Page 1 :

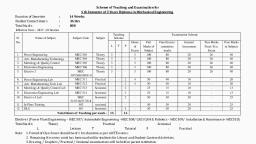

operate a CNC lathe., , operate a CNC milling machine., , diagnose common problems in CNC machines., explain the trends in the field of automation., , DETAILED CONTENTS, Introduction (06 Periods), , Introduction to NC, CNC & DNC, their advantages, disadvantages and applications,, Machine Control Unit, input devices, serial communication and Ethemet techniques,, selection of components to be machined on CNC machines, Problems with conventional, NC, New developments in NC, Axis identification, PLC Control and its components., , Constructional details and Tooling (08 Periods), Design features, specification Chart of CNC machines, use of slideways, balls, rollers and, coatings, motor and leadscrew, swarf removal, safety and guarding devices, various, , cutting tools for CNC machines, overview of tool holder, different pallet systems and, automatic tool changer system, management of a tool room., , Part Programming (12 Periods), , Part programming and basic concepts of part programming, NC words, part programming, formats, simple programming for rational components, part programming using canned, , CORRECTED AND APPROVED BY BOARD OF TECHNICAL EDUCATION,U.P,LUCKNOW IN MEETING HELD ON, 10.07.2019 @RASHMI SONKAR, , Page 177, , cycles, subroutines and do loops, tool off sets, cutter radius compensation and wear, compensation., , System Devices (08 Periods), , Actuators, Transducers and Sensors, Tachometer, LVDT, opto-interrupters,, potentiometers for linear and angular position, encoder and decoder, axis drives, open, loop system, close loop system., , Problems in CNC Machines (06 Periods), , Common problems in mechanical, electrical, pneumatic, electronic and PC components, of NC machines, diagnostic study of common problems and remedies, use of on-time, fault finding diagnosis tools in CNC machines., , Automation and NC system (06 Periods), , Role of computer in automation, emerging trends in automation, automatic assembly,, manufacture of magnetic tape, manufacture of printed circuit boards, manufacture of, integrated Circuits, Overview of FMS, Group technology, CAD/CAM and CIM., , CNC operations involved in Turning and Milling (10 Periods), , 7.1 Introduction to operations involved in turning machines- Facing OD and ID Rough, cut, Finish cut, Taper turning, Drilling, Threading, Grooving and cut-off (parting)., , 7.2 Introduction to operations involved in Milling-contouring, pocketing, Drilling,, Facing, Circular tools paths., , 7.3. Different terms like clearance, Retract, Feed plane, Depth of cut, lead in, lead out,, overlap., , 74 Simple programmes in Milling and Turning involving different operations., , LIST OF PRACTICALS, , 1, , Study the constructional details of CNC lathe., Study the constructional details of CNC milling machine., , Study the constructional details and working of:, Automatic tool changer and tool setter