Page 1 :

4.1 Hoisting Equipments, Principle and working of Tower cranes, Crawler, cranes, Truck mounted cranes, gantry cranes, Mast, cranes, Derricks., 4.2 Conveying Equipments, Working of belt conveyors. Types of belts and, conveying mechanism., Capacity and use of dumpers, tractors and trucks, , 1

Page 2 :

5.1 Excavation Equipments, Use, Working and output of bulldozers, scrapers,, graders, and power shovels, JCB, draglines., 5.2 Compacting Equipments, Use of rollers, Roller types- Plain rollers, Sheep, footed rollers, Vibratory, rollers,, pneumatic, rollers. Rammers- use and working., , 2

Page 3 :

6.1 Concrete Mixers, Types of concrete mixers. Weigh batching equipments,, Equipments for transportation of concrete- trollies,, lifts. Transit mixers, Concrete vibrator- Needle vibrators,, Screed vibrators., Automatic concrete plants – layout, process and working., 6.2 Stone Crushers, Types of stone crushers, capacities and working. Equipments, for production of artificial sand., , 3

Page 4 :

7.1 Miscellaneous Equipments, Pile driving equipment, Pile hammers, selection of hammers., Working of hot mix bitumen plant, Bitumen paver., Grouting equipments, Floor polishing machine., 7.2 Equipment Management, Standard equipment,, Special, equipment,, Selection of equipment, Owning and operating cost of, construction equipment. Economic life of construction, equipment. Preventive maintenance, of equipment, Break, down maintenance of equipments., , 4

Page 5 :

Advance Construction, Methodology And Equipment, , 5

Page 6 :

In Case of major construction projects, the speed and the timely completion, of work is very important. Due to the reason, the mechanization of most of, the construction work is required, in which the construction equipment, play the most important role. The proper use of the appropriate equipment, contribute to economy, quality, safety, speedy and timely completion of the, project., The cost of construction is a major factor in all the projects. The factors, that influence construction costs mainly are materials, labour, construction, equipments, overhead and profit., The cost of construction equipment for civil engineering construction, projects ranges from 25 % to 40 % of the total project., The amount which is invested in the purchase of a construction equipment, should be recovered during the useful period of such equipment., , 6

Page 7 :

A hoist is a device used for lifting or lowering a load, by means of a drum or lift-wheel around which rope or, chain wraps. It may be manually operated, electrically, or pneumatically driven and may use chain, fiber or, wire rope as its lifting medium. The load is attached to, the hoist by means of a lifting hook., Tower cranes, Crawler cranes, Truck mounted cranes,, gantry cranes, Mast cranes, Derricks., , 7

Page 8 :

o, o, o, , Tower crane provides high lifting and good working radius., There are three common crane, Special vertical boom arrangement on truck, A mobile crane superstructure mounted atop a tower, A vertical tower with a jib, Upto a height of 400 feet can be normally above 400’ lateral, bracing is required and the maximum limit of height of tower, crane is 1000’., The ground area required for such cranes is very small., Tower cranes employed for the construction of skyscrapers, and large high-rise buildings., 8

Page 9 :

9

Page 10 :

A mobile crane is a cable-controlled crane mounted, on crawlers or rubber-tired., It is a hydraulic-powered crane with a telescoping, boom mounted on truck-type carriers., They are designed to easily transport to a site and use, with different types of load and cargo with little or no, setup or assembly., , 10

Page 11 :

11

Page 12 :

Crawler cranes are cranes mounted on crawlers, that, provide stability and mobility. The main advantage, of crawler cranes is that they can move around on site, and perform each lift with little set-up, since, the crane is stable on its tracks with no outriggers., Maximum boom length 100-400ft, Maximum lifting capacity 30-600 tons., , 12

Page 13 :

13

Page 14 :

A gantry crane is a type of overhead crane with a single or, double girder configuration supported by freestanding legs, that move on wheels or along a track or rail system., Uses of Gantry Cranes in Industry. Gantry crane lift object by a hoist, which is fitted in a hoist trolley and can move horizontally on a rail or pair, of rails fitted under a bean. ... The small gantry cranes can be used in, workshops like lifting automobile engines out of vehicles., In large workshops, there are separate machines for fabrications or repairs, of the machine parts., The machine or the components, which are to be repaired, can be, transferred to the place of fabrication or assembly with the help of Gantry, cranes., , 14

Page 15 :

15

Page 16 :

16

Page 17 :

The derrick cranes are of two types, namely:, (1) Guy derrick and (2) Stiff leg derrick, The guy derrick consists of a vertical mast. This mast is supported by the, number of guys and can revolve through 360 degree., While revolving, the radius of revolution should be such that the revolving, structure is not obstructed by the guy wires., The power is supplied by a diesel engine or by an electric motor., This derrick can be constructed upto 200 tons capacity ., In stiff leg type derricks, the guy wires are replaced by trussed structure., This type of derricks are suitable for loads from 10 to 50 tons, , 17

Page 18 :

A derrick cranes may be used on a wide range of works, , Construction of high rise buildings., Erection of steel and industrial plants., Hoisting works at ship yards., Loading and unloading at shipyards, loading & unloading Cargos at ports., , 18

Page 19 :

19

Page 20 :

20

Page 21 :

❑, ❑, ❑, , Conveyor belts employed for transporting large quantities or heavy materials, from one area to another., They can convey material in a variety of directions, either vertically, horizontally or, on an incline, using a consecutive chain belt to push materials through quickly. In, most mining operations, and for the movement of concrete,., Belt conveyors operate using a rubber belt that runs over a series of drums or, pulleys. These types of conveyors handle all kinds of materials, both wet and dry,, and can convey thousands of tons of material per hour over long distances. They, are also lightweight and have speed control functions to increase or decrease, output., Advantages to their use include:, Saving time, Increasing overall output, Running continuously, , 21

Page 22 :

22

Page 23 :

BELT CONVEYOR, SCREW CONVEYOR, BUCKET CONVEYOR, , 23

Page 24 :

24

Page 25 :

Hauling is defined as movement of materials from one, place to another place., Equipments used for this process is hauling, equipments., Examples, dump truck, tractor, truck etc, , 25

Page 26 :

The equipment which perform excavation,, digging of large quantities of earth, moving, them to distances,placement,compacting,, leveling, grading, hauling etc., are called earth, moving equipment., , 26

Page 27 :

The equipments under this are broadly classified in, three category, Excavating equipment, Excavating and earth moving equipment, Earth compacting equipment, , 27

Page 28 :

Excavating equipment, Power shovel, Trenching machine, Back hoe, Clamshell, Excavating and earth moving equipment, Scrapers Bull dozer Tractor, Earth compacting equipments, Road rollers, , Drag line, , 28

Page 29 :

Normally consist of revolving deck, driving & controlling, unit, boon and bucket., Power shovels are used primarily to excavate earth and load it, into trucks or tractor or onto conveyer belts., They are capable of excavating all classes of earth, except, solid rock, without prior loosening., Long lasting., Wheel mounted (high speed - firm ground), crawler mounted (low speed - unstable soil), Bucket ( size 0.375 to 5 cubic meter ), , 29

Page 30 :

30

Page 31 :

Excavation and loading of earth., It is used for various projects like road construction,, mining work etc., , 31

Page 32 :

A backhoe , also called a rear actor or back actor , is a type of, excavating equipment or digger consisting of a digging bucket at, end and loader at front. This are typically mounted on pneumatic, wheel. The section of the arm closest to the vehicle is known as, the boom, and the section which carries the bucket is known as, the dipper or dipper stick, The boom is attached to the vehicle through a pivot known as, kingpost, which allows the arm to slew left and right ,usually, through a total of around 200 degrees . Modern backhoes are, powered by hydraulics, It is the most suitable machine for digging below the machine, level, such as, trenches, footings, basements etc., It can be efficiently used to dress or trim the surface avoiding, the use of manual effort for dressing the excavated the surface., 32

Page 33 :

33

Page 34 :

Unlike the shovel, it has a long & light crane boom and, the bucket is loosely attached to the boom through, cables., Because of this construction, a dragline can dig and, dump over larger distances than a shovel can do., Drag lines are useful for digging below its track level, and handling softer materials., The basic parts of a drag line including the boom, hoist, cable, drag cable, hoist chain, drag chain and bucket., , 34

Page 35 :

35

Page 36 :

A bulldozer is a large powerful equipment, also called as, crawler tractor (track type or chain type)., It is use for following purpose, ❑ Clear site of work, ❑ Leveling of land, ❑ Prepare roads on hilly areas as well as hard ground, ❑ Excavate the material and haul in between 100 meters, distance., ❑ Spreading earth, ❑ Backfilling trenches, ❑ Maintaining haul roads, 36

Page 37 :

37

Page 38 :

A clamshell is a one-piece container consisting of two, halves joined by a hinge area which allows the, structure to come together to close. Clamshells are, often made of a shaped plastic material, in a way that is, similar to a blister pack. The name of the clamshell is, taken from the shell of a clam, which it resembles both, in form and function., , 38

Page 39 :

39

Page 40 :

A Trencher is a piece of construction equipment used, to dig trenches especially for laying pipes or cables for, installing drainage or in preparation for trench warfare, Trenchers may range in size from walk-behind models,, to attachments for a skid loader or tractor to very heavy, tracked heavy equipment., , 40

Page 41 :

41

Page 42 :

Tractor pulled scraper are designed to load, haul, and, dump loose material., In civil engineering a wheel tractor-scraper is, a heavy equipment used for earthmoving. The rear, part of the scraper has a vertically moveable hopper, with a sharp horizontal front edge which can be, raised or lowered. The front edge cuts into the soil,, like a carpenter's plane cutting wood, and fills the, hopper. When the hopper is full it is raised, closed,, and the scraper can transport its load to the fill area, where it is dumped., 42

Page 43 :

43

Page 44 :

It is used for grading and finishing the upper surface of, the earthen formations and embankments. They usually, operate in the forward direction., Grading - Process of bringing the earthwork to the, desired shape and elevation., Finishing Involves smoothing slopes, shaping ground, and bringing earthwork to the elevation required by the, plans and specification, , 44

Page 45 :

45

Page 46 :

Road Rollers, Sheep foot Rollers, Pneumatic Type Rollers, , 46

Page 47 :

Roller compactor is mainly used to for compaction of earth, and other materials in large works of highways, canals and, airports., May be classified by weight, in tons, Some rollers may be ballasted with water or sand to increase, the weight, If designated 8-12 tons, minimum weight 8 tons and maximum, weight 12 tons, , Application, Earthwork rolling, Soil Stabilization, Rolling granular bases, (WBM, moorum etc.) ,Surface dressing , bituminous macadam, Rolling of asphaltic concrete, 47

Page 48 :

Sheep foot rollers consist of hollow circular drums of, steel 1.2- 1.5m long and 0.9- 1.2m diameter, The weight of a single drum is in the range 1200- 1800, kg when empty and 2200-2800 kg when ballasted., A speed of 4 kmph is common., Suitable on cohesive soils specially when water, content is on the higher side., The Number of passes of rollers depends upon the types of, soil, moisture content and density desired ., Generally 8-16 passes are needed., , 48

Page 49 :

49

Page 50 :

Generally there are four wheels in the front and five in the rear., Weights in the range 12- 45 tones are common., The layer thickness should be 10-20 cm when compacting., The number of passes required is about 8-12 ., One Pneumatic tire rollers consists of a box mounted over two, axles, the rear axle having one more wheel than the front axles so, arranged that they are located in plan in between the rear wheels., Roller is generally required for an output of 25 cu m /hour., Rolling nonplastic silts and silt soils, Rolling of asphaltic concrete, , 50

Page 51 :

51

Page 52 :

Sand, gravel and large stones respond well to, compaction produced by a combination of pressure and, vibration, On vibration the particles settle to increase density of, the mass., Vibrations may vary from 1,000 to 5,000 per minute, Better compaction efficiencies and economy are, attained by moving at slow speeds - 2.5 to 4 Km/h, , 52

Page 53 :

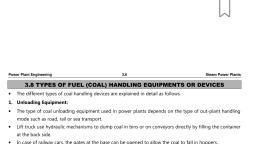

The concrete production, transportation and placement, relies, on the use of very specialized equipment. The proper, production, transportation and placement of concrete on-site is, associated with the proper use of the existing equipment., The concrete production equipment has an important role,, since it allows performing mixtures of concrete constituents in, several forms, moreover, allows performing appropriate, mixtures regarding the required final properties of concrete., , 53

Page 54 :

54

Page 55 :

A concrete mixer is a device that homogeneously, combines cement, aggregate such as sand or gravel, and, water to form concrete., For smaller volume works portable concrete mixers are, often used so that the concrete can be made at the, construction site., Major parts are wheel and axes ,Drum,engine, tilting, hooper., Usually, the material is loaded manually into the drum, from ground level and the Hooper dumps the material, tilting up mechanically, 55

Page 56 :

Agitator truck, A vehicle carrying a drum or agitator body, in which freshly, mixed concrete can be conveyed from the point of mixing to, that of placing, the drum being rotated continuously to agitate, the contents., ❑ Concrete crew and equipment must be ready onsite to handle, concrete., ❑ Haul distances must allow discharge of concrete within 1½, hours., ❑, , 56

Page 57 :

57

Page 58 :

Non agitator truck, Used for Transport concrete on short hauls(small distance), over smooth roadways., ❑ Advantages: Cost of non-agitating equipment is lower than, that of truck agitators or mixers., ❑, , Trolleys, ❑, , Hand driven trolley also used for convey at short distance., This also called wheel borrow., , ➢ Lift, ❑, , Lift is used to reach at higher elevation. This is electrically, operated machine., 58

Page 59 :

They are used for horizontal and vertical, transportation of large volumes of concrete in short, duration., capacity:- 30cum/hr (ordinary construction), 120cum/hr(specialized construction), , 59

Page 60 :

Ready mixed concrete is proportioned and mixed off, at the project site and is delivered to the construction, area in a freshly mixed and unhardened state., It can be manufactured by any of the following, methods:, ❑ Central-mixed concrete, ❑ Truck-mixed concrete, , 60

Page 61 :

Non agitator truck, Used for Transport concrete on short hauls(small, distance) over smooth roadways., Advantages: Cost of non-agitating equipment is lower, than that of truck agitators or mixers., , 61

Page 62 :

Needle vibrator, Screed vibrator, Needle vibrator: this is the most common type of, vibrator. It is essentially consist of a steel tube having, eccentric vibrating element inside. This is connected, with motor through a flexible tube. Diameter of steel, tube vary from 40mm to 100mm., Needle vibrator used for vibrating concrete in column,, beam, retaining wall etc., 62

Page 63 :

Screed vibrator, Screed vibrator is also called surface vibrator this is directly, placed on concrete surface., ❑ It is use for the shallow depth of concrete. The depth of, surface should not increase by 150mm., ❑ vibrator is attached with a beam and electrically operated., ❑, , 63

Page 64 :

64

Page 65 :

65

Page 66 :

Components, Cold feed system, Drum dryer, Hot screen, Hot bin, Weight hopper, Asphalt handling system, Pug mill mixer, , 66

Page 67 :

Cold feed system- it provide aggregate storage., Drum dryer- the purpose of drum dryer to heat and, dry the aggregate., Hot screen- this enables gradation control of, aggregates., Hot bin- the aggregate from hot screen are stored in, hot bins., Weight hopper- aggregate from hot bin is dropped, into weight hopper situated below the bin and above, the pug mill. It control the weight of aggregate., 67

Page 68 :

Asphalt handling system the asphalt is stored at the, plant in a heated tank and ready to discharge in pug, mill., Pug mill this is mixing unit it has capacity from 1.5, to 5 tons., , 68

Page 69 :

A crusher is a machine deigned to reduce large rocks into, a smaller rocks, gravels, or rock dust. Crusher may be, used to reduce the size, or change the form, of waste, material so they can more easily disposed of or recycled,, or to reduced the size of a solid mix of raw material., , 69

Page 70 :

Crushing plants make use of a large range of, equipment, such as a pre-screener, loading conveyor,, intake hopper, magnetic separator, crushing etc., Belt conveyor, Vibration feeder, Vibrating screen, Crusher, Jaw crusher, Gyratory crusher, Cone crusher, Roll crusher, Impact crusher, , 70

Page 71 :

This machine allowing stone to flow into the space, between two jaw, one is stationary and other is, movable., Jaw crusher has simple structure, operational reliability, and low operation cost., Jaw crusher has low noise and little dust, Jaw crusher has light weight for easy transportation and, assembly., This mechanical pressure is achieved by the two jaws, of crusher of which one is fixed while other, reciprocate., 71

Page 72 :

72

Page 73 :

These crushers are characterized by a gyrating mantle, within a deep bowl., They provide continuous crushing action and are used, for both primary and secondary crushing of hard,, tough, abrasive rock., , 73

Page 74 :

74

Page 75 :

Cone crushers are used as secondary or tertiary, crushers., They are capable of producing large quantities of, uniformly fine crushed stone., , 75

Page 76 :

76

Page 77 :

Roll Crusher are used for producing additional, reductions in the size of stone after the output of a, quarry has been subjected to one or more stages of, prior crushing., A roll crusher consist of a heavy cast-iron frame, equipped with either one or more hard-steel rolls, each, mounted on a separate horizontal shaft., , 77

Page 78 :

78

Page 79 :

In impact crushers stones are broken by the application, of high speed impact forces., Impact crusher involve the use of impact rather than, pressure of crush material., Advantage is also taken of the rebound between the, individual stones and against the machine surface to, utilize fully the initial impact energy., , 79

Page 80 :

VSI Sand maker or VSI crusher is a type of sand crusher, suitable for the crushing of soft, hard and extremely hard, material., the material is vertically fell to the impeller of the sand crusher, with the high speed rotation from the upper, and then, combines with another part under the effect of centrifugal, force with a high speed, which is in the shape of umbrella, form shunt around the impeller material, and a powerful, vortex can be formed between the impeller and the casing,, which can be repeated again and again until the material can, be crushed into the final result. And the final material can be, discharged from the discharging opening, and the last step is to, experience the process of screening and washing, 80

Page 81 :

81

Page 82 :

82

Page 83 :

JAW,GYRATOR, FEEDER, , PRIMARY, CRUSHER, , SCREENING, , FINAL, PRODUCT, TERTIARY, CRUSHER, , SCREENING, , SECONDARY, CRUSHER, GYRATOR,, CONE,ROLL, IMPACT, , FINAL, PRODUCT, 83

Page 84 :

Hammer Driving, Vibratory Pile Driver, Water Jetting And Hammering, Partial Augering Method, , 84

Page 85 :

A drop hammer is a heavy metal weight that is lifted, by a rope, then released and allowed to fall on top of, the pile., Standard drop hammers are made in sizes which vary, from about 225 to 1360 kg., The height of drop or fall most frequently used varies, from 1.5 to 6 m., Drop hammers may strike 4 to 8 blows per minute., , 85

Page 86 :

Small investment in equipment., ➢ Simplicity of operation., ➢ Ability to vary the energy per blow by varying the, height of fall., ❑ Slow rate of driving piles., ❑ Danger of damaging piles by lifting a hammer too high., ❑ Danger of damaging adjacent buildings as a result of, the heavy vibration caused by a hammer., ❑ Cannot be used directly for underwater driving., ➢, , 86

Page 87 :

In road construction two types of aggregate is used, one is cold and second one is hot. Hot mix asphalt, drum plant is used for production of hot mix asphalt., This type of asphalt plant is available with burner and, dryer unit., , 87

Page 88 :

A self-propelled formless machine with a floating, screed. HMA(Hot mix asphalt) is loaded in the front,, carried to the rear by a set of flight feeders (conveyor, belts), spread out by a set of augers, then leveled and, compacted by a screed., The tractor contains the material feed system, which, accepts the HMA at the front of the paver, moves it to, the rear and spreads it out to the desired width in, preparation for screed leveling and compaction., , 88

Page 89 :

The Hopper is used as a temporary storage area for HMA, delivered by the transport vehicle., The Auger receives HMA from the conveyor and spreads it, out evenly over the width to be paved., The most critical feature of the paver is the self-leveling, Screed unit, which determines the profile of the HMA being, placed. The screed takes the head of HMA from the material, delivery system, strikes it off at the correct thickness and, provides initial compaction., , 89

Page 90 :

Grouting pumps, ❑ Grouting mortar pumps, ❑ Grouting cement pumps, ❑ Grouting concrete pumps, Pressure grouting machines, ❑ Low pressure, ❑ High pressure, ❑ Cement grouting machine, ❑ Hydraulic grouting machine, , 90

Page 91 :

A tunnel boring machine (TBM), also known as a "mole", is a machine used, to excavate tunnels with a circular cross section through a variety of soil, and rock strata. They can bore through anything from hard rock to sand. Tunnel, diameters can range from a meter (done with micro-TBMs) to 19.25m. Tunnels, of less than a meter or so in diameter are typically done using trenchless, construction methods or horizontal directional drilling rather than TBMs., Tunnel boring machines are used as an alternative to drilling and blasting, (D&B) methods in rock and conventional "hand mining" in soil. TBMs have, the advantages of limiting the disturbance to the surrounding ground and, producing a smooth tunnel wall. This significantly reduces the cost of lining, the tunnel, and makes them suitable to use in heavily urbanized areas. The, major disadvantage is the upfront cost. TBMs are expensive to construct, and, can be difficult to transport. The longer the tunnel, the less the relative cost of, tunnel boring machines versus drill and blast methods. This is because, tunneling with TBMs is much more efficient and results in shortened, completion times, assuming they operate successfully., , 91

Page 92 :

92

Page 93 :

Initial cost, Initial cost is the capital investment required to own the, equipment. It includes purchase cost, sales tax, transportation, cost (or freight charges) to bring the equipment to company's, storage yard or construction site and cost of assembly and, installation of the equipment., Salvage value, salvage value represents expected cash inflow that will be, received by disposing of equipment at the end of its useful life., , 93

Page 94 :

Interest cost or cost of capital investment, It is the annual cost of interest charged on the borrowed, money or that of capital investment to acquire the ownership, of the equipment. If the equipment is purchased by borrowing, money from a lender, then interest cost is the interest charged, (at interest rate charged by lender) on the borrowed amount., Taxes, It represents the property taxes to be paid to the state or central, government. It depends on the value of the equipment owned, and the applicable tax rate for a given location., , 94

Page 95 :

Insurance cost, It represents the annual premium to be paid to, insurance companies to cover the cost incurred due to, accident, fire, theft etc. for the construction equipment., Storage cost, It is the cost of keeping the equipment in storage yards when it, is not operating at the work site. Storage cost includes the, rental and maintenance charge for storage yards, wages of, security guards and wages of workers employed for bringing, in and out of the storage yards. It is around 0.5 to 1.5% of the, average annual investment or book value of equipment., 95

Page 96 :

Operating cost is incurred only when the equipment is, operated. The operating cost of the equipment is, influenced by various parameters namely number of, operating hours, location of job site, operating, conditions, category of equipment etc. The operating, cost consists of the following; a) Repair and, maintenance cost, b) Fuel cost, c) Cost of lubricating, oil, filter and grease, d) Tire cost e) Equipment operator, wages, f) Cost of replacing high-wear items and g) Cost, of mobilization, demobilization and assembly., , 96

Page 97 :

97