Page 1 :

FITTER, , NSQF LEVEL - 5, , 1st Year (Volume II of II), TRADE THEORY, , NIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMINIMIHPBW, , SECTOR: Production & Manufacturing, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright Free Under CC BY Licence

Page 2 : Sector, , : Production & Manufacturing, , Duration : 2 - Years, Trade, , : Fitter 1st Year (Volume II of II) - Trade Theory - NSQF level 5, , First Edition : December 2018, Copies : 10,000, , Rs.215/-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical, including, photocopy, recording or any information storage and retrieval system, without permission in writing from the National, Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone : 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected],

[email protected], Website: www.nimi.gov.in, (ii), , Copyright Free Under CC BY Licence

Page 3 :

FOREWORD, , The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of every, four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy. Industrial, Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled manpower., Keeping this in mind, and for providing the current industry relevant skill training to Trainees, ITI syllabus, has been recently updated with the help of Mentor Councils comprising various stakeholder's viz. Industries,, Entrepreneurs, Academicians and representatives from ITIs., The National Instructional Media Institute (NIMI), Chennai has now come up with instructional material to, suit the revised curriculum for Fitter 1st Year Trade Theory NSQF Level - 5. The NSQF Level - 5, Trade Theory will help the trainees to get an international equivalency standard where their skill, proficiency and competency will be duly recognized across the globe and this will also increase the, scope of recognition of prior learning. NSQF Level - 5 trainees will also get the opportunities to promote, life long learning and skill development. I have no doubt that with NSQF Level - 5 the trainers and trainees, of ITIs, and all stakeholders will derive maximum benefits from these IMPs and that NIMI's effort will go a, long way in improving the quality of Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, Director General/ Addl. Secretary, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright Free Under CC BY Licence

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Employment and Training (D.G.E & T), Ministry of Labour and Employment, (now under Directorate, General of Training, Ministry of Skill Development and Entrepreneurship) Government of India, with technical, assistance from the Govt. of the Federal Republic of Germany. The prime objective of this institute is to, develop and provide instructional materials for various trades as per the prescribed syllabi under the Craftsman, and Apprenticeship Training Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials are, generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book, Practical, book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and Transparencies) and, other support materials., The trade practical book consists of series of exercises to be completed by the trainees in the workshop., These exercises are designed to ensure that all the skills in the prescribed syllabus are covered. The trade, theory book provides related theoretical knowledge required to enable the trainee to do a job. The test and, assignments will enable the instructor to give assignments for the evaluation of the performance of a trainee., The wall charts and transparencies are unique, as they not only help the instructor to effectively present a, topic but also help him to assess the trainee's understanding. The instructor guide enables the instructor to, plan his schedule of instruction, plan the raw material requirements, day to day lessons and demonstrations., In order to perform the skills in a productive manner instructional videos are embedded in QR code of the, exercise in this instructional material so as to integrate the skill learning with the procedural practical steps, given in the exercise. The instructional videos will improve the quality of standard on practical training and, will motivate the trainees to focus and perform the skill seamlessly., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the Media, Development Committees specially drawn from Public and Private sector industries, various training institutes, under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment & Training, of various State Governments, Training Departments of Industries both in the Public and Private sectors,, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators, but for, whose active support NIMI would not have been able to bring out this materials., , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Chennai - 600 032, , (iv), , Copyright Free Under CC BY Licence

Page 6 :

INTRODUCTION, TRADE THEORY, The manual of trade theory consists of theoretical information for the Second Semester Course of the Fitter, Trade. The contents are sequenced according to the practical exercise contained in NSQF LEVEL - 5 syallabus, on Trade practical. Attempt has been made to relate the theoretical aspects with the skill covered in each, exercise to the extent possible. This correlation is maintained to help the trainees to develop the perceptional, capabilities for performing the skills., Module 1, , Drilling, , 150 Hrs, , Module 2, , Fitting assembly, , 150 Hrs, , Module 3, , Turning, , 125 Hrs, , Module 4, , Basic Maintenance, , 75 Hrs, , Module 5, , In-plant training/Project work, , 50 Hrs, , Total, , 550 Hrs, , The Trade Theory has to be taught and learnt along with the corresponding exercise contained in the manual, on trade practical. The indications about the corresponding practical exercises are given in every sheet of this, manual., It will be preferable to teach/learn the trade theory connected to each exercise atleast one class before, performing the related skills in the shop floor. The trade theory is to be treated as an integrated part of each, exercise., The material is not for the purpose of self learning and should be considered as supplementary to class room, instruction., TRADE PRACTICAL, The trade practical manual is intented to be used in practical workshop . It consists of a series of practical, exercises to be completed by the trainees during the Second Semester Course of the Fitter Trade, supplemented and supported by instructions/ informations to assist in performing the exercises. These, exercises are designed to ensure that all the skills in compliance with NSQF LEVEL - 5 syllabus are covered., The manual is divided into five modules. The distribution of time for the practical in the five modules are given, below., The skill training in the shop floor is planned through a series of practical exercises centred around some, practical object. However, there are few instances where the individual exercise does not form a part of project., While developing the practical manual a sincere effort was made to prepare each exercise which will be easy, to understand and carry out even by below average trainee. However the development team accept that there, is a scope for further improvement. NIMI looks forward to the suggestions from the experienced training faculty, for improving the manual., , (vi), , Copyright Free Under CC BY Licence

Page 7 :

CONTENTS, Lesson No., , Title of the Lesson, , Page No., , Module 1: Drilling, 2.1.61, , Drills, , 1, , 2.1.62, , Drill angles, , 4, , 2.1.63 - 65, , Drilling - Cutting speed, feed and r.p.m , drill holding devices, , 6, , 2.1.66, , Counter sinking, , 9, , 2.1.67, , Reamers, , 16, , 2.1.68 - 69, , Screw thread and elements, , 22, , 2.1.70, , Tap wrenches, removal of broken tap, studs, , 32, , 2.1.71, , Dies and die stock, , 36, , 2.1.72 - 73, , Drill troubles - Causes and remedy, drill kinds, , 40, , 2.1.74 - 75, , Standard marking system for Grinding wheels, , 46, , 2.1.76, , Radius/Fillet gauge, feeler gauge, hole gauge, , 55, , 2.1.77 - 78, , Pig Iron, , 60, , Module 2: Fitting assembly, 2.2.79 - 80, , Necessity of Interchangeability in engineering field, , 63, , 2.2.81, , Vernier height gauge, , 73, , 2.2.82, , Wrought iron and plain carbon steels, , 75, , 2.2.83 - 85, , Simple scrapers and scraping, , 81, , 2.2.86 - 88, , Vernier micrometer, screw thread micrometer, graduation & reading, , 86, , 2.2.89, , Dial test indicator, comparators, digital dial indicator, , 93, , Module 3: Turning, 2.3.90, , Safety to be observed while working on lathes, , 102, , 2.3.91, , Lathe main parts, , 104, , 2.3.92, , Feeding & thread cutting mechanism, , 110, , 2.3.93, , Holding the job between centre and work with catch plate and dog, , 113, , 2.3.94, , Simple description of facing and roughing tool, , 115, , 2.3.95, , Nomanclature of single point cutting tools and multi point cutting tools, , 117, , 2.3.96, , Tool selection based on different requirements, , 120, , 2.3.97, , Necessity of grinding angles, , 123, , (vii), , Copyright Free Under CC BY Licence

Page 8 :

Lesson No., , Title of the Lesson, , Page No., , 2.3.98, , Lathe cutting speed and feed, use of coolants, lubricants, , 125, , 2.3.99, , Chucks and chucking - the independent 4 jaw chuck, , 130, , 2.3.100, , Face plate, , 136, , 2.3.101, , Drilling, , 138, , 2.3.102, , Boring & boring tools, , 139, , 2.3.103, , Tool setting, , 141, , 2.3.104, , Tool post, , 145, , 2.3.105, , Lathe operation - Knurling, , 147, , 2.3.106, , Standard tapers, , 150, , 2.3.107, , Screw thread, , 154, , 2.3.108, , Principle of cutting screw thread in centre lathe, , 158, , 2.3.109, , Principle of chasing screw thread, , 161, , Module 4 : Basic Maintenance, 2.4.110, , Total productive maintenance, , 168, , 2.4.111, , Routine maintenance, , 170, , 2.4.112, , Preventive maintenance, , 172, , 2.4.113, , Inspection, types of inspection and gadgets for inspection, , 177, , 2.4.114, , Lubrication survey, , 180, , 2.4.115, , Causes for assembly failures and remedies, , 183, , 2.4.116, , Assembly techniquies, , 184, , (viii), , Copyright Free Under CC BY Licence

Page 9 :

LEARNING / ASSESSABLE OUTCOME, On completion of this book you shall be able to, • Produce components by different operations and check accuracy, using appropriate measuring instrument. [ Different OperationsDrilling, reaming, tapping, dieing., Appropriate measuring, instruments - Vernier, screw gauge, micrometer.], • Make different fit of components for assembling as per required, tolerance observing principle of interchargeability and check for, functionality. [ Different fit-sliding, angular, step fit, ‘T’ fit, square fit, and profile fit., Required tolerance; ± 0.04 mm, angular tolerace: 30, min], • Produce components involving different operations on lathe, observing standard procedure and check for accuracy. [ Different, operations - Facing, plain turning, step turning, parting, chamfering,, shoulder turn, grooving, knurling, boring, taper turning, threading, (external ‘V’ only.], • Plan & perform simple rapair, overhauling of different machines, and check for functionality. [ Different machines - Drill machine,, power saw, bench grinder and lathe.], , (ix), , Copyright Free Under CC BY Licence

Page 10 :

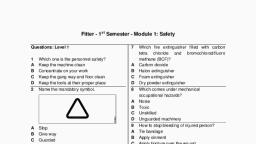

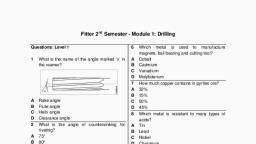

SYLLABUS, 1st Year (Volume II of II), Week, No., , Ref. Learning, Outcome, , 27, , Produce componentsby, different operations and, check accuracy using, appropriate measuring, instruments.[Different, Operations-Drilling,, Reaming, Taping, Dieing;, Appropriate Measuring, Instrument – Vernier, Screw, Gauge, Micrometer], , 28, , -do-, , Duration: Six Month, Professional Skills, (Trade Practical), with Indicative hours, 61 Mark off and drill through holes., (5 hrs.), 62 Drill on M.S. flat. (1 hrs.), 63 File radius and profile to suit gauge, (13 hrs.), 64 Sharpening of Drills.(1 hrs.), , 66 Counter sink, counter bore and, ream split fit (three piece fitting)., (5 hrs.), , 68 Form internal threads with taps to, standard size (through holes and, blind holes).(3 hrs.), 69 Prepare studs and bolt.(15 hrs.), , -do-, , Drill- material, types, (Taper shank,, straight shank) parts and sizes., Drill angle-cutting angle for different, materials, cutting speed feed., R.P.M. for different materials. Drill, holding, devicesmaterial,, construction and their uses., , 65 Practice use of angular measuring, instrument. (5 hrs.), , 67 Drill through hole and blind holes., (2 hrs.), , 29, , Professional Knowledge, (Trade Theory), , 70 Form external threads with dies to, standard size. (10 hrs.), 71 Prepare nuts and match with, bolts.(15 hrs.), , Counter sink, counter bore and spot, facing-tools and nomenclature,, Reamermaterial,, types (Hand and machine reamer),, kinds, parts and their uses,, determining hole size (or reaming),, Reaming procedure., Screw threads: terminology, parts,, types and their uses. Screw pitch, gauge: material parts and uses., Taps British standard (B.S.W.,, B.S.F., B.A. & B.S.P.) and metric /, BIS (course and fine) material, parts, (shank body, flute, cutting edge)., , Tap wrench: material, parts, types, (solid &adjustable types) and their, uses removal of broken tap, studs, (tap stud extractor). Dies: British, standard, metric and BIS standard,, material, parts, types, Method of, using dies. Die stock: material,, parts and uses., , (x), , Copyright Free Under CC BY Licence

Page 11 :

30, , -do-, , 72 File and make Step fit, angular fit,, angle, surfaces (Bevel gauge, accuracy 1 degree).(15 hrs.), 73 Make simple open and sliding fits., (10 hrs.), , 31, , 32, , -do-, , -do-, , 74, , Enlarge hole and increase internal, dia. (2 hrs.), , 75, , File cylindrical surfaces.(5 hrs.), , 76, , Make open fitting of curved, profiles.(18 hrs.), , 77 Correction of drill location by binding, previously drilled hole.(5 hrs.), 78 Make inside square fit. (20 hrs.), , 33, , Make different fit of, components, for, assembling as per, required tolerance, observing principle, of interchangeability, and check for, f u n c t i o n a l i t y., [Different Fit –, Sliding, Angular, Step, fit, ‘T’ fit, Square fit, and Profile fit;, Required tolerance:, ±0.04 mm, angular, tolerance: 30 min.], , 34, , -do-, , 79, , -do-, , Grinding wheel: Abrasive, grade, structures, bond, specification, use,, mounting and dressing. Selection of, grinding wheels. Bench grinder parts, and use. Radius/fillet gauge, feeler, gauge, hole gauge, and their uses, care, and maintenance., , Pig Iron: types of pig Iron, properties, and uses. Cast Iron: types, properties, and uses., , Make sliding „T. fit.(2 hrs.), , Interchangeability: Necessity in Engg,, field definition, BIS. Definition, types of, limit, terminology of limits and fits-basic, size, actual size, deviation, high and low, limit, zero line, tolerance zone Different, standard systems of fits and limits., British standard system, BIS system, , 80 File fit- combined, open angular, and sliding sides. (10 hrs.), , Method of expressing tolerance as per, BIS Fits: Definition, types, description, of each with sketch. Vernier height, gauge: material construction, parts,, graduations (English & Metric) uses,, care and maintenance., , 81 File internal angles 30minutes, accuracy open, angular fit.(15 hrs.), , 35-36, , Drill troubles: causes and remedy., Equality of lips, correct clearance, dead, centre, length of lips. Drill kinds:, Fraction, metric, letters and numbers,, grinding of drill., , 82 Make sliding fit with angles other, than 90°.(25 hrs.), , Wrought iron- : properties and uses., Steel: plain carbon steels, types,, properties and uses. Non-ferrous metals, (copper, aluminum, tin, lead, zinc), properties and uses., , (xi), , Copyright Free Under CC BY Licence

Page 12 :

37, , -do-, , 83 Scrap on flat surfaces, curved surfaces, and parallel surfaces and test. (5 hrs.), 84 Make & assemble, sliding flats, plain, surfaces. (15 hrs.), , Simple scraper- circular, flat, half, round, triangular and hook scraper, and their uses. Blue matching of, scraped surfaces (flat and curved, bearing surfaces), , 85 Check for blue math of bearing surfaces, - both flat and curved surfaces by with, worth method.(5hrs.), , 38, , -do-, , 86 File and fit combined radius and, angular surface (accuracy ± 0.5 mm),, angular and radius fit. (18 hrs.), 87 Locate accurate holes & make accurate, hole for stud fit.(2 hrs.), 88 Fasten mechanical components / subassemblies together using screws,, bolts and collars using hand tools., (5 hrs.), , 39, , -do-, , 40, , Produce components, involving different, operations on lathe, observing standard, procedure and check for, accuracy. [Different, Operations – facing,, plain turning, step, turning,, parting,, chamfering, shoulder, turn, grooving, knurling,, boring, taper, turning, threading, (external ‘V’ only)], , 41, , -do-, , Vernier micrometer, material, parts,, graduation, use, care and intenance., Calibration, of, measuring, instruments. Introduction to, mechanical fasteners and its uses., Screw, thread, micrometer:, Construction, graduation and use., , 89 Make sliding fits assembly with, parallel and angular mating surface., (± 0.04 mm) (25 hrs.), , Dial test indicator, construction,, parts, material, graduation, Method, of use, care and maintenance., Digital dial indicator. Comparatorsmeasurement of quality in the, cylinder bores., , 90 Lathe operations-, , Safely precautions to be observed, while working on a lathe, Lathe, specifications, and constructional, features. Lathe main parts, descriptions- bed, head stock,, carriage, tail stock, feeding and, thread cutting mechanisms. Holding, of job between centers, works with, catch plate, dog, simple description, of a facing and roughing tool and their, applications., , 91 True job on four jaw chuck using knife, tool.(5 hrs.), 92 Face both the ends for holding between, centers. (9 hrs.), 93 Using roughing tool parallel turn ±, 0.1 mm. (10 hrs.), 94 Measure the diameter using outside, caliper and steel rule.(1hrs.), , 95 Holding job in three jaw chuck.(2 hrs.), 96 Perform the facing, plain turn, step turn,, parting, deburr, chamfercorner, round, the ends, and use form tools. (11 hrs.), , Lathe cutting tools- Nomenclature, ofsingle point & multipoint cutting, tools, Tool selection based on, different requirements and necessity, of correct grinding, solid and tipped,, throw away, , (xii), , Copyright Free Under CC BY Licence

Page 13 :

97 Shoulder turn: square, filleted,, beveled undercut shoulder, turningfilleted under cut, square beveled., (11 hrs.), , type tools, cutting speed and feed and, comparison for H.S.S., carbide tools., Use of coolants and lubricants., , 98 Sharpening of -Single point Tools., (1 hrs.), , 42, , -do-, , 99 Cut grooves- square, round,V., groove. (10 hrs.), 100 Make a mandrel-turn diameter to, sizes. (5 hrs.), 101 Knurl the job.(1 hrs.), 102 Bore holes –spot face, pilot drill,, enlarge hole using boring tools., (9 hrs.), , 43, , -do-, , 103 Make a bush step bore-cut recess,, turn hole diameter to sizes.(5 hrs.), 104 Turn taper (internal and external)., (10 hrs.), 105 Turn taper pins. (5 hrs.), 106 Turn standard tapers to suit with, gauge.(5 hrs.), , 44, , -do-, , 107 Practice threading using taps, dies, on lathe by hand. (2 hrs.), 108 Make external „V. thread.(8 hrs.), 109 Prepare a nut and match with the, bolt.(15 hrs.), , 45-46, , Plan & perform, simple, repair,, overhauling of, different machines, and check for, f u n c t i o n a l i t y., [Different Machines, – Drill Machine,, Power Saw, Bench, Grinder and Lathe], , 110 Simple repair work: Simple assembly, of machine parts from blue prints., (15 hrs.), 111 Rectify possible assembly faults during, assembly.(19 hrs.), 112 Perform the routine maintenance with, check list (10 hrs.), 113 Monitor machine as per routine, checklist (3 hrs.), 114 Read pressure gauge, temperature, gauge, oil level (1 hrs.), 115 Set pressure in pneumatic system, (2 hrs.), , Chucks and chucking the independent, four-jaw chuck. Reversible features of, jaws, the back plate, Method of clearing, the thread of the chuck-mounting and, dismounting, chucks, chucking true,, face plate, drilling - method of holding, drills in the tail stock, Boring tools and, enlargement of holes., , General turning operations- parallel or, straight, turning. Stepped turning,, grooving, and shape of tools for the, above operations. Appropriate method of, holding the tool on tool post or tool rest,, Knurling: - tools description, grade,, uses, speed and feed, coolant for, knurling, speed, feed calculation., Taper – definition, use and method of, expressing tapers. Standard taperstaper, calculations morse taper., Screw thread definition – uses and, application. Square, worm, buttress,, acme ( non standard-screw threads),, Principle of cutting screw thread in, centre lathe –principle of chasing the, screw thread – use of centre, gauge,setting tool for cutting internal and, external threads, use of screw pitch, gauge for checking the screw thread., , Maintenance, -Total productive maintenance Autonomous maintenance -Routine, maintenance -Maintenance schedule, -Retrieval of data from machine, manuals Preventive maintenanceobjective and function of Preventive, maintenance, section inspection., Visual and detailed, lubrication survey,, system of symbol and colour coding., Revision, simple estimation of, materials, use of handbooks and, reference table. Possible causes for, assembly failures and remedies., , (xiii), , Copyright Free Under CC BY Licence

Page 14 :

47, , 48-49, , -do-, , 116 Assemble simple fitting using, dowel pins and tap screw, assembly using torque wrench., (25 hrs.), , In-plant training / Project work, 1, 2, 3, 4, , 50-51, 52, , Assembling techniques such as, aligning, bending, fixing, mechanical, jointing, threaded jointing, sealing, and, torquing.Dowel pins: material,, construction, types, accuracy and uses., , Pipe Fixture, Adjustable Clamp, Hermaphrodite/ Inside Caliper, Chuck Key, , Revision, Examination, , (xiv), , Copyright Free Under CC BY Licence

Page 15 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise 2.1.61, , Drills, Objectives: At the end of this lesson you shall be able to, • state drilling, • state the necessity of drilling, • name the types of drills used, • identify the parts of a twist drill., Drilling: Drilling is the production of cylindrical holes of, definite diameters in workpieces by using a multi-point, cutting tool called a ‘drill’. It is the first operation done, internally for any further operation., , The flutes provide a correct cutting angle which provides, an escape path for the chips. It carries the coolant to the, cutting edge during drilling. (Fig 3), , Types of drills and their specific uses, Flat drill (Fig 1) : The earliest form of drill was the flat drill, which is easy to operate,besides being inexpensive to, produce. But it is difficult to hold during operation,and the, chip removal is poor. Its operating efficiency is very low., , Twist drill : Almost all drilling operation is done using a, twist drill. It is called a twist drill as it has two or more, spiral or helical flutes formed along its length. The two, basic types of twist drills are, parallel shank and taper, shank. Parallel shank twist drills are available below 13mm, size (Fig 2)., , The portions left between the flutes are called ‘lands’. The, size of a drill is detemined and governed by the diameter, over the lands., The point angle is the cutting angle, and for general purpose, work, it is 118°. The clearance serves the purpose of, clearing the back of the lip from fouling with the work. It is, mostly 8°., Deep hole drills, Deep hole drilling is done by using a type of drill known as, ‘D’ bit (Fig 4), Parts of a twist drill : Drills are made out of high speed, steel. The spiral flutes are machined at an angle of 27 1/, 2° to its axis., , Drills are made of high speed steel., , 1, , Copyright Free Under CC BY Licence

Page 16 :

FIN216114, , A slow helix drill is used on materials like brass, gun metal,, phosphor-bronze and plastics. (Fig 5b), A quick helix drill is used for copper, aluminium and other, soft metals (Fig 5c), , FIN216115, , Drills are manufactured with varying helix angles for drilling, different materials. General purpose drills have a standard, helix angle of 27 1/2°. They are used on mild steel and, cast iron. (Fig 5a), A quick helix drill should never be used on brass, as it will ‘dig in’ and the workpiece may be, thrown from the machine table., , Drill (Parts and functions), Objectives: At the end of this lesson you shall be able to, • state the functions of drills, • identify the parts of a drill, • state the functions of each part of a drill., Drilling is a process of making holes on workpieces.The, tool used is a drill. For drilling, the drill is rotated with a, downward pressure causing the tool to penetrate into the, material. (Fig 1), , Parts of a Drill (Fig 2), The various parts of a drill can be identified from figure 2., Point, The cone shaped end which does the cutting is called the, point. It consists of a dead centre, lips or cutting edges,, and a heel., Shank, , Body, , This is the driving end of the drill which is fitted on to the, machine. Shanks are of two types., , The portion between the point and the shank is called the, body of a drill., , Taper shank, used for larger diameter drills, and straight, shank, used for smaller diameter drills. (Fig 3), , Flutes (Fig 3), , Tang, This is a part of the taper shank drill which fits into the slot, of the drilling machine spindle., 2, , The parts of the body are flute, land/margin, body clearance, and web., , Flutes are the spiral grooves which run to the length of the, drill. The flutes help, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.61, , Copyright Free Under CC BY Licence

Page 17 :

-, , To form the cutting edges, , -, , To curl the chips and allow these to come out, , -, , The coolant to flow to the cutting edge., , Land/Margin (Fig 3), , The diameter of the drill is measured across the land/, margin., Body clearance (Fig 3), Body clearance is the part of the body which is reduced in, diameter to cut down the friction between the drill and the, hole being drilled., Web (Fig 4), , Web is the metal column which separates the flutes. It, gradually increases in thickness towards the shank., , The land/margin is the narrow strip which extends to the, entire length of the flutes., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.61, , Copyright Free Under CC BY Licence, , 3

Page 18 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise: 2.1.62, , Drill angles, Objectives: At the end of this lesson you shall be able to, • identify the various angles of a twist drill, • state the functions of each angle, • list the types of helix for drills as per ISI, • distinguish the features of different types of drills, • designate drills as per ISI recommendations., Like all cutting tools the drills are provided with certain, angles for efficiency in drilling., , Twist drills are made with different helix angles. The helix, angle determines the rake angle at the cutting edge of the, twist drill., , Drill angles, They are different angles for different purposes. They are, listed below., Point angle, helix angle, rake angle, clearance angle and, chisel edge angle., Point angle/ cutting angle (Fig 1), , The helix angles vary according to the material being drilled., According to indian standards, three types of drills are, used for drilling various materials., •, , Type N - For normal low carbon steel., , •, , Type H - For hard and tenaceous materials., , •, , Types S - For soft and tough materials., , The type of drill used for general purpose drilling work is, type N., Rake angle (Fig 5), , The point angle of a general purpose (standard) drill is, 118°. This is the angle between the cutting edges (lips)., The angle varies according to the hardness of the material, to be drilled. (Fig 1), Helix angle (Figs 2,3 and 4), Rake angle is the angle of flute (helix angle)., Clearance angle (Fig 6), , 4, , Copyright Free Under CC BY Licence

Page 19 :

The clearance angle is meant to prevent the friction of the, tool behind the cutting edge. This will help in the penetration, of the cutting edges into the material. If the clearance, angle is too much, the cutting edges will be weak, and if it, is too small, the drill will not cut., , Designation of drills, , •, , Diameter, , Chisel edge angle/web angle (Fig 7), , •, , Tool type, , •, , Material, , Twist drills are designated by the, , Example, A twist drill of 9.50 mm dia. of tool type ‘H’ for right hand, cutting and made from HSS is designated as:, Twist drill 9.50 - H - IS5101 - HS, where H = tool type, IS5101 = IS Number, This is the angle between the chisel edge and the cutting, lip., , HS = tool material, 9.5 = diameter of the drill., If the tool type is not indicated in the designation, it should, be taken as type ‘N’ tool., , DRILLS FOR DIFFERENT MATERIALS, Recommended drills, Material to be, drilled, , Point, angle, , Helix angle, d=3.2-5 5-10, , 10-, , Material to be, drilled, , Steel and cast steel, up to 70 kgf/mm2, strength, Gray cast iron, Malleable cast iron, Brass, German silver, nickel., , Copper (up to 30 mm, drill diameter), Al-alloys,forming, curly chips, Celluloid, , Brass, CuZn 40, , Austenitic steels, Magnesium alloys, , Steel and cast steel, 70...120 Kgf/mm2, , Stainless steel;, Copper (drill diameter, more than 30 mm), Al-alloy, forming, short broken chips, , Point, angle, , Helix angle, d=3.5-5, , 5-, , Moulded plastics, (with thickness s>d), , Moulded plastics,, with thickness s<d, Laminated plastics,, hard rubber (ebonite), marble, slate, coal, , Zinc alloys, Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.62, , Copyright Free Under CC BY Licence, , 5

Page 20 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise 2.1.63 - 65, , Drilling - Cutting speed, feed and r.p.m , drill holding devices, Objectives: At the end of this lesson you shall be able to, • define cutting speed, • state the factors for determining the cutting speed, • differentiate between cutting speed and rpm, • determine r.p.m/spindle speed, • select r.p.m for drill sizes from the tables., For a drill to give a satisfactory performance, it must, operate at the correct cutting speed and feed., , Cutting speed calculation, , Cutting speed is the speed at which the cutting edge, passes over the material while cutting, and is expressed, in metres per minute., , Cutting speed (V), , Cutting speed is also sometimes stated as surface speed, or peripheral speed., The selection of the recommended cutting speed for drilling, depends on the materials to be drilled,and the tool, material., Tool manufacturers usually provide a table of cutting, speeds required for different materials., The recommended cutting speeds for different materials, are given in the Table 1. Based on the cutting speed, recommended, the r.p.m, at which a drill has to be driven, is determined., TABLE 1, , n-, , r.p.m., , v-, , Cutting speed in m/min., , d-, , diameter of the drill in mm., , π=, , 3.14, , Examples, Calculate the r.p.m for a high speed steel drill ∅ 24 to cut, mild steel., The cutting speed for mild steel is taken as 30 m/min from, the table., , Recommendad cutting speeds, Materials being drilled (HSS Tool), Aluminium, , 70 - 100, , Brass, , 35 - 50, , Bronze(phosphor), , 20 - 35, , Cast iron (grey), , 25 - 40, , Copper, , 35 - 45, , Steel (medium carbon/mild steel), , 20 - 30, , Steel (alloy, high tensile), , 5-8, , Thermosetting plastic (low speed, due to abrasive properties), , 20 - 30, , It is always preferable to set the spindle speed to the, nearest available lower range., The r.p.m. will differ according to the diameter of the drills., The cutting speed being the same, larger diameter drills, will have lesser r.p.m and smaller diameter drills will have, higher r.p.m., The recommended cutting speeds are achieved only by, actual experiment., , Feed in drilling, Objectives: At the end of this lesson you shall be able to, • state what is meant by feed, • state the factors that contribute to an efficient feed rate., Feed is the distance (X) a drill advances into the work in, one complete rotation. (Fig 1), , Feed is expressed in hundredths of a millimeter., , 6, , Copyright Free Under CC BY Licence

Page 21 :

The table gives the feed rate which is based on the average, feed values suggested by the different manufacturers of, drills. (Table 1), TABLE 1, Drill diameter, (mm) H.S.S, , Rate of feed, (mm/rev), , 1.0 - 2.5, , 0.040 - 0.060, , 2.6 - 4.5, , 0.050 - 0.100, , 4.6 - 6.0, , 0. 075 - 0.150, , 6.1 - 9.0, , 0.100 - 0.200, , Example - 0.040mm/ rev, , 9.1 - 12.0, , 0.150 - 0.250, , The rate of feed is dependant up on a number of factors., , 12.1 - 15.0, , 0.200 - 0.300, , 15.1 - 18.0, , 0.230 - 0.330, , 18.1 - 21.0, , 0.260 - 0.360, , 21.1 - 25.0, , 0.280 - 0.380, , •, , The finish required, , •, , Type of drill (drill material), , •, , Material to be drilled, , Factors like rigidity of the machine, holding of the workpiece and the drill, will also have to be considered while, determining the feed rate. If these are not to the required, standard, the feed rate will have to be decreased., It is not possible to suggest a particular feed rate taking, all the factors into account., , Too coarse a feed may result in damage to the cutting, edges or breakage of the drill., Too slow a rate of feed will not bring improvement in surface, finish but may cause excessive wear of the tool point, and, lead to chattering of the drill., For optimum results in the feed rate while, drilling, it is necessary to ensure the drill cutting, edges are sharp. Use the correct type of cutting, fluid., , Drill-holding devices, Objectives: At the end of this lesson you shall be able to, • name the different types of drill-holding devices, • state the features of drill chucks, • state the functions of drill sleeves, • state the function of drift., For drilling holes on materials, the drills are to be held, accurately and rigidly on the machines., The common drill-holding devices are drill chucks, sleeves, and sockets., Drill chucks: Straight shank drills are held in drill chucks., (Fig 1A) For fixing and removing drills, the chucks are, provided either with a pinion and key or a knurled ring., The drill chucks are held on the machine spindle by means, of an arbor (Fig 1B) fitted on the drill chuck., Taper sleeves and sockets (Fig 2): Taper shank drills, have a Morse taper., Sleeves and sockets are made with the same taper so that, the taper shank of the drill, when engaged, will give a good, wedging action. Due to this reason Morse tapers are called, self-holding tapers., Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.63 - 65, , Copyright Free Under CC BY Licence, , 7

Page 22 :

In order to make up the difference in sizes between the, shanks of the drills and the bore of machine spindles,, sleeves of different sizes are used. When the drill taper, shank is bigger than the machine spindle, taper sockets, are used. (Fig 2), While fixing the drill in a socket or sleeve, the tang portion, should align in the slot. This will facilitate the removal of the, drill or sleeve from the machine spindle., Use a drift to remove drills and sockets from the machine, spindle. (Fig 3), , While removing the drill from the sockets/sleeves don’t, allow it to fall on the table or jobs., The drills are provided with five different sizes of Morse, tapers, and are numbered from MT 1 to MT 5., , Drill chucks are made from special alloy steel, Drill sleeves are made from case hardened, steel, , 8, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.63 - 65, , Copyright Free Under CC BY Licence

Page 23 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise 2.1.66, , Counter sinking, Objectives: At the end of this lesson you shall be able to, • state countersinking, • list the purposes of countersinking, • state the angles of countersinking for the different applications, • name the different types of countersinks, • distinguish between Type A and Type B counter sink holes., What is countersinking?, Countersinking is an operation of bevelling the end of a, drilled hole. The tool used is called a countersink., , The commonly used countersinks have multiple cutting, edges and are available in taper shank and straight shank., (Fig 2), , Countersinking is carried out for the following purposes:, •, , To provide a recess for the head of a countersink screw,, so that it is flush with the surface after fixing (Fig 1), , •, , To deburr a hole after drilling, , •, , For accommodating countersink rivet heads, , •, , To chamfer the ends of holes for thread cutting and other, machining processes., , For countersinking small diameter holes special, countersinks with two or one flute are available. This will, reduce the vibration while cutting., Countersinks with Pilot (Fig 3), , Angles for countersinking, Countersinks are available in different angles for different, uses., 75°, , countersink riveting, , 80°, , countersink self tapping screws, , 90°, , countersink head screws and deburring, , 120° chamfering ends of holes to be threaded or other, machining processes., , For precision countersinking, needed for machine tool, assembling and after machining process, countersinks, with pilots are used., They are particularly useful for heavy duty work., The pilot is provided at the end for guiding the countersink, concentric to the hole., Countersinks with pilots are available with interchangeable, and solid pilots., , Countersinks, , Countersink hole sizes, , Countersinks of different types are available., , The countersink holes according to Indian Standard IS, 3406 (Part 1) 1986 are of four types: Type A, Type B, Type, C and Type E., 9, , Copyright Free Under CC BY Licence

Page 24 :

Type A is suitable for slotted countersink head screws,, cross recessed and slotted raised countersink head screws., These screws are available in two grades i.e. medium and, fine., The dimensions of various features of the Type 'A', countersink holes, and the method of designation are given, in Table 1., Type 'B' countersink holes are suitable for countersink, head screws with hexagon socket., The dimensions of the various features and the method of, designation are given in Table II., Type 'C' countersink holes are suitable for slotted raised, countersink (oval) head tapping screws and for slotted, countersink (flat) head tapping screws., The dimension of the various features and the method of, designation are given in Table III., Type 'E' countersinks are used for slotted countersink, bolts used for steel structures., The dimensions of the various features and the method of, designation are given in Table IV., , TABLE I, Dimensions and designation of countersink - Type A according to IS 3406 (Part 1) 1986, , 10, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence

Page 25 :

TABLE I, For Nominal Size, , 1, , 1.2, , (1.4), , 1.6, , (1.8), , 2, , 2.5, , 3, , 3.5, , 4, , (4.5), , Medium, , d1 H13, , 1.2, , 1.4, , 1.6, , 1.8, , 2.1, , 2.4, , 2.9, , 3.4, , 3.9, , 4.5, , 5, , Series, , d2 H13, , 2.4, , 2.8, , 3.3, , 3.7, , 4.1, , 4.6, , 5.7, , 6.5, , 7.6, , 8.6, , 9.5, , t1 ³, , 0.6, , 0.7, , 0.8, , 0.9, , 1, , 1.1, , 1.4, , 1.6, , 1.9, , 2.1, , 2.3, , Fine, , d1 H12, , 1.1, , 1.3, , 1.5, , 1.7, , 2, , 2.2, , 2.7, , 3.2, , 3.7, , 4.3, , 4.8, , Series, , d3 H12, , 2, , 2.5, , 2.8, , 3.3, , 3.8, , 4.3, , 5, , 6, , 7, , 8, , 9, , t1 ³, , 0.7, , 0.8, , 0.9, , 1, , 1.2, , 1.2, , 1.5, , 1.7, , 2, , 2.2, , 2.4, , t2 + 0.1, 0, , 0.2, , 0.15 0.15 0.2, , 0.2, , 0.15 0.35 0.25 0.3, , 0.3, , 0.3, , (m), , (f), , For Nominal Size, , 5, , 6, , 8, , 10, , 12, , (14), , 16, , (18), , 20, , Medium, , d1 H13, , 5.5, , 6.6, , 9, , 11, , 13.5, , 15.5, , 17.5, , 20, , 22, , Series, , d2 H13, , 10.4, , 12.4, , 16.4, , 20.4, , 23.9, , 26.9, , 31.9, , 36.4, , 40.4, , (m), , t1 ³, , 2.5, , 2.9, , 3.7, , 4.7, , 5.2, , 5.7, , 7.2, , 8.2, , 9.2, , Fine, , d1 H12, , 5.3, , 6.4, , 8.4, , 10.5, , 13, , 15, , 17, , 19, , 21, , Series, , d3 H12, , 10, , 11.5, , 15, , 19, , 26, , 30, , 34, , 37, , t1 ³, , 2.6, , 3, , 4, , 5, , 5.7, , 6.2, , 7.7, , 8.7, , 9.7, , t2 + 0.1, 0, , 0.2, , 0.45, , 0.7, , 0.7, , 0.7, , 0.7, , 1.2, , 1.2, , 1.7, , (f), , 23, , Note 1 : Size shown in brackets are of second preference., Note 2 : Clearance hole d1 according to medium and fine series of IS : 1821 ' Dimensions for, clearance holes for bolts and screws (second revision)', Designation : A countersink Type A with clearance hole of fine (f) series and having nominal size 10 shall be designated, as – Countersink A f 10 - IS : 3406., TABLE II, Dimensions and designation of countersink - Type B according to IS 3406 (Part 1) 1986, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence, , 11

Page 26 :

For Nominal Size, , 3, , 4, , 5, , 6, , 8, , 10, , 6.4, , 8.4, , 12, , (14), , 16, , (18), , 20, , 22 24, , Fine, , d1 H12, , 3.2, , 4.3, , 5.3, , 10.5 13, , 15, , 17, , 19, , 21, , 23 25, , Series, , d2 H12, , 6.3, , 8.3, , 10.4 12.4 16.5 20.5 25, , 28, , 31, , 34, , 37, , 48.2 52, , (f), , t1 ³, , 1.7, , 2.4, , 2.9, , 7, , 7.5, , 8, , 8.5, , 13.1 14, , t2 + 0.1, , 0.2, , 3.3, , 0.3, , 4.4, , 5.5, , 6.5, , 0.4, , 0.5, , 1, , Note 1: Sizes shown in brackets are of second preference., Note 2: Clearance hole d1 according to medium and fine series of IS : 1821- 1982., Designation : A countersink Type B with clearance hole of fine (f) series and having nominal size 10 shall be designated, as – Countersink B f 10 - IS : 3406., TABLE III, Dimensions and designation of countersink - Type C according to IS 3406 (Part 1) 1986, , For Screw Size No. (0), , (1), , 2, , (3), , 4, , (5), , 6, , (7), , 8, , 10, , (12), , 14, , (16), , d1 H12, , 1.6, , 2, , 2.4, , 2.8, , 3.1, , 3.5, , 3.7, , 4.2, , 4.5, , 5.1, , 5.8, , 6.7, , 8.4, , d2 H12, , 3.1, , 3.8, , 4.6, , 5.2, , 5.9, , 6.6, , 7.2, , 8.1, , 8.7, , 10.1, , 11.4, , 13.2, , 16.6, , t1 ³, , 0.9, , 1.1, , 1.3, , 1.5, , 1.7, , 1.9, , 2.1, , 2.3, , 2.6, , 3, , 3.4, , 3.9, , 4.9, , Note : Sizes given in brackets are of second preference., Designation : A countersink Type C for screw size 2 shall be designated as – Countersink C 2 - IS : 3406., TABLE IV, , 12, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence

Page 27 :

Dimension and designation of countersink - Type E according to IS 3406 (Part 1) 1986, For Nominal No., , 10, , 12, , 16, , 20, , 22, , 24, , d1 H12, , 10.5, , 13, , 17, , 21, , 23, , 25, , d2 H12, , 19, , 24, , 31, , 34, , 37, , 40, , 5.5, , 7, , 9, , 11.5, , 12, , 13, , t1 ³, α ± 1°, , 75°, , 60°, , Note: Clearance hole d1 according to fine series of IS : 1821 - 1982, Designation : A countersink Type E for nominal size 10 shall be designated as – Countersink E 10 - IS : 3406., Methods of representing countersink holes in drawings, Countersink hole sizes are identified by code designation, or using dimension., , Use of code designation, , Use of dimension, The dimension of the countersink can be expressed by the, diameter of the countersink and the depth of the, countersink., , Counterboring and spot facing, Objectives: At the end of this lesson you shall be able to, • differentiate counterboring and spot facing, • state the types of counterbores and their uses, • determine the correct counterbore sizes for different holes., Counterboring, , Counterbore (Tool), , Counterboring is an operation of enlarging a hole to a given, depth, to house heads of socket heads or cap screws with, the help of a counterbore tool. (Fig 1), , The tool used for counterboring is called a counterbore., (Fig 2) Counterbores will have two or more cutting edges., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence, , 13

Page 28 :

Spot facing, Spot facing is a machining operation for producing a flat, seat for bolt head, washer or nut at the opening of a drilled, hole. The tool is called a spot facer or a spot facing tool., Spot facing is similar to counterboring, except that it is, shallower. Tools that are used for counterboring can be, used for spot facing as well. (Fig 4), , Spot facing is also done by fly cutters by end-cutting, action. The cutter blade is inserted in the slot of the holder,, which can be mounted on to the spindle. (Fig 5), , At the cutting end, a pilot is provided to guide the tool, concentric to the previously drilled hole. The pilot also, helps to avoid chattering while counterboring. (Fig 3), , Counterbore sizes and specification, Counterbore sizes are standardised for each diameter of, screws as per BIS., There are two main types of counterbores. Type H and, Type K., The type H counterbores are used for assemblies with, slotted cheese head, slotted pan head and cross recessed, pan head screws. The type K counterbores are used in, assemblies with hexagonal socket head capscrews., For fitting different types of washers the counterbore, standards are different in Type H and Type K., , Counterbores are available with solid pilots or with, interchangeable pilots. The interchangeable pilot provides, flexibility of counterboring on different diameters of holes., , 14, , The clearance hole d1 are of two different grades i.e., medium (m) and fine (f) and are finished to H13 and H12, dimensions., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence

Page 29 :

The table given below is a portion from IS 3406 (Part 2), 1986. This gives dimensions for Type H and Type K, counterbores., , Dimensions for H and K Type counter bores, While representing counterbores in drawings, counterbores, can be indicated either by code designation or using the, dimensions., , Counterbore and Clearance Hole Sizes for Different Sizes, of Screws, , Table - 1, , For, Nominal size 1, , 1.2 1.4 1.6 1.8, , 2, , 2.5, , 3 (3.5) 4, , 5, , 6, , Medium (m) 1.2 1.4 1.6 1.8 2.1 2.4 2.9 3.4 3.9 4.5 5.5 6.6, H13, d1, fine (f), H12, d2 H13, d3, , 1.1 1.3 1.5 1.7, , -, , -, , 0.8 0.9, , 1, , -, , -, , 10, , 12 (14) 16, , 18, , 20 22, , 24 27, , 30, , 33, , 36, , 9, , 11 13.5 15.5 17.5 20, , 22 24, , 26 30, , 33, , 36, , 39, , -, , 2.2 2.7 3.2 3.7 4.3 5.3 6.4 8.4 10.5 13, , 2.2 2.5 2.8 3.3 3.8 4.3, -, , Type H, , 2, , 8, , -, , 1.2 1.5 1.6, , 21 23, , 25, , 24 26, , 30, , 33 36, , 40 43, , 48, , 53, , 57, , 15.5 17.5 19.5 22, , 24 26, , 28, , 36, , 39, , 42, , 20, , -, , -, , 6, , 6.5, , 8, , 10, , -, , -, , -, , -, , -, , -, , -, , -, , 4, , 4.7, , 6, , 7, , 8, , 9 10.5 11.5 12.5 13.5 14.5 -, , 4.6 5.7 6.8, , 9, , 11, , 13, , 15 17.5 19.5 21.5 23.5 25.5 28.5 32, , 2.4 2.9 3.2, , 18, , 19, , 5, , 2, , 11 15, , 15 17, , 33, -, , -, , -, , -, , t1, Type K, , Tolerances, , -, , -, , 1.6 1.8, , -, , 2.3 2.9 3.4, , -, , +0.1, , +0.2, , +0.4, , +0.6, , 0, , 0, , 0, , 0, , 35, , 38, , Note : Sizes given in brackets are of second preference. For details refer IS : 3406 (Part2) 1986., Using code designation (Fig 7), , Using dimensions (Fig 8), , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.66, , Copyright Free Under CC BY Licence, , 15

Page 30 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise 2.1.67, , Reamers, Objectives: At the end of this lesson you shall be able to, • state the use of reamers, • state the advantages of reaming, • distinguish between hand and machine reaming, • name the elements of a reamer and state their functions., What is a reamer?, A reamer is a multipoint cutting tool used for enlarging by, finishing previously drilled holes to accurate sizes. (Fig 1), , Reaming by using hand reamers is done manually for, which great skill is needed., Machine reamers are fitted on spindles of machine tools, and rotated for reaming., Machine reamers are provided with morse taper shanks for, holding on machine spindles., Hand reamers have straight shanks with ‘square’ at the, end, for holding with tap wrenches. (Figs 2 (a) and (b), Parts of a hand reamer, The parts of a hand reamer are listed hereunder. Refer to, Fig 3., , Advantages of ‘reaming’, Reaming produces, High quality surface finish, Dimensional accuracy to close limits., Also small holes which cannot be finished by other, processes can be finished., Classification of reamers, Reamers are classified as hand reamers and machine, reamers. (Figs 2a and 2b), , Axis, The longitudinal centre line of the reamer., Body, The portion of the reamer extending from the entering end, of the reamer to the commencement of the shank., Recess, The portion of the body which is reduced in diameter below, the cutting edges, pilot or guide diameters., 16, , Copyright Free Under CC BY Licence

Page 31 :

Shank, , Cutting edge, , The portion of the reamer which is held and driven. It can, be parallel or taper., , The edge formed by the intersection of the face and the, circular land or the surface left by the provision of primary, clearance. (Fig 4), , Circular land, Face, The cylindrically ground surface adjacent to the cutting, edge on the leading edge of the land., Bevel lead, The bevel lead cutting portion at the entering end of the, reamer cutting its way into the hole. It is not provided with, a circular land., , The portion of the flute surface adjacent to the cutting edge, on which the chip impinges as it is cut from the work., (Fig 4), Rake angles, The angles in a diametral plane formed by the face and a, radial line from the cutting edge. (Fig 5), , Taper lead, The tapered cutting portion at the entering end to facilitate, cutting and finishing of the hole. It is not provided with a, circular land., Bevel lead angle, The angle formed by the cutting edges of the bevel lead and, the reamer axis., Taper lead angle, The angle formed by the cutting edges of the taper and the, reamer axis., Terms relating to cutting geometry, Flutes, , Clearance angle, , The grooves in the body of the reamer to provide cutting, edges, to permit the removal of chips, and to allow the, cutting fluid to reach the cutting edges. (Fig 4), , The angles formed by the primary or secondary clearances, and the tangent to the periphery of the reamer at the cutting, edge. They are called primary clearance angle and secondary, clearance angle respectively. (Fig 6), , Helix angle, Heel, , The angle between the edge and the reamer axis. (Fig 7), , The edge formed by the intersection of the surface left by, the provision of a secondary clearance and the flute., (Fig 4), , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.67, , Copyright Free Under CC BY Licence, , 17

Page 32 :

Hand reamers, Objectives: At the end of this lesson you shall be able to, • state the general features of hand reamers, • identify the types of hand reamers, • distinguish between the uses of straight fluted and helical fluted reamers, • name the materials from which reamers are made and specify reamers., General features of hand reamers (Fig 1), , Parallel hand reamer with parallel shank (Fig 4a), , Hand reamers are used to ream holes manually using tap, wrenches., These reamers have a long taper lead.(Fig 2) This allows to, start the reamer straight and in alignment with the hole, being reamed., , A reamer which has virtually parallel cutting edges with taper, and bevel lead. The body of the reamer is integral with a, shank. The shank has the nominal diameter of the cutting, edges. One end of the shank is square shaped for tuning it, with a tap wrench. Parallel reamers are available with, straight and helical flutes. This is the commonly used hand, reamer for reaming holes with parallel sides., Reamers commonly used in workshop produce H7 holes., Hand reamer with pilot (Fig 4b), , Most hand reamers are for right hand cutting., Helical fluted hand reamers have left hand helix. The left, hand helix will produce smooth cutting action and finish., Most reamers, machine or hand, have uneven spacing of, teeth. This feature of reamers helps to reduce chattering, while reaming. (Fig 3), Types, features and functions, , For this type of reamer, a portion of the body is cylindrically, ground to form a pilot at the entering end. The pilot keeps, the reamer concentric with the hole being reamed., , Hand reamers with different features are available for, meeting different reaming conditions. The commonly used, types are listed here under:, 18, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.67, , Copyright Free Under CC BY Licence

Page 33 :

Socket reamer with parallel shank (Figs 5a and 5b), This reamer has tapered cutting edges to suit metric morse, tapers. The shank is integral with the body, and is square, shaped for driving. The flutes are either straight or helical., The socket reamer is used for reaming internal morse, tapered holes., Taper pin hand reamer (Fig 5c), , Material of hand reamers, When the reamers are made as a one-piece, construction, high speed steel is used. When, they are made as two-piece construction, then the cutting portion is made of high, speed steel while the shank portion is made, of carbon steel. They are butt-welded, together before manufacturing., Specifications of a reamer, To specify a reamer the following data is to be given., This reamer has tapered cutting edges for reaming taper, holes to suit taper pins. A taper pin reamer is made with a, taper of 1 in 50. These reamers are available with straight, or helical flutes., , Type, Flute, , Use of straight and helical fluted reamers (Fig 6), , Shank end, , Straight fluted reamers are useful for general reaming work., Helical fluted reamers are particularly suitable for reaming, holes with keyway grooves or special lines cut into them., The helical flutes will bridge the gap and reduce binding and, chattering., , Size, Example : Hand reamer, Straight flute, Parallel shank of, Ø 20 mm., , Drill size for reaming, Objective: At the end of this lesson you shall be able to, • determine the hole size for reaming., For reaming with a hand or a machine reamer, the hole, drilled should be smaller than the reamer size., , Drill size = Reamed size – (Undersize + Oversize), Finished size, , The drilled hole should have sufficient metal for finishing, with the reamer. Excessive metal will impose a strain on, the cutting edge of the reamer and damage it., Calculating drill size for reamer, A method generally practised in workshop is by applying, the following formula., , Finished size is the diameter of the reamer., Undersize, Undersize is the recommended reduction in size for, different ranges of drill diameter. (Table 1), , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.67, , Copyright Free Under CC BY Licence, , 19

Page 34 :

Undersizes for reaming, , Note: If the reamed hole is undersize, the cause, is that the reamer is worn out., , TABLE 1, Diameter of, ready reamed, hole (mm), , Undersize of, rough bored, hole (mm), , Always inspect the condition of the reamer before, commencing reaming., For obtaining good surface finish, , under 5, , 0.1.....0.2, , 5......20, , 0.2.....0.3, , 21....50, , 0.3.....0.5, , over 50, , 0.5.....1, , Oversize, , Use a coolant while reaming. Remove metal, chips from the reamer frequently. Advance the, reamer slowly into the work., Defects in reaming - Causes and Remedies, •, , It is generally considered that a twist drill will make a hole, larger than its diameter. The oversize for calculation, purposes is taken as 0.05 mm - for all diameters of drills., , Reamed hole undersize, - If a worn out reamer is used, it may result in the, reamed hole bearing undersize. Do not use such, reamers., - Always inspect the condition of the reamer before, using., , For light metals the undersize will be chosen 50% larger., Example, •, A hole is to be reamed on mild steel with a 10 mm reamer., What will be the diameter of the drill for drilling the hole, before reaming?, Drill size = Reamed size – (Undersize + Oversize), (Finished size), , =, , 10, , mm, , Undersize as per, table, , =, , 0.2 mm, , Oversize, , =, , 0.05 mm, , Drill size, , =, , 10 mm -- 0.25 mm, , =, , 9.75 mm, , Determine the drill hole sizes for the following reamers:, i, , -, , The causes may be any one of the following or a, combinations thereof., , -, , Incorrect application, , -, , Swarf accumulated in reamer flutes, , -, , Inadequate flow of coolant, , -, , Feed rate too fast, , -, , While reaming apply a steady and slow feed-rate., , -, , Ensure a continuous supply of the coolant., , -, , Do not turn the reamer in the reverse direction., , Determining the drill size for reaming, Use the formaula,, , 15 mm, , ii 4, , Surface finish rough, , drill diameter = reamed hole size. (undersize + oversize), , mm, , iii 40 mm, , Refer to the table for the recommended undersizes in, Related Theory on DRILL SIZES FOR REAMING., , iv 19 mm, Answer, i _________________________________________, ii _________________________________________, iii _________________________________________, iv _________________________________________, , 20, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.67, , Copyright Free Under CC BY Licence

Page 35 :

Reaming, Objectives : At the end of this lesson you shall be able to, • state the procedure for hand reaming and machine reaming., Reaming, Reaming is the operation of finishing and sizing a hole, which has been previously drilled, bored, casteed holes., The tool used is called a reamer, which has multiple cutting edges. Manually it is held in a tap wrench and reamed., Machine reamer are used in drilling machine using sleeves, (or) socket. Normally the speed for reaming will be 1/3rd, speed of drilling., Hand Reaming, Drill holes for reaming as per the sizes determined., Place the work on parallels while setting on, the machine vice. (Fig 1), , Chamfer the hole ends slightly. This removes burrs and, will also help to align the reamer vertically. (Fig 2) Fix the, work in the bench vice. Use vice clamps to protect the, finished surfaces. Ensure that the job is horizontal. (Fig 2), , Fix the tap wrench on the square end and place the reamer, vertically in the hole. Check the alignment with a try square., Make corrections, If necessary. Turn the tap wrench in a, clockwise direction applying a slight downward pressure, at the same time. (Fig 3) Apply pressure evenly at both, ends of the tap wrench., , Do not turn in reverse direction it will scratch the reamed, hole. (Fig 4), , Ream the hole through, ensure that the taper lead length, of the reamer comes out well and clear from the bottom of, the work. Do not allow the end of the reamer to strike on, the vice., Remove the reamer with an upward pull until the reamer is, clear of the hole. (Fig 5), , Remove the burrs from the bottom of the reamed hole., Clean the hole. Check the accuracy with the cylindrical, pins supplied., , Apply cutting force, Turn the tap wrench steadily and slowly, maintaining the, downward pressure., Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.67, , Copyright Free Under CC BY Licence, , 21

Page 36 :

Production & Manufacturing, Fitter - Drilling, , Related Theory for Exercise 2.1.68 - 69, , Screw thread and elements, Objectives: At the end of this lesson you shall be able to, • state the terminology of screw threads, • state the types of screw threads., Screw thread terminology, Parts of screw thread (Fig 1), , Minor Diameter, , The top surface joining the two sides of a thread., , For external threads, the minor diameter is the smallest, diameter after cutting the full thread. In the case of internal, threads, it is the diameter of the hole drilled for forming the, thread which is the minor diameter., , Root, , Pitch Diameter (effective diameter), , The bottom surface joining the two sides of adjacent, threads., , The diameter of the thread at which the thread thickness is, equal to one half of the pitch., , Flank, , Pitch, , The surface joining the crest and the root., Thread angle, , It is the distance from a point on one thread to a correspond, ing point on the adjacent thread measured parallel to the, axis., , The included angle between the flanks of adjacent threads., , Lead, , Depth, , Lead is the distance of a threaded component moves along, the matching component during one complete revolution., For a single start thread the lead is equal to the pitch., , Crest, , The perpendicular distance between the roots and crest of, the thread., Major Diameter, In the case of external threads it is the diameter of the, blank on which the threads are cut and in the case of, internal threads it is the largest diameter after the threads, are cut that are known as the major diameter. (Fig 2), This is the diameter by which the sizes of screws are, stated., , Helix Angle, The angle of inclination of the thread to the imaginary, perpendicular line., Hand, The direction in which the thread is turned to advance. A, right hand thread is turned clockwise to advance, while a, left hand thread is turned anticlockwise.( Fig 3), , 22, , Copyright Free Under CC BY Licence

Page 37 :

Screw threads - types of V threads and their uses, Objectives: At the end of this lesson you shall be able to, • state the different standards of V threads, • indicate the angle and the relation between the pitch with the other elements of the thread, • state the uses of the different standards of V threads., The different standards of V threads are:, -, , BSW thread: British Standard Whitworth thread, , -, , BSF thread: British Standard fine thread, , -, , BSP thread: British Standard pipe thread, , -, , B.A thread: British Association thread, , -, , I.S.O Metric thread: International Standard Organisation, metric thread, , -, , ANS: American National or sellers’ thread, , -, , BIS Metric thread: Bureau of Indian Standard metric, thread., , BSW thread (Fig 1), , BSF thread, This thread is similar to BSW thread except the number of, TPI for a particular diameter. The number of threads per, inch is more than that for the BSW thread for a particular, diameter. For Example, 1” BSW has 8 TPI and 1 “BSF has, 10 TPI. The table indicates the standard number of TPI for, different dia. of BSF threads. It is used in automobile, industries., BSP thread, This thread is recommended for pipe and pipe fittings. The, table shows the pitch for different diameters. It is also, similar to BSW thread. The thread is cut externally with a, small taper for the threaded length. This avoids the leakage, in the assembly and provides for further adjustment when, slackness is felt., BA thread (Fig 2), , It has an included angle of 55° and the depth of the thread, is 0.6403 x P. The crest and root are rounded off to a, definite radius . The figure shows the relationship between, the pitch and the other elements of the thread., BSW thread is represented in a drawing by giving the major, diameter. For example : 1/2” BSW, 1/4” BSW. The table, indicates the standard number of TPI for different diameters., BSW thread is used for general purpose fastening threads., , This thread has an included angle of 47 1/2°. Depth and, other elements are as shown in the figure. It is used in small, screws of electrical appliances, watch screws, screws of, scientific apparatus., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence, , 23

Page 38 :

Unified thread (Fig 3), , For the fine series, the letter ‘M’ is followed by the major, diameter and pitch., , For both the metric and inch series, ISO has developed this, thread. Its angle is 60°. The crest and root are flat and the, other dimensions are as shown in the figure. This thread is, used for general fastening purposes., , Ex : M14 x 1.5, M24 x 2, American National Thread (Fig 4), These threads are also called as seller’s threads. It was, more commonly used prior to the introduction of the ISO, unified thread., , This thread of metric standard is represented in a drawing, by the letter ‘M’ followed by the major diameter for the, coarse series., Ex : M14, M12 etc., , Screw pitch gauge, Objectives: At the end of this lesson you shall be able to, • state the purpose of a screw pitch gauge, • state the features of a screw pitch gauge., Purpose, A screw pitch gauge is used to determine the pitch of a, thread., , The thread profile on each blade is cut for about 25 mm to, 30 mm. The pitch of the blade is stamped on each blade., The standard and range of the pitches are marked on the, case. (Fig 1), , It is also used to compare the profile of threads., Constructional features, Pitch gauges are available with a number of blades, assembled as a set. Each blade is meant for checking a, particular standard thread pitch. The blades are made of, thin spring steel sheets, and are hardened., Some screw pitch gauge sets will have blades provided for, checking British Standard threads (BSW, BSF etc.) at one, end and the metric standard at the other end., , Taps, Objectives: At the end of this lesson you shall be able to, • state the uses of hand taps, • state the features of hand taps, • distinguish between the different taps in a set., Use of hand taps: Hand taps are used for internal, threading of components., 24, , Features (Fig 1): They are made from high speed steel., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence

Page 39 :

The threads are cut on the periphery and are accurately, finished., To form the cutting edges, flutes are cut across the thread., The end of the shank of the tap is made of square shape for, the purpose of holding and turning the taps., The end of the taps are chamfered (taper lead) for assisting,, aligning and starting of the thread., The size of the taps, the thread standard, the pitch of the, thread, the dia. of the tapping hole are usually marked on, the shank., Marking on the shank are also made to indicate the type, of tap i.e. first, second and plug., Types of taps in a set : Hand taps for a particular thread, are available as a set consisting of three pieces. (Fig 2), , The taper tap is to start the thread. It is possible to form full, threads by the taper tap in through holes which are not, deep., The bottoming tap (plug) is used to finish the threads of a, blind hole to the correct depth., , These are:, – First tap or taper tap, – Second tap or intermediate tap, , For identifying the type of taps quickly - the taps are either, numbered 1,2 and 3 or rings are marked on the shank., , – Plug or bottoming tap., These taps are identical in all features except in the, tap lead., , The taper tap has one ring, the intermediate tap has two, and the bottoming tap has three rings. (Fig 2), , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence, , 25

Page 40 :

Table for tap drill size, B.S.F. (55°), , B.S.W. (55°), Tap size, (inch), , Threads per, inch, , Tap drill, size (mm), , Tap size, (inch), , Threads per, inch, , Tap drill, size (mm), , 3/16, , 24, , 3.7mm, , 3/16, , 32, , 3.97mm, , 7/32, , 24, , 4.5mm, , 7/32, , 28, , 4.6mm, , 1/4, , 20, , 5.1mm, , 1/4, , 26, , 5.3mm, , 5/16, , 18, , 6.5mm, , 5/16, , 22, , 6.75mm, , 3/8, , 16, , 7.94mm, , 3/8, , 20, , 8.2mm, , 7/16, , 14, , 9.3mm, , 7/16, , 18, , 9.7mm, , 1/2, , 12, , 10.5mm, , 1/2, , 16, , 11.11mm, , 9/16, , 12, , 12.1mm, , 9/16, , 16, , 12.7mm, , 5/8, , 11, , 13.5mm, , 5/8, , 14, , 14mm, , 11/16, , 11, , 15mm, , 11/16, , 14, , 15.5mm, , 3/4, , 10, , 16.257mm, , 3/4, , 12, , 16.75mm, , 7/8, , 9, , 19.25mm, , 7/8, , 11, , 19.84mm, , 1”, , 8, , 22mm, , 1”, , 10, , 22.75mm, , NPT National pipe thread, Tap size, (inch), , 26, , Threads per, inch, , Tap drill, size inch, , Tap size, (inch), , Threads per, inch, , Tap drill size, inch, , 1/8, , 27, , 11/32, , 1, , 11 1/2, , 1 5/32, , 1/4, , 18, , 7/16, , 1 1/4, , 11 1/4, , 1 1/2, , 3/8, , 18, , 19/32, , 1 1/2, , 11 1/2, , 1 23/32, , 1/2, , 14, , 23/32, , 2, , 11 1/2, , 2 23/16, , 3/4, , 14, , 15/16, , 2 1/2, , 8, , 2 5/8, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence

Page 41 :

Tap drill sizes ISO Inch (Unified) thread, NC National coarse, Tap size, (inch), , Threads per, inch, , NF National Fine, Tap drill, size inch, , Tap size, (inch), , Threads per, inch, , Tap drill size, inch, , 1/4, , 20, , 13/64, , 1/4, , 28, , 7/32, , 5/16, , 18, , 17/64, , 5/16, , 24, , 17/64, , 3/8, , 16, , 5/16, , 3/8, , 24, , 21/64, , 7/16, , 14, , 3/8, , 7/16, , 20, , 25/64, , 1/2, , 13, , 27/64, , 1/2, , 20, , 29/64, , 9/16, , 12, , 31/64, , 9/16, , 18, , 33/64, , 5/8, , 11, , 17/32, , 5/8, , 18, , 37/64, , 3/4, , 10, , 21/32, , 3/4, , 16, , 11/16, , 7/8, , 9, , 49/64, , 7/8, , 14, , 13/16, , 1”, , 8, , 7/8, , 1”, , 14, , 15/16, , 1 1/8, , 7, , 63/64, , 1 1/8, , 12, , 1 3/6, , 1 1/4, , 7, , 17/64, , 1 1/4, , 12, , 1 11/6, , 1 3/8, , 6, , 17/32, , 1 3/8, , 12, , 1 19/64, , 1 1/2, , 6, , 1 11/32, , 1 1/2, , 12, , 1 27/64, , 1 3/4, , 5, , 1 9/16, , 2”, , 4 1/2, , 1 25/32, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence, , 27

Page 42 :

Machine taps, Objectives: At the end of this lesson you shall be able to, • state the characteristics of machine taps, • name the different types of machine taps, • state the features and uses of different types of machine taps., Machine taps: Machine taps of different types are available., The two important features of machine taps are, – Ability to withstand the torque needed for threading, holes, – Provision for eliminating chip jamming., Types of machine taps, , Flute-less taps are used for tapping through holes on, materials which are not thicker than the diameter of the, holes. Flutless spiral point taps are best suited for tapping, soft materials or thin metal sections., Helical fluted taps/spiral fluted taps: These taps have, spiral flutes which bring out the chips from the hole being, tapped. (Fig 4), , Gun tap (Spiral pointed tap) (Fig 1), , These taps are especially useful for machine tapping of, through holes. In the case of blind hole tapping, there, should be sufficient space below to accommodate the, chips. While tapping, the chips are forced out ahead of the, tap. (Fig 2), , These are useful for tapping holes with slots. The helical, land of the tap will bridge the interruption of the surface, being threaded. The helical flutes of the tap provide a shear, cutting action, and are mostly used to tap holes in ductile, materials like aluminium, brass, copper etc., Spiral fluted taps are also available with fast spiral. (Fig 5), These taps are best suited for tapping deep holes as these, can clear the chips faster from the hole. (Fig 6), , This prevents the clogging of the chips and thus reduces, the chances of tap breakage. These taps are stronger, since the flutes are shallow. The flutes of these taps do not, convey chips., Flute-less spiral pointed tap (Stub flute taps) (Fig 3):, Thread forming taps (Fluteless taps), These taps form threads in the hole by displacing the, material and not by cutting action. (Fig 7), These taps have short angular flutes ground on the chamfered, end, and the rest of the body is left solid. These taps are, stronger than gun taps., , 28, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence

Page 43 :

These taps have projecting lobes which actually help in, forming the thread. (Fig 8) Since there are no chips in the, process, it is very valuable in places where chip removal, poses problems. These taps are excellent for tapping, copper, brass, aluminium, lead etc. The thread finish is, also comparatively better than in the fluted taps., , General informative points on taps, Objectives: At the end of this lesson you shall be able to, • differentiate between hand tap and machine tap, • identify the parts of a machine tap, • state the constructional features of a machine tap., Unlike tapping with the three piece set of hand taps, the, machine tap cuts the entire threaded profile in one operation., The machine tap is normally made of tool steel and, consists of the shank (2) and the cutting section (1) as, shown in (Fig 1). The cutting section itself is subdivided, into two areas. The start (3), which serves for cutting, and, the guiding section (4) for the feeding motion and smoothing, of the newly cut thread. (Fig 1), , The number of flutes (5), may be even or odd. With an even, number of flutes, measuring of the diameter (7) is easier., (Figs 2a and 2b), , Straight and spiral groove machine taps are available. The, diameter of the shank and the shape of its end vary between, the various standards. The shank diameter may be, smaller, equal to or larger than the thread diameter. The, shank ends are available in straight design, with square, ends as shown in (6) or with driving shoulders., , Accordingly three types of taps are available., Type normal (Fig 3b ) with a rake angle of approximately, 12°., Type soft (Fig 3c) with a rake angle of approximately 20°., Type hard (Fig 3a) with a rake angle of approximately 3°., , The normal type of rake angle taps can be used in most, cases. The start must be ground symmetrical. Before, using the tap, it is necessary to check that the cutting, edges are not chipped, and all the edges are sharp., The ‘hard’ type tap is used for tapping brittle materials like, cast iron. In case a ‘normal’ type tap is used on cast iron,, the tap cutting edges get blunt soon and the tap cannot be, used again on ductile materials like mild steel. The fine, cast iron splinters wear the external diameter of the cutting, edges of the tap causing them to tend to become blunt, and, when the same tap is used on steel which is more flexible, it is elastically pressed away (8) at the cutting point., Behind the cutting edge the material returns to the machined, diameter. The depth of the groove also causes jamming of, the guiding section of the tap. (Fig 4), , Chip removal (flow) takes place at the start of the tap. The, rake angle must be adapted to the material to be machined., Hard and brittle materials require a small rake angle and, soft materials need a larger rake angle., , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence, , 29

Page 44 :

Pipe Threads and Pipe Taps, Objectives: At the end of this lesson you shall be able to, • state parallel and taper pipes threads, • determine the wall thickness and threads per inch (TPI) of BSP threads, • state the method of sealing pipe joints, • determine blank sizes for threading as per B.S 21 - 1973 and I.S. 2643 - 1964., Pipe threads, The standard pipe fittings are threaded to British Standard, pipe (BSP). The internal pipe threads have parallel threads, whereas the external pipes have tapered threads as shown, in Fig 1., , The pipe joint shown in Fig 4 consists of the following:, 1 Parallel female thread, 2 Tapered male thread, 3 Hemp packing, The hamp packing isused to ensure that any small space, between two metal threads (male and female threads) is, sealed to prevent any leakage., , B.S.P. threads, Glavinized iron pipes are available in sizes ranging from, 1/2” to 6” in several different wall thickness. The table, shows outside diameters and threads per inch from, 1/2” to 4”. (Fig 2), Table, BSP - Pipe sizes, or DIN 2999, (inside) (B), , The next two threads have fully formed bottoms but that, tops. (B), The last four threads have flat tops and bottoms. (C), Sealing pipe joint, Fig 3 shows that the pipe has several fully formed threads, at the end. (A), , 30, , Threads, inch, , Outside diameter/, mm of the pipe (A), , 1/2”, , 14, , 20.955 mm, , 3/4”, , 14, , 26.441, , 1”, , 11, , 33.249, , 11/4”, , 11, , 41.910, , 11/2”, , 11, , 47.803, , 2”, , 11, , 59.614, , 2 1/2”, , 8, , 75.184, , 3”, , 8, , 87.884, , 4”, , 8, , 113.030, , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence

Page 45 :

Pipe taps, Internal pipe threads are usually cut with standard taper, pipe taps. (Fig 5), , In gauging internal pipe threads, the pipe plug thread gauge, should be screwed tight by hand into the pipe until the, notch on the gauge is flush with the face. When the thread, is chamfered the notch should be flushed with the bottom, of the chamfer. (Fig 6), , Production & Manufacturing: Fitter (NSQF Level - 5) RT for Ex No. 2.1.68 - 69, , Copyright Free Under CC BY Licence, , 31

Page 46 :