Page 1 :

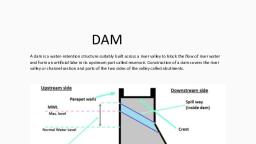

. Introduction, Tunnels are linear opening below the ground or through natural obstacles and act as an element of, transport. The other horizontal variants of tunnels include water pressure tunnel, used for carrying, water from reservoir to power generating unit, driftis smaller version of tunnel can be used as starting, point for larger diameter tunnel, adit, a linear small opening as an approach to the tunnel for carrying, out forward exploration and to act as conduit for men and machine. Half tunnelto act as underground, by pass, Chunnelor subaqueous tunnel or bridge. Most of the above-mentioned linear openings are, straight to curvilinear and horizontal to slightly sloping. Its vertical variants such as shaft and raise are, used for taking men and machine in underground mines and also to provide ventilation for all kinds of, underground openings. Tunnels and shafts are important part of all variants of underground mining., Parts of Tunnel, The terminology used in tunneling industry is similar to mining industry. The typical cross sections and, parts are shown in Fig. 3. Most of the transport tunnels in soil have square sections and in rocks arch or, horseshoe shaped sections. Water carrying tunnels are invariably have circular section. Mostly tunnels, run as single tube but twin tubes tunnels are not uncommon for example a tunnel, between England, and France below English Channel.The top most part of the tunnel is called as portal, as seen from inside, the ceiling is called as roof or back of the tunnel. The tunnel sides are its wall and the bottom ground is, termed as floor or invert. The line where arch meets the wall is called as springline., Fig. 3 Different kinds of tunnel cross-sections and parts of the tunnel. Square cross-section (a) for soft, ground, Arch (b) and Horse Shoe (c) shaped transportation tunnel and circular cross (d) section of water, pressure tunnel. (e) A twin tube tunnel cross sectioty

Page 2 :

IoDepending upon the purpose of utility, tunnels are mainly of two types, namely hydraulic tunnels and, traffi c tunnels. Tunnels are also constructed for other purposes such as storage of fuel, nuclear, installation, and disposal of hazardous materials., Hydraulic tunnel, In a hydraulic tunnel, the works of the tunnels are associated only with the passage of water. Hydraulic, tunnels may be of different types. Power tunnels carry water to hydroelectric projects plants. Irrigation, tunnels convey water from the storage behind a barrage or dam for irrigation purpose. Diversion tunnels, serve the temporary purpose of river diversion for dam construction. Spillway tunnels are constructed, for releasing water from the reservoir. Tunnels are also used for sewage conveyance or water supply., Numerous water conductor tunnels of all these types are prevalent in India., Traffic tunnels, These include tunnels used as highways, subways, and railways for transportation. The 3 km-long, Banihal tunnel connecting Jammu and Srinagar is an example of highway traffic tunnel constructed in, rock. Some of the major cities in India have railway traffi c tunnels (e.g., Kolkata Metro Railway tunnel), constructed in subsoil to ease the congestion of traffi c movement by surface transports., Problems in Soft Ground Tunneling:, The removal of soil, if not naturally well compacted may show following problems:, Reveling Ground- chunks or pieces of material drop from the excavated walls during excavation., Running Ground- dry and less compacted gravel and coarse sand start coming in the opening., Squeezing Ground- Moist soil moving into opening, slowly as plastic material, floor may also heave., Swelling Ground- Soil moving in due to swelling of clays without getting detached to main mass., Flowing Ground- Wet saturated soil flowing as slurry in excavated opening., Groundwater Incursion- If tunnel is excavated below the groundwater table then groundwater is bound, to come in the opening. Sometimes due to piping surface water may also flood the opening., Problems in Hard Ground Tunneling:, Rocks offer different tunneling conditions starting from intact ground, which do not require any support, to stratified, jointed, blocky, crushed, swelling and squeezing rocks, requiring different kinds of, tunneling operations and support mechanism based on the dead load. The tunneling operation in rocks, have their own set of problems, such as:Spalling Ground- Falling of rock pieces and chunks from the exposed back and walls., Popping Ground- Sudden projection of rocks into opening without getting detached from rock mass., Blowouts- sudden detachment of rocks and forceful flying rocks in the tunnel opening., Bumping Ground- Also termed as rock bursts resulting into local tremors with sound., Squeezing Ground- Movement of rock mass as creep and heaving of tunnel floor in the opening.

Page 3 :

Swelling Ground- Volume expansion of moist rocks rich in clay and its movement in tunnel opening., Groundwater Incursion- Seepage of surface water or groundwater., Under and over break- Breakage of rocks less or more than what is required., Effect of Bedded Rocks on Tunnel Lining, Geotechnical evaluation of rock condition at depth and predicted rock pressure on the tunnel heading, are very important at the planning stage for consideration of the data in the design of structure. The, following are the schematic descriptions of the behaviour of rock mass and rock pressures on the tunnel, lining or support because of the varying conditions of stratifi cation and rock structures:, (i) In case of a tunnel passing through horizontal or low dipping beds, there will be uniform vertical, pressure on tunnel lining,, (ii) If the bed is vertical dipping and tunnel line perpendicular to strike, the tunnelling will also, experience uniform vertical pressure,., (iii) When the tunnel alignment is parallel to the strike of the vertical dipping strata, there will be heavy, pressure on arch,, (iv) If the tunnel axis is perpendicular to the strike of the dipping strata, the lining will experience, uniform vertical pressure with longitudinal thrust,, (v) In case the tunnel is aligned parallel to the strike of dipping beds, there will be pressure, concentration on the sides of tunnel linbed., (vi) When the tunnel axis is oblique to the strike and dip of inclined beds, the pressure will be, concentrated on the sides,

Page 4 :

Effect of a Fault Traversing a Tunnel, A fault traversing a tunnel as shown in Fig. (a) has the following effects on a tunnel depending upon its, location:, (i) If a tunnel is in the hanging wall of a fault, as shown in Fig. 1(d), it should be located away from the, hanging wall side of the fault as far as practicable to avoid the offshoots of fault. If it is a reverse fault,, the hanging wall block containing the tunnel moves, which is an unfavourable condition., (ii) When a tunnel is in the foot wall of a fault, as shown in Fig. (c), in a normal fault, the foot wall block, is subjected to movement. This position at the foot wall block is the worst scenario for tunnel driving., (iii) When the tunnel alignment traverses perpendicular to the trend of the fault as shown Fig. (b), the, zone of intersection of the tunnel and fault will cause problems, but this situation is better than the, tunnel aligned oblique to the fault., (iv) When the tunnel traverses oblique to the fault, it will meet a thicker zone of crushed rock, as shown, in Fig. (e). It is necessary to take the tunnel through the position where the width of the fault zone is of, minimum thickness, even by giving a kink to the tunnel alignment, if needed., In all the cases of a tunnel traversing a fault Fig. (a) , it is to be seen whether it is an active fault, which is, always an unfavourable feature for tunnelling. An alignment for tunnel should be so chosen that it does, not run along the fault zone. If a tunnel cuts the fault, the crushed rock and the gouge of fault zone will, cause serious damage to the lining. A low angle fault (thrust) is the most damaging feature for the, tunnel. The pressure of water fl owing through the fault zone might cause overbreak and even collapse, of the tunnel structure. The clayey gouge may swell with soaking of water and exert pressure on tunnel, heading to cause deformation of rocks., , Effect of Folds on Tunnel Lining

Page 5 :

The following are the effects of folds on tunnel lining:, (i) A tunnel will experience intense lateral pressure if it passes through an anticline at the portal portion, with fold axis aligned nearly parallel to tunnel line (Fig. 16.8(a)). There will be more bending of the, anticlines in the upper strata and more joints due to tension stresses compared to lower strata. As such,, it is advisable to locate the tunnel in a deeper part where the joints will not create problem of, tunnelling., (ii) A tunnel passing through syncline, see Fig. 16.8(b) will experience more lateral pressure in the, middle part away from the portals. If the rocks of a syncline passing through a tunnel is permeable in, nature, surface water may permeate to the tunnel creating problem of dewatering (draining out water, using pumps). The presence of such folded structure and its demerits need to be identifi ed during, geological investigation at the planning stage of a tunnel for necessary drainage arrangement in the, design, as it may cause adverse problems during tunnel excavation., , Bedded rocks with unfavourable strike and dips and structures such as folds or faults may lead to, instability of tunnel rocks if located close to the hill slope. For example, a dipping bed towards the lower, valley if traversed by a tunnel at right angles is likely to be affected by slope failure. In case of horizontal, or vertical bed, there may not be any serious problem if the tunnel line is aligned parallel to it. However,, if the strata or fault planes dip towards the slope or the folded rock with axial dip is inclined towards the, slope, it will lead to the problem of slide, especially after saturation with water., Rock Cover and Overbreaks in Relation to Joints, Relationship between tunnel diameter and extent of overbreak of tunnel rock guided by the

Page 6 :

Inclination of joint and stratifi ed rock:, (i), (ii), (iii), (iv), (v), , In horizontal strata traversed by inclined joints, the overbreak may be up to half the tunnel, Diameter., In vertical strata with horizontal joints, the overbreak is restricted to one-fourth of the Tunnel, diameter., In inclined strata traversed by joints at any angle, the caving in of rock is restricted to a, Maximum thickness of half the tunnel diameter., In highly jointed or crushed rock, the overbreak may extend up to three times the diameter Or, three times the sum of height and width of the tunnel., It is also noticed that pulses due to blasting are not transmitted beyond the distance of Twice, the tunnel diameter., , Types of Tunnel Supports Including Rock Bolting, A support is necessary in a newly excavated tunnel portion to keep the opening stable and avert any, collapse of roof or tunnel wall. This installed initial support system is important for safe tunnelling until, lining is provided. The conventional supports provided in a tunnel can be one or more combination of, the following types:, , (vi), (vii), (viii), , (i) Timber planking, (ii) Steel ribs, (iii) Steel ribs with pre-cast or cast-in-site concrete slabs, (iv) Shotcreting with or without wire mesh, Perfobolt with shotcreting, Forepoling, Rock bolting, The type of support provided depends on the size of the tunnel cavity, geological condition of, rock, measured or anticipated rock load, and water fl ow conditions. In adverse condition of, tunnel rock, timber planks or steel rib supports are provided immediately after tunnel driving to, avoid any overbreak, see Fig. 16.19 (a). In general, the supports are kept permanently. If the, tunnel rock is not very weak, the supports by timber logs or steel ribs may be of temporary, nature until the rock becomes stable when the supports are removed and concrete lining is, provided. The steel rib support is very common and may be taken up alone or in, combinationwith concrete lining of tunnel interior and fi lling of the caved space between rock, and the support by rubble or concrete, see Fig. 16.19 (b).

Page 7 :

Supporting the rock by shotcreting is done in many tunnels for arresting the overbreak when, the rocks are extensively jointed, having a tendency to collapse immediately. Shotcreting is, the process of concrete spraying into the place by a nozzle. It is generally of 5–8 cm thickness, and contains some additive with capacity of immediate setting. It prevents cavity formation, in addition to collapse of rock. In case of soft and weak rocks, shotcreting of more thickness, and with wire meshing is provided. Once shotcreting stops the tendency of caving, permanent, support by steel rib is provided to contain the total rock load. Shotcreting can be made without, or with wire mesh or reinforcing fi bres., Perfobolts are perforated hollow tubes that are fi lled with grout inserted into the drill holes., The grout is extruded to fi ll the annular space around the tube when a piece of reinforcing rod, is pushed into the grout fi lling the tube. Perfobolt is provided after shotcreting has made it, possible to keep the rock intact. In case of hard rock with blocky joints, perfobolts are, successfully used for retaining the rock by extending the rods several metres inside sound rock., Forepoling technique consists of providing an umbrella of suitable material (pipes or pointed, rocks) over the reach of the tunnel where fl owing ground condition is noticed or expected., Typically, these are devices in overlapping arrangement as shown in Fig. 16.20 (a). The aim, of forepoling is to ensure that there is no movement of material above the umbrella during the, removal of muck. The two ends of the forepole rods are supported, one end on steel ribs and, the other on undisturbed muck, ahead of the heading, shown in Fig. 16.20 (b). Steel channels, are also used when the materials of the fl owing ground are clay gouge and sheared materials, without any big rock fragments. In case rock chunks are present, multiple rods or forepoles, are used. Forepoles such as rods or channels provide a complete umbrella over the entire zone, , from where fl ow takes place. In multiple forepoling , there are added rows of forepoles to bear, the pressure acting on the section. Forepoling techniques are used in extremely weak rock, condition as noticed in many tunnels constructed in the Himalayan region., Rock bolting is undertaken when the rock loads are excessive, especially in a large-diameter, tunnel (Fig. 16.21). Rock bolting reinforces and supports partially detached, laminated, or, otherwise incompetent rocks that would be subjected to failure by gravity and loss of frictional, effect. The effectiveness of rock bolting can be improved by providing a wire net over the rock, surface followed by concrete spray. Rock bolting of wedge type is undertaken along with, shotcreting or grout ring to hold the rock in excavated profi le before

Page 8 :

any breach. Rock bolting is applicable in hard but jointed rock and blocky and seamy rock, but, not in crushed rock or in swelling rocks.