Page 1 :

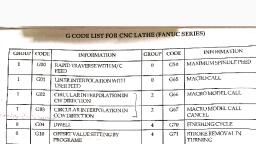

THELATHE = 111., , the split nuts and thus engages or disengages with the lead screw. The half, nuts slide within the guide or frame 2. Closing the half nuts causes the, carriage to move a fixed distance for each revolution of the spindle. The, direction in which it moves depends upon the position of the feed reverse, jever on the headstock. The split nut is used only for thread cutting and, never for any other operation., , 32 LATHE ACCESSORIES AND ATTACHMENTS, , Lathe accessories include centres, catch plates iers, chucks, collets,, , face plates, angle plates mandjels, and rests, They are used either for, holding and supporting the work or for holding the tool., , Attachments are additional equipment used for specific purposes., They include stops, ball turning rests, thread chasing dials, and taper, turning, milling, grinding, gear cutting, turret, cutter, relieving and crank, pin turning attachments., , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , Figure 3.22 Lathe centre, A. Ordinary centre, B. Ball centre, C. Frictionless centre— 1. Insert type centre, 2., Nut, 3. Roller bearing, 4. Thrust bearing, 5. Housing, D. Half centre, E. Tipped, centre-1. Brazed tip, F, Insert type centre-1. Insert, G. Pipe centre, H. Use of half, centre-1. Half centre, 2. Facing tool., , Scanned with CamScanner

Page 2 :

112 ELEMENTS OF WORKSHOP TECHNOLOGY, , v, Lathe centres : The _most_ common method of holding the work in lathe is, , ‘between-the-two-centres—live centre and dead_centre, These two centres, , take up the thrust due to metal cutting and the entire load of the workpiece, on small bearing surface. So they are made of very hard materials to resist, deflection and wear. The dead centre is subjected_to-wear-due to friction., The included_angle_of-the-centre is usually 60° for general purpose work, and 75° for heavy_work. The shanks of all the centres are machined to the, Morse (0 to 6) or Metric (4 and 6) standard tapers. Different types of centre, , for different types of work are shown in Fig.3.22. /, , The ordinary centre is the type-used for most general work. In the ©, , tipped centre, the point consists of a hard alloy tip brazed into an ordinary ~, steel shank. This is more expensive type of centre, one which will give, excellent service against, wear and strain. The ball, centre—is_used_to_minimize, wear_and_strain_on_ the, ordinary centre except that, little less than half of the, centre has been ground, away. This construction, facilitates facing of the bar, ends without removal of the, centre. Fig.3.22-H, illustrates the use of a halfcentre in a facing operation., The insert type of centre is, used for reasons of, economy as only the highspeed steel “insert” can be, replaced instead of, replacing the whole centre., The rotating ot Frictionless, centre_is_ always used in, enire J CS, tailstock for __-supporting, heavy work-revolving at a, _high speed, An ordinary, insert type centre revolves Figure 3.23 Catch plates and carriers, freely on the ball and the A, Single pin catch plate, B. Straight tail cartiel,, roller bearings fitted in a C. Double pin catch plate, D. Double slot!, housing having a taper carrier, E. Double slotted catch plate, F. Doub! 3, , shank corresponding to the tail carrier, G. Bent tail carrier., , , , , , , , , , , , , , Scanned with CamScanner

Page 3 :

Et, , THE LATHE 113, , i i i duce friction, coer of the tailstock spindle. The _b: aring e, tt eh up end thrust and allow t the work fos a, q 1, , period without_ developing any appreciable heat. The pipe centre is_, ro 0 orting the open end of pipes, shells, etc. for thread cutting or, used for supp, turning in the athe. j :, , To reduce friction at the dead centre point tallow, tallow and, graphite or graphitized oil may be used., , Carriers and catch plates: Carriers and catch plates are used to drive a, workpiece when it is held between two centres. Carriers or driving dogs are, attached to the end of the workpiece by a set screw, and catch plates are, either screwed or bolted to the nose of the headstock spindle. A projecting, pin from the catch plate or carrier fits into the slot provided in either of, them. This imparts a positive drive between the lathe spindle and, workpiece. Fig.3.23 illustrates different types of catch plates and carriers., The projecting pin of a single pin catch plate drives the straight end or tail, of a carrier attached to the workpiece. Two pins of a double pin catch plate, engage with the double tail or double slotted carrier and provide uniform, drive. The bent tail type is used in conjunction with a face plate or slotted, , catch plate., , Chucks : A chuck { 9 3 v4, , is one of the most i, , important devices 7 ;, 6, , , , , , , , , , , , , , for holding and, totating a piece of, work in a lathe. C(t LI, Workpieces of, Short length, and, large diameter or, of irregular shape, Which cannot be, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , Conveniently, Mounted between Figure 3.24 Four jaw independent chuck, centres are held 1. Concentric circle, 2. Chuck body, 3. Jaw screw,, , Quickly and rigidly 4. Jaw, 5. Gripping surface, 6. Recess for back plate., Moa chuck. A, , chuck is attached, , eae lathe spindle by means of bolts with the back plate screwed on to the, effected pone ee of the chuck with the lathe axis is, 2) SPigotting, The differenttypés Ofchucksare:sSts—=—CS~S, , —————, , ——, , , , , , , Scanned with CamScanner

Page 4 :

114 ELEMENTS OF WORKSHOP TECHNOLOGY, , 1. Four jaw independent chuck 5, Collet chuck, , <4, ‘Three jaw universal chuck _- 6. Combination chuck, _ 3. Air or hydraulic operated chuck ~~ 7. Drill chuck :, 4, Magnetic chuck, , , , , , , ~Four jaw independent chuck : A four jaw independ uuck is, _illustrated in Fig.3.24. This chuck has four jaws which may be made to, slide within the slots provided in the body ofthe chuck for gripping °, different sizes of work piece. Each jaw may be independently by, rotating the screw which meshes with the teeth cut on the underside of the, jaw. Each jaw made of tough steel has ‘three inner and one outer gripping’, surfaces. ‘The outer, gripping surface is 3 4, , used for holding 2 5, larger sizes of ;, workpiece by -’ 1 f, , , , , , , , , , , , , , , , , , reversing the jaw.., Concentric _circlés, inscribed on the face ;, of the chuck facilitate, quick centering of the, , workpiece. This type, , , , of chuck .___is Figure 3.25 Universal chuck, particularly used in 1. Beyel pinion, 2. Scroll disc, 3. Bevel teeth on scroll, : the —seiting__up__ of | disc, 4. Chuck body, 5. Jaw., , heavy and irregular ., shaped articles. The diameter of the \, body Specifies the size of the chuck. 1 2 4, , Universal or self centering | \, chuck : In a three jaw_universal 54 =, , =, , _ chuck. illustrated in Fig.3.25 all the, jaws may be made to slide, simultaneously by an equal amount am _, within the slots provided on the.body, by rotating any one of i three, pinions which meshes with the, teeth, cut,on the underside of the scroll, disc. The scroll disc having a spiral, , groove cut on.the top face meshes oa k, , with the teeth on the jaws. When the Figure326 Combination chv’, , 1, Chuck body, 2. Frame, 3. Screw,, 4. Jaw, 5. Scroll., , , , , , , , , , , , , , , , disc is made to rotate by any one of, , Scanned with CamScanner

Page 5 :

THE LATHE 115, , the pinions, all the. three jaws, move backward or forward by /, equal amount. The chuck is, suitable_for_holding round,-or, hexagonal, “and” other “simi lar, shaped workpiece and_the_ job, is centered--automatically and, quickly.-But-it-has less gripping, capacity-as-only-three_jaws. are, used and-centerifg-accuracy is | ~, soon fost duo to wear. = Pe, , Combination chuck, As the name implies, a, combination chuck, shown in, Fig.3.26, may be used both as a, , , , Figure 327 Magnetic chuck, 1. Magnets, 2, Chuck body., , self_centering and _an, independent chuck to, ca take advantage of both, "| i the types. The jaws may, NV ZEN be operated individually, ae \ : by separate screws or, La simultaneously by the, . scroll disc: The screws, mounted on the frame, ee 3.28 Principle of magnetic chuck 2 teeth cut on its, - Work, 2. Non magnetic material, 3. Keepers, underside which meshes, 4. Face plates, 5. Magnet. with the scroll and all the, screws ; jaws together with the, move radially when the scroll is made to rotate by a pinion., fiesoe ee chuck : The front view of a magnetic chuck is shown in, ma netic misteealot; olding_-a-very-thin-workpiece- made. of, aon where ‘erial which cannot be held in an ordinary chuck. It is also, is Undesirabe a omtion of the work piece duc to the pressure of the jaws, olding powe, The working of a magnetic chuck is shown in Fig.3.28. The, either from he = the chuck is obtained by the magnetic flux radiating, Within the chs k lectro-magnets or from the permanent magnets introduced, and grips it L - In the ON Position the flux passes through the workpiece, contact with . OFF position the Magnets are set aside bringing them in, Prevent the, Pa Permeable “keepers” which short circuit the flux and ™m from passing through the workpiece., , , , , , , , , a, , Scanned with CamScanner