Page 1 :

ENGINEERING DRAWING, (NSQF), 1st Year, Common for All Engineering Trades under CTS, (Not applicable for Draughtsman Trade Group), (For all 1 Year & 2 Year Trades), , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright Free. Under CC BY License.

Page 2 : Engineering Drawing (NSQF) - 1st Year, Common for all Engineering Trades under CTS (Not applicable for Draughtsman Trade Group), , Developed & Published by, , National Instructional Media Institute, Post Box No.3142, Guindy, Chennai - 32, INDIA, Email:

[email protected], Website: www.nimi.gov.in, Printed by, National Instructional Media Institute, Chennai - 600 032, , First Edition, , :November 2019, , Rs.170/-, , ©, , (ii), , Copyright Free. Under CC BY License.

Page 3 :

FOREWORD, , The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of, every four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy., Industrial Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled, manpower. Keeping this in mind, and for providing the current industry relevant skill training to Trainees,, ITI syllabus has been recently updated with the help of comprising various stakeholder's viz. Industries,, Entrepreneurs, Academicians and representatives from ITIs., The National Instructional Media Institute (NIMI), Chennai, has now come up with instructional material to, suit the revised curriculum for Engineering Drawing 1st Year (For All 1 year & 2 year Trades) NSQF, Commom for all engineering trades under CTS will help the trainees to get an international equivalency, standard where their skill proficiency and competency will be duly recognized across the globe and this, will also increase the scope of recognition of prior learning. NSQF trainees will also get the opportunities, to promote life long learning and skill development. I have no doubt that with NSQF the trainers and, trainees of ITIs, and all stakeholders will derive maximum benefits from these IMPs and that NIMI's effort, will go a long way in improving the quality of Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, Director General/ Addl. Secretary, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright Free. Under CC BY License.

Page 4 :

PREFACE, The National Instructional Media Institute(NIMI) was set up at Chennai, by the Directorate General of Training,, Ministry of skill Development and Entrepreneurship, Government of India, with the technical assistance, from the Govt of the Federal Republic of Germany with the prime objective of developing and disseminating, instructional Material for various trades as per prescribed syllabus and Craftsman Training Programme(CTS), under NSQF levels., The Instructional materials are developed and produced in the form of Instructional Media Packages (IMPs),, consisting of Trade Theory, Trade Practical, Test and Assignment Book, Instructor Guide, Wall charts,, Transparencies and other supportive materials. The above material will enable to achieve overall improvement, in the standard of training in ITIs., A national multi-skill programme called SKILL INDIA, was launched by the Government of India, through a, Gazette Notification from the Ministry of Finance (Dept of Economic Affairs), Govt of India, dated 27th, December 2013, with a view to create opportunities, space and scope for the development of talents of, Indian Youth, and to develop those sectors under Skill Development., The emphasis is to skill the Youth in such a manner to enable them to get employment and also improve, Entrepreneurship by providing training, support and guidance for all occupation that were of traditional, types. The training programme would be in the lines of International level, so that youths of our Country can, get employed within the Country or Overseas employment. The National Skill Qualification Framework, (NSQF), anchored at the National Skill Development Agency(NSDA), is a Nationally Integrated Education, and competency-based framework, to organize all qualifications according to a series of levels of Knowledge,, Skill and Aptitude. Under NSQF the learner can acquire the Certification for Competency needed at any, level through formal, non-formal or informal learning., The Engineering Drawing 1st Year (Comon for All 1 year & 2 year Engineering Trades under CTS) is one, of the book developed by the core group members as per the NSQF syllabus., The Engineering Drawing (Common for All 1 year & 2 year Engineering Trades under CTS as per NSQF), 1st Year is the outcome of the collective efforts of experts from Field Institutes of DGT, Champion ITI’s for, each of the Sectors, and also Media Development Committee (MDC) members and Staff of NIMI. NIMI, wishes that the above material will fulfill to satisfy the long needs of the trainees and instructors and shall, help the trainees for their Employability in Vocational Training., NIMI would like to take this opportunity to convey sincere thanks to all the Members and Media Development, Committee (MDC) members., , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Chennai - 600 032, , (iv), , Copyright Free. Under CC BY License.

Page 5 :

ACKNOWLEDGEMENT, The National Instructional Media Institute (NIMI) sincerely acknowledge with thanks the co-operation and, contribution of the following Media Developers to bring this IMP for the course Engineering Drawing (1st Year, (For All 1 year & 2 year Trades)) as per NSQF., , MEDIA DEVELOPMENT COMMITTEE MEMBERS, Shri. M. Sangara pandian, , -, , Training Officer (Retd.), CTI, Guindy, Chennai., , Shri. G. Sathiamoorthy, , -, , Jr.Training Officer (Retd.), Govt I.T.I, DET - Tamilnadu., , NIMI CO-ORDINATORS, Shri. Nirmalya Nath, , -, , Deputy General Manager,, NIMI, Chennai - 32., , Shri. G. Michael Johny, , -, , Assistant Manager,, NIMI, Chennai - 32., , NIMI records its appreciation of the Data Entry, CAD, DTP Operators for their excellent and devoted services in, the process of development of this IMP., NIMI also acknowledges with thanks, the efforts rendered by all other staff who have contributed for the development, of this book., , (v), , Copyright Free. Under CC BY License.

Page 6 :

INTRODUCTION, Theory and procedure along with the related exercises for further practice, This book on theory and procedure along with related exercises contains theoretical information on 1st year, Engineering drawing (for engineering trades of 1 year and 2 year) and procedure of drawing/ sketching different, exercise for further practice are also available. Wherever required, BIS specification has been used.., Exercise for further practice, The practice exercise is given with Theory and procedure for 1st Year book made obsolete as it was felt that, it is, very difficult to work in workbook using drawing instruments. It is well known fact that, any drawing is prepared on, suitable standard size of drawing sheets only., The instructor is herewith advised to go through the instructions given below and to follow them in view of imparting, much drawing skill in the trainees., Acquiring the above said ability and doing small drawings is not a simple task. These books will provide a good, platform for achieving the said skills., Time allotment:, Duration of 1st Year, , : 80 Hrs, , Time allotment for each module has been given below. Common to all 1 year and 2 year Engineering Trades., S.No, , Title, , Exercise No., , Time allotment, , 1, , Engineering Drawing Introduction, , 1.1.01 - 1.1.04, , 1, , 2, , Drawing Instrument, , 1.2.05 - 1.2.07, , 1, , 3, , Free hand drawing, , 1.3.08 - 1.3.14, , 10, , 4, , Lines, , 1.4.15 & 1.4.16, , 2, , 5, , Drawing of Geometrical figures, , 1.5.17 - 1.5.21, , 8, , 6, , Lettering & Numbering, , 1.6.22, , 6, , 7, , Dimensioning and its Practice, , 1.7.23 - 1.7.25, , 4, , 8, , Sizes and layout of drawing sheets, , 1.8.26, , 2, , 9, , Method of presentation of Engineering Drawing, , 1.9.27 & 1.9.28, , 2, , 10, , Symbolic representation – different symbols, used in the trades, , 1.10.29 - 1.10.33, , 6, , 11, , Projections, , 1.11.34 - 1.11.37, , 15, , 12, , Orthographic projection from isometric projection, , 1.12.38, , 15, , 13, , Reading of fabrication drawing, , 1.13.39, , 8, 80 Hrs, , Instructions to the Instructors, It is suggested to get the drawing prepared on A4/A3 sheets preferably on only one side. If separate table and chair, facility is available for every trainee then it is preferred to use A3 sheets and if the drawing hall is provided with, desks then A4 sheets may be used. However while preparing bigger drawings on A4 sheets suitable reduction, scale to be used or muiltiple sheets may be used for detailed and assembly drawings., First the border and the title block to be drawn only for the first sheet of the chapter. Eg. for conical sections only, first sheet will have the title block whereas the rest of the sheets of that chapter will have only borders., Serial number of sheet and total no. of sheets to be mentioned on each sheet., The completed sheet to be punched and filled in a box file/ suitable files and preserved by the trainees carefully, after the approval of instructors, VPS and Principals of the Institute., The file may be reffered by the authority before granting the internal marks at the end of 1st year., (vi), , Copyright Free. Under CC BY License.

Page 7 :

CONTENTS, Exercise No., , Title of the Exercise, , Page No., , Engineering Drawing Introduction, 1.1.01, , Introduction to engineering drawing, , 1, , 1.1.02, , Conventions, , 4, , 1.1.03, , Views of engineering drawing sheets, , 5, , 1.1.04, , Method of folding of printed drawing sheets as per BIS SP: 46-2003, , 7, , Drawing Instrument, 1.2.05, , Drawing instruments - Drawing board, T - square, drafter (drafting machine), , 9, , 1.2.06, , Drawing instruments - Setsquares, protractor and scale, , 11, , 1.2.07, , Drawing Instruments box and pencils, , 12, , Free hand drawing, 1.3.08, , Free hand drawing of lines, , 15, , 1.3.09, , Free hand drawing - Polygons and ellipse, , 20, , 1.3.10, , Free hand drawing of geometrical figures and block with dimension, , 24, , 1.3.11, , Free hand drawing of transferring measurement from the given object, , 25, , 1.3.12, , Free hand drawing of solid figures, cubes, cuboids, cone, prism, pyramid,, frustum of cone with dimensions, , 29, , 1.3.13, , Freehand drawing of hand tools and measuring tools used in common trades, , 32, , 1.3.14, , Freehand drawing of simple fasteners (bolts, nuts and rivets etc.), trade related sketches, , 49, , Lines, 1.4.15, 1.4.16, , Lines - Definition, types and applications in drawing as per BIS: 46-2003, and classification of lines, , 51, , Lines - Drawing lines of given length (straight, curved), drawing of parallel lines,, perpendicular line and methods of division of line segment, , 55, , Drawing of Geometrical figures, 1.5.17, 1.5.18, 1.5.19, 1.5.20, 1.5.21, , Drawing of geometrical figures - Definition, nomenclature and practice of angle,, measurement and its types, and types of angle and triangle, , 59, , Drawing of geometrical figures - Method of bisecting practice of angles, and triangles, , 61, , Geometrical figures - Square, rectangle, rhombus, parallelogram, circle, and its elements, , 66, , Drawing of geometrical figures - Practice of square, rectangle, parallelogram,, rhombus and circle, , 68, , Drawing of geometrical figures - Different polygons and their values of included, angles. Inscribed and circumscribed polygons, , 74, , Lettering & Numbering, 1.6.22, , Lettering and numbering - Single stroke, double stroke and inclined, , (vii), , Copyright Free. Under CC BY License., , 77

Page 8 :

Exercise No., , Title of the Exercise, , Page No., , Dimensioning and its Practice, 1.7.23, 1.7.24, 1.7.25, , Dimensioning - Definition, and its types, types of arrow heads and leaderline, with text, , 85, , Dimensioning and its practice - Methods of dimensions and position of, dimensioning (aligned, unidirectional), , 87, , Symbols preceding the value of dimension and dimensional tolerance, , 97, , Sizes and layout of drawing sheets, 1.8.26, , Sizes and layout of drawing sheets - Selection of sizes, title Block, its position, & content and item reference on drawing sheet (item list), , 100, , Method of presentation of Engineering Drawing, 1.9.27, , Method of presentation of engineering drawing - Pictorial view and isometric view, , 104, , 1.9.28, , Method of presentation of engineering drawing - Orthographic views, , 114, , Symbolic representation – different symbols used in the trades, 1.10.29, , Symbolic representation - different symbols used in the trades - Fastener, (bolts, nuts and rivets), , 116, , 1.10.30, , Symbolic representation of bars and profile sections, , 119, , 1.10.31, , Symbolic representation of weld, brazed and soldered joints, , 120, , 1.10.32, , Symbolic representation of electrical and electronic elements, , 122, , 1.10.33, , Symbolic representation of piping joints and fittings, , 126, , Projections, 1.11.34, , Projections - Concept of axes plane and quadrant, , 128, , 1.11.35, , Projections - Orthographic projection, , 131, , 1.11.36, , Projection - Method of 1st angle and 3rd angle projections (Deifinition and, difference), , 136, , Projection - Symbol of 1st angle and 3rd angle projection as per IS specification, , 138, , 1.11.37, , Orthographic projection from isometric projection, 1.12.38, , Drawing of orthographic projection from isometric projection, , 139, , Reading of fabrication drawing, 1.13.39, , Reading of fabrication drawing for sheet metal worker trade, , 143, , LEARNING / ASSESSABLE OUTCOME, On completion of this book you shall be able to, • Read and apply engineering drawing for different application in the, field of work., , (viii), , Copyright Free. Under CC BY License.

Page 9 :

SYLLABUS, 1st Year, , Common for all Engineering trades under CTS, Duration: One Year, (Not applicable for Draughtsman trade Group), , S.no., I, , Syllabus, , Time in Hrs, , Engineering Drawing – Introduction, , 1, , Introduction to Engineering Drawing and Drawing Instruments –, 1 Conventions, 2 Viewing of engineering drawing sheets., 3 Method of Folding of printed Drawing sheet as per BIS SP: 46-2003, II, , Drawing Instrument, , 1, , 1 Drawing board, T-square, Drafter (Drafting M/c), Set squares, Protector, Drawing, Instrument Box (Compass, Dividers, Scale, Diagonal Scales etc.), pencils of, different grades, Drawing pins/ Clips., III, , Free hand drawing of –, , 10, , 1 Lines, polygons, ellipse etc., 2 Geometrical figures and blocks with dimension, 3 Transferring measurement from the given object to the free hand sketches., 4 Solid objects - Cube, Cuboids, Cone, Prism, Pyramid, Frustum of Cone with, dimensions., 5 Free hand drawing of hand tools and measuring tools, simple fasteners (nuts, bolts,, rivets etc.) trade related sketches, IV, , Lines, , 2, , 1 Definition, types and applications in drawing as per BIS: 46-2003, 2 Classification of lines (Hidden, centre, construction, extension, Dimension,, Section), 3 Drawing lines of given length (Straight, curved), 4 Drawing of parallel lines, perpendicular line, 5 Methods of Division of line segment, V, , Drawing of Geometrical figures:, , 8, , Definition, nomenclature and practice of –, 1 Angle: Measurement and its types, method of bisecting., 2 Triangle: different types, 3 Rectangle, Square, Rhombus, Parallelogram., 4 Circle and its elements, 5 Different polygon and their values of included angles. Inscribed and circumscribed, polygons, , (ix), , Copyright Free. Under CC BY License.

Page 10 :

S.no., VI, , Syllabus, , Time in Hrs, , Lettering & Numbering, , 6, , 1 Single Stroke, Double Stroke, Inclined., VII, , Dimensioning and its Practice, , 4, , 1 Definition, types and methods of dimensioning (functional, non-functional, and auxiliary), 2 Position of dimensioning (Unidirectional, Aligned), 3 Types of arrowhead, 4 Leader line with text, 5 Symbols preceding the value of dimension and dimensional tolerance., VIII, , Sizes and layout of drawing sheets, , 2, , 1 Selection of sizes, 2 Title Block, its position and content, 3 Item Reference on Drawing Sheet (Item list), IX, , Method of presentation of Engineering Drawing, , 2, , 1 Pictorial View, 2 Orthographic View, 3 Isometric View, X, , Symbolic representation – different symbols used in the trades, , 6, , 1 Fastener (Rivets, Bolts and Nuts), 2 Bars and profile sections, 3 Weld, Brazed and soldered joints, 4 Electrical and electronics element, 5 Piping joints and fitting, XI, , Projections, , 15, , 1 Concept of axes plane and quadrant, 2 Orthographic projections, 3 Method of first angle and third angle projections (definition and difference), 4 Symbol of 1st angle and 3rd angle projection., XII, , Orthographic projection from isometric projection, , 15, , XIII, , Reading of fabrication drawing, , 8, , Total, , 80, , (x), , Copyright Free. Under CC BY License.

Page 11 :

For Engineering Trades, Engineering Drawing, , Exercise 1.1.01, , Introduction to engineering drawing, Communication, , Limitations of graphical language, , There are many different ways of communicating ideas,, informations, instructions, requests, etc. They can be, transmitted by signs or gestures, by word of mouth, in, writing, or graphically. In an industrial context the graphical, method is commonly used, communication being achieved, by means of engineering drawings., , 1 Information /feelings can be conveyed effectively but, still there are chances for imagination (communication, gap)., , If oral and written communication only were used when, dealing with technical matters, misunderstandings could, arise, particularly in relation to shape and size. The lack, of a universal spoken language makes communication and, understanding even more difficult because of the necessity, to translate both words and meaning from one language, to another., , Limitations of vocal language, , However, the universally accepted methods used in, graphical communication through engineering drawings, eliminate many of these difficulties and make it possible, for drawing prepared by a British designer to be correctly, interpreted or “read” by, for example, his German, French, ot Dutch counterpart., , 2 Viewer may image anything in his mind due to the, absence of written language., 1 Speaker and the listener should be aware of same, language., 2 Still there are chances of misunderstanding due to, communication gap., 3 Some languages (without alphabets) are existing on, tongues only., 4 Written language can also be misunderstood as each, and every word gives more than one meaning., Limitations of computer language, 1 Used only by computer programmers., , Equally important, the components shown on the drawings, could be made by suitably skilled craftsmen of any, nationality provided they can “read” an engineering drawing., , 2 Cannot be used for general communication., , Conventionally prepared engineering drawing provide the, main means of communication between the “ideas” men, (the designers and draughtsman) and the craftsmen, (machinists, fitters, assemblers, etc.). For the, communication to be effective, everyone concerned must, interpret the drawing in the same way. Only then will the, finished product be exactly as the designer envisages it., , Effective communication is possible when graphical, language is supported by written language/vocal language, and vice versa., , To ensure uniformity of interpretation the British Standards, Institution have prepared a booklet entitled BS 308:1972,, Engineering Drawing Practice. Now in three parts, this, publication recommends the methods which should be, adopted for the preparation of drawing used in the, engineering industry., The standards and conventions in most common use and, hence those required for a basic understanding of, Engineering Drawing are illustrated and explained in this, book., , Conclusion, , Engineering drawing is a language which uses both, graphical language and written language for effective, communication, Eg. In FM radios jockeys use vocal language, Eg. News papers use graphical language + Written, language, Eg. In television they use Graphical language (motion/, still pictures) + written language + vocal language, For Effective communication, Engineering drawing is a graphical language, which also uses written language for effective, communication, , Limitations of sign language, , Importance of Engineering Drawing, , 1 Information/feelings cannot be conveyed effectively, , The economical success of any country is mainly, depended on its industrial development. Due to the, globalization any industry of our country expected to be of, global market standard. Due to the above said reason our, Indian product required to be of very high quality with, respect to size of dimension, fit, tolerance and finish etc., , 2 Chances of misunderstanding the information / feelings, 3 Both the communicator and the receiver to be present, at the same place, , 1, , Copyright Free. Under CC BY License.

Page 12 :

To produce a best standard product all the technical, personnel (Engineers to Craftsman) in an industry must, have a sound knowledge in engineering drawing because, engineering drawing is the language of engineers., Engineering drawing is a universal language. Different types, of lines are its alphabets. Technical personnel in any, industry including craftsmen are expected to communicate, anything concerning a part or a component by drawings, involving lines, symbols, convention and abbreviations etc., With our spoken languages it is impossible to express, the details of a job or a product. Engineering drawing, knowledge and practice are must for designing or producing, a component or part. Even a small mistake in the drawing, may reflect very badly in the product. Therefore reading, and doing engineering drawing are very much essential for, craftsmen and engineers, A drawing is a graphical representation of an object, or, part of it, and is the result of creative thought by an engineer, or technician. When one person sketches a rough map in, giving direction to another, this is graphic communication., Graphic communication involves using visual materials to, relate ideas. Drawings, photographs, slides,, transparencies, and sketches are all forms of graphic, communication. Any medium that uses a graphic image, to aid in conveying a message, instructions, or an idea is, involved in graphic communication., One of the most widely used forms of graphic, communication is the drawing. Technically, it can be, defined as "a graphic representation of an idea, a, concept or an entity which actually or potentially, exists in life", Drawing is one of the oldest forms of communicating,, dating back even farther than verbal communication. The, drawing itself is a way communicating necessary, information about an abstract, such as an idea or concept, or a graphic representation of some real entity, such as a, machine part, house or tools. There are two basic types, of drawings: Artistic and Technical drawings., , 2, , Technical drawings, Technical drawings allows efficient communication among, engineers and can be kept as a record of the planning, process. Since a picture is worth a thousand words, a, technical drawing is a much more effective tool for, engineers than a written plan., The technical drawing, on the other hand is not subtle, or, abstract. It does not require an understanding of its creator,, only on understanding of technical drawings. A technical, drawing is a means of clearly and concisely communicating, all of the information necessary to transform an idea or a, concept in to reality. Therefore, a technical drawing often, contains more than just a graphic representation of its, subject. It also contains dimensions, notes and, specifications., Fields of use:, Technical drawing is the preferred method of drafting in all, engineering fields, including, but not limited to, civil, engineering, electrical engineering, mechanical engineering, and architecture., Purpose of studying engineering drawing:, 1 To develop the ability to produce simple engineering, drawing and sketches based on current practice, 2 To develop the skills to read manufacturing and, construction drawings used in industry., 3 To develop a working knowledge of the layout of plant, and equipment., 4 To develop skills in abstracting information from, calculation sheets and schematic diagrams to produce, working drawings for manufacturers, installers and, fabricators., Main types of Engineering drawing:, Regardless of branch of engineering the engineering drawing, is used. However based on the major engineering, branches, engineering drawing can be classified as follows:, (Fig 1), , Engineering Drawing : (NSQF) Exercise 1.1.01, , Copyright Free. Under CC BY License.

Page 13 :

Mechanical engineering drawings:, Some examples of mechanical engineering drawings are, part and assembly drawings, riveted joints, welded joints,, fabrication drawings, pneumatics and hydraulics drawings,, pipeline diagrams, keys coupling drawings etc. (Fig 2), , Electrical Engineering drawings, Wiring diagrams of home and industries, circuit diagrams,, electrical installation drawings etc., Example, The voltage supply to a filament lamp is 10.8V. The voltage, should be 12V. (Fig 4), , Audio amplifier (Fig 5), , Answer the following questions., 1 Discuss the different types of drawings?, 2 Explain the different applications of technical drawing?, 3 What is graphical communications?, , Engineering Drawing : (NSQF) Exercise 1.1.01, , Copyright Free. Under CC BY License., , 3

Page 14 :

For Engineering Trades, Engineering Drawing, , Exercise 1.1.02, , Conventions, , TYPE, , CONVENTION, , MATERIALS, Steel, Cast Iron, Copper and its Alloys,, Aluminium and its alloy, etc, , Metals, Lead, Zinc Tin White-metal, etc., , Glass, , Glass, , Porcelain, Stoneware, Marble, Slate etc, , Packing and Insulating, materials, , Asbestos, Fibre, Felt, Synthetic resin,, Products, Paper, Cork, Linoleum,, Rubber, Leather, Wax, insulating &, Filling Materials etc, , Liquid, , Water, Oil, Petrol, Kerosene etc, , Wood, , Wood, Plywood etc, , Concrete, , Concrete, , 4, , Copyright Free. Under CC BY License.

Page 15 :

For Engineering Trades, Engineering Drawing, , Exercise 1.1.03, , Views of engineering drawing sheets, Drawing paper: These are of two types:, •, , Hand-made paper, , •, , Mill-made paper, , TABLE 1, Designation, , Hand-made papers have rough surfaces, pale in colour and, not used for regular work, but meant for charts., Mill-made papers are most commonly used for regular, work, and are available in different sizes and rolls. They are, specified by their weight in kg per ream or density in grams, per square meter., Size of drawing sheets (in mm): While working or, handling, the papers are liable to tear on the edges. So, slightly large size (untrimmed) sheets are preferred. They, are trimmed afterwards. IS:10811:1983 lays down such as, designation of preferred trimmed and untrimmed sizes., The basic principle involved in arriving at the sizes of the, drawing paper is as under. The area of the biggest size (A0), is 1m2 and its breadth and length are in the ratio 1 : 2 . Let, x and y are the sides of the paper. The surface area of A0, is 1m2, then the sides are x = 0.841 m and y = 1.189 m., (Fig1), , A0, A1, A2, A3, A4, A5, , Trimmed size, , Untrimmed size, , 841 x 1189, 594 x 841, 420 x 594, 297 x 420, 210 x 297, 148 x 210, , 880 x 1230, 625 x 880, 450 x 625, 330 x 450, 240 x 330, 165 x 240, , For drawings which cannot be accommodated in above, sheets, elongated series are used. Elongated series are, designated by symbols A1 x 3; A2 x 4 etc., Special elongated series increasing its widths, double,, treble etc. are designated as follows A3 x 3, A3 x 4, A4 x, 3, A4 x 4, A4 x 5. Please refer Table 2, TABLE 2, Special elongated series, Designation, , Size, , A3 x 3, A3 x 4, , 420 x 891, 420 x 1189, , A4 x 3, A4 x 4, A4 x 5, , 297 x 630, 297 x 841, 297 x 1051, , Exceptional elongated series, Designation, , Two series of successive sizes are obtained by either, halving or doubling along the length. The area of the, successive sizes are in the ratio of 1:2., Designation of sheets: The drawing sheets are designated, by symbols such as A0, A1, A2, A3, A4 and A5. A0 being, the largest. Table 1 below gives the length and breadth of, the above sizes of sheets. (Trimmed and untrimmed), The relationship between two sides is same as that of a, side of a square and its diagonal., , Size, , A0 x 2, A0 x 3, , 1189 x 1682, 1189 x 2523, , A1 x 3, A1 x 4, , 841 x 1783, 841 x 2378, , A2 x 3, A2 x 4, A2 x 5, , 594 x 1261, 594 x 1682, 594 x 2102, , A3 x 5, A3 x 6, A3 x 7, , 420 x 1486, 420 x 1783, 420 x 2080, , A4 x 6, A4 x 7, A4 x 8, A4 x 9, , 297 x 1261, 297 x 1471, 297 x 1682, 297 x 1892, , 5, , Copyright Free. Under CC BY License.

Page 16 :

A4 x 3 means the length of A4 size is retained and the other, side is 3 times the width of A4., A4 x 3 = 297 x 630 (210 x 3), Fig 2 & 3 shows how the sheet sizes are formed by halving/, doubling and similarity of format., , Quality drawing paper: The drawing papers should have, sufficient teeth or grain to take the pencil lines and, withstand repeated erasing., White drawing papers which do not become yellow on, exposure to atmosphere are used for finished drawings,, maps, charts and drawings for photographic reproductions., For pencil layouts and working drawings, cream colour, papers are best suited., , 6, , A backing paper is to be placed on the drawing board before, fixing drawing/tracing paper, to get uniform lines. Before, starting the drawing, the layout should be drawn. (Ref:, IS:10711), , Engineering Drawing : (NSQF) Exercise 1.1.03, , Copyright Free. Under CC BY License.

Page 17 :

For Engineering Trades, Engineering Drawing, , Exercise 1.1.04, , Method of folding of printed drawing sheets as per BIS SP: 46-2003, Method of folding of printed drawing sheets as per, BIS SP: 46-2003, , When the drawings are to be released to shop floor for, reference during manufacturing of a component, , When drawings sheets are in more numbers, they have to, be folded and kept in order to save the trace required for, preserving them (Fig 1)., , Applicability, Folding of drawings applies to only the drawings which, are released for shop floor for manufacturing of components, / reference. Original drawings will never be taken out of, drawing office and they should be kept under safe custody., Drawings which are prepared on tracing sheets/, transparencies like cloth, polymer, acrylic polymer, transparencies should never be folded. They should be, kept in polythene folders and kept in filing cabinets., Sometimes the blue prints/photo copies of drawings which, are released to shop floor are also laminated for extending, their life., Requirement, While folding the drawings following care to be taken., It is required to fold the drawings such that, they should, not get defaced damaged., Drawing sheet to be folded such that the title block is, easily visible to retrieve it and keeping it back., , 7, , Copyright Free. Under CC BY License.

Page 18 :

The following is the method of folding printed drawing sheets, as recommended by BIS (Fig 2), , 8, , Engineering Drawing : (NSQF) Exercise 1.1.04, , Copyright Free. Under CC BY License.

Page 19 :

For Engineering Trades, Engineering Drawing, , Exercise 1.2.05, , Drawing instruments - Drawing board, T - square, drafter (drafting machine), The following are the commonly used equipment in a, drawing office., Drawing board (Fig 1): Drawing board is one of the main, equipment of Draughtsman. It is used for supporting the, drawing paper/tracing paper for making drawings. It is, made of well seasoned wood strips of about 25 mm thick, or masonite, free from knots and warping. It should be, softer enough to allow insertion and removal of drawing, pins. Two battens are fastened to the board by screws, in, slotted joints. They prevent warping and at the same time, permit expansion and contraction of the strips due to the, change of moisture in the atmosphere., , Sl. No., , Designation, , Blade length, , 1, , T0, , 1500, , 2, , T1, , 1000, , 3, , T2, , 700, , 4, , T3, , 500, , The ‘T’ square is used with its head against the ebony edge, of the drawing board to draw horizontal lines, parallel lines, and to guide/hold the setsquares, stencils etc., Fig 2b shows how the ‘T’ square is used., ‘T’ square should never be used as a hammer or as guide, for trimming papers, , One of the shorter edges of the drawing board, is provided, with an “ebony edge” (hard wood) fitted perfectly straight., Standard drawing boards are designated as follows as per, IS:1444-1989., Sl. No., , Designation, , Size (mm), , 1, , D0, , 1500 x 1000 x 25, , 2, , D1, , 1000 x 700 x 25, , 3, , D2, , 00 x 500 x 15, , 4, , D3, , 500 x 350 x 15, , The working edge (ebony) must be straight., Now-a-days the drawing boards are available with laminated, surfaces. The flatness can be checked by placing a, straight edge on its surface. If no light passes between, them, the surface is perfectly flat., ‘T’ Square: It is of ‘T’ shape, made of well seasoned wood., It has two parts., head and blade. One of the edge of the, blade is the working edge. The blade is screwed to this, head such that the working edge is at right angle to head., (Fig 2a), The standard ‘T’ square are designated as follows with, dimensions shown in mm; as per IS:1360-1989., , Drafting in the machine (Fig 3): It serves the functions of, a Tee square, set square, protractor and scale. They come, in different sizes and a pattern called ‘Pantagraph’ type. It, is fitted on the top left side, edge of the drafting board,, mounted on an adjustable frame or table. It requires large, area of working place. The angle of the drafting board can, be adjusted by pedal operating system. There are two, counter weights to balance the angular position of the, board and the drafting head. It is more suitable for production, drawing office., , 9, , Copyright Free. Under CC BY License.

Page 20 :

On the other end, a protractor head H with swivelling and, locking arrangement is fitted with two scales at right, angles., The protractor head has a spring loaded clutch relieving, handle, which rotates and locks at 15 0 intervals, automatically. For setting any angle other than multiples of, 150, the clutch spring is released and by rotating the centre, knob, the zero line is set to the required angle and the, friction clutch knob is tightened. It is capable of rotating, 1800, thereby any angle can be set., The scales are bevelled on both sides, graduates to 1:1 &, 1:2., They can be reversed with the help of dovetail slide, fitting., There is a fine adjusting mechanism on the drafting head, to set the scale parallel to the edge of the board. The scales, also can be adjusted if there is any error in measuring 900, between them., Mini drafter is an important device used for making drawing, quickly& accurately. This instrument has the combination, of T-square, setsquare, protractor and scales, it helps to, draw the drawings at a faster rate. (Fig 4,5 & 6), , 10, , Erasing shield: When, on a drawing, if a part of a line or, some lines among many other lines need to be erased or, modified, in normal way of erasing will damage the other, nearby lines. In such a situation an erasing shield is, effectively useful. It is a thin metallic sheet having small, openings of different sizes and shapes. A suitable opening, is aligned to the line to be erased and the line is removed, by the eraser. (Fig 7), , Engineering Drawing : (NSQF) Exercise 1.2.05, , Copyright Free. Under CC BY License.

Page 21 :

For Engineering Trades, Engineering Drawing, , Exercise 1.2.06, , Drawing instruments - Setsquares, protractor and scale, Set square (IS:1361-1988): Transparent celluloid /Plastic, setsquares are preferred and are commonly used rather, ebonite ones. They are two in number, each having one, corner with 90°. The setsquare with 60°-30° of 250 mm long, and 45° of 200mm long is convenient for use. Setsquares, sometimes loose their accuracy due to internal strains. So, they should be tested periodically. (Fig 1), , The angles can be set or measured from both sides,, aligning the reference line and point ‘0’ with the corner point, of the angle., Figure 3 shows how to read or set the angle. Protractor can, also be used to divide a circle or drawing sectors., , French curves, , Sometimes set squares have french curves. Set squares, are used to draw all straight lines except horizontal lines., It is convenient to draw horizontal lines using Mini drafter., With the help of Mini drafter and manipulating the 45°, 30°60° setsquares, angular lines in the multiples of 15°;, Parallel lines to a given inclined line and perpendicular to, can be drawn., , These are made in many different shapes, normally come, in sets of 6,12,16 etc. French curves are best suited to draw, smooth curves/ arcs (which cannot be drawn by a compass), with ease. To draw a smooth curve using french curve first, set it by trial against a part of the line to be drawn, then shift, it to the next portions., Each new portion should fit atleast three points on the curve, just drawn. It should be seen that the curve (radius) is, increasing or decreasing smoothly and no corner should be, formed on the curve(Fig 4)., , Set squares with graduated, bevel edge and french curve, openings are preferable. They are also used to draw, smooth curves. Setsquare should never be used as guide, for trimming papers., Scales: Scales are used to transfer and or to measure the, dimensions. They are made of wood, steel, ivory, celluloid, or plastic, stainless steel scales are more durable. different, types of scales used are shown in Figs 1,2 & 3. They are, either flat, bevel edged or triangular cross-section. Scales, of 15cm long, 2cm wide or 30cm long 3.5cm wide flat, scales are in general use. Thin section or bevel edged, scales are preferred over thick flat scales. Parallax error will, be nil or least while using thin / tapered edge scales. (Fig2), , Fig 5 show how to use the french curve and draw a smooth, curves. They are made of transparent celluloid (no bevel, edge)., , Protractor: Protractor is an instrument for measuring, angles. It is semi-circular or circular in shapes and is made, of flat celluloid sheet., 11, , Copyright Free. Under CC BY License.

Page 22 :

For Engineering Trades, Engineering Drawing, , Exercise 1.2.07, , Drawing Instruments box and pencils, The quality of a good drawing does not only depend on the, talent of the craftsmen but also on the quality of instruments, he uses., Drawing instruments are generally sold in sets in boxes,, but they are also available separately. The main parts of, high grade instruments are generally made of nickel or, brass. They must be rust proof. Tool steel is used for, making the blades of the inking pen, bow instruments and, various screws., An instrument box contains the following: (Fig 1a to h), •, , Large compass (with attachment facility) (a), , •, , large divider (b), , •, , Bow compasses, bow divider (c), , •, , Lengthening bar (d), , •, , Pen point for attachment (e), , •, , Screw driver (f), , •, , Lead case (g), , •, , Liner (h), , Large compass (Fig 2) : It has a knee joint in one leg that, permits the insertion of pen or pencil point or attaching, lengthening bar with pen or pencil point attached to it. It is, used for drawing large circles/arcs also for taking large, measurements. The pin on the other leg can be swivelled, to vertical position when drawing large circles, while, drawing the circles of arcs it should be held in such a way, that the needle point leg and pencil point leg should be bent, so as to make perpendicular to the paper., , As a rule while drawing concentric circles,, small circles should be drawn first before the, centre hole gets worn., Large divider: It is used to transfer dimensions and, dividing lines into a number of equal parts. Divider with, adjustable joints is preferable rather than plain legs. (Fig 3), , 12, , Copyright Free. Under CC BY License.

Page 23 :

Bow instruments: Bow pencil and bow pen compass are, used for drawing circles of approximately 25 mm radius., Bow divider is used for marking or dividing smaller spaces., There are two types (i) Integral legs with spring action (4e), (ii) two legs held with a curved spring on top with handle on, it., , Inking pen or liner or ruling pen (Fig 6): It is used to ink, the straight lines drawn with the instruments but never for, free hand lines or lettering., , Bow instruments may have adjusting wheel and nut. To, draw circles, it is better to mark the required distance, separately and set the instruments and check. Then only, the circles or arcs should be drawn on the drawing., Fig 4 shows different types of bow instruments. Adjustment, should be made with the thumb and middle finger. The, instrument is manipulated by twisting the knurled head, between the thumb and finger., , Lengthening bar (Fig 7): To draw larger circles, it is fitted, to the compass. The pencil point or pen point is inserted, to its end., , Replaceable spare pencil, pen and needle points for, compass are available in the instrument box., Screw driver (Fig 8): Used for adjusting the screws of the, instruments., , Lead case (Fig 9): Lead case is the box for holding the, pencil leads., Drop spring bow pencil and pen (Fig 5): Drop spring bow, pencil and pen are designed for drawing multiple identical, small circles. Example: rivet holes, drilled/reamed holes., The central pin is made to move freely up and down through, the tube attached to the pen or pencil unit. It is used by, holding the knurled head of the tube between thumb and, middle finger while the index finger is placed on the top of, the pin. The pin point is placed on the centre point of the, circle to be drawn (Fig 5) and pencil or pen is lowered until, it touches paper. The instrument is turned clockwise and, the circle is drawn., , Pin, Clip, Cello tape: Drawing sheet should be fastened, on to the drawing board firmly on temporary basis so that, it does not shake during preparing drawing. For this, purpose the pins, clips and cello tapes are used (Fig 10), , Pencils, Grade and Selection, Pencils (Fig 11): In drawing office, standard pencils (lead, encased in wood) and semi-automatic pencils are made, use. Pencil leads are made of graphite with kaolin (clay) of, varying proportion to get the desired grades. More the, kaolin higher the hardness., Grades of pencils: Pencils are graded according to the, hardness or softness of the lead., , Engineering Drawing : (NSQF) Exercise 1.2.07, , Copyright Free. Under CC BY License., , 13

Page 24 :

In summer the pencil leads become softer due to rise in, temperature, so slightly harder pencils can be made use of, softer grade pencils are used on smooth surfaces for, lettering and arrow head. During rainy season or when, humidity is more, the drawing paper expands and wrinkles, form, pencil leads become harder. So softer pencils are to, be used. Whatever may be grade of pencil you use, always, prefer quality pencils/leads viz., Venus, Kohinoor, Apsara, etc., For better line work, i.e., dense black lines, prefer paper, which is not having too much teeth (roughness)., Hardest pencil is 9H grade and softest pencil is 7B, grade. Selection of grade of pencils depends on the type, of line work required and paper on which it is used., Softer lead pencils are used to produce thicker and darker, line work, but they wear out quickly. Medium grade of H,, 2H are used for general line work as well as for lettering., Harder grade leads produce lighter and thinner lines. Most, construction line work is done with 4H, 5H and 6H pencil, leads, producing thin but also sufficiently dark by exerting, pressure. Depending upon the individuals touch and the, style of writing, right pencil may be selected., For any drawing on drawing paper or tracing paper, lines, should be black, particularly drawings which are to be, reproduced. For this purpose, the pencil chosen must be, soft enough to produce jet black lines as well hard enough, not to smudge easily. The point should not crumble under, normal working pressure. The pencils should not be hard, and cut grooves on the p0aper while drawing with normal, pressure, Pencils H, 2H or 3H depending upon the paper, (quality) and weather conditions are selected., , 14, , Selection of pencils: Pencil grades vary from one brand, to another brand. Select the grades of the pencil depending, upon the type of line work. For construction lines, you can, choose 2H or 3H, for lettering and object lines grade H, pencils. In general H, HB and 2H are used., H medium hard, HB medium soft, 2H hard, Pencils used for drawing are always hexagonal in cross, sections as they do not roll easily even when they are, placed on slope surfaces. Its cross section helps in, rotating the pencil, while drawing lines, to give uniform line, thickness., Now-a-days automatic (Mechanical) pencils or clutch, pencils are available in different sizes (lead dia 0.3, 0.5, 0.7, or 0.9 mm). They are easy to handle as there is no, reduction of holding length pencil leads can be replaced, as, per required grade of hardness. They produce lines of, uniform width without sharpening. (Fig 11), , Engineering Drawing : (NSQF) Exercise 1.2.07, , Copyright Free. Under CC BY License.

Page 25 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.08, , Free hand drawing of lines, Sketch by free hand, , 2 To draw vertical lines in thick and thin. (Fig 2), , Follow the procedure and sketch the following practice, No.1 to 17 in A3/A4 sheets., , •, , Sketch two horizontal thin guide lines AB & CD., , •, , Mark points on the horizontal lines AB & CD, 5 mm, intervals., , •, , Sketch the line in free hand between the two points with, thick and thin alternatively., , Practice, 1 To draw horizontal thick and thin lines. (Fig 1), •, , Sketch two vertical thin guide lines AB & CD., , •, , Mark points on the vertical lines AB & CD, 5 mm, intervals approximately., , •, , Draw the lines by free hand between the two points, sketch thick and thin alternatively., , Vertical lines are drawn from top to bottom., (Fig 2B), , Lengthy lines can be drawn with the forearm, motion and short lines are drawn with the wrist, motion., Keep uniform pressure while sketching., Horizontal lines are drawn from left to right., (Fig 1B), While sketching straight lines between two, points keep your eyes on the point to which the, line is to go rather than the point of pencil., Avoid of drawing whole length of line in one, single stroke., Prevent using eraser often., , 3 Sketch the inclined lines as shown in figure with, thick and thin lines. (Fig 3), •, , Sketch two axis AB & CD., , •, , On the horizontal and vertical axis AB and CD, mark, points with 5 mm intervals., , •, , Draw thick and thin lines in the direction as shown in the, figure alternatively., 15, , Copyright Free. Under CC BY License.

Page 26 :

Inclined lines running upward are drawn left to, right i.e bottom to top. (Fig 3B), The pencil point need not to be too sharp., Hold the pencil freely and not close to the point., It is better that the pencil can be hold 30 mm, away from the tip of the pencil lead., , 5 Sketch the plane figure as shown. (Fig 5), •, , Sketch a square box of 30 mm side in thin lines., , •, , Mark off the dimensions as shown in figure, approximately., , •, , Thick the required lines., , •, , Erase the unwanted lines and complete the figure., , 6 Sketch the plane figure as given. (Fig 6), •, , Form a square box of 30 mm side in thin lines., , •, , Set of the dimensions and angle as shown in figure., , •, , Draw the lines and remove the unwanted lines., , •, , Complete the figure., , 4 Sketch the given plane figure as shown. (Fig 4), •, , Draw the horizontal straight line in free hand and mark, off 60 mm approximately., , •, , Draw a vertical straight line of 60 mm long from the base., , •, , Draw horizontal & vertical parallel lines and form a, square box of 60 mm sides., , •, , Darken the lines of the surfaces in figure using thick, line., , •, , Erase the unwanted lines and complete the plane, figure., , 7 Sketch a circle of diameter 50 mm. (Fig 7), , Do not place any dimensions in the figure., , •, , Sketch a square box of given diameter, mark the mid, points and join the mid points of horizontal and vertical, sides. (Fig 7A), , •, , Join the corners (diagonals) of the square box and mark, the radius of the given diameter. (Fig 7B), , 16, , Engineering Drawing : (NSQF) Exercise 1.3.08, , Copyright Free. Under CC BY License.

Page 27 :

•, , Join all the 8 points by a smooth curve and complete the, circle. (Fig 7C), , •, , Erase the unwanted lines and darken the curve. (Fig 7D), , •, , Sketch a rectangular box of 85 mm x 60 mm., , •, , Mark of the dimensions as shown in figure., , •, , Follow the method given in Ex.7,8 and sketch the circle., , Side of the square = Diameter of the circle, , •, , Thick the required lines., , Radius of circle = Half of the square side., , •, , Erase the unwanted lines and complete the figure., , 10 Sketch the blank shown in figure. (Fig 10), •, , Sketch a rectangular box of 75 mm x 60 mm as is figure., , •, , Mark the other dimensions as shown in figure., , •, , Thick the required lines of the template., , •, , Erase the unwanted lines and complete the figure., , 8 Sketch the template as shown in figure. (Fig 8), •, , Sketch a square box of 60 mm side., , •, , Sketch the semi-circle on right side of the square as, shown in figure., , •, , Darken the lines as in figure and complete the shape of, the template., , 11 Sketch the curved shape blank plane figure as, given in figure. (Fig 11), •, , Draw a vertical straight line and horizontal straight line, intersecting each other at right angles., , •, , Mark off 20 mm on either side of the vertical line from the, intersecting point of the straight lines., , •, , Sketch semi-circle of R 20 mm top and bottom as in, figure., , •, , Join the two semi-circles with vertical lines., , •, , Sketch the three circles of 10 mm., , •, , Darken the lines and complete the figure., , 9 Sketch the given figure. (Fig 9), , Engineering Drawing : (NSQF) Exercise 1.3.08, , Copyright Free. Under CC BY License., , 17

Page 28 :

12 Sketch the template as shown. (Fig 12), , •, , Darken the squares as per exercise drawing., , •, , Draw a vertical straight line., , •, , •, , Draw two horizontal straight lines intersecting the, vertical line keeping 40 mm away., , Rub off the thin construction lines and complete the, exercise., , •, , Sketch the two curves as in figure and join the curves., , •, , Erase the unwanted lines and complete the figure., , 15 Draw the pattern of sides 70 mm and 35 mm by free, hand proportional to the size. (Fig 15), •, , Draw a rectangle proportionately., , •, , Join the diagonals., , •, , Draw parallel lines to the diagonals approximately at 10, mm distance from each other as shown in the exercise., , 13 To sketch an ellipse of given major and minor, axis. (Fig 13), •, , Draw a horizontal and a vertical line intersecting each, other at right angles., , •, , On the horizontal line mark the half of the major axis on, either side of the centre and similarly half of the minor, axis on the vertical line., , •, , Through these points draw horizontal and vertical parallel, lines and form a rectangular box., , •, , Sketch the small arcs with thin lines., , •, , Join the other portion by smooth curve and complete the, ellipse., , 16 Draw a square ABCD of side 80 mm approximately, by free hand. (Fig 16), •, , Join diagonals (thin line)., , •, , Draw the perpendicular bisectors from two adjacent, sides (free hand)., , •, , On side AB, mark EF = 20 mm., , •, , Join E and F to centre of square., , •, , Draw a line at a distance 10 mm parallel to EF., , •, , The parallel line cuts the inclined lines EO and FO at G, and H., , •, , Join GH, GE and HF., , •, , Follow the procedure and draw trapeziums similar to, EFHG on the remaining three sides., , •, , Join the lines shown in the Fig 16 and rub off the thin line, and finish the drawing., , 14 Draw the pattern of 50 mm side by free hand., (Fig14), •, , Draw a square by free hand., , •, , Divide one horizontal and one vertical side into each ten, equal parts., , •, , Draw a thin horizontal and vertical line through the parts, marked., , 18, , Engineering Drawing : (NSQF) Exercise 1.3.08, , Copyright Free. Under CC BY License.

Page 29 :

17 Sketch the given pattern by free hand. (Fig 17), •, , Mark the mid point of the line AB., , •, , Draw free hand circles of 35 and 50 on the mid point, of the vertical line., , •, , Draw two circles 20 mm using A and B are the centres., , •, , Draw two circles of 10 from points A and B., , •, , Complete the drawing after removing unwanted lines., Plane figures for which the procedure are not, given follow the constructional methods given, in Skill sequences and the Procedures for, plane figures and complete them., , Vertical line (Fig 21a): Lines which are perpendicular to, horizontal lines are called vertical lines. It can be treated as, a line along the plumb line of the plumb bob or parallel to, a plumb line. (Fig 21b), , Inclined line or Oblique line: A straight line which is, neither horizontal nor vertical is called an inclined line., (Fig22), , Types of lines, A point represents a location in space, having no width or, height. It is represented by drawing intersection of lines or, a dot. (Fig 18), , Curved line: It is the path of a point which always change, its direction. Examples of curved lines are shown in (Fig23)., , Line is the path of a point when it moves. It has no thickness, and are of two types:, •, , Straight line, , •, , Curved line, , Parallel lines: They are the lines with same distance, between them. They may be straight lines or curved line, Parallel lines do not meet when extended. (Fig 24), , Straight line: It is the path of a point when it is moving in, a particular direction. It has only length and no width.(Fig19), Also a straight line is the shortest distance between two, points. Straight line, depending on its orientation are, classified as Horizontal, Vertical and Inclined or Oblique, line., Perpendicular lines: When two lines meet at 90°,the, two lines are said to be perpendicular to each other. One, of the lines is called as reference line. (Fig 25), , Horizontal line (Fig 19): Horizontal lines are those which, are parallel to a horizontal plane. Example of horizontal, plane is the surface of a still water. (Fig 20), Engineering Drawing : (NSQF) Exercise 1.3.08, , Copyright Free. Under CC BY License., , 19

Page 30 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.09, , Free hand drawing - Polygons and ellipse, Names of polygons: Polygons are named in terms of their, number of sides as given below: (Fig 1), , S.No, 1, 2, 3, 4, 5, 6, 7, 8, , •, , Pentagon inscribed polygon. (Fig 2), , •, , Name, , No. of sides, , Pentagon – a, Hexagon – b, Heptagon – c, Octagon – d, Nonagon – e, Decagon – f, Undecagon – g, Duodecagon – h, , Five sides, Six sides, Seven sides, Eight sides, Nine sides, Ten sides, Eleven sides, Twelve sides, , Pentagon circumscribed polygon. (Fig 3), , -, , O as centre and OF as radius describe a circle of dia, 50 mm., , -, , Draw the line DF vertically beyond the top of the, circle., , 20, , Copyright Free. Under CC BY License.

Page 31 :

-, , Divide the circle into 10 equal parts. (Twice as many, equal parts as the number of sides), , -, , Points 1,3,5,7 and 9 are the tangent points of the, pentagon., , -, , Join 02, 04, 06, 08, 010 and extend to a convenient, length., , -, , Draw a tangent to the circle through point 1 (F)., , •, , Hexagon regular heptagon (Fig 8), , •, , Semi-circular method heptagon (Fig 9), , •, , Hexagon perpendicular bisector method. (Fig 10), , •, , Special method octagon (Fig 11), , Hexagon, •, , The sum of the interior angle and the corresponding, external angle is 180°. (Fig 4), , •, , Hexagon arc method (Fig 5), , •, , Hexagon arc method (Fig 6), , •, , Hexagon across flats method (Fig 7), , Engineering Drawing : (NSQF) Exercise 1.3.09, , Copyright Free. Under CC BY License., , 21

Page 32 :

Freehand drawing of ellipse, Elements of an ellipse (Fig 1), , •, , String and pins method, , •, , Paper trammel method, , •, , 4 centre method, , •, , Conjugate diameters method, , •, , Eccentricity method, , Practical applications: In general, a circle in a pictorial, drawing is represented by an ellipse. The use of elliptical, shape is rarely used for engineering applications. Ellipse, is dealt extensively in mathematical books. Elliptical, shape is adopted for better aesthetics., Major axis: It is the longest distance which passes, through the centre, at right angle to the fixed lines called the, directrix. AB is the major axis., , 1 Construct an ellipse by concentric circle method., Major axis 80 mm. Minor axis 40 mm. (Fig 2), , Minor axis: It is the maximum distance which bisects the, major axis at right angle. It will be parallel to the directrix., CD is the minor axis., Directrix: It is a straight line perpendicular to the major, axis., Focus: When an arc is drawn with C or D as centre and, radius equal to half the major axis i.e, , , it is cut at two, , points F1 and F2 on the major axis. F1 and F2 are the focal, points of an ellipse F1 or F2 is the focus. The sum of the, distances from F1, F2 to any point on the curve i.e., F1P +, F2P is always constant and equal to the major axis., , •, , Draw the major axis AB (80 mm) and minor axis CD, (40 mm), bisecting at right angle at 0., , •, , Eccentricity: The ratio between the distances from the, vertex to focus and vertex to the directrix is called the, eccentricity and is always less than one., , '0' as centre OA and OC as radius, draw two, concentric circles., , •, , Draw a number of radial lines through '0' (say 12), cutting the two circles., , AF1/A0 is less than one., , •, , Mark the points on the outer circle as a,b,c., , It can also be stated as the ratio of the distance from focus, onto any point on the curve, say P1 and the perpendicular, distance of P1 from the directrix. i.e P1F1/P1M is a, constant., , •, , Similarly mark the corresponding intersecting points, on inner circle as a',b',c'., , •, , From points such as a,b,c... draw lines parallel to, minor axis., , •, , From points such as a', b',c'.... draw lines parallel to, the major axis to intersect with the corresponding, vertical lines at points P1, P2,P3.... etc., , •, , Join all these points with a smooth curve by free, hand or using "french curve" and form the ellipse., , •, , To find the 'Foci' - with half the major axis (a) as, radius and with 'C' on the minor axis as centre, draw, an arc cutting the major axis, at two points, mark, them as F1F2 the focus points of the ellipse., , Focal radii: The distances from point P on the curve to the, focal points F1 and F2 are called focal radii. Sum of the focal, radii is equal to the major axis., , Vertex: The end points of the major axis on the curve are, called vertex. (A, B), Tangent and normal to an ellipse: Normal is the line, bisecting the angle F1PF2 in Fig 1. Tangent in a line at 90°, to the normal and touching the ellipse., Directrix, axis, focus, vertex and tangent are the elements, common to ellipse, parabola and hyperbola., All ellipse can be constructed in different methods:, •, , Rectangle method (oblong), , •, , Concentric circle method, , •, , Arcs method, , 22, , 2 Construct an ellipse by four centre method - Major axis, = 80 mm and Minor axis = 40 mm - Type A. (Fig 3), , Engineering Drawing : (NSQF) Exercise 1.3.09, , Copyright Free. Under CC BY License.

Page 34 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.10, , Free hand drawing of geometrical figures and block with dimension, Free hand sketching: Apart from making drawing using, instruments, often craftsman will be required to make, drawings by free hand., Free hand sketching is an easiest method to express the, shape of a piece part or a component by an engineer or, craftsman., , Materials for free hand sketching: A4 size sheet, (preferably a pad instead of loose papers) pencils of soft, grade. Example H, HB, and a good quality eraser are the, only materials required. For drawing different darkness,, the pencil points should be sharpened to conical shape., , Here are a few examples of situation wherein free hand, sketches will have to be necessarily made., •, , On the site sketching for production/maintenance., , •, , Recording of initial idea of a design., , •, , For quick exchange of ideas among designer,, draughtsman, technician., , •, , Urgency (free hand sketching takes less time), , To make free hand drawings/sketches, the craftsman has, to acquire new skills and one has to have considerable, practice to be able to make good free hand sketches., Ability to make good free hand sketches is an asset to any, craftsman., Free hand sketches are not usually made to scale., However, they should be as nearly to the proportions as, possible., Cube (Fig 2), , Rectangular block (Fig 4), , Square block (Fig 5), Square block (Fig 3), , Cylinder (Fig 6), , 24, , Copyright Free. Under CC BY License.

Page 35 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.11, , Free hand drawing of transferring measurement from the given object, , 25, , Copyright Free. Under CC BY License.

Page 36 :

26, , Engineering Drawing : (NSQF) Exercise 1.3.11, , Copyright Free. Under CC BY License.

Page 37 :

Transfer all the dimensions from the figures 1 to 10 of page nos.25 & 26 to the given objects below, , Engineering Drawing : (NSQF) Exercise 1.3.11, , Copyright Free. Under CC BY License., , 27

Page 38 :

28, , Engineering Drawing : (NSQF) Exercise 1.3.11, , Copyright Free. Under CC BY License.

Page 39 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.12, , Free hand drawing of solid figures, cubes, cuboids, cone, prism, pyramid,, frustum of cone with dimensions, Cube (Fig 1), , •, , Similarly draw two more lines parallel to AB and AE, mark G interesting point from F and C., , •, , Draw lines parallel to DC and FG Draw lines parallel to, DF and GC., , •, , Join all the points., , Cylinder (Fig 3), , •, , Draw square of a, b, c and d., , •, , Draw 300 lines from point b, c and d for the length of, 25mm., , •, , Mark point g from b, f from c and e from d as shown in, figure., , •, , Joint all points., , Rectangular prism (Fig 4), , Cuboid (Fig 2), , Square Prism (Fig 5), Draw the isometric drawing of a cuboid of base 30 mm x, 40 mm and the height 20 mm. (Fig 2), Drawthe three isometric axes through point ‘A’., •, , Mark AB = 40mm, AE = 30mm and AD= 20mm, representing the three sides of cuboid., , •, , Draw two vertical lines parallel to the line EF and BC, from point E and B respectively., , 29, , Copyright Free. Under CC BY License.

Page 40 :

Triangular Prism (Fig 6), , base. All the slant triangular faces join at a common point, called APEX., Similar to prisms, pyramids also are known by the shape, of their base viz triangular, square, rectangular, pentagonal,, hexagonal etc. The imaginary line joining the centre of the, base to the apex is called the AXIS., Fig 10 shows some pyramids and their views., , Pentagonal prism (Fig 7), , Hexagonal prism (Fig 8), , When a semi-circle revolves about its diameter a sphere is, generated. A sphere has no flat surface. (Fig 11D), , Cone: When a right angled triangle revolves about one of, its side forming the right angle, a cone is generated. Cone, forming has a circular face and a slant curved surface., (Fig9), , The term solids of revolution is a mathematical concept and, a physical requirement in geometry., Frustums: Pyramid/cone is cut parallel to the base and the, top portion is removed. The remaining bottom portion is, called frustum of a pyramid/cone., If the cutting plane is at an angle to the axis/base, of the, pyramids or cone they are called "Truncated pyramids or, cones"., Fig 12&13 shows frustums and truncated pyramids., All items we use are solids. Their shapes may confirm to, individual geometrical solids like prisms, cones or other, combination., , Pyramids: Pyramids are polyhedron solids having a base, surface whose shape may be triangular, square or polygon, and as many slant triangular faces as there are sides in the, 30, , Figure 13 shows some items., Draw the isometric view of a cone whose base diameter 40, mm and height 60 mm when its base rest on horizontal, plain surface. (Fig 14), , Engineering Drawing : (NSQF) Exercise 1.3.12, , Copyright Free. Under CC BY License.

Page 41 :

•, , From ‘0’ draw tangents to the isometric circle of the, base and complete the required isometric view of the, cone. (Fig 14c), , Draw the isometric views of a hexagonal pyramid of side, base 30 mm and height 75 mm given its position as under:, , •, , •, , Its base resting on HP and the edge of the base parallel, to VP. (Fig 15), , •, , Draw the top view and front view of the pyramid (true, scale) and enclose the top view in the rectangle PQRS., (Fig 15a), , •, , Draw the parallelogram with two of its adjacent edges, at 300 to the horizontal. (Fig 15b) PQ = Isometric length, of pq and PS = Isometric length of PS., , •, , Draw an isometric hexagon ABCDEF in the, parallelogram PQRS. (Fig 15b), , Draw the front view and top view of the cone in the true, scale as shown in the Fig 14a., , •, , Draw the isometric view of the base circle, (by four, centre method) (Fig 14b), , •, , Mark the centre ‘O’ and draw a vertical line from point, ‘O’ of height to 75 mm in isometric scale., , •, , Mark the centre and draw vertical line 0.01 such that 0.01, equals to 60 mm in isometric scale., , •, , Join ‘O’ with ABCDE&F to complete the required, isometric projection of the hexagonal pyramid. (Fig15c), , Engineering Drawing : (NSQF) Exercise 1.3.12, , Copyright Free. Under CC BY License., , 31

Page 42 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.13, , Freehand drawing of hand tools and measuring tools used in common trades, Hand Tools, Files (Fig 1), , Hacksaw (Fig 6), , a Curved cut file, , b Rasp cut file, , c Single cut file, , d Double cut file, , Ball pein hammer (Fig 7), , Scriber (Fig 2), Chisel (Fig 8), , Divider (Fig 3), , ‘C’ clamp (Fig 9), , Outside caliper (Fig 4), , Screw driver (Fig 10), , Inside caliper (Fig 5), , 32, , Copyright Free. Under CC BY License.

Page 43 :

Bench vice (Fig 11), , Hammers (Fig 16), , Measuring Tools, Steel rule (Fig 17), Centre punch (Fig 12), , Try square (Fig 18), , Cutting plier (Fig 13), , Vernier caliper (Fig 19), , Open end spanner (Fig 14), , Micrometer (Fig 20), , Marking gauge (Fig 15), Vernier height gauge (Fig 21), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 33

Page 44 :

Feeler gauge (Fig 22), , Combination set (Fig 26), , Bevel protractor (Fig 23), , Vernier depth gauge (Fig 27), , Slip gauge box (Fig 24), , Depth micrometer (Fig 28), , Sine bar with dial gauge (Fig 25), , 34, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 45 :

Freehand drawing of hand tools and measuring tools used in electrician,, electronics mechanic and wireman trades, Screw driver (Fig 1), , Instrument screw driver (Fig 4), , Screw driver interchangeable tips (Fig 5), , Screw driver with cross type tips (Fig 2), , Special type screw driver (two rectangular recesses) (Fig6), Screw tips aided screw heads (Fig 3), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 35

Page 46 :

Special type screw driver (two round recesses) (Fig 7), , Melted solder blocking flux cores (Fig 10), , Pliers (Fig 8), , Soldering iron (Fig 11), , Ratchet brace (Fig 12), , Analog multimeter (Fig 9), Neon Tester (Fig 13), , 36, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 47 :

Gimlet (Fig 14), , Electric drilling machine (Fig 18), , Bradawl & poker (Fig 15), , Hand drill (Fig 19), , Electrician’s knife (Fig 16), , Mallet (Fig 17), Rawl plug tool (Fig 20), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 37

Page 48 :

Freehand drawing of hand tools and measuring tools used in mechanic, motor vehicle and mechanic diesel trades, Spanners (Fig 1), , Adjustable spanner (Fig 3), , Socket spanner (Fig 4), , Sliding ‘T’ handle socket spanner (Fig 2), , 38, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 49 :

Pliers (Fig 5), , Socket extension bars (Fig 7), , Round nose plier (Fig 8), , Cutting plier (Fig 6), , Stillson pipe wrench (Fig 9), , Pipe cutter (Fig 10), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 39

Page 50 :

Puller (Fig 11), , Piston ring expander (Fig 14), , Testing valve spring tension (Fig 15), , Valve spring compressor & valve grinder (Fig 12), , Connecting rod alignment fixture (Fig 16), , Wooden block & ring compressor (Fig 13), , 40, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 51 :

Freehand drawing of hand tools and measuring tools used in plumber, trade, Face wrench (Fig 1), , Mortar pan (Fig 5), , Bricklaying trowel (Fig 6), Hook wrench (Fig 2), , Jointing board (Fig 7), Spade (Fig 3), , Steel square (Fig 8), Pickaxe (Fig 4), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 41

Page 52 :

Spirit levels (Fig 9), , Chain pipe vice (Fig 14), , Line and pins (Fig 10), Pipe cutter (Fig 15), , Square and bevel (Fig 11), , Multi wheel chain pipe cutter (Fig 16), , Gin wheel (Fig 12), , Accurate tube bender (Fig 17), , Pipe vice (Fig 13), , Pinch-off tool (Fig 18), , 42, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 53 :

Freehand drawing of hand tools and measuring tools used in welder trade, Electrode holder (Fig 1), , A.C welding transformer (Fig 5), , Earth clamp (Fig 2), , Cable attachments (Fig 6), , Work cable attachments (Fig 3), , Cutting torch (Fig 7), , Goggles (Fig 4), , Regulator (Fig 8), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 43

Page 54 :

Freehand drawing of hand tools and measuring tools used in carpenter trade, Collapsible carpenter rule (Fig 1), , Try square (Fig 5), , Plumb bob (Fig 6), Folding rule (Fig 2), , Crow bar (Fig 7), Tape Measure (Fig 3), , Carpenter’s work bench (Fig 4), Marking knife or striking knife (Fig 8), , 44, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 55 :

Marking knife (Fig 9), , Coping saw (Fig 14), , ‘T’ - Bevels (or) bevel square (Fig 10), , Standard wire gauge (Fig 11), , Fret saw (Fig 15), , Compass saw (Fig 16), , Bow saw (Fig 17), , Panel gauge (Fig 12), , Steel scriber (Fig 18), , Cross cut saw (Fig 13), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 45

Page 56 :

Butt gauge (Fig 19), , Pairs of pincers (Fig 20), , Marking gauge (Fig 21), , Freehand drawing of hand tools and measuring tools used in foundryman trade, Trowels (Fig 1), , Cleaner or lifter (Fig 2), , Rammers (Fig 3 & 4), , 46, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 57 :

Spirit level (Fig 9), , Vent wire (Fig 5), , Hand bellow (Fig 10), , Draw spike (Fig 6 & 7), , Foundry brush (Fig 11), , Mallets (Fig 12), , Leveler (Fig 8), , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License., , 47

Page 58 :

Swab (Fig 13), , Riddle (Fig 16), , Water sprinkler (Fig 17), Hand shovel (Fig 14), , Runner and riser pins (Fig 15), , Smoothers (Fig 18), , 48, , Engineering Drawing : (NSQF) Exercise 1.3.13, , Copyright Free. Under CC BY License.

Page 59 :

For Engineering Trades, Engineering Drawing, , Exercise 1.3.14, , Freehand drawing of simple fasteners (bolts, nuts and rivets etc.) trade, related sketches, Hexagonal headed bolt (Fig 1), , Square nuts (Fig 5), , Square headed bolt (Fig 2), , Hexagonal nuts (Fig 3 & 4), , Dome nut and cap nut (Fig 6), , Collared nut (Fig 7), , 49, , Copyright Free. Under CC BY License.

Page 60 :

Types of rivets (Fig 8), , 50, , Engineering Drawing : (NSQF) Exercise 1.3.14, , Copyright Free. Under CC BY License.

Page 61 :

For Engineering Trades, Engineering Drawing, , Exercise 1.4.15, , Lines - Definition, types and applications in drawing as per BIS: 46-2003 and, classification of lines, Drawings are made up of different types of lines. Just as, language with alphabets and grammar., Lines of different thickness and features are used for, specific use (Fig 1 and 2)., , Technical drawings are drawn with different types of lines., By proper choice and application of lines product features, can be correctly defined in a drawing. Different types of, lines recommended for specific applications are given in, Table 1., , Table 1, Types of lines and their application, Lines, , Description, , General applications, See figure and other relevant figure, , Continuous thick, , A1, A2, , Visible outlines, Visible edges, , Continuous thin, (straight), , B1, B2, B3, B4, B5, B6, B7, B8, B9, , Imaginary lines of intersection, Dimension lines, projection lines or extension line, Leader lines, Hatching, Outlines of revolved sections in place, Short centre lines, Thread line, Diagonal line, , Continuous thin, free hand, , C1 Limits of partial or interrupted views &, sections, if the limit is not a chain thin, , Continuous thin, (Straight) with zig-zags, , D1, , Line (See figures), , Dashed thick, , E1, E2, F1, F2, , Hidden outlines, Hidden edges, Hidden outlines, Hidden edges, , Dashed thin, Chain thin, , G1 Centre lines, G2 Lines of symmetry, G3 Trajectories, , Chain thin, thick at ends, & changes of direction, , H1 Cutting planes, , Chain thick, , J1, , Indication of lines or surfaces to, which a special requirement applies, , Chain thin doubledashed, , K1, K2, , Outlines of adjacent parts, Alternative and extreme positions of, movable parts, Centroidal lines, Initial outlines prior to forming, Parts situated in front of the cutting plane, , K3, K4, K5, , 1 This type of line is suited for production of drawings by machines., 2 Although two alternatives are available, it is recommended that on any one drawing, only one type of line be used., Thickness of the line should be chosen according to the, size and type of the drawing from the following range., (IS:10714-1983) 0.18, 0.25, 0.35, 0.5, 0.7, 1, 1.4 & 2 mm., , In the above range, for craftsman 0.5 is preferred. The Table, 2 shows the 0.5 line range and other lines under this range., The numbers in right side of the lines refers the line, thickness in mm., 51, , Copyright Free. Under CC BY License.

Page 62 :

– without a dot or arrow head (Fig 5), , Table 2, , Hatching lines (B5): Hatching lines are the lines inclined, parallel lines. The minimum space between these lines, should be more than twice the thickness of the heaviest line, in the drawing. It is recommended that these spacings, should never be less than 0.7 mm. (Fig 4), For showing the limits of partial or interrupted views and, sections continuous thin free hand lines (C1) or continuous, thin straight lines with zig-zag (D1) are used. (Fig 6), All the views of a component drawn to one particular scale, should have the same range of line thickness., Types of lines: Ten types of lines are used in general, engineering drawing as per IS:10714-1983. Out of which, first four types of lines are continues lines of both thick and, thin. (Type A to D), Continuous thick line (A type) is used for drawing visible, outlines (A1) and visible edges (A2). (Fig 3) These lines are, also called as object lines., , Lines of type E to K in Table 1 are of the non-continuous, type. Some of these thin and some are thick. For hidden, lines both thick and thin dashes (E & F type) are available,, it is recommended that on any one drawing, only one type, of (Thick or thin) line be used. (Fig 7), , Continuous thin lines (B type): Continues thin lines are, used for many applications as stated in Table 1. A few, applications of B types of lines are shown in Fig 4., , Chain lines (Thin): Chain lines are used for drawing centre, lines of circles, cylinders etc. Same lines are also used to, show the axis of symmetry in symmetrical objects. To, save time and space a partial of a whole component is, drawn. The line of symmetry is identified at its ends by two, thin short parallel lines drawn at right angle to it. (Fig 8), , A leader line - B4 (Fig 4): A leader line is a line referring, to a feature (dimension, object, outline etc). A leader line, should terminate, – with a dot, – with an arrow head, 52, , Another method of representing symmetrical shape is to, extend the object lines beyond the axis of the symmetry., (Fig 9) In this case the short parallel lines described above, is omitted. The same lines are also used to show the, repetitions of features of a component. (Fig 10), For drawing a sectional view, plane of cutting is to be shown, in other view. Cutting plane (H1) in Table 1 is drawn with, thin chain, thick at ends and also at the places of direction, change. (Figs 11 & 12), , Engineering Drawing : (NSQF) Exercise 1.4.15, , Copyright Free. Under CC BY License.

Page 63 :

If thick chain lines (J1) in table 1 are drawn on a surface, it, indicates some special treatment/application on that, surface. (Fig 13), Chain thin double dashed (K) lines are applied for the, following:, K1, , -, , Outlines of adjacent parts (Fig 13), , K2, , -, , Alternative and extreme positions of moving, parts. (Fig 13), , K3, , -, , Centroidal lines (Fig 14), , Engineering Drawing : (NSQF) Exercise 1.4.15, , Copyright Free. Under CC BY License., , 53

Page 64 :

K4, , -, , Initial outlines prior to forming (Fig 13), , K5, , -, , Parts situated in front of the cutting plane, (Fig14), , 54, , Engineering Drawing : (NSQF) Exercise 1.4.15, , Copyright Free. Under CC BY License.

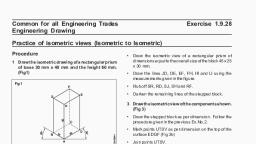

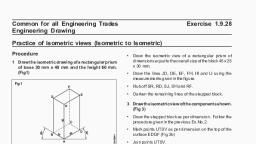

Page 65 :