Page 1 :

| Chapter BI, a Q, , INERGY CONSERVATION IN ELECTRICAL MACHINES, , Teaching Hours 12, Total Marks 14, 2.1 Need for Energy Cons:, , ervation in Induction Motor and Transformer., 2.2 Energy Conservation Techniques in Induction Motor by, , (a) Improving power quality., (b) Motor survey,, (C) Matching motor with loading., (d) Minimizing the idle and redundant running of motor,, (e) Operating in star mode., (f) Rewinding of motor., (g) Replacement by energy efficient motor., (h) Periodic maintenance. :, 2.3 Energy Conservation Techniques in Transformer :, (a) Load sharing., (b) Parallel Operation., (©) Isolation techniques., (d) Replacement by energy efficient transformers., (e) Periodic maintenance., , 2.4 Energy Conservation Equipments : Soft Starters, Automatic Star Delta Converter,, Automatic Power Factor Controller, , Variable Frequency Drives,, (APFC), Intelligent Power Factor Controller (IP, (AHF)., , FC), Active Harmonic Filter, , _ 2.5 Energy Efficient Motor : Significant features, Advantages, Applications and Limitations., 2.6 Energy Efficient Transformers, Amor, , phous Transformers;, Transformer., , Epoxy Resin Cast Transformer/Dry Type of, , Learning Objectives, 2a. Describe the techniques for energy conservation in the given electrical machine., , 2b. Explain with sketches the working principle of the given energy conservation equipment., , 2c. Select relevant energy conservation equipment for given electrical machine with justification,, , 2d. Describe the technique(s) to improve the performance efficiency of the given type of electrical machine’, 2e. Describe with sketches the construction and applications of specified energy efficient transformer., , ‘1 NEED OF ENERGY CONSERVATION IN INDUCTION MOTOR, _AND TRANSFORMER ce 3, , (s)., , , , , , MSBTE Questions, nin induction motor,, , electrical motor,, , Scanned with CamScanner, , 1. Describe the need of energy conservatio!, 2. State the need of energy conservation in

Page 2 :

Energy Conservation and Audit (Elect. Engg,, , Energy Conservation in Electrica; Man, , , , r.) (Sem. V) 2.2, , , , [2.1.1 (A) Need of Energy Conservation in Induction Motor|, , ergy Conservatio, , , , MSBTE Questions, 1. Explain the necessity of energy conservation in electrical motors. i, , ly depends on ind', 9 India is a growing economy and the economic growth of any country largely dep!, , ., , Hes, , fee, , 4, , Power Supply Quality :, , Ustrialisati., , energy consumption. ., aving at each possible .,, The growing cost of energy due to limited stock of energy sources calls for power saving P F, an industry. 4, ici in an industry., The three-phase induction motors consume about 70% of the electricity used in TY:, Hence the running cost of these induction motors is the real challenge., ; initi: motor rather tha,, Earlier, induction motor design and fabrication was based more with the initial cost of the ler thar, much energy it consumes. t th, The materials such as aluminium or copper wires and steel laminations, were selected to meet the perfor,, requirements of the motor., , Hence induction motors have low power factors, more losses and low efficiency. After 90's the cost of ¢, starts increasing which directly affected the motor cost as the motors were less efficient., , This leads the customers to search for other more energy efficiency options., Therefore the manufacturers started to figure out different methods to increase the efficiency of motors., , To achieve these, manufacturers started use of good and thin steel lamination materials having low losse, more number of copper wires in windings to increase the efficiency of induction motor., , The standard induction motors in a process plant consume large amount of energy due to low efficiency., , To save energy consumption in a process plant, the use of energy efficiency motors are chosen over stands, induction motor., , , , Energy efficient motors have better efficiency and power factor than standard induction motors., , The use of energy efficient motors reduces energy consumption of the plant, The payback period for ene, efficiency motors is very less as compared to standard motors., , “The motors having high efficiency, good power factor and fewer losses are called energy efficie’, motors". Energy efficient motors have efficiency 2-3% more than standard motors., , In the improvement of energy efficient motors, different technologies are made., , The changes in slot shape increase the efficiency and thus reduce the internal motor losses., , The use of energy efficient motors offers the utilities for Possibility of achieving sustainable energy and dema, reduction., , Need of energy conservation can be summarised as, , Cost of electricity is increasing, so conservation methods to motors be Provided., , Motor must work at higher efficiency so provisions of reducing losses be Provided., , Inefficient motors need large power for the same work output., , To save power, therefore energy efficient newly designed motors be Provided (replacing old design moto", , Good quality materials for core and windings be used by the Manufacturers to improve efficiency °, conserving energy., , New design changed the shapes of slots, 7. Saving in cost of operation com, , lower losses, higher efficiency an, Factors affecting the motor efficie, , need of energy conservation is felt because :, , WRWNP, , a, , to get more efficiency,, pels us to go for modern designed ", id hence conserving the energy., ncy and minimising motor losses in operation :, , energy efficient” motors workind, , ¢ Motor performance is affected considerably by the, frequency available at motor terminals vis-a, voltage unbalance across the three phases,, , : quality of input power, that is the actual volts 2”, vis rated values as well as voltage and frequency variations *”, , Scanned with CamScanner

Page 3 :

|, Energy Conservation in Electr..., , Energy Conservation and Audit (Elect, Engg. Gr.) (Sem. V) 2.8, , he purchase of less expensive motors y,, i . e, , ° Price : Many USETS are first-cost sensitive, leading to t, , more, , Costly on a lifecycle basis because of lower efficiency:, , ically save within a ;.,, rn iqgned motors typica’ y a fe !, , Some salient fea, , tures are given below :, 1. Reactive Power q, , Fawn (kVAR) by the motor. d Motors while IS 12615 ., 2. The Indian Standard Is 879 addresses technical performance of Standar, , ology whereir, the efficiency criteria of High Efficiency Motors. Both follow IEC ae elas ae in., are assumed as 0.5% of input power. By the IEC test method, the i Pe, IEEE test Methodology, the motor efficiency values would be further lo) Aa Fart upto 59, 3. Indian Standard 325 for standard motors allows 15% tolerance on efficiency OU k, and 10% for Motors over 50 kW rating. i indi, 4. In the selection Process, the coe at 75% of loading can be a meaningful indicator, efficiency,, , 5. The cost benefits can be worked out on the basis of premium required for high efficiency versus, annual savings., , , , The energy Savings by motor replacement can be worked out by the simple relation :, kW saving = kw output x [1/Moid - 1/Mnew), where, Noid and Tew are the existing and proposed motor efficiency values., 7. It would be Prudent for buyers to Procure motors based on test certificates rather than labelled Values, , 2.1.1 (B) Need of Energy Conservation in Transformer, , , , , , , , , , , , , , MSBTE Questions, , 1. State the need of energy conservation in transformer. Explain the use of Epoxy Resin Cast/Encapsulated :, type transformer from energy conservation point of view, (S-16/4, , * Transformer is a vital Power equipment in a power system, which plays significant role in genera, transmission and distribution of electrical energy,, , ww Transformer Operating efficiency directly affects, , ¢ Ina typical power distribution grid, electric tra, , transmission and distribution loss. ‘, , In distribution system, the demand of distribution transformer is ever increasing,, , "\o- The Power loss generated by transformers cai, Operating time., , 2 According to the Statistics, total power loss generated by the transf;, Capacity. Therefore, study of transforme:, , , , the costs and benefits of the whole power system., nsformer power loss contributes to about 40-50% of the to, n be considerable due to its large transportation energy and, , ormer can be about 10% of total generat", T energy conservation is Necessary,, , domestic., , * Thus even a small Positive change in transfor: ici i 3t, H mer efficiency will | oa oneral, capacity requirement, cy lead to remarkable teduction in ge, , Scanned with CamScanner

Page 4 :

hines, Energy Conservation and Audit (Elect. Engg. Gr.) (Sem. V) 2.9 Energy Conservation in Electrical Mac!, , 2.2 ENERGY CONSERVATION TECHNIQUES IN INDUCTION MOTOR oe, , , , MSBTE Questions, 1, Explain the energy conservation technique "by improving power quality” for induction motor. [s-18/4 M)|, 2. Explain energy conservation method in induction motor by improving power quality., , 3. Explain energy conservation technique in induction motor by improving mechanical power and transmission], (W-17/4 M), , , , , , efficiency., 4, Explain the following energy conservation methods of electrical motor :, (a) Rewinding of motor (b) Operating in star mode. (W-17/4 M), , , , (a) Improving Power Quality :, MSBTE Questions |, , a 1. List out the energy conservation techniques to be adopted to reduce losses in the induction motor., , , , Motor performance can be increased by maintaining the voltage level within in BIS standards i.e. within the, to @ limit of + 6% and keeping the frequency within the tolerance of + 3%. This is achieved by avoiding voltage, unbalance, maintaining voltage and frequency values and avoiding harmonic distortion., , Voltage unbalanace : 3-phase motors are designed to operate on balanced supply. Unblanace voltage causes, excessive heating and vibrations. This leads to increase I’R losses. Remedy on this is to distribute single-phase loads, on 3-phases., , Harmonic filters are used to reduce harmonics in the system, maintaining frequency as constant., , (b)Motor Survey:, , ~ Motor survey is important aspect in energy conservation. Conducting a motor survey is the best way to correctly, size a replacement motor. A motor survey should begin by reviewing and cataloging the nameplate information on, the existing motor to obtain the parameters such as rating of motor, rated speed, efficiency, full-load current, etc., The motor nameplate is the first step of a motor survey. It gives available information, such as speed and full-load, current, which is helpful while selecting the right size motor. Motors operate most efficiently near full load, so, determining load requirements accurately is important. The highest efficiency is achieved above 80 percent of fullload torque, below that efficiency starts to drop dramatically. ‘, , (c) Matching Motor with Loading :, , ‘S he characteristics of‘ motors vary widely with their load and the type of duty they are expected to perform. For, example, the applications like constant speed, constant torque, variable speed, steep/sudden start, continuous/, intermittent duty, frequent start/stops, etc. should be taken into consideration carefully when deciding for the type, of a motor for that specific application. Proper selection of the range of the motor according to load requirements, will reduce the power consumption. The efficiency of motors operating at loads below 40% is likely to be poor and, energy savings are possible by replacing these with properly sized motors, new or interchanging with another load., An incorrect selection of motor oe to various problems such as premature failure of the motor causing, severe production loss, cae, , (d) Minimizing the Idle and Redundant Running of Motor :, , By Minimizing the idle and redundant running of motors, prolonged idle running of machine tools, conveyors,, exhaust fan, lights etc. can be avoided. Idle running of auxiliaries like cooling towers, air compressors, pumps etc., during prolonged stoppage of production machines can be avoided., , (e) Operating in Star Mode : , , In loads Operating at less than 30% of the full load, ie., at light loads, operation of ‘Delta’ connected motor in, Star connection can save energy. If a motor is oversized and continuously loaded below 30% of its rated shaft load,, Energy can be saved by permanently connecting the motor in Star. In many cases, the load is below 30% most of the, time, but sometimes the load exceeds 50% in this condition automatic Star-Delta changeover switches can be, Installed, This can save upto 5 to 15% of the existing power consumption., , Scanned with CamScanner

Page 5 :

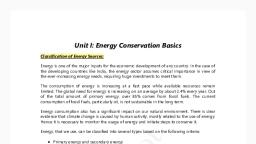

Energy Conservation in Electrica M, Energy Conservation and Audit (Elect. Engg. Gr.) (Sem. Vv) 2.10 =, , (f) Rewinding of Motor :, , ron A ion i In ways., ¢ Rewinding of electric Motors when they fail can be a cost-effective option in mal ys, , ; : inging the motor back to a jj,, ° While the rewinding process is expected to be extensive and capable of bringing t a lik, , fe sc 1 followed in eve;, condition, most rewinders do Not follow every step or the precision needed to b ny st, rewinding,, , This has Major impact o, Most of the motors,, , New technologies are avai, Motor's efficiency increase, A common Problem occu, be damaged, thereby incr, A change in the air gap m., , Efficiency an be improve, Process,, , n the efficiency of a rewound motor. Rewinding will decrease the efficiency by 2., , lable which help reduce the losses in a rewound motor; rare cases have shown ¢, d after being rewound., , rs when heat is applied to strip old windings : the insulation between lamination, easing eddy current losses., , ay affect power factor and output torque,, d by changing the winding design, though the power factor could be affected j,, , ° Using wires of large cross sec, , (g) Energy Efficient Motor, * AM EEM generates the same shaft output, , tion would reduce stator losses thereby increasing efficiency., , power, but uses less input power than a standard efficiency motor., ° Energy efficient motors apply less electricity and last longer than standard motors of the same size., * Energy-efficient motors are defined as the motor in which | se, , design improvements are incorporated specifically to, increase efficiency of motors,, , Design improvements. fo, , cus on reducing intrinsic motor, losses., , Improvements include the use of lower-loss silicon steel, a, longer core (to increase active Material), thicker wires (to, reduce resistance), thinner laminations, smaller air gap, between stator and rotor, copper instead of aluminium bars, in the rotor, Superior bearings and a smaller fan, etc., Energy-efficient motors now 10 20 30 50 75 125200, efficiencies that are ty Motor Rating (kW), , than standard motors, Fig. 2.1, , (h) Periodic Maintenance :, , Machine cleaning : To ensure t, , Efficiency (%), , , , , , 70, available in India Operate with, , BEG, pically 3 to 4 Percentage points higher, , hat ventilation and Motor cooling is Proper,, , Other factors are :, (i) By phase balancing,, @ Matching the motor in star(k) Use high quality bearings t, (0 Use small Cooling fan to re, (m) Lower air 9ap reduces ma, , Mode., , ‘0 reduce friction losses,, duce fan load,, 9Netic losses., , Scanned with CamScanner

Learn better on this topic

Learn better on this topic

Learn better on this topic

Learn better on this topic