Page 1 :

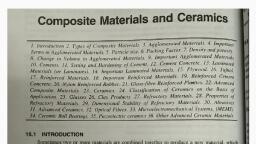

Chapter 4, , Unit;, —com| osite Materials, , , , 1) INTRODUCTION, , All the engineering materials (high polymers, metals and, ossess their outstanding characteristics as well as, jimitations. None of these ean be properly used where very, , nt and specific requirements are required, e.g., high, temperature reactors, supersonic aircrafts, missiles, etc. In order, to meet such a stringent and specific requirements, scientists, and technologists have developed a new class of materials, , called “composites”., , ceramics) P, , stringe, , ( 4.2) DEFINITION, , A composite material may be defined as, “a material, system consisting a mixture of two (or) more micro-constituents,, which are mutually insoluble, differing in form (or) composition, and forming distinct phases’. Such a combination, possesses, properties different from those of any of its constituents., , \4.3) NEED FOR COMPOSITES, , Il. As composites never rust and have le, toughness than metals, we need different composites., , ss fracture, , * To reduce maintenance cost and ensure long-term, , 3 Stability composites are essential., , ” : is essential because according to the needs, using, different fibres and matrix, properties of composites can, be modified., , yi need of power, , 'clecommunication industries, e increasing, a ae . USES, Sg nission along with data transmission 1s 0, $0 © 5 a, “oOMposites are highly essential., , tr,, , ore |, , Scanned with Oken Scanner

Page 2 :

STE, , 42 _Engineering Chemistry, , $ Composites are highly required beemnie, of its lower, weight reduces fuel consumption atl eqniaaiort, , 6 As carlin fibre weighs about 25% as much as steel and, 209 as much ac aluminium and is much stronger and, stiffer than both materials, we need composites, , 4.4) ADVANTAGES (OR) CHARACTERISTICS, ~~" OF COMPOSITES, , (i) They possess higher specific strength and lower specific, gravity., , Gi) They possess lower electrical conductivity and thermal, expansion., , (iii) They possess better creep, fatigue strength, corrosion and, oxidation resistance., , (iv) They maintain very good strength, even upto high, temperatures., , (45 CONSTITUENTS OF COMPOSITES, Composites consist of two important constituents., , G) Matrix phase (or) Matrix resin, (ii) Dispersed phase (or) Reinforcement., , 4.5.1. Matrix Phase (or) Matrix resin, , Matrix phase is the continuous body constituent, whieh, encloses the composite. Matrix phase may be metals, ceramics, (or) polymers (liquid resins), composites using these matrix are, known a, , (i) Metal Matrix Composites (MMC), (ii) Ceramic Matin Componites (CMC), , (iii) Polymer Matrix Composites (PMC) respectively,, , Scanned with Oken Scanner

Page 3 :

sit materials, 4.3, , compe, , 27 Resins, olymers used as adhesives, potting compounds, a liquid form are called as liquid resins we clenl, , elc.,, Epoxy adhesives, polysulphides are typical, ron commercially available adhesives i, , Cure re ;, Formation, , action., , Cure reactions are done by using a curing agent. These, linked linear polymers contain functional groups (or), s. They are usually not high molecular weight resin, e form of liquid resins. They are also called as, * The liquid resins will be cured in the moulding, ss of cross linked products., , of cross-linking in certain polymers is known, , as cure Fe, , uncrossdouble bond, and are in th, “pre-polymers:, to get solid ma:, , Phase (or) Reinforcement, , ructural constituent, which, , 4.5.2 Dispersed, , Dispersed phase is the st, determines the internal structure of composite., , Fibres, Particulates, Flakes, Whiskers., , , , Examples, , , , , , Reinforcement, , It is a process of improving the characteristics of the, plastic matrix by adding reinforcing agents. The reinforcing, agents may be organic (or) inorganic in nature. They may be, in the form of powder, flakes, fib, characterised by high strength to, resistance to erosion, corrosion, ¢tc.,, Hr effective structural performance,, ee bond between the matrix phase, , ispersed ‘phase (or) reinforcing agents., , res. These materials are, i0, excellent, , and ease of fabrication., , there should be a strong, , (or) matrix resin and, , weight rat, , 1. Fibres, , subs Fibres are long and thin filament of ms oT, , ria such ‘as ° polymer, metal (or) ceramic havin€ 2, gth to diameter ratio at least 100:1., , , , Scanned with Oken Scanner

Page 5 :

jals, materi eet 46, , . Compost Matern ———— 4.2, E . wool Fibre: Wool is an animal protein fibre, Like other, Ee ( — wool is also made up) of Geaminoacids, ‘These, , raids ats joined end-to mo in the form of peptide chains, - long chain miolentlies, Many of the physical and, rica properties of wool are due to the disulphide bonds, Fommed DY the covalent cross-linking of the cystein molecule,, A ny chemical that alfect the disulphide bonds may cause, Feructural break down of the fibre. The clastic properties of, ool fibre is due to the presence of hydrogen bond between, , , , the W' ., various peptide chain., , (c) Silk: Silk is a natural protein fibre produced by the, insect, silk worm. It possesses all the desirable qualities of fibre, such as softness, strength, elongation, etc. It has a bright lusture, and it is an excellent insulator of heat, hence it is warm in, , winter and cool in summer., , (d) Sisal: Sisal is another low-cost fibrous material, which, is also used in phenolic based dough moulding compounds., , (e) Jute and Coir: They are also low-cost fibrous material, for reinforcement for polyester resin. They can be used as, woven cloth (or) in yarn form for filament winding. A variety, of objects like houses, fishing boats have been developed., , (ii) Synthetic Fibres, , (a) Polyethylene terephthalate (PET) (or) Terylene (or), , Dacron, (EG eel is produced by the condensation of ethylene glycol, Sere terephthalic acid (TPA). This fibre is used as mute, fies ¢s which can be used to provide improved chemical and, fabricg.| tesistance, They may be used in light weight woven, thong They are rarely used as the main reinforcement, shoal they give laminates with high im resista, | vt chemical and abrasion resistance. Generally they are, 'N Combination with glass fibres., , (b) p, 2, “ly Propylene: \t is obtained by polymers, , Propyt, lene oy Anaee, iene. ‘These fibres possess better hardness,, , pac t, , ation of, strength,, , Scanned with Oken Scanner