Page 1 :

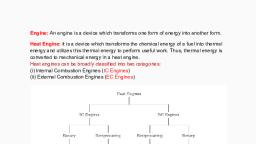

Automobile Engineering, ME602, Module 1, Types of automobiles, vehicle construction and layouts, chassis, frame and body, vehicle aerodynamics, IC engines- components, function and materials., Introduction of Automobile or Vehicle:, An Automobile is a self-propelled vehicle which contains the power source for its propulsion and is used for carrying passengers and goods on the ground, such as car, bus, trucks, etc., Types of Automobiles:, The automobiles are classified by the following ways:, On the Basis of Load:, Heavy transport vehicle (HTV) or heavy motor vehicle (HMV), Light transport vehicle (LTV), Light motor vehicle (LMV), On the Basis of Wheels :, Two wheeler vehicle, for example: Scooter, motorcycle, scooty, etc., Three wheeler vehicle, for example : Auto rickshaw,, Three wheeler scooter for handicaps and tempo, etc., Four wheeler vehicle, for example: Car, jeep, trucks, buses, etc., Six wheeler vehicle, for example: Big trucks with two gear axles., On the basis of Fuel Used:, Petrol vehicle, e.g. motorcycle, scooter, cars, etc., Diesel vehicle, e.g. trucks, buses, etc., Electric vehicle which use battery to drive., Steam vehicle, e.g. an engine which uses steam engine., Gas vehicle, e.g. LPG and CNG vehicles, where LPG is liquefied, On the basis of body style:, Sedan Hatchback car., Coupe car Station wagon Convertible., Van Special purpose vehicle, e.g. ambulance, milk van, etc., On the basis of Transmission:, Conventional vehicles with manual transmission, e.g. car with 5 gears., Semi-automatic, Automatic: In automatic transmission, gears are not required to be changed manually., On the basis of Drive:, Left hand drive, Right hand drive, On the basis of Driving Axle, Front wheel drive, Rear wheel drive, All wheel drive, Position of Engine:, Engine in Front - Most of the vehicles have engine in the front. Example : most of the cars,, Engine in the Rear Side Very few vehicles have engine located in the rear. Example : Nano car., Vehicle construction and layouts:, The main components of an automobile refer to the following components:, Frame,, Chassis,, Body,, Power unit,, Transmission system., An automobile is made up of mainly two units, these are Chassis and Body., “Frame” + “Base components” = “Chassis”, “Chassis” + “Body” = “Vehicle”, Frame :, The frame is the skeleton of the vehicle. It serves as a main foundation and base for alignment for the chassis., Types:, Conventional frame,, Semi integral frame;, Integral or untidiest frame., Chassis:, If the frame contains the base components it’s called as chassis. The components are like Engine, radiator, clutch, gearbox, silencer, road wheels, fuel tank, wirings, differential units, etc., Body:, Body is the superstructure of the vehicle and it is bolted to the chassis., Types:, Car,, Truck,, Tractor,, Delivery van,, Jeep,, Bus, etc., Vehicle Aerodynamics, Aerodynamics, Aerodynamics, from Greek ἀήρ aer (air) + δυναμική (dynamics), is a branch of dynamics concerned with studying the motion of air, particularly when it interacts with a solid object, such as an airplane wing., Aerodynamics is a sub-field of fluid dynamics and gas dynamics, and many aspects of aerodynamics theory are common to these fields. The term aerodynamics is often used synonymously with gas dynamics, with the difference being that "gas dynamics" applies to the study of the motion of all gases, not limited to air., Modern aerodynamics only dates back to the seventeenth century, but aerodynamic forces have been harnessed by humans for thousands of years in sailboats and windmills, and images and stories of flight appear throughout recorded history, such as the Ancient Greek legend of Icarus and Daedalus. Fundamental concepts of continuum, drag, and pressure gradients, appear in the work of Aristotle and Archimedes., Fundamental Concept, Understanding the motion of air around an object (often called a flow field) enables the calculation of forces and moments acting on the object. In many aerodynamics problems, the forces of interest are the fundamental forces of flight: lift, drag, thrust, and weight. Of these, lift and drag are aerodynamic forces, i.e. forces due to air flow over a solid body., Calculation of these quantities is often founded upon the assumption that the flow field behaves as a continuum. Continuum flow fields are characterized by properties such as velocity, pressure, density and temperature, which may be functions of spatial position and time., These properties may be directly or indirectly measured in aerodynamics experiments, or calculated from equations for the conservation of mass, momentum, and energy in air flows. Density, velocity, and an additional property, viscosity, are used to classify flow fields., IC engines- Components, Components of an Engine, Even though reciprocating internal combustion engines look quite simple, they are highly complex machines. There are hundreds of components that have to perform their functions satisfactorily to produce output power. There are two types of engines, viz., spark ignition (S1) and compression-ignition (CI) engine. Let us now go through the important engine components and the nomenclature associated with an engine., Terms connected with IC Engines:, Bore: The inside diameter of the cylinder is called bore., Stroke: The linear distance along the cylinder axis between two limiting position s is called stroke., Top Dead Center (T.D.C.): the top most position of the piston towards cover end side of the cylinder is called T.D.C., Bottom dead Center (B.D.C.): The lowest position of the piston towards the crank end side of the cylinder is called B.D.C., Clearance Volume: The volume contained in the cylinder above the top of the piston, when the piston is at top dead center, is called the clearance volume., Swept Volume: The volume swept through by the piston in moving between T.D.C. and B.D.C, is called swept volume or piston displacement., Compression Ratio: It is the ratio of Total cylinder volume to clearance volume., Definition of ‘Engine’, An engine is a device, which transforms one form of energy into another form. Normally, most of the engines convert thermal energy into mechanical work and therefore they are called ‘heat engines’., Engine Components, The major components of the engine and their functions are briefly described below:, Cylinder Block:, The cylinder block is the main supporting structure for the various components. The cylinder of a multi-cylinder engine is cast as a single unit, called cylinder block. The cylinder head is mounted on the cylinder block., The cylinder head and cylinder block are provided with water jackets in the case of water- cooling with cooling fins in the case of air-cooling. Cylinder head gasket is incorporated between the cylinder block and cylinder head. The cylinder head is held tight to the cylinder block by number of bolts or studs. The bottom portion of the cylinder block is called crankcase. A cover called crankcase, which becomes a sump for lubricating oil is fastened to the bottom of the crankcase. The inner surface of the cylinder block, which is machined and finished accurately to cylindrical shape, is called bore or face., Cylinder, As the name implies it is a cylindrical vessel or space in which the piston makes a reciprocating motion. The varying volume created in the cylinder during the operation of the engine is filled with the working fluid and subjected to different thermodynamic processes. The cylinder is supported in the cylinder block., Piston, It is a cylindrical component fitted into the cylinder forming the moving boundary of the combustion system. It fits perfectly (snugly) into the cylinder providing a gas-tight space with the piston rings and the lubricant. It forms the first link in transmitting the gas forces to the output shaft., Combustion Chamber, The space enclosed in the upper part of the cylinder, by the cylinder head and the piston top during the combustion process, is called the combustion chamber. The combustion of fuel and the consequent release of thermal energy results in the building up of pressure in this part of the cylinder., Inlet Manifold, The pipe which connects the intake system to the inlet valve of the engine and through which air or air-fuel mixture is drawn into the cylinder is called the inlet manifold., Gudgeon Pin, It forms the link between the small end of the connecting rod and the piston., Exhaust Manifold, The pipe that connects the exhaust system to the exhaust valve of the engine and through which the products of combustion escape into the atmosphere is called the exhaust manifold., Inlet and Exhaust Valves, Valves are commonly mushroom shaped poppet type. They are provided either on the cylinder head or on the side of the cylinder for regulating the charge coming into the cylinder (inlet valve) and for discharging the products of combustion (exhaust valve) from the cylinder., Connecting Rod, It interconnects the piston and the crankshaft and transmits the gas forces from the piston to the crankshaft. The two ends of the connecting rod are called as small end and the big end. Small end is connected to the piston by gudgeon pin and the big end is connected to the crankshaft by crankpin., Crankshaft, It converts the reciprocating motion of the piston into useful rotary motion of the output shaft. In the crankshaft of a single cylinder engine there is pair of crank arms and balance weights. The balance weights are provided for static and dynamic balancing of the rotating system. The crankshaft is enclosed in a crankcase., Piston Rings, Piston rings, fitted into the slots around the piston, provide a tight seal between the piston and the cylinder wall thus preventing leakage of combustion gases., Camshaft, The camshaft and its associated parts control the opening and closing of the two valves. The associated parts are push rods, rocker arms, valve springs and tappets. This shaft also provides the drive to the ignition system. The camshaft is driven by the crankshaft through timing gears., Cams, These are made as integral parts of the camshaft and are designed in such a way to open the valves at the correct timing and to keep them open for the necessary duration., Fly Wheel, The net torque imparted to the crankshaft during one complete cycle of operation of the engine fluctuates causing a change in the angular velocity of the shaft. In order to achieve a uniform torque an inertia mass in the form of a wheel is attached to the output shaft and this wheel is called the flywheel., Function and Materials, Steels: Steel is the most commonly used material in the internal combustion engine because of its overwhelming advantages: Relatively low cost, highest endurance strength of available materials, naturally hard surfaces, and strength and hardness controlled through a wide range of heat treatments. Although, steel does have several disadvantages: Subject to rapid corrosion, relatively low thermal conductivity, and not easily cast. With steel’s given properties, it is the preferred material for the composition of moving parts like crankshafts, gears, connecting rods, and auxiliary shafts as well as fasteners. In general, steels can be classified into six categories: Cast steels, stainless steels, low carbon steels (Carbon = 0.10 to 0.20%), medium carbon steels (Carbon = 0.30 to 0.50%), high carbon steels (Carbon = 1.0 %), and special steels., Carbon steels are generally used in machine elements which are small and in which stresses are low. Some common uses are for the screw fasteners not under heavy loads, oils pans, small case hardened parts, and covers. Carbon steel is also used when weldability is necessary. Alloy steels have the advantage over carbon steels of being able to have a slower cooling rate, which can result in more uniformity of physical properties and has less residual stresses, deformations, or cracks. This allows alloyed steel to be treated for significantly higher strengths and hardness. These properties are especially important as the machine elements increase in size and have more complex shapes. Its only major disadvantage is that it is more costly than carbon steel., Stainless steel are characterized by their high chromium content, giving them an almost corrosion-proof characteristic. They are limited to the amount of heat treatment, which make them undesirable for application where a hard surface is necessary. In general, stainless steels are only used for exhaust valves and pipes and rarely for combustion chamber inserts. Special alloys are mostly used in highly stressed parts that need to be tolerant of high temperatures such as exhaust turbine nozzles, rotors, and blades as well as valves. These steel must have the non-oxidizing characteristics of stainless steel while also having high endurance and creep strength for the working temperatures., Surface Hardening:, Surface hardening can be employed in the manufacturing of the machine elements to increase their strengths and other properties. Casehardening is used on steel with low carbon contents, which increases the outer shell hardness, while not adversely effecting the inner micro-structure of the material. Surface heat treatments may be employed on medium carbon steels. Elements such as crankshafts and camshaft bearing surfaces use the heat treatment method to meet design requirements. Nitriding can be used to produce an extremely hard, wear resistant surface. Plating is used to reduce wear of elements such as piston rings and cylinder bores using chromium., Cast Iron, In general, the main engine block is made from gray cast iron, except for application which need lightweight components, such as race cars. Gray cast iron has the exceptional characteristic that it can be cast into intricate shapes with relative ease. And while the endurance limit is lower than steel, its notch sensitivity is very low. Gray cast iron also makes an excellent bearing material. Chilled cast iron is used to obtain very hard surfaces from gray cast iron. With its added beneficial characteristics, it is used for camshafts and tappets and other low cost automobile parts. Malleable iron, or ”white” iron, is annealed after casting which gives it great strength and ductility characteristics. It is advantageous because it can be used in some cases where previously, parts had to be forged, which saves money in the production of the part. Nodular steel has a very high tensile and endurance strength compared with normal gray iron. This is achieved through a casting method which makes free carbon granules spherical opposed to stringy. Nodular steel is used for crankshafts, Aluminum, Aluminum has become very popular for producing pistons, bearing surfaces, cylinder heads because of its numerous advantages: Low density, high heat conductivity, good resistance to corrosion, ease of casting, and good bearing characteristics against steel and iron. But it does have several disadvantages which also must be taken into consideration in the design process: Low hardness, high thermal expansion coefficient, cost of material, and adverse effects of high temperatures. Aluminum pistons are generally used for pistons under 6-inch bore because the aluminum tends to reduce the working temperature of the piston., Magnesium:, Magnesium is generally used for covers and other parts which are lightly loaded for application in which weight is a significant factor. It is lighter than aluminum, but also more expensive and softer., REVIEW QUESTIONS: Module 1, Illustrate the functions of a frame? (Applying), Illustrate various loads that are acting on the frame? (Applying), List any four characteristics of a good chassis. (Understanding), Point out the materials used in an IC engines? (Applying), Express about Vehicle Aerodynamics? (Analyzing), Describe the purpose of IC engines. (Understanding), Explain in details about Vehicle Aerodynamics. (Analyzing), What are the Requirements of bodies for various types of vehicle? (Evaluating), Explain the materials used to manufacture the components of engine. (Understanding), Point out any two requirement of good frame. (Analyzing), END OF MODULE 1