Page 1 :

BE BBB eu See eee, EaIEN, , 30), , t Iron and Non Ferrous, —___ Alloys", , , , , , , , , , , = Gray C.l., White C.1., Nodular C.I. chilled, , pper alloys, aluminium alloys, Nickel alloys,, , , , , , , , loys of carbon and iron in which the carbon, the majority of cases, the cast iron used is in, y be present in very different forms : either, S cementite, or dissolved in the iron in the, he alloy great hardness. It may also exists in, in tum may be in the form of flakes or, ‘iron base materials that contain :

Page 2 :

metallurgy (P) =, , Cast Iron & Non Ferrous Alloys, , or S| : &, For special re: 5 clements are ofien added to cast irons, such, easons, other ., , nickel, chromium. When these are added cast iron is known as allo’ ‘i eScopper,, ‘ y cast iron., , Cast iron may be classified as ;, White cast iron, Malleable cast iron, , , , , , , , , , , , , , , Gray cast iron, , Nodular cast iron., , , , e during solidification., , ith Si, Mn, S and P in substantial amounts., , |, rolled, drawn ctc., , and sizes (with or without machining)., , ted pig iron., , sJectric arc, and induction furnaces, reverberatory, , ks silvery-white due to white cementite and that is, , hus, imparts gray colour to the fracture., cause brittle fracture., , le., hardness of Gray Cast Iron are close to that of steel., , trength, bending, and torsional strength, ductility, are much less than steel.

Page 3 :

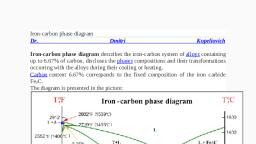

5-3 ___ Cast Iron & Non Ferro Me, Metallurgy (P), 5.1.2 Graphite Flakes :, , brittle and gray and thus imports gray colour to fracture, Qqy, papi: is a : flakes) are thus, called gray cast irons. Under MICroscope,, containing graphite as lar strands with pointed ends. In fact, we are observing, od ie Br iskes which in reality are shaped like ‘corn flakes’, Thy, through graphi 2 %, , in cross section as pointed ends act as stress-raisers in the, , , , , , , , , , , , , , , , , hoto micrograph of gray C.1,, , Sists of graphite flakes embedded in the, ns of ferrite and pearlite. The properties of, , of both the matrix and the amount, size,, ns. Graphite flakes have Wea, , akening and, owdry and brittle, breaking the continuity of, , , , , , tion in Cast Irons (Graphitisation) :, , Pec. 2001, May 2003, May 2004 11!), , Pate: The erystal structure of, dex orthorhombic), but differs, ture), The carbon content of, lentite (6.67%) as compared (0

Page 4 :

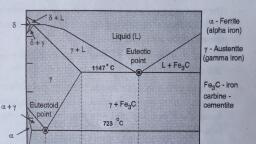

tallurgy (P), ye 5-4, Cast Iron & Non Ferrous Alloys, , saphite (100 %) i.e. 6.67%. C should Segre, , Bate to nucleate c: :, ementit, graphite. , whereas 100%, , segregation of carbon is essential to nucleate, , , , , F(A + Cementite), , 1147 1153, Temp'c — >, , , , , , , , (complex or orthorhombic) similar to FCC - 7, , wourable, then graphite can form because graphite is more, than cementite. Mixture of ferrite + graphite has lesser, of ferrite + cementite. Also it is true that a mixture of, lesser free energy than austenite + cementite at all

Page 5 :

44 Cast Iron & Non Ferro:, tallurgy (P) 5:5 US Alloys, , ctors affecting Graphitisation :, Chemical composition (including presence of nuclei of graphite, etc.)., , ling rate form molten state., , , , , , , , , , arbon, more is the graphite formed and lower the mechanica, , owers the melting point of metal, and thus acts as graphitise, , =, n., , certs the greatest controlling effect on th, bon and free graphite and thus, serves t, epending on the amount of silicon (als, secondary cementite may decompose t, ay vary between 1.0% to 3.5 %. It also :, , , , , , & Gian 7i0, , , , d silicon content of Cl