Page 1 :

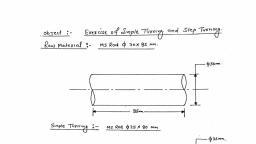

Object, , ADVANCE TURNING SHOP, JOB NO -2, , : Exercise of simple turning and step turning, , Requirements:, , Theory:, , Procedure:, , @ Materials : A Mild Steel Rod, (i) ~— Tools : Engg. Scale, Vernier Calliper, Callipers, Spanner Set, Central, Drills, Single Point Cutting Tool,, , (iii) | Machines : A Centre Lathe and Power Hacksaw, , Turning in a lathe to remove excess material from the workpiece to produce a cone, shape or a cylindrical surface. The various types of turning made in lathe work for, various purposes are standard or common operation and special or rare operations., Standard or common operations include plain or simple turning and step turning. The, work is held between centers. The left hand work piece is firmly gripped in a lathe, chuck. And the right hand end of the work piece is supported on the dead centre fitted, in the tail stock. Work piece revolves during the operation and the tool is fed against, the job., , @ First cut the mild steel rod with the help of power hacksaw as per given, dimensions., , (i) — After cutting the mild steel rod, hold it in a chuck having three or four jaws, fitted on the head stock of the Lathe Machine. And true the job with the help, of needle block., , (iii) The single point cutting tool is fitted to the tool post, and true the tool with, help of dead center fitted on the tail stock., , (iv) Do the facing operation of the work piece with the help of single point cutting, tool., , (v) Then Centre the Job with the help of center drills in the drill chuck and the, hold the drill chuck in the tail stock., , (vi) Then tool is fitted in 90° of the work piece and set the parallel with the axis of, rotation of the work piece and the cutting edge touch the work piece for light, cut., , (vii) Check the direction of rotation of the spindle and give few cut on the job., , (viii) Then give the depth of cut and feed of the tool according to the work piece, material and finish required.

Learn better on this topic

Learn better on this topic

Learn better on this topic

Learn better on this topic