Page 1 :

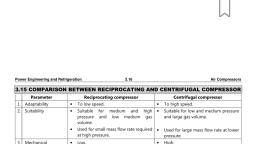

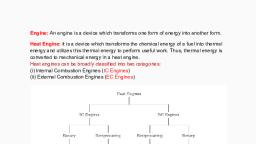

An Air compressor is a machine which takes in atmospheric air, compresses it with the help of, some mechanical energy and delivers it at higher pressure. It is also called air pump., , Application:, 1. Air refrigeration and cooling of large buildings,, 2. Driving pneumatic tools in shops like drills, riveters, screw drivers, etc., 3. Driving air motors in mines, where electric motors and IC engines cannot be used because of, fire risks due to the presence of inflammable gases, etc., 4. Cleaning purposes,, 5. Blast furnaces,, 6. Spray painting and spraying fuel in Diesel engines,, 7. Hard excavation work, tunneling, boring, mining, etc., 8. Starting of heavy-duty diesel engines,, 9. Operating air brakes in buses, trucks and trains etc., 10. Inflating automobile and aircraft tyres,, 11. Supercharging internal combustion engines,, 12. Conveying solid and powder materials in pipelines,, 13. Process industries,, 14. Operating lifts, hoists, cranes and to operate pumps etc., 15. Pump sets for oil and gas transmission line,, 16. Automobile suspension system, , Classification:, The compressors are mainly classified as, (i) Reciprocating compressors, and, (ii) Rotary compressors., , A reciprocating compressor is used to produce high-pressure gas. It uses the displacement of, piston in the cylinder for compression. It handles a low mass of gas and a high pressure ratio.

Page 2 :

The rotary compressors are used for low and medium pressures. They usually consist of a, bladed wheel or impeller that spins inside a circular housing. They handle a large mass of gas., These compressors may be single stage or multistage to increase the pressure ratio., 1., , 2., , 3., , 4., , 5., , 6., 7., , 8., , Single-acting compressor is a compressor in which suction, compression and delivery of, a gas take place only on one side of the piston during a cycle of one revolution of the, crank shaft., Double-acting compressor is a compressor in which suction, compression and delivery, of gas take place on both sides of the piston and two cycles take place during one, revolution of the crank shaft., Single-stage compressor is a compressor in which the compression of gas to final, delivery pressure is carried out in one cylinder only., Multistage compressor is a compressor in which the compression of gas to the final, pressure is carried out in more than one cylinder in series., Pressure ratio is defined as the ratio of absolute discharge pressure to absolute suction, pressure., Free air is the air that exists under atmospheric condition., Compressor displacement volume, It is the volume created when the piston travels a stroke. V=, ., Where d is the bore of the cylinder and L is stroke of the piston., Induction volume flow or volume flow rate:, the compressor is expressed in m3/s and is given as, V = Volume inducted per cycle * No. of inductions per revolution * Number of, revolutions per second, For the single-acting reciprocating compressor, only one cycle (thus, one induction) takes, place for each revolution of the crank., Thus, for a compressor without clearance ̇ =, For the double-acting reciprocating compressor, the induction takes place on both sides, of the piston for each revolution., Thus ̇ =, , 9. Capacity of a compressor is the actual quantity of air delivered per unit time at atmospheric, conditions., 10. Free Air delivery (FAD) It is the discharge volume of the compressor corresponding to, ambient conditions., 11. Piston speed is the linear speed of the piston measured in m/min., It is expressed as Vpiston = 2 LN

Page 3 :

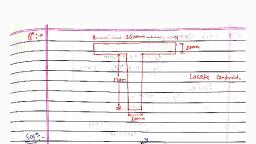

Reciprocating compressor:, A machine which takes in air or gas during suction stroke at low pressure and then compresses it, to high pressure in a piston–cylinder arrangement is known as a reciprocating compressor., External work must be supplied to the compressor to achieve required compression., Single acting reciprocating compressor:, , Construction:, , It consists of a piston, cylinder with cooling arrangement, connecting rod, crank, and inlet and, delivery valves. The piston fitted with piston rings, reciprocates in the cylinder. The prime mover, (an engine or electric motor) drives the crank shaft; the crank rotates and converts rotary motion, into reciprocating motion of piston with the help of a connecting rod. The cylinder head consists, of spring-loaded inlet and delivery valves, which are operated by a small pressure difference, across them. The light spring pressure gives a rapid closing action. The piston rings seal the gap, between the piston and cylinder wall. The cylinder is surrounded by a water jacket or metallic, fins for proper cooling of air during compression., Double acting reciprocating compressor:

Page 4 :

Its construction is very similar to that of a single-acting air compressor, except for two inlet and, two delivery valves on two ends of the cylinder in order to allow air entry and delivery on two, sides of the piston. When the piston compresses the air on its one side, it creates suction on the, other side. Thus, the suction and compression of air take place on two sides of the piston, simultaneously., Working of Single Acting air compressor:, As the piston moves in a downward stroke (from TDC to BDC), any residual compressed air left, in the cylinder from the previous cycle expands first. On further movement of the piston, the, pressure in the cylinder falls below the atmospheric pressure., The atmospheric air pushes the inlet valve to open and fresh air enters the cylinder as shown in, Fig. The line c-1 represents the induction stroke. During this stroke, the compressed air in the, storage tank acts on the delivery valve, thus it remains closed. As the piston begins its return, stroke from BDC to TDC, the pressure in the cylinder increases, and closes the inlet valve. The, air in the cylinder is compressed by piston as shown by the curve 1-2., During the compression stroke, as air pressure reaches a value, which is slightly more than the, pressure of compressed air acting outside the delivery valve, the delivery valve opens and the, compressed air is discharged from the cylinder to storage tank. At the end of the compression, stroke, the piston once again moves downward, the pressure in the cylinder falls below the, atmospheric pressure, the delivery valve closes and inlet valve opens for next cycle. The suction,, compression and delivery of air take place with two strokes of the piston which is one revolution, of the crank., Figure shows the p–V diagram for a reciprocating compressor without clearance.

Page 5 :

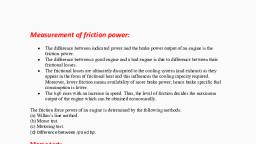

The processes are summarized below:, , Indicated work of single acting compressor without clearance:, Indicated work done on the air per cycle = Area behind the curve, i.e., area c –1–2–d–c, = Area (2–d –0 –b–2) + Area (1–2–b –a –1) – Area (1–c – 0 –a –1), = p2V2 (Flow work during discharge at constant pressure p2) –ʃpdV (Piston, displacement work from p1 to p2) - p1V1 (Flow work during suction at constant pressure p1)

Page 8 :

Compression Work Minimization:, , From the diagram that among the three processes considered, the area with isentropic, compression is maximum. Thus it requires maximum work input and with isothermal, compression, the area of indicator diagram is minimum. Thus, the compressor with isothermal, compression will require minimum work input.

Page 9 :

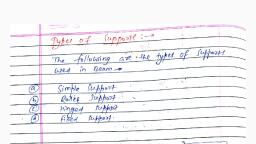

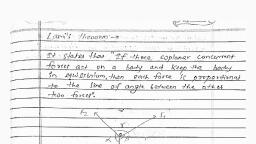

Clearance Volume in a Compressor:

Page 10 :

The indicated work done is given by the area 1–2–3–4–1 on a p–V diagram., Indicated work = Area 1 –2–3–4–1 = Area 1–2–e–d – Area 3– e–d–4, the compression work equivalent to area 1–2–e–d, can be obtained with index of compression nc., Area 1–2–e–d;

Page 11 :

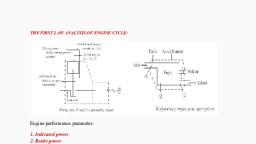

Actual indicator diagram on a p–V plane for a single-stage reciprocating air compressor is, shown in Fig

Page 12 :

During the suction process 4–1, the pressure drops in the cylinder until the inlet valve is forced, by atmospheric air to open. During the suction stroke, the piston creates vacuum in the cylinder., Thus pressure reduces and atmospheric air enters the cylinder., Similarly, during delivery process 2–3, some more pressure is required to open the delivery valve, and to displace the compressed air through narrow valve passage. Thus, gas throttling takes place, during delivery, reducing the pressure gradually to the state 3., The waviness of lines during these processes is due to valve bounce and wire drawing effect, through the valves., , Volumetric Efficiency:

Page 13 :

The factors which lower volumetric efficiency are the following:, 1., 2., 3., 4., 5., , Two large Clearance Volume;, Obstruction at Inlet Valve, High speed of Compressor, Heated cylinder walls, Leakage past piston

Page 14 :

Free air delivery (FAD):, The volume of compressed air corresponding to atmospheric conditions is known as free air, delivery (FAD)., The free air delivered volume is less than the compressor displacement volume due to the, following reasons:, 1. Obstruction at inlet valve It offers the resistance to air flow through the narrow passage of, valve., 2. Re-expansion of high pressure air in clearance volume It reduces effective suction stroke., 3. Presence of hot cylinder walls of compressor Air gets heated as it enters the cylinder., Thus, it expands and reducing the mass of air sucked into the cylinder., , Limitation of Single stage compression:, The pressure ratio for a single-stage reciprocating air compressor is limited to 7. Increase in, pressure ratio in a single-stage reciprocating air compressor causes the following undesirable, effects:, 1. Greater expansion of clearance air in the cylinder and as a consequence, it decreases, effective suction volume (V1 – V4) and therefore, there is a decrease in fresh air induction.

Page 15 :

2. With high delivery pressure, the delivery temperature increases. It increases specific, volume of air in the cylinder, thus more compression work is required., 3. Further, for high pressure ratio, the cylinder size would have to be large, strong and heavy, working parts of the compressor will be needed. It will increase balancing problem and high, torque fluctuation will require a heavier flywheel installation., All the above problems can be reduced to minimum level with multistage compression, , Multistage compression:, The compression of air in two or more cylinders in series is called multistage compression., Advantage:, 1. The gas can be compressed to a sufficiently high pressure., 2. Cooling of air is more efficient with intercoolers and cylinder wall surface., 3. By cooling the air between the stages of compression, the compression can be brought to, isothermal and power input to the compressor can be reduced considerably., 4. By multistaging, the pressure ratio of each stage is lowered. Thus, the air leakage past, the piston in the cylinder is also reduced., 5. The low pressure ratio in a cylinder improves volumetric efficiency., 6. Due to phasing of operation in stages, in a multistage compressor, the negative and positive, forces are balanced to a large extent. Thus, more uniform torque and better mechanical balance, can be achieved., 7. Due to low pressure ratio in stages, the compressor speed could be higher for same isothermal, efficiency., 8. Low working temperature in each stage helps to sustain better lubrication., 9. The low-pressure cylinder is made lighter and high-pressure cylinders are made smaller for, reduced pressure ratio in each stage.