Whitewash is not recommended for workpieces of high, accuracy., Cellulose Lacquer, This is a commercially available marking medium. It is, made in different colours, and dries very quickly., , Copper sulphate needs to be handled carefully as it is, poisonous. Copper sulphate coating should be dried well, before commencing marking as, otherwise, the solution, may stick on the instruments used for marking., The selection of marking medium for a particular job, depends on the surface finish and the accuracy of the, workpiece., , Prussian Blue, This is used on filed or machine-finished surfaces. This, will give very clear lines but takes more time for drying, than the other marking media. (Fig 2), , Cleaning tools, Objectives : At the end of this lesson you shall be able to, • state the different types of Cleaning Tools and their use, • state the precautions to be observed in the use of Cleaning Tools., Mechanical Cleaning Involves, brushing and abrasive, Cleaning. It should be used very carefully on soft metals., Heavy deposits that exists even after chemical Cleaning, can be removed by mechanical cleaning., The General Cleaning Tools are, 1) Wire brushes, 2) Emery sheets., , 22, , Wire Brushes, Wire brushes are generally used for cleaning the work, surfaces., It is made of steel wires (or) Nylon bristles fitted on a, wooden piece., The steel wires are hardened and tempered for long life to, ensure good cleaning action. Different types of wire, brushes is shown in Fig 1., , Copyright @ NIMI Not to be Republished

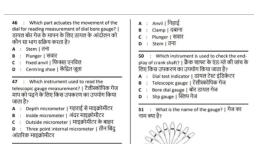

Page 35 :