Page 2 :

SYLLABUS, Introduction to Mechatronics, Sensors & Transducers , Introduction to Mechatronics Systems - Measurement Systems - Control Systems -Sensors and Transducers - Performance Terminology - Sensors for-Displacement, Velocity, Force, Fluid Pressure, Liquid Flow, Liquid Level, Temperature, Light Sensors, Selection of Sensors.

Page 3 :

WHAT IS MECHATRONICS?, The word “mechatronics” was first coined by Mr. Tetsuro Moria, a senior engineer of a Japanese company, Yaskawa, in 1969. , , Mechatronics is the synergistic combination of mechanical engineering (“mecha” for mechanisms), electronic engineering (“tronics” for electronics), and software engineering.

Page 4 :

MECHATRONICS SYSTEM, Its also defined as the complete integration of mechanical system with electrical, electronic and computer system into single system.

Page 5 :

Advantages and disadvantages Mechatronics, 1.The products produced are cost effective and very good quality., 2. High degree of flexibility, 3. Greater extent of machine utilization, 4. Greater productivity, 5. High life expected by proper maintenance., 6. The integration of sensor and control system in a complex system reduces capital expenses., DISADVANTAGE, 1. Higher initial cost of the system., 2.Important to have Knowledge of different engineering fields for design and implementation., 3. Is expenses to incorporate Mechatronics approaches to existing/old systems., 4.Specific problem of various systems will have to be addressed separately and properly.

Page 6 :

Application of Mechatronics system?, 1. Automotive machines., 2. Fax and photocopier mechanics, 3. Dishwashers., 4. Automatic washing machine, 5. Air conditioners, elevator controls., 6. Documents scanners, 7. IC manufacturing systems., 8. Robotics employed in welding, nuclear inspection, painting etc.,, 9. VCRs(Videocassette recorder) and CD Players.

Page 7 :

MEASUREMENT SYSTEM, A group of device/element arranged in rational manner to achieve the act of measurement., Generally a measurement system consists of 3 basic elements., 1. Sensor/transducer., 2. Signal conditioner., 3. Display/read out devices., In addition to the above, electrical power is also required.

Page 8 :

CONTROL SYSTEM:, The word control implies to regulate direct or command A controlled system can be used to control its output to to specific value., Example: A temperature control unit unit speed control unit,sound control unit., , , , Control system mainly classifed into two types, 1.open loop control system, 2. closed loop control system

Page 9 :

Open loop control system, Example: On-Off of electric lamp:, An electrical switch serves to control the flow of current in a circuit .the input signal is filling of switch on off and corresponding output signal (bulb) flow electric current in circuit or no flow., A control system in which the output is dependent of the input or controlling action is independent of output or change in output is called open loop control system.

Page 10 :

Advantages and Dis-advantages of Open Loop Control, Advantages:, Simple in construction, Low cost, good reliability, easy maintenance, less chance of breakdown., Disadvantages:, No feedback unit, often in accurate, no correction for error., The controller never actually knows if the actuator did what it was supposed to do, i.e. it is inaccurate, Unable to sense the environmental changes or disturbances

Page 11 :

Closed loop control system, In the closed loop system input is dependant on the output of the system. it has feedback elements. gives the required value., Basic element of closed loop system

Page 12 :

Example of CLCS, HAND REACHING ON COMPONENT :

Page 13 :

Advantages:, High system Accurate, since the controller modifies and manipulates the actuating signal such that the error in the system will be zero., Self-correcting,because always compare actual value with required value, Senses the environmental changes, and disturbances in the system., Disadvantages:, Complicated to design, Costly, Instable, since due to feedback , system tries to correct the error., Advantages and Dis-advantages of Closed Loop Control

Page 14 :

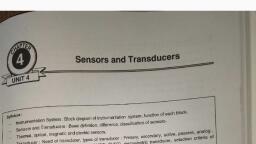

Sensors and Transducer, Sensor, “A device which provides a usable output in response to a specified measurand.”, Transducer , Transducer – a device that converts a primary form of energy into a corresponding signal with a different energy form ., , Primary Energy Forms: mechanical, thermal, electromagnetic, optical, chemical, etc.

Page 15 :

PERFORMANCE TERMINOLOGY, Range :The range of a sensor indicates the limits between which the input can vary. , 2. Span: The span is difference between the maximum and minimum values of the input. , 3. Error :Error is the difference between the result of the measurement and the true value of the quantity being measured., 4. Accuracy: The accuracy defines the closeness of the agreement between the actual measurement result and a true value of the measurand. It is often expressed as a percentage of the full range output or full–scale deflection., 5.Sensitivity: Sensitivity of a sensor is defined as the ratio of change in output value of a sensor to the per unit change in input value that causes the output change. It has both Linear & nonlinear behavior

Page 16 :

6.Nonlinearity :The nonlinearity indicates the maximum deviation of the actual measured curve of a sensor from the ideal curve. , , 7.Hysteresis:The hysteresis is an error of a sensor, which is defined as the maximum difference in output at any measurement value within the sensor’s specified range when approaching the point first with increasing and then with decreasing the input parameter., 8.Resolution: The resolution of a sensor is the smallest increment of input that can be detected output signal.

Page 17 :

9.Repeatability :Repeatability It specifies the ability of a sensor to give same output for repeated applications of same input value, , 10. Stability: Stability is the ability of a sensor device to give same output when used to measure a constant input over a period of time. , , 11.Dead band/time: The dead band or dead space of a transducer is the range of input values for which there is no output. , , 12.output impedance: when sensor giving an electrical output is interfcaed with an electronic circuit is called output impedance

Page 18 :

Basic Principle of Sensor / Transduction, Sensor is a device that when exposed to a physical phenomenon (temperature, displacement, force, etc.) produces a proportional output signal (electrical, mechanical, magnetic, etc.). , , Transducer is a device that converts one form of (energy) signal into another form of (energy) signal.

Page 19 :

SENSORS, Classification of sensors and transducers applications in manufacturing is as follows. , A. Displacement, position and proximity sensors, • Potentiometer , • Strain-gauged element , • Capacitive element , • Differential transformers , • Eddy current proximity sensors, • Inductive proximity switch , • Optical encoders , • Pneumatic sensors , • Proximity switches (magnetic), • Hall effect sensors

Page 20 :

B. Velocity and motion , • Incremental encoder, • Tachogenerator, • Pyroelectric sensors , C. Force , • Strain gauge load cell , D. Fluid pressure , • Diaphragm pressure gauge , • Capsules, bellows, pressure tubes , • Piezoelectric sensors, • Tactile sensor, E. Liquid flow, • Orifice plate, • Turbine meter

Page 21 :

F. Liquid level, • Floats , • Differential pressure, G. Temperature, • Bimetallic strips, • Resistance temperature detectors , • Thermistors , • Thermo-diodes and transistors , • Thermocouples, • Light sensors , • Photo diodes, • Photo resistors, • Photo transistor

Page 22 :

DISPLACEMENT SENSOR, POTENTIOMETER, , A rotary potentiometer is a variable resistance device that can be used to measure angular position

Page 23 :

STRAIN GAUAGE, The strain in an element is a ratio of change in length in the direction of applied load to the original length of an element. The strain changes the resistance R of the element.

Page 24 :

CAPACITIVE ELEMENT BASED SENSOR, Capacitive sensor is of non-contact type sensor and is primarily used to measure the linear displacements from few millimeters to hundreds of millimeters.

Page 25 :

Cont..

Page 26 :

LINEAR VARIABLE DIFFERENTIAL TRANSFORMER, ‘LVDT’ is a transducer for measuring linear displacement, It must be excited by an AC signal to induce AC response on secondary., The core position can be determined by measuring secondary response.

Page 27 :

EDDY CURRENT PROXIMITY SENSORS, Eddy current proximity sensors are used to detect non-magnetic but conductive materials. They comprise of a coil, an oscillator, a detector and a triggering circuit.

Page 28 :

INDUCTIVE PROXIMITY SWITCH, Inductive proximity switches are basically used for detection of metallic objects.

Page 29 :

OPTICAL ENCODERS, Schematic Diagram, Typical Construction

Page 30 :

PNEUMATIC SENSORS, Pneumatic sensors are used to measure the displacement as well as to sense the proximity of an object close to it. The displacement and proximity are transformed into change in air pressure.

Page 31 :

PROXIMITY SWITCHES

Page 32 :

APPLICATION OF PROXIMITY SENSORS

Page 33 :

HALL EFFECT SENSOR, . Hall effect sensors work on the principle that when a beam of charge particles passes through a magnetic field, forces act on the particles and the current beam is deflected from its straight line path.

Page 34 :

VELOCITY, MOTION, FORCE AND PRESSURE SENSORS, TACHO GENERATOR, Tachogenerator works on the principle of variable reluctance., , It consists of an assembly of a toothed wheel and a magnetic circuit as shown in figure

Page 36 :

STRAIN GAUGE AS FORCE SENSOR, Strain gauge based sensors work on the principle of change in electrical resistance. , When, a mechanical element subjects to a tension or a compression the electric resistance of the material changes. This is used to measure the force acted upon the element.

Page 37 :

FLUID PRESSURE

Page 38 :

PIEZOELECTRIC SENSOR

Page 39 :

LIQUID FLOW(TURBINE METER), Turbine flow meter has an accuracy of ±0.3%. It has a multi blade rotor mounted centrally in the pipe along which the flow is to be measured

Page 40 :

LIQUID LEVEL, DIFFERENTIAL PRESSURE, FLOATS

Page 41 :

TEMPERATURE SENSORS, Temperature conveys the state of a mechanical system in terms of expansion or contraction of solids, liquids or gases, change in electrical resistance of conductors, semiconductors and thermoelectric emfs., BIMETALLIC STRIPS

Page 42 :

LIGHT SENSORS, A light sensor is a device that is used to detect light.., SELECTION OF SENSORS, 1.Nature of measurement, 2. Nature of output required from the sensor., 3.Then possible sensor can be identified