Page 2 :

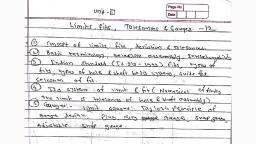

1, , LIMIT , FIT ,TOLERANCES AND GAUGES, LIMITS:- The maximum and minimum permissible sizes within which the actual size of a component, lies are called limits., Limits are fixed with reference to the basic size of that dimension., Upper limit (The high limit) for that dimension is the largest size permitted and the low limit is the, smallest size permitted for that dimension., Ex: it a 20mm nominal dia is to be produced the limits may be 19.9 to 20.1 mm., , Fits:- Fit is defined as the degree of tightness or looseness between two making parts to perform a, definite function when they are assembled together., Ex shaft in a bearing., TOLERANCE:- Tolerance is the permissible variation in the dimension of a part as it is not possible to, produce a part to exact specified dimension. It is the differences between higher and lower limits of, dimension of a part., It may be unilateral and bilateral, , Tolerance = Higher Limit - Lower Limit., TERMINOLOGY -The terminology used in fits and tolerances is shown in Fig below. The important, terms are, , Basic size: It is the exact theoretical size arrived at by design. It is also called nominal size., Actual size: The size of a part as may be found by measurement.

Page 3 :

2, Maximum limit of size: The greater of the two limits of size., Minimum limit of size: The smaller of the two limits of size., Allowance: It is an intentional difference between maximum material limits of mating parts. It is a, minimum clearance or maximum interference between mating parts., Deviation: The algebraic difference between a size (actual, maximum, etc.) and the corresponding basic, size., Actual deviation: The algebraic difference between the actual size and the corresponding basic size., Upper deviation: The algebraic difference between the maximum limit of size and the corresponding, basic size, Upper deviation of hole = ES (& art Superior), Upper deviation of shaft = es, Lower deviation: The algebraic difference between the minimum limit of size and the corresponding, basic size., Lower deviation of hole = El (Ecart Inferior), Lower deviation of shaft = ei, Upper deviation Lower deviation + Tolerance, Zero line: It is the line of zero deviation and represents the basic size., Tolerance zone: It is the zone bounded by the two limits of size of the parts and defined by its, magnitude, i.e. tolerance and by its position in relation to the zero line., Fundamental deviation: That one of the two deviations which is conveniently chosen to define the, position of the tolerance zone in relation to zero line, as shown in fig below., , Basic shaft: A shaft whose upper deviation is zero., Basic hole: A hole whose, lower deviation of zero., Clearance: It is the positive difference between the hole size and the shaft size., Maximum clearance: The positive difference between the maximum size of a hole and the minimum, size of a shaft.

Page 4 :

3, Minimum clearance: The positive difference between the minimum size of a hole and the maximum size, of a shaft., , TYPES OF FIT, , (i) Clearance Fit: This means there is a gap between the two mating parts. Let’s see the following, schematic representation of clearance fit. The diameter of the shaft is smaller than the diameter of the, hole. There is a clearance between the shaft and the hole. Hence the shaft can easily slide into the hole., In clearance fit the difference between the maximum size of the hole and the minimum size of the shaft, is known as the Maximum clearance and the difference between the minimum size of the hole and the, maximum size of the shaft is known as the Minimum clearance., , (ii) Interference Fit: There is no gap between the faces and there will be an intersecting of material will, occur. In the following schematic representation of the Interference fit. The diameter of the shaft is, larger than the hole diameter. There will be the intersection of two mating components will be, occurred. Hence the shaft will need additional force to fit into the hole., In Interference fit the difference between the maximum size of the shaft and the minimum size of the, hole is known as the Maximum Interference and the difference between the minimum size of the shaft, and the maximum size of the hole is known as the Minimum Interference.

Page 5 :

4, , (iii) Transition Fit: Transition fit is neither loose nor tight as like clearance fit and interference fit. The, tolerance zones of the shaft and the hole will be overlapped between the interference and clearance, fits. See the following schematic representation of the transition fit., , SYSTEMS OF FITS:, There are two systems of fit for obtaining clearance, interference or transition fit., These are:, 1. Hole basis system, 2. Shaft basis system, 1. Hole Basis System: In the hole basis system, the size of the hole is kept constant and shaft sizes are, varied to obtain various types of fits. In this system, lower deviation of hole is zero, i.e. the low limit of, hole is same as basic size., The hole basis system is commonly used because it is more convenient to make correct holes of fixed, sizes, since the standard drills, taps, reamers and branches etc. are available for producing holes and, their sizes are not adjustable.

Page 6 :

5, 2. Shaft Basis System: In the shaft basis system, the size of the shaft is kept constant and different fits, are obtained by varying the size of the hole. Shaft basis system is used when the ground bars or drawn, bars are readily available. In this system, the upper deviation (fundamental deviation) of shaft is zero,, , TOLERANCES:, Tolerance can also be defined as the amount by which the job is allowed to go away from accuracy and, perfectness without causing any functional trouble, when assembled with its mating part and put into, actual service.

Page 7 :

6, , There are two ways of writing tolerances:, (a) Unilateral tolerance (b) Bilateral tolerance., 1.)Unilateral Tolerance: In this system, the dimension of a part is allowed to vary only on one side of the, basic size, i.e. tolerance lies only on one side of the basic size either above or below it (As shown in fig)., , 2.)Bilateral Tolerance: In this system, the dimension of the part is allowed to vary on both the sides of, the basic size, i.e. the limits of tolerance lie on either side of the basic size, but may not be necessarily, equally disposing about it.

Page 8 :

7, , INTERCHANGEABILITY & SELECTIVE ASSEMBLY, what is interchangeability?, Manufacture of machine tools, automobiles, IC engines air craft etc require thousands of components, which are identical. In such large scale production (or mass production) each male component should fit, with corresponding female component without interchanging the parts present in a lot of identical, items (i.e called random assembly) as shown in fig 3.9. if this condition exist it is called interchangeability, in manufacturing or simply interchangeability. Interchangeability is essential in mass production., Interchangeability is possible only when certain standards are strictly followed. Required fit in an, assembly can be obtained by either, , Selective assembly (or group assembly), In selective or group assembly the components produced by machine are classified into several groups, according to size. This is done both for hole and shaft. A group of shafts having a particular range of size, will match properly with the corresponding group of holes. Because of wider tolerance the, manufacturing lost is also reduced. As an example if some parts (shafts holes) to be assembled are, manufactured to normal tolerance of 0.01mm. and the size distribution of shaft holes follow normal, distribution pattern as shown below fig 3.10

Page 9 :

8, , Taylors principle of gauge design, Limit gauges are designed based on taylor’s principle, It states that, (i) Go gauges should be designed to check the maximum materials limit while the No go gauges should, be designed to check the minimum material limit of shaft/hole, (ii) Go gauges should check all the related dimensions simultaneously whereas NOGO gauge should, check only one element of dimension., , i.e. According to Taylor’s principle, the GO gauge should be made for maximum material limit and it has, to incorporate as many dimensions as possible to inspect in one pass and NO-GO gauge can be made for, minimum material limit and separate NO GO gauge should be made for each separate dimension.

Page 10 :

9, , GAUGES:, Limit Gauges: Two sets of limit gauges are necessary for checking the size of various parts. There are, two gauges: Go limit gauge, and Not Go limit gauge., 1. Go Limit: The Go limit applied to that of the two limits of size corresponds to the maximum material, condition, i.e. (1) an upper limit of a shaft, and (ii) the lower limit of a hole. This is checked by the Go, gauge., 2. Not Go Limit: The Not Go limit applied to that of the two limits of size corresponds to the minimum, material condition, i.e. (1) lower limit of a shaft, and (ii) the upper limit of a hole. This is checked by the, Not Go gauge., The types are:, 1. Plug Gauge, 2. Snap Gauge, 3. Ring Gauge, 1. Plug Gauge: A plug gauge is a cylindrical type of gauge, used to check the accuracy of holes. The plug, gauge checks whether the whole diameter is within specified tolerance or not. The ‘Go’ plug gauge is the, size of the low limit of the hole while the ‘Not-Go’ plug gauge corresponds to the high limit of the hole., , Snap Gauge: A snap gauge is a U-Shaped frame having jaws, used to check the accuracy of shafts and, male members. The snap gauge checks whether the shaft diameter is within specified tolerances or not., The ‘Go’ snap gauge is the size of the high (maximum) limit of the shaft while the ‘Not-Go’ snap gauge, corresponds to the low (minimum) limit of the shaft.

Page 11 :

10, Ring Gauge: A ring gauge is in the form of a ring, used to check the shafts and male members. The “Go’, and ‘Not Go’ members may be separate or in a single ring. The opening or hole in the Go gauge is larger, than that in the Not-Go gauge., , .Gauge design – Basic design rules for plus and ring gauges Appropriate materials and dimensions are, two important aspects of gauge design., (i) Gauge material A good quality high carbon steel (cheaper) with suitable heat treatment. Cr/Wc plated, steel for wear and conversion resistant, (ii) Determination of dimension The following problem will give a guide line for the determination of, dimension.

Page 12 :

11