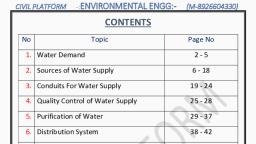

Page 2 :

Conveyance, Types of Pipes Used for Conveyance of water, Cast iron pipe, These pipes are strong & durable, resistant to corrosion as, well as easy to install., But these pipes are also brittle and easily gets cracked or, breaks. And not used when pressure in pipes exceed, 0.7N/mm2., Wrought iron pipe, More lighter. Easy to cut, thread, worked., But more costly and less durable., , Kamble P S

Page 3 :

Steel pipe, Light in weight, available in large lengths and hence the, number of joints becomes less, can withstand to high internal, pressure., But these pipes are much affected by corrosion,, maintenance cost is high, life period is about 25 to 50 years, and cannot withstand external load., , Concrete pipe, , Used up to 600 mm diameter., Pipes above 600 mm diameter are reinforced., , Asbestos pipe, Lightweight, easy to cut, drilled, unaffected by corrosive, elements, cheap in cost as well as suitable for distribution of, small pipe size., But these pipes are brittle, less durable, cannot be laid in, Kamble P S, exposed places.

Page 4 :

Copper pipe, , Not liable to corrode. Can be easily bent, do not sag if hot water is, used., , Lead pipe, , Used in sanitary fittings. These pipes are mostly used in chlorination, and alum dosing., But cause poisoning. Sag, when hot water is used., , GI pipe, Cheap, lightweight and easy to handle & transport., But lifespan of this pipe is short & can be easily affected by, acidic and alkaline water., , Kamble P S

Page 5 :

Factors affecting selection of pipe material :, 1. Water carrying capacity, 2. Durability, 3. Quality of water to be conveyed and its possible, corrosive effects on the pipe material., 4. Availability of funds., 5. Maintenance cost, repairs or removal etc., , Kamble P S

Page 6 :

Types of Joints, Joints in Cast Iron Pipe, a) Bell and Spigot Joint:, Most commonly used joint., Jute or yarn is wound round, the spigot & inserted into the, bell-end of the pipe already, laid. A gasket or joining ring is, clamped around the joint to, make tight fitting., , Kamble P S

Page 7 :

b) Expansion Joint :, This is provided where piles are subjected to high change, in temperature., A rubber gasket is inserted in between the spigot and, bell ends which make the joint watertight., A flanged ring is bolted to the bell which expands and, contracts along with the bell end., , Kamble P S

Page 8 :

c) Flanged Joint :, Used where the water pressure is light and diameter of, pipe is more than 300 mm., The two ends of the pipes are provided with wide flange,, which are bolted together., Rubber gasket is inserted between the flanges, which are, bolted makes joint watertight., This type of joint should not be used at places where it has, to bear deflection or vibration., , Kamble P S

Page 9 :

VALVES, “The fixtures which are fixed along the distribution system to, serve following purpose are known as valve.”, Uses:, 1) Control the rate of flow of water., 2) Prevents or detects leakage., 3) Releases or admits air into the pipeline, 4) Meets the demand during emergencies, 5) Make the distribution system more efficient., Types Of Valve, 1) Sluice valve, 2) Air relief valve, 3) Pressure relief valve, 4) Scour valve, 5) Reflux valve, , Kamble P S

Page 10 :

Sluice Valve :, The entire distribution system is divided into blocks by, providing these valve Small size sluice, valves are enclosed in guard pipe around the spindle and, supported over brick work large valves are fixed in, chamber., The entire distribution system is controlled by this valve., USE:, This valve are provided in pipe line to control the flow of, water., , Location :, Provided in straight pipe length at 150-120 m interval and, when pipeline is inserted, valves are fixed on both the, sides, Kamble, P S of, intersection.

Page 12 :

Air Relief Valve, Water contains some quantity, air, When it flows, the air tries to, accumulate at higher point of, pipeline and this may cause air, lock reducing the discharge in, pipe., Use: For automatic allowance, of air to escape through it., , Location: they are provided at, summit points in the alignment, of pipe., Kamble P S

Page 13 :

Scour Valve:, These valve are also known as the blow off valve or drain or, wash out valves, They are ordinary sluice valve and are operated with hand, and enclosed down immediately after clear water is seen, passing through them., USE: these valve are use to remove sand or silt deposited in, pipe line, Location : They are located at the dead ends and depression, or lowest points in the mains., , Kamble P S

Page 14 :

Pressure Relief Valve, Also called safety valves, provided at a point along the, pipeline where pressures are likely to exceed permissible limit., Use : These are used to relieve pressure automatically, when, it exceeds a fixed limit., Location : They are located at the following situations, a) Two pipe lines connecting pipe networks., b) At two different elevations in pipeline., , Kamble P S

Page 15 :

Reflux Valve, This valve are also known as non return valve or checkvalves., Reflux valve is an automatic device which allows water to, go in one direction only., USE: These are used in a pipe line when it is required to pass, the discharge only., Location: These valves are used in water pipe which obtain, water directly from pump., , Kamble P S