Page 1 :

2, Composite Systems and, Temperature Stresses, 2-1 Composite System, A System consisting of more than one bar or tube of the, , same or different material rigidly, connected in such a way that when subjected to loads or variations in temperature, each individual, , component undergoes equal changes in length, is called a composite system., 2-1-1, , Composite System of Equal Lengths Subjected, , to Load. Consider three bars of different materials and different, areas of cross-section but of equal length subjected to a load P as, shown in Fig. 2-1. We are interested to find out the load carried by, , each bar and the stress induced in each. Let A1,A2, Ag be the areas, of cross-section of the bars and E1, E2, E3 their respective moduli, of elasticity. Let P1, P2, Pa be the loads taken by the bars, then, , O, P= P1 + P2 + P3, Since all the bars are rigidly connected together, they all undergo, equal change in length and length of each bar is the same,, therefore, strain is also the same in each bar., Al= Change in length l, , Let, , Fig. 2-1, Then, , strain in each bar, , = xE, , Stress in each bar, , Load taken by bar 1,, , P, , xEzA, , Load taken by bar 2,, Load taken by bar 3,, , P=xE3Ay, , A(A, E, +Az Eg +AgEa) -P, or in general,, , or, , Al=-, , A, , Al =, , PL, , 2A,, i=1, , Pl, , E, , +Ag Eg + Ag Eg, ..(2.1)

Page 2 :

28, , STRENGTH OF MATERIALS, , where, , n, , nunber of, , bars,, , Loads taken by bars become,, , PA E1, , or, , A E +A, Eg +A3Ba, Pa, , 1, , PA2 E2, , A, , A, , +A, Eg +Ag E3, , E, , P, , P1 =, , A2 BA3 E,, , AE, , P, , +1+A, , B3, , Az E, , E, , PA3B3, , P, , A E +Az Eg +Ag E3 A E1A Ez+1, Aa EAs Es, Stress in each bar becomes,, PE, +A E2 +AsEs, , O1AE, Similarly,, , P, , A1E At E3 As, E2, , P, , E1A+Az*, E, E, BA, *E3B AtAs, E3, PE;, , or in general,, , .(2-2), , A,E, i=1, , P, , 2.1-2, , No, , N, , Composite System, , of, , Unequal Length, , Subjected to Load. Consider two tubes of different materials of, areas A and A2 and of, unequal lengths as shown in Fig. 2-2, subjected to load P. Since the inner tube is larger than the outer, tubes by an amount 4,, therefore, upon application of load P, the, inner tube takes up the whole load until it is shortened, by A., ., , Compressive strain in, , inner tube, , Compressive stress in the inner tube, Compressive load taken by, Fig. 2.2, This, in Art. 2.1-1., , Remaining load, , =, , P-, , 1, P1=, , P-A, A, , )4,E1, +A2 E2, , =, , A2 E2 7, , Aq Ea, , remaining load is then shared between both the tubes, , Loard taken by tube, , the inner tube, , accroding to the analysis made

Page 3 :

APOSITE SYSTEMS AND TEMPERATURE STRESSES, , 29, , Total load taken by tube 2, Pa =Ag E P-A, AEaiA2E2, A E +A, E2, Stresses in tubes become,, , P-A,E9E, , 1, , A AE, , ag, 2, If the outer tube is, , larger than, , +A2 E2, , 2,(P-4,, Ap, by, , an, , ....2-4), , amount A, then, , P-A,EE, A E +A,, , 1, , E2, , P-A,B)E, AE +A1 E2, , 2, , )E,, , A E +Ag Ez, , the inner tube, , ,, , ..(2-3), , ..2-5), , .(2-6), , 2-1-3 Composite or Equivalent Modulus. To determine the common extension of a, composite bar it is convenient to consider it as a single bar of an imaginary matarial with an, equivalent or composite modulus E. It shall be necessary to assume that both the extension and, , the original lengths of the individual members of the composite bar are the same; the strains in, all members will then be equal. Now total load on composite bar, , P=, , P1, , +, , Pz. +Pa, , Ifo is the stress in the equivalent single bar, then, o A +Ag+... +A,) = o1A1 + o2Ag +... +oAn, , Dividing throughout by the common strain s, we get, , (A +Agt..+A,)=, or, , E, A, , A1+Ag t..A, , +A2 t.. +A,) = (E1A1 + EAg t.. + E,A, , E,A, ...(2.7), , or, , i=1, , P, , Stress in equivalent bar, , 2A, , Strain in equivalent bar, , Common extension,, , B,A, al, , Pl, , A, , ...(2-8), , Example 2.1 A steel rod 20 mn diumeter is passed through a brass iube 25 mm interna

Page 4 :

30, , STRENGTH OF MATERIALS, , lameter and 30 mm external diameter. The tube is 80 cm, , long and is closed by thin rigid, na fastened by nuts, screwed to the rod., washers, LS 5 RN., The nuts are tighened until the, compressive force in the tube, Calculate the stresses in the rod and in the tube., E, , = 200 GPa,, , Solution. The tube, Fig. 2.3., Area of, steel rod, A,, , mbly, , is shown in, , =, , E 80 GPa., , and rod asse-, , washer, x, , Nut, , -Brass, , (20, , steel rod7, , tube, , = 314 mm2, , Area, , of brass tube,, , As, , 20mm-25mm-30mm, , (302-25), , =, , 216 mm2, Since the rod and tube are, , 80 cm, , rigidly, fixed, therefore, strains in both are the same., Let Al, , =, , common, , Strain in tube, , decrease in, , length,, , and rod=, , Fig. 2-3, mm, , 800, A, , Stress in steel rod,, , xE,, , =, , 800, , Al, , 800, , x 200 x 103, , A103 MPa, AL, , Stress in brass tube,, , O 0 x E, =, , 800, , x 80 x 103, , = Alx 102 MPa, Force in steel rod,, , P,, , Force in brass, , P, , tube,, , Total force,, Al, , =, , o,, Ob, , A,, , x, , Ab, , x, , =x105, Al, , =, , x, , 102, , 314, , x, , x, , 216, , =, , 78-5, , =, , 21-6, , x, , x, , Ps+ P =P, (78-5+ 21-6) 103=5, Al=, , Al kN, , 103, = 0-04995 mm, , 100.1, , 0-04995x 103 12.4875 MPa (Tensile), , Os, o, , x, , Al kN, , =, , =, , 0-04995, , x, , 102, , =, , 4:995 MPa, , (Compressive), , Example 2-2 A load of 30 kN is jointly supported by three, equidistant vertical rods in the, same vertical plane. The rods are so, adjusted that they share load equally. Al the rods are 25 mm, diameter. Calculate the final stresses if an additional load 20, of kN is added., E, = 2 E = 210 GPa., , Solution. The rods, , are, , shown in, , A,, Initial load taken by each rod, , Fig., , =A, =, , 2.4., , d-, , kN, ==10, 3, , x, , (25), , 491, , mm2

Page 5 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, , 31, , When the additional load of 20 kN is added,, the decresase in length, A l, of all the rods will be, , 30 kN, , equal., , Al, , Strain in steel rod,, , 83x 10, Al, , Strain in copper rod & c, , 3m, , 2-5 x 10, Stress in steel rod, o, =8, x E,, , Al, , 3x 103, , X, , 210x 103, , = 70 x Al MPa, , Stress in, , copper rod,, , Total load, , Ec, , X, , o, =Ec, , 2 o, , A_, , Fig. 24, , 210 x 103, , Al, 2:5 x 10, , 2, , =42x Al MPa, , Oc x Ac, = 2 x 70xAlx 491 +42 x Alx 491, =, , X, , +, , 182 x Alx 491 = 20x 103, Al = 0.22381 mm, , Final stress in copper rod,, 0-22381, , 210x 10, , 10 x 103, , 2, , 491, , c, , 2-5 x 10, Final stress in steel rod,, 0-22381, , x, x 103, , 3, , x, , 210, , x, , 10 +, , 10, , x, , 9.40 +20-367 29.767 MPa, , 103, =, , 491, , 15-67+ 20-367 36-0374 MPa, , Example 2-3 A rigid bar AB is supported by three bars in the same vertical plane and are, equidistant from each other as shown in Fig. 2-5. The outer bars are made of steel, 2:5 cm diameter, and 50 cm long each. The central bar is made of brass and is 75 cm long and 2 cm diameter. Calculate, , the forces in the bars due to an applied force of 150 kN, assuming that AB remains horizontal after the load is applied., , Assume E, = 210 GPa and E, = 105 GPa., , Solution., A, = x, Ab, , (25)2, , =, , 491 mm2, , x (20)2 = 314 mm2, , Let Al be the vertical deflection of the bar AB when 150, , kN load is applied to it., , E, , horizontal, therefore all the bars, elongate by the same amount A l., Since AB, , remains, , Strain in steel bar,, , Al, , &s, , 500, A, , Strain in brass bar,, Stress in steel bar, o,, , Eb750, =, , Es, , X, , E, , 20, , 20, , CM, , Cm, , TmTTT, , TTTTT, , ALLLLLLLL5U KNIzLuuLULu, Fig. 2-5

Page 6 :

32, , STRENGTH OF MATERIALS, AL, 500, Al, , Stress in brass bar, Oj = 7, , x 210x 103= 420 x AlMPa, x 105 x 103 = 140 x Al MPa, , Total load carried by the three bars = 2 oA, + oyAz, , = 2x, , 420 xAlx 491, , 140, , +, , x Alx 314, , = 456400 xAl= 150x 103, Al= 0-32866 mm, Load taken by brass bar,, 140, , P, , x, , 0-32866, , x, , 314, , x, , 0-32866, , x, , 491, , =, , 14-4479 kN, , Load taken by each steel bar,, , P,, , 420, , =, , =, , 67-7763 kN, , Example 2:4 Two vertical wires are suspended at a distance of 30 cm apart as shown in, Fig. 2-6. Their upper ends are firmly secured and their lower ends support a rigid horizontal bar, , which earries a load of 2500N. The left hand wire has a diameter of 5 mm and is made of copper., The right hand wire has a diameter of 1-5 cm and is made of steel. Both are 5 m long initially., , (a) Determine where the load of 250 N should be kept so that both the wires will extendby, the same amount., , (6) Determine also the load, stresses and extension of each wire due to the load of 2500 N., Neglect the weight of the horizontal bar,, , E,, , =, , and, , 210 GPa, , E =125 GPa, Solution., A x, , A,, , (5) = 19.64 mm2, , x 4 (15)" =176:76 mm2, , Let the load of 2500N be placed at a distance x cm from the, copper wire. IfP, and Pe are the loads taken by steel and copper wires, respectively, then taking moments about copper wire, we get, , 5m, , 2500x x = Ps x 30, , P200z, =250 N, 30, , 30cm, , Pe 2500 00x =250 N, 2500 N, Stress in, , Fig. 2.6, LXtension, , Oc, , N/mm, 19-64, , Ae, , xl=250x 5 x 103, E, 19.64x 125 x 103, , of copper wire, 8l,, , Stress in steel wires,, Extension of stecl wire, 81,, , copper wire,, , A, =, , Os, , 30-mm, 3, , 250 x, , 1767N/mm, , 3x 176.7 m m, , 250xx 5 x 103, , Es xl=,3x 176.76 x 210x 10, , mm

Page 7 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, , 33, , (6) For the wires to extend by the same amount., dl, = 8le, , 250, 3, , x, , x, , 5, , x, , 176-76, , x, , 10 x*, 210, , x, , 250x 5 x 10, , 103, , 19-64, , x, , 125, , 30-x, , 103, , x, , 30 x, 176-76 x 210, , 19.64 x 125, , x = 15:12 (30-x), 16.12 x = 15.12 x 30, x = 28-14 cm, , (6) Load taken by copper wire,, , Pe, , =, , 250, , (30- 28.14, , 250x 1-86155 N, , 3, , Load taken by steel wire, P, =:250x, , 2814 2345, , N, , 3, , 155 = 7-892 N/mm2, , o, , 19-64, , 2345, , 176.76, , 13.267 N/mm*, 7-892, , x 5x 10, , x125125 x10, , Extension,, , =0.3157 mm, , centrally through, , a, in diameter and 25 cm long, passes, brass tube of 25 cm length, having an outside diameter of35 mm and inside diameter of25 mm. The, , Example 25 A steel bolt 20, , mm, , screw has 4 threads per cm and the nut is initially just tight on one end of the brass tube. Find the, 30°., in stress in the bolt and the tube due to tightening of the nut by turning it through, , change, , E,, , =, , 210, , GPa, E,, , =, , 100 GPa, , As (20)2 = 314 mm2, , Solution., , A (35)- (25)1, Contraction induced due to turning, , Contraction of, , 471-4, , mm2, , = 4 cm, , Pitch of threads, , Contraction, , =, , the nut through 30°, Extension, , of the brass tube +, , brass tube, , A,E,, , 471-4, , x, , 105, , mm, , =, , 48, , mm, , P x 250, , A,E,, , 314x 210 x, , Px2501, , 105, , 471-4, , 106, , 471.4, , P=., , of the steel bolt, , -_Px 250, , Pl, P, , Extension of steel bolt, , 10 mm, , 360, , x, , mm, , 103, , 1, , 314 x 2-1, , x 314 x 21, , 48x 250 x 1130-8, , 48, , 22907 N

Page 8 :

34, , STRENGTH OF MATERIALS, P_229007, , 31472-952 N/mm2, , P 22907, , 48-593 N/mm2, , =, , Ab, A, , 471-4, , Example 2-6 A mild steel bar 25 mm diameter and 250 mm, tube, having an external diameter, long is placed inside a brass, mm and internal diameter, of, 30, mm., The combination is, of 25, Subjected to an axial load of 45 kN. Find (a) the stress, then, in, the, tube, and the rod, (6) the, of the rod., shortening, , E,, , =, , 210, , GPa, E,, , 8, , =, , Pa., , Solution., , A x(25)2 =491 mm?, A, =(900-625) =x, , 275 _216 mm2, 4, , Let Al be the, , common, , Strain in steel, , shortening of the steel, 250, A, , 9 5 x E , =4, x 210 x 103 MPa, 250, , Load taken by steel bar,, Stress in brass tube,, , by, , brass, , Now, , mm., , AlAl, , bar,, , Stress in steel bar,, , Load taken, , bar and brass tube in, , Ps O, , X A, = 50x210 x 103 x 491 N, , 250E,, Ob950 Eb250, , tube, P,, , =, , o,, , x, , Ap, , x, , AL, , s250, , =, , x, , 80, , 80, , x, , x, , 10, , 103, , x, , MPa, 216 N, , P+Pp= 45 x 103, x x 210x 10 x 491+ AL x 80 x 103 x 216 = 45000, 250, , 250, AL, , OEX 105 [103.11 + 17-28] =45000, Al, , Stress, , in steel, , Stress in brass tube,, , bar,, , Os, , b, , 45000, , x, , 250, , 0-0934163 mm, , 10 x 120-39, 0-0934163, , 5 0 x 210 x 103 = 78-495 MPa, 250, , 0-0934163, 250, , x, , 80, , x, , 103, , =, , 29.903 MPa, , Example 2-7 An aluminium solid cylinder of 7:5 cm diameter, loosely inside a steel tube, having 10 cm external diamneter and 8 cm internal diameter. The steelfits, tube is 0-02 cm longer than, aluminium cylinder and is 250 cm long before the load is applied. Calculate, the safe load which can, be placed on a rigid flat plate on the top of the steel tube., Safe stress for steel is 95 MPa, and for, , aluminium 65 MPa, E, = 210 GPa, E, = 70 MPa., , Solution. The, , cylinder-tube system, , is, , shown in Fig., , 2:7.

Page 9 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, , 35, , Agx (75) =4320 mm, JP, , A, (100-64) =2830 mm2, , o02cm002cm, , Strain in steel tube 4 /, , 10cm, , Stress in steel tube, , 8 cm, , -steel, , F75cm, , 0-02, 250, , O-02 x 210 x 10" = 16-8 MPa, 250, Compressive load taken by the steel tube alone, before the initial gap of 0-02 cm is eliminated, , Aluminiumn, , = 16-8 x 2830, , Remaining load, , 47-544 kN, , = (P-47-544) kN, , This load is then shared by the composite system., Fig. 2-7, , Additional compressive load taken by the steel, , tube,, , pP-47-544), E,A,_ (P-47-544)x210 x10 x 2830, P, A, E, +A,E., , 2830 x 210 x 103+ 4320 x 70 x 103, , P- 47-544P-47-544, 1-5088, , 1+0-5088, , 24-1904, P-47 544 P+, P+24:1904, , =47-544, , Total load in steel tube, , KN, , 1-5088, , 1-5088, , Safe load for steel tube = o, x A, = 95 x 2830 N, P+24-1904, =, , 1-5088, , 95, , x, , 2830, , x, , 10-3, , P 405-6409-24 1904, , 381.4505 kN, , Load taken by aluminium cylinder,, P, , P-47-544P-47-544, 9653, , P-47 544, , 47-544, , PaAE+1, A,E, , 2830, , 210 x 103, , 4320, , 70x103, , +1, , 1-9653 1, , Safe load for aluminium cylinder, Oa, , x Aa, , =, , 65, , x, , 4320 N, , P-47-54465 x 4320 x10, 2-9653, , P, Hence safe load, , 832-656 + 47-544, , =, , 880-200 kN, , = 381-4505 kN, , is loaded at Bas shown in Fig. 2-8. It is supported, 2-8 A beam AB hinged, cm, square for the first 1-5 m length and, vertical steel bar CD which is 3-5, 2m, the, a, long, rom roof by, the load is applied the beam hangs horizontally., cm square for the remaining length, Before, 6, bar CD and (b) the total elongation of the bar. E,, the maximum stress in the steel, , Example, , at A, , =, , etermine (a), 210 GNIm?, , bar CD. Taking moments about A,, Solution. Let P be the pull in the, Px 0-5 = 50 x 0.75, , we, , get

Page 10 :

STRENGTH OF MATERIALS, , 36, , P= 75 kN, DE, (a) The stress shall be maximum in the portion, the steel bar CD., , Omax, , of, , 3-5 cm Sq, , 1.5m, , 75 x 103, -4, 2-5 x 2.5 x 10, , 120 MN/m2, , (6) Total elongation of bar CD, , 0-5m, 75, , x, , 1-5, , 0-5, , 10, , 2 5 cm Sq, , 210x 106-25 x 10-4, , 12-25 x 10, , B, , A, 05025,, , 75x, 210, , 10, , 50 kN, , 109(ou8+0-12245), , x, , = 0-0724 x 107 m = 0-724, , Fig. 2-8, , mm, , A and supported by a copper rod 2 m long and, Example 2.9 A rigid bar AB is hinged at, load of 150 kN at the free end B as shown in Fig. 2.9 (a). The, a steel rod 1-5 m long. It carries a, Find the stress in each rod and, cm and 2.5 cm respectively., diameters of copper and steel rods are 3, , reaction at A. E, = 2 Ec = 207 GN/m2, , Copper, , Steel, , 2m, , 15m, 25cm, , im, , 3 cm, , 1-5m-, , 0-5m, D, , D, B, , A, , 1m, , -1.5 m, , 0-5m, 150kN, , (a), , (b), Fig. 2:9, , Solution. Let P, and P. be the loads taken by the steel and copper rods respectively. Taking, moments about A, we get, P, or, , x 1+Pe x 2-5 150 x 3, , P+2:5 P.= 450, , .a), , If &L, and 1, be elongations of steel and copper rods respectively then after the load is, applied at the end B, the bar AB will assume the position as shown in Fig. 2-9 (6)., , From similar triangles,, , ACC, , and ADD', , we, , get

Page 11 :

cOMPOSITE, , 37, , SYSTEMS AND TEMPERATURE STRESSES, , 1, , 25, , ..6), , 2-5 6,, Pele, , Pex 10 x 2, , 8Pe x 107, , oleAE x9x 10 xEc, , Now, , 9TxE, 6P x 107, , P x 103 x 1-5, , A.E., , and, , T 6-25, , 6-25TxEs, , 10 x Bs, , x, , Substituting in Eq. (6), we get, , 8Pe x 10, , 6P, x1015 P, x 10, 6-257 x E, 12-57x E., , 2.5 x, , 97Tx E, , Ps8 x 12:, Pc, , 0-74074, , 9x 15, , ..(c), , Substituting Eq. (c) in Eq. (a), we get, , Pe (0-74074 +2-5), , 450, , =, , 450, , P, , 3-24074, , 138-857 kN, , =, , Ps= 102-857 kN, , Stress in copper rod,, , Pe, , 10, , =, , =, , A., , be the reaction at A, , Example 2.10 A rigid, A and suspended at two points B, , MN/m2, , =209-54 MN/m*, , x6-25 x 10-, , acting downwards,, , RA +150 =138.857+, RA, , 196-44, , x9x 104, 102-857, , ,, , Ra, , x, , *, , Stress in steel rod, 0,, Let, , 138-857, , oc A, , then, , 102-857, , 91-714 kN, , =, , bar ABC is hinged at, and C by two bars BD, , ALUMINIUM, , and CE made of aluminium and steel respectively as, load, , STEEL, , of, , Fig. 2.10 (a). The bar ABC carries, 20 kN midway between B and C. The cross-sectional, and 2 mm', area of the bar BD and CE is 3 mm2, the bars, respectively. Determine the loads taken up by, a, , shown in, , im, , Im, , and the stress developed in each., , Eal, , 70, , GN/m2; E,, , =200 GN/m?., , A, we get, , Pal, , x, , 1+Ps, , x, , 2, , Pal + 2Ps, , or, , Elongations, , of the, , =, , =, , 20, , x, , 30, , two bars are, , -0-5m0-5m, (a), , in the, , pulls, Solution. Let Pal and Ps, about, moments, Taking, bars BD and CE respectively., be the, , 20kN, , A-, , B, B, (b), , 15, ..a), , Fig. 2-10, , Sls

Page 12 :

38, , STRENGTH OF MATERIA|s, 0al, , Pal x 103x 1, , Pal x, Aal, , xEt3x, , 70, , x, , 10, , P,x 103 x1, , P, , 8,, , 10-6x, , A x E,2x 10-6x200x 10, , Pal, 210, , m, , 210, , P, 400, , m, , After elongation of the bars the position ofthe rigid bar ABC is shown in Fig. 2.10(6). Fo, , From, , similar triangles AB B' and AC C', we get, , 8a8, 1, , 8l2 6lal, , Pal, , -2x, , ., , 6, , 400, , OT, , 400, 3:8095b, 210, , Pal, , C), , Substituting Eq. (c) in Eq. («), we get, Pat (1 + 7-619) = 30, , Pal, , 3-4807 kN, , Ps = 13:2596 kN, , Stress, , in steel, , bar,, , o., , =, , =, , A, , 13-2596x10 6629.83 MN/m2, 2x 10-6, , Stress in aluminium bar,, , ala=3:4807x 103= 1160-23 MN/m2, Aal, Example 2.11, , 3 x 10-, , Two vertical wires are suspended at a, , distance of 50cm apart as shown in Fig. 2-11. Their upper ends are, firmly secured and their lower ends support a rigid horizontal bar, which carries a load W. The left hand wire has a diameter of 1-5, , Steel, 1mm, , mm and is made ofcopper and the right hand wire has a diameter Copper, of1-0mm and is made of steel. Both wires initially are 4.5 m long. n, , -50-, , Determine (a) the position of line of action of W if, due to W, both, wires extend by the same amount and (6) the slope of the rigid bar, , Cm, , ifa load of200Nis hung at the centre ofthe bar. Neglect theweight, 4-5m, , of the bar. Eeu = 130 GN/m2, E, = 210 GNIm2, Solution. Area of copper wire,, , Au (1-52x 10-6 = 1-7671 x 10- m2, Area of steel wire,, , A, , x, , 1 x 10-6 = 0-7854 x 10-6 m2, , (a) Let the weight W be placed at a distance x from the, copper wire, and Peu and P, be the loads taken by the copper and, steel wires respectively. Taking moments about the copper wire,, , we get, , W, , TEI, Rigid beam, Fig. 2-11

Page 13 :

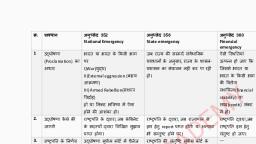

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, , Pa, , 0-5x 10s, , 43, , 20 x10x 200 x 10, , x, , 1, , =-2P1, , P2+ 2 P1=2 x 105, Solving, , for, , P1, P2, , and, , Pa from Eqs. (a),, , ..c), (6) and (c),, , we, , get, , P-105N; P=19 x 105 N P=, 7, , 103, , 1, , 20, , 105, , ,=, , 23, , G3, 2-2, , x1041429, , 20x 10, , x, , 105, 20 x 10-4, , 7, , x105 N, , MPa (compressive), , 71-43 MPa (tensile), 42-86 MPa (compressive), , Temperature Stresses, When the temperature of a material is changed, its dimensions change. If this change in, , dimensions is prevented, then a stress is set up in the material, which is called a temperature, stress., , Let, , l = length of a bar at temperature to, t = increase in temperature, , a =coefficient of linear expansion for the material, Change in length of the material = alt, = l (1 + at), , Expanded length, , Strain,, Stress,, , alt, , at, , tT1+at) 1+at a t (l- at), o, , =at, , = Eat, , ..(2-10), , When the temperature rises, the material is prevented from expanding and, therefore,, compressive stress is induced in the material. On the other hand, when the temperature decreases,, the material is prevented from contracting and thus tensile stress is induced., , 2-2-1 Composite System of Equal Lengths Subjectedto Variation of Temperature., When a composite system is subjected to a change in temperaturethen different components change, in length by different amounts due to the diference in their coefficients of linear expansions. A, having higher coefficient of thermal expansion than the other increases in length more, material, than the other one. Ifthis increase in length is prevented then the material having higher coefficient, , oflinear expansion will be in a state of compressive stress and the other material will besubjected, to tensile stress. If no external force is applied then the compressive force Pin the material having, , higher coefticient oflinear expansion will be equal to the tensile force P in the material having lower, coefficient of thermal expansion., , Consider a composite systemconsisting oftwotubes as shownin Fig. 2-16 (a), ofequal length, I but ofdifferent materials. When the temperature ofthe whole system is increased by t°C then free, increase in length of inner tube is a,tl and the free increase in the length of outer tube is datl, as, shown in Fig. 2-16 (6) and assuming a1 to be greater than a2., , length (a1-a2)t, Now if this difference is eliminated by compressing the inner tube by a force P and pulling, , Difference in increase in, , =, , out the outer tube by an equal tensile force P as shown in Fig. 216 (c), then

Page 14 :

44, , STRENGTH OF MATERIALS, ALS, , IP, , tl, , P, , Al2, , LLM, (a), , (c), , (b), Fig. 2-16, , Contraction for inner tube due to P, Al1 =, , P, , Extension of outer tube due to P, Al2 =, , Pl, , A E2, The difference in, , length, , is, , eliminated,, , when, , (a-a2) tl = aly + A l2 = Pl | -, , 1, , A E A, E2, , P, , -2), 1, , ..(2-11), , AE Ag Ea), Hence, , compressive, , stress induced in inner, , O1, , tube,, , (1-a2), , .(2-12), , and tensile stress in outer tube is,, , o, , -2), (A2, A1, , ..(2-13), , Composite system of equal lengths containing more than two components, subjected to variation of temperature. Consider three bars of diferent materials, each of, 2-2-2, , length, having coefficients of linear expansions a, Gg and ag and moduli of elasticity E1,B, B3, connected, at their ends as shown in Fig. 2-17. Let rC be the rise in, respectively,, rigidly, together, temperture. Then,

Page 16 :

6, , STRENGTH MATERIALs, , P+ta,A,E, i=1, , Al=, , 2 A,E, , .2-15), , i=1, , Example 2.17 A rod is 2 m long at a, when the, temperature of 10°C. Find the expansion, is raised to 80°C., If this expansion is, of the rod.temperature, of the rod, Take E 100 GN/M2, and a =12 x 10-5/°C. prevented find the stress in the, material, Solution. Rise in, t, temperature,, 10, 80 70°C, Strain, at, 12, 10-5 70 840 x 10-6, =, , =, , Stress, , Example, , =, , x, , =, , 100, , G Ee, , 2.18 Two, , x, , x, , 10, , 840, , x, , x, , 10-5, , 84, , MN/m2, , parallel walls 6 m apart are stayed, diameter at a, by a steel rod 25 cm, temperature, of, 80°C, passing through washers and nutstogether, exerted by the rod when it, at, each, end., has cooled, Calculate the pull, to 22°C:, (a) if the walls do not, yield, and, (6) if the total, at, yield the two ends is 1-5 mm., E, a, , Solution. (a), , Fall in, , =, , 200 GNIm2, 11, 10-6/C., x, , temperature,, t, , = 80 22, , Strain,, , E, , Stress,, , =at, , O, , Et, , Pull exerted,, , P, , (6) Length at 22°C, Decrease in length, Due to, , yielding, , aA, =, , =, , =, , 58°C, , 10-5 58 638x 10-6, 200x 10x 638 10-6, 127-6 MN/m2, =127-6x 105 xx 625 10-4, 11, , x, , x, , x, , =, , =62-635 kN, , x, , l (1, , -at), , 6 (1-11, , 10-6x 58) =5.996172 mm, 0-003828 m, of walls by 15 mm, the actual, decrease in length, 0-003828 0-0015 0-002328 m 2328 x, 10=, , =, , x, , 6-5-996172, , =, , =, , Strain, , 2328 x 10-388 106, , m, , x, , Pull exerted,, , P, , E& A, , =200, , x, , 109, , x, , 388, , Example 2.19, , x, , 10-6, , xx6-25 10-6 =38-092 kN, x, , A copper bar 25 cm long is, fixed by means of a sinking, amount 0-01 cm. 1f the temperature of the bar is, , which yields by an, stresses induced in the bar., , support, , Coefficient of linear expansion for copper., a, , 17:5 x 10, , per °C, E = 98 GPa., , Solution. Free extension of the bar, ac tl = 17-5 x 10-5 x 120 x 25 =0-0525 cm, , Actual extension allowed, , yielding of the support = 0-01 cm, Constrained extension 0-0525 0-01 =0-0425 cm, =, , Constrained strain, , at its., , s, , raised by 20°C, calculate the, , 0-0425, 0-0017, 25

Page 17 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, Stress induced, , 0-0017x 98, , =, , 47, , 103, , x, , =166-6 MPa (Compressive), , Example 2-20 A steel bar 25 cm diameter is rigidly attached to two parallel supports 8 m, a.nart. Find the pull exerted by the bar on the support when the temperature is increased by 100°C, , (a) if the supports do not yield, (b) if yielding of both supports is 0-25 cm., a, , = 12 x 10-6 per °C, Es = 210 GPa., , Solution. (a) Free increase in length of the bar, as tl, , =, , 12, , =, , x, , 10, , x, , 100, , x, , 800, , =, , 0-96, , cm, , 0-96, , Constrained strain, , 8 0 0 - O 0 1 2, , Constrained stress, , 0-0012, , =, , x, , Pull exerted, , x, , 210, , x, , 103, , =, , 252 MPa, , (252x 252 123-75 kN, , (b) When the supports yield by 0-25 cm., then, = 0-96 0-25, , Constrained elongation, , 0.71 cm, , 0-71, , Constrained strain, , 0-0008875, 800, = 0-0008875 x 210 x 103 = 186-375 N/mm2, , Stress induced in the bar, , Pull exerted, , x625 x 0-0008875 x 210 x 103 =91-523 kN, , Example 2.21 A composite bar shown in Fig. 2-18 is rigidly attached to the end supports., , The temperature of the composite system is raised by 60°C. Find out the stresses in three portions of, the bar (a) if the supports are rigid, (b) the supports yield by 0-05 cm., E, = 200 GPa,, , a, = 12 x 10-5 per C, , E, , ag =20 x 10-6 per C,, , E, , = 90 GPa,, =, , a, , 100 GPa,, , = 16 x 10- per °C., , Solution. Free elongation of copper section, = a, , tle = 16 x 10-6 x 60 x 25 = 24 x 10-3 cm, , Free extension of aluminium section = aat la, , Aluminium, , oem, , 2 0 x 10-6 x 60 x 50 6 0 x 10- cm., , Free extension of stee! section, , oatl, , =, , 12, , x, , 10-5x, , [tScm, , 60 x 25 =18, , Total free extension of the, , x, , 10-3, , F25cm, , cm., , composite bar, , 50cm, , Scm, , +25em-, , Fig. 2-18, , = (24 + 60 + 18) 10-3 = 0.102 cm = 1-02 mm, , Since this extension is prevented by the rigid supports, therefore, compressive stresses are, , induced in the bar., Let P be the, , compressive force in the bar in N., , Stresses are:, , OeA, P, , aAa, P, , a,A,, , 4PN/mm, x2500 Nmm, P, Tx4 104, 4 P, Tx 2500, , mm2, N/mm2

Page 18 :

48, , STRENGTH OF MATERlA., , EE., ., , T x 25 x 10D, 4P, Tx 70 x 10, , 4P, Tx 10* x 70 x 10°, , Oa, , &a, , 4 P, , 4 P, Tx 2500 x 100 x 10°, , Oc, , Strains are:, , 4 P, , 4 P, , E,Tx 2500 x 200x 10, , Tx, , Tx, , Extensions are, , Al, , =¬,, , xl,=4Px, , 250, , 4 P, , 20 P, , Px 500, , aatx70 x 107 nx 7 x 10°, 4Px250, , al, , 50, , Tx, , 10, , x, , 2P, , =, , x, , 10, , mm, , Ttx 106, , Tx 25 x 10, , 4, , 50, , mm, , mm, , 10, , x, , (a) Now Al, + Alg + Al, = 1.02, , -102, P, , TX106 14, , +2-857 +, , 2=1-02, , Px8-85-1-02, TTx 10°P, , P Tx10 x 1-02, , 361-795 kN, , 8-857, , 4 x361796 = 184-26 MPa, Tx 2500D, a, , a, , X, , 36179, , 46065 MPa, , Tx 104, , TX2500184-26 26 MPa, (6) When the supports yield by 0-05 cm, then, Al + Ale + Al, = 1-02- 0-50, , 0-52 mm, , P Tx10 x 0-52, , 184445 N, , 8-857, , 4x 184445, Tx 25000, , a, , _, , 93.936 MPa, , 4 x 18444*5 - 23.484 MPa, Tx 104, , Example 2-22 A bar of steel and two ofcoPper,each of the same area and length, have th, , ends rigidly connected at a temperature of 15°C. The steel bar lies between the two copper bars., raising the temperature to 250°C, the length of the bar is increased by 0-2 cm. Determinethe origu, length and final stresses in each ofthe bars. E, = 210 GPa, E = 100 GPa, a, = 12 x 10-5 per, o =17-5, , x, , 10-5 per °C., , Solution. Rise in temperature, t= (250 - 15) = 235°C

Page 19 :

cOMPOSITE, , SYSTEMS AND, , TEMPERATURESTRESSES, , 49, , Let the initial length of ench bar at 16°C be =l cm, , elongation of steel bar, , a t = 12 x 10-6 x 235 x l = 2820 x 10-6 xl em, Free elongation of each of copper bars, , Free, , =atl17-5 x 10- x 235xl : 4112-5 10-l, , cm, , 0-00282l-0-2, , Constrained strain in steel bar, , 0-00411251-0-2, Constrained strain in each of copper bars =Stress in steel bar, , (0-002821-0-2 210x 103 N/mm, , Stress in each of copper bars, , (0-0041125-0-2, , 100, , x, , 103 N/mm, , Let the area of cros-section of each bar be = 1 mm2, Total force in the composite bar, , (0-002821-0-2 210 103+2 (0-0041125l-0-2105, x, , Since there is no external force acting on the bar, therefore, total force should be equal to, zero. Hence,, , (0-00282 1-02 210 x10 (0-00411251-0-22 x103 =0, 2.1 (0-000282, , -, , 0-2) +2 (0-0041125 1 - 0-2) = 0, , (0-005922 +0-0082250), , =0-82, , 0-014147l, , =0.82, , l = 57-96 cm, , (0-00282 x 57-96-02, , 210 x 103, , 7 .96, -0-036545, x, , 210, , x, , 57-96, , 10, , =, , -, , 1324, , N/mm, , 0-0041125 x 57 96-0-2 105, 57 96, , 0-03836x 10, , 66-184 N/mm, , 57 96, enclosed in a steel tube, 8 cm, 2.23 A copper bar 5 cm in diameter is completely, to the axis of the combination near, external diameter. A pin 25 mm diameter is fitted transversely, Caleulate the intensity of shear stress induced in, each end to secure the copper bar to the steel tube., 50°C,, he pin when the temperature of the whole is raised by, 100 GPa, ac 16 x 10-6 per °C, , Example, , E, , E,, , =, , =, , =, , 210, , GPa,, , a,, , =, , 12, , x, , 10-, , per °C, for, , bar is, , than steel, , tube,, , copper, Solution. Since the coefficient of linear expansion, free, elongation is prevented, the copper bar will, it will elongate more than steel. As this, therefore,, be under compression and the steel tube in tension (Fig. 2-19)., more

Page 20 :

50, , Let l, , =, , STRENGTH OF MATERI, , length, , of copper bar and, steel, Free, of, elongation copper bar =a,tl, =, , Free, , difference in length, 4 Pl, 2500 x, , AE, , 2500, , Pl, , x, , l, , mm, , x, , 50, , x, , 10-6), , A, BTx 3900, is, , Bm, , nm, , 105, , x, , 4 Pl, , eliminated,, , 210 x103 mm, , x, , when, , 4 PL, , 10, , Tx, , 3900, , 210, , x, , 200x x, , 10, , 200 x 10- x, , =200, , = 30086, , 4x0-05221, , is in double shear., , a3, 103, , 0-05221, , x, , P, , x, , Fig. 2.19, , +0-01221 200x 10, , P, , stress in, , 50, , x, , 4 PI, T x, , 7x 10, , Shear, , mm, , -pin25Cm, , Pl, , 4P, , pin, , 10-5, , x, , P, then,, , 0-04, Tx 10, , The, , l, , x, , length is prevented by applying a, compressive, pulling the steel tube by the same force, , of copper bar, , Tx, , 50, , x, , = (a-a)tl, , Extension of steel tube, The, , 12, , =, , mm, , = (16 x 50x 10-6-12, = 200x 10-5 x l mm, , If this difference, in, to the, copper bar and, , Contraction, , 10-5, , x, , elongation of steel tube =a,tl, , Difference in elongation, , force P, , 16, , tube,, , x, , 10-6, , N, , 30086x4 -31-645 N/mm, , pin, , 2 x Tx 625, , Example 2.24 A steel rod 25 mm diameter passes, 30 mm external diameter. The nut, through a brass tube 25 mm internal and, on the rod is, until, a stress, tightened, rod. The temperature, of 12 MPa is reached in the, tube and the rod is then raised, of, the, by 60°C. What are the stresses in the rod, and the tube ?, E,, , E, Solution., , =, , =, , A x, A, , 210, GPa, a,, 80 GPa, at=, , =, , 11:5, 19, , x, , 10-6 per °C., 10- per °C., x, , (25)2 =491 mm?, , = i(30)2 - (25 ] = 216 mm2, , Tensile force in the rod due to, tightening of nut, P, 12 x 491 5892N, Since the composite system is in, the, , equilibrium,, , same, , force P must act, , Stress in the tube = 892 27-277 N/mm2, (compressive), 216, Let Al be the change in length due to, temperature rise then, . ., , E-114,E, -o, , on, , the tube.

Page 21 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSEs, , 51, , - 11-5 x10- x 60| 491 x 210 x 103 + | - 19x 10- x60 216 x 80 x10 = 0, a, , a, , x, , 10 (4-91, , 2.1+2:16, , x, , 107(10-311, , 1728), , x, , =, , 0-8) =600(115, , x, , 600 (118-5765 +, , 4.91x 2:1, , +, , 19, , x, , 2-16, , 0-8), , x, , 32-832), , AL, , x107 x 12039 =600 x 151-4085, = 75459 x 10-4, , Stress in steel rod, , = (754-59x 10-6-115 x 10-6 x 60) 210 x 103, =, , 6459, , 10-6x 210x, , x, , 103 13-564 N/mm2 (tensile), , Stress in brass tube, = (754-59x 10-5, =, , 19 x 10-6 x 60) 80 x 103, , (754 59-1140)10-6, , x, , 80x 103=-30-833 N/mm, , (compressive), , Total stress in steel rod = 12 +13-564 = 25-564 N /mm2 (tensile), , Total stress in brass tube = 27-278 + 30-833 =58 111 N/mm2 (compressive), Example 2-25 A composite bar is formed as shown in Fig. 2:20 at 100°C. Find the stresses, , in each, when the temperature of the whole assembly is (a) raised to 120°C, (6) lowered to 80°C., If at the new temperatures in case (a) and (b) a tensile load of 150 kN is applied to the, composite bar, what are the final stresses in steel and copper?, , E,, Ec, , =, , 200, , GPa,, , a,, , =, , 10, , x, , 10-6 per °C., , =, , 100, , GPa,, , a, , =, , 15, , x, , 10-6 per °C., , Solution., Copper, , Ae x(50)2 =1963-5 mm2, , Scm-75 cm, , A =x(752 =4437-5 mm2, (a) Net resultant strain, = (oe-ag)t = (15- 10) 10- x 20, , =10-1, s, 200x, , 103, , 10, + 106, 10, , og + 20 = 20, , Now, , As, , Op Ac, , steel, , 2Scm10-4, , copper, 5cm, , 30cm, Fig. 2-20, , 25cm

Page 22 :

52, , STRENGTH OF MATERlAT., -.s= 4437-5, , A, g+4-52 o, =20, , x, , 1963-5, , Og 2:26 os, , 20, EO =3623 N/mm2 (tensile), , g, , O2-26 x 3.623 = 8.188 N/mm2 (compressive), , When the external load of 150 kN is, A s +Gc A, , then, , = 150 x103, , s, , and, , applied,, , c, , E, 4437-5 o + 1963.5 G = 150 x 103, , s, , c, , 2 x 10, , 105, , Og, , 2 o, , (8375 + 1963-5) oc = 150 x 103, 150x 103, 10838-5, , O c, , -, , =, , 13-87, , N/mm, , (tensile), , os 27-74 N/mm2 (tensile), , Resultant stresses are :, , Stress in steel, 27.74 + 3:623 31-363, N/mm2 (tensile), Stress in copper, 13-87 8-188 5-682 N/mm2, (tensile), (b) When the temperature is lowered to, then, 80°C,, there, will, be contraction in, will be more than the contraction in steel., copper, which, steel will try to pull the, Therefore,, bar and the, bar, copper, will, tend to produce, copper, in the steel bar, so there will, be tensile stress in, and compressive stress in steel.compression, copper, =, , =, , Here again,, , t= (100 -, , Therefore, the magnitude, , 80), , = 20°C, , of stresses will remain the, , same., , os = 3:623 N/mm2 (compressive), , o, , 8-188 N/mm2 (tensile), , The stresses due to 150 kN load will remain, ., , ., , same., , Resultant stress in steel, =, , 27-74-3-623, , 24 117 N/mm2 (tensile), , Resultant stress in copper = 13-87 +8.188, , 22-058 N/mm2 (tensile), Example 2.26 A steel bolt 25 mm diameter and 30 cm long pásses, through a copper tube, having internal and external diameters of 30 mm and 40 mm, The, bolt has 4 threads, respectively., per cm and the nut is intitially just, tight. Calculate (a) the angle through which the nut is turnea, , through to cause a tensile stress of 80 MPa in the bolt, (6) stress in the tube, and (c) the change n, stress in the bolt and the tube due to an increase in, temperature of 30°C., E, 200 GPa, a, = 10 x 10-6, °C,, E, , = 100 GPa, , per, , a = 15 x 10- per C.

Page 23 :

cOMPOSITE SYSTEMS AND TEMPERATURE STRESSES, 53, , Soution., , A, , x (25)2 = 491 mm2, , A, , (1600- 900) 650 mm2, =, , o, , (a), , 80 N/mm2, , oA Oe Ae, 80 x 491, , =71-43, 71-43 N/mm, 550, , Total elongation, , Total distance travelled, , =, , Let be the angle turned through by the nut., , al,+l =, o, , 10, , by the, , nut., , 360, , 10, 360, , 80 x 300, , 71-43 x 300, , 200 x 103, 12x, , *, , 105, , 10-+21-43, , x, , 10, , 10-2, , =, , 360, , 144, , 33-43 x 10-2 x 144, (6) Stress in the tube, 71-43 N/mm2, , 48.14°, , (c) Net change in length of steel bolt, = ( - )t, , = (15-10) x 10- x 30 x 300 = 0-045 mm, IfP is the force developed due to differential expansion, then, , E.A AE, , AlPl,, or, , Also, , E,A, , Ale, , 550 x 10°, 50-56, 491 x 2x 10, , Ale, Al,, , = 0.045, =, , 0-02885, , mm, , =, , 001615, , mm, , in tensile stress in steel bolts, , 1*, Change, , Ple, , Al,+Ale =0-045, 1-56 A l, , Change, , A, E, , Ale, , F, , 0-01512, x, 300, , 105, , =, , 10-76 Nmm-, , in compressive stress in copper tube, , e, , 105-9.62 N/mm*, E 0-02885, 300, , 6-25 cm2 in section, 2.27 A weight of200 kNis supportd by three short-pillars each, Example, as shown in Fig. 2:21. The central pillar is of steel and the two outer ones of copper. The pillars are

Page 24 :

54, , STRENGTH OF MATERIAIS, ALS, , $o adjusted that at a temperature of 15°C, each carries one-third of the total load. The temperat, is then raised to 115°C. Estimate the stress in each pillar at 15°C and at 115°C., , E, , E = 210 GPa,, , ay = 12 x 10-5 per °C,, , emperature, , = 84 GPa, ae = 18-5 x 10-5 per °C., 200 kN, , Solution. (a) Stress in each pillars at 15°C, 200 x 103, , =, , 106-667 N/mm2, , 3 x 625, , b) Temperature rise, t = 115, , 15 = 100°C, , E = Common strain in the bars., , Let, , Strain due to rise in temperature = at, Net strain due to load carried = t - at, , Ee-at) EA, , =, , P, , Fig. 2-21, , (e -a, t) E, A, + 2 (6 - ac t) E, Ac =P, , (E- 12 x 10-6 x 100) x 210 x 103 x 625, , +2(E, , 18-5x 10-6x 100) x 84, (21+2 x 0-84) x 625 x 105x, , x, , 103, , x, , 625, , =, , 200, , x, , 103, , 625 x 10-1 x 100 (12 x 2.1+ 2 x 18-5 x 0-84) + 200 x 103, 3-78 x 625 x 105 x t = 625 x 10 x 56-2+ 200 x 103, 551-25 x 103, , 551-25 x 103, 3-78 x 625 x 105, , = 2:33333x 10-3, , o, = (6- a,t) E,, , = (2333-33 x 10-6-12 x 10-6 x 100) x 210 x 103, = 23-807 N/mm2, , O, , (compressive), , (e at) E, = (2333-33 x 10-6 x 10-6 x 100) x 84 x 103, = 40-572 N/mm2, , (compressive), , Example 228 A steel rod 2-5 cm diameter is fitted inside a brass tube 2-5 cm internal, diameter and 3-75 cm external diameter. The projecting ends ofthe steel rod are provided with nuts, , and washers and the nuts are tightened up so as to produce a pull of 5 kN in the rod. The compound, tube is then placed in a lathe and the brass tube is turned down to 0-5 em thickness. Caleulate the, stress in the two materials (a) when owing to turning the temperature is cooled to its original value., E, = 210 GPa,, , ag, , E, = 98 GPa, , 11 x 10-6 per °C, a, , = 19 x 10-6 per °C, , Solution.A, =x(25)2 =491 mm2, , A x(37-52 (25] =613-6 mm?, 5 x 103, Strains due to tightening are, Es491 x 210 x 10348-5 x 10-6, , 491 x 210 x 103, , 5 x 103, F, , 613-6 x 98 x 10°, , = 83-15 x 10-6