Page 1 :

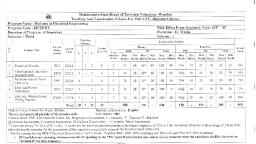

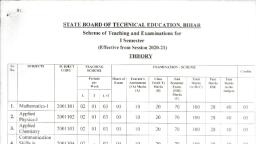

Mechanical Engineering Materials Comse Code: 22343, Program Name : Diploma in Mechanical Engineering, , Program Code :ME, , Semester : Third, , Course Title : Mechanical Engineering Materials, , Course Code 2 22343, , 1. RATIONALE, , With the advances made in the field of material science millions of materials are now, available to cater various need of mankind. These needs and service conditions dictate the, properties to be developed in the materials therefore the subject mechanical engineering, materials has attracted lot of attention. Materials like ferrous and non ferrous metals, polymer., ceramics and composites are widely used in verity of engineering applications. This course, deals with these materials along with advance materials. their metallurgical considerations., heat treatment processes. structure property relationship and applications. This course will, enable diploma engineering students to identify variety of material and their selection for, various applications., , 2, COMPETENCY, The aim of this course is to help the student to attain the following industry identified, competency through various teaching learning experiences:, , e Use relevant mechanical engineering materials in different applications., , & COURSE OUTCOMES (COs), The theory, practical experiences and relevant soft skills associated with this course are to be, taught and implemented, so that the student demonstrates the following industry oriented, COs associated with the above mentioned competency:, a. Identify properties of materials., Select relevant ferrous materials for mechanical components., Select relevant cast iron for the engineering application., Use non-ferrous metals for mechanical components., Suggest relevant advanced materials for mechanical components., Select relevant heat treatment process., , meeaog, , 4, TEACHING AND EXAMINATION SCHEME, , ae Examination Scheme, Credit Theory Practical, L |r| p {eet Paper |__ESE PA Total ESE PA Total, Hrs. |Max |Min | Max |Min | Max| Min| Max | Min | Max | Min | Max | Min, 3 | -]2 5 2 |70*#*] 28 | 30* |} 00 | 100 | 40 | 25# 10 25 10 50 20, , , , , , , , , , ():Online Exam; (*): Under the theory PA, Out of 30 marks, 10 marks are for micro-project, assessment to facilitate integration of COs and the remaining 20 marks is the average of 2, tests to be taken during the semester for the assessment of the cognitive domain UOs required, for the attainment of the COs., , Legends: L-Lecture; T — Tutorial/Teacher Guided Theory I ra, ESE - End Semester Examination; PA - Progressive Assess), , Reeitic al; C — Credit,, , , , , , MSBTE - Updated on 11.10.2018 Page 1 of 9

Page 3 :

Mechanical Engineering Materials Conse Code: 22343., ‘ - | Approx., * Practical Outcomes (PrOs) Unit ths., No No. ., =| i ee required, sample. _ s, 4 | Use Rockwell Hardness tester to determine the hardness of given I 2*, sample. _, 5 | Use relevant hardness tester to determine the hardness of mild steel Il 2, before and after heat treatment. __, 6 | Use relevant hardness tester to determine the hardness of alloy steel II Qe, before and after heat treatment., 7 | Use Metallurgical microscope to interpret micro structure of cast il 2*, iron on standard specimen., 8 | Use Metallurgical microscope to interpret aluminum on standard IV 2, specimen. — — _, | 9 | Use relevant hardness tester to determine the hardness of copper. IV |, 10 | Use relevant peel tester to determine the adhesive strength of Vv 2*, cellophane tape and, duct tape on a smooth surface., 11 _| Perform flame test to identify different types of plastic: Vv 2, 12 | Use High-temperature oven or electrical current to Identify Vv an, behavior of the shape-memory alloy as a function with regards to, temperature., 13 | Use relevant peel tester to determine the adhesive strength of scotch Vv 2, tape, electrical tape and masking tape on a smooth surface. L, 14 | Use muffle /box type furnace to compare VI 4*, e the effect of gil as quenching media on the hardness of mild, steel, e the effect of water as quenching media on the hardness of, mild steel, e the effect of Brine as quenching media on the hardness of, mild steel __|, Total | 30, Note, , i. A suggestive list of PrOs is given in the above table. More such PrOs can be added to, attain the COs and competency. A judicial mix of minimum 12 or more practical need to be, performed, out of which, the practicals marked as ‘*’ are compulsory, so that the student, reaches the ‘Precision Level’ of Dave’s ‘Psychomotor Domain Taxonomy’ as generally, required by the industry., , ii. The ‘Process’ and ‘Product’ related skills associated with each PrO is to be assessed, according to a suggested sample given below:, , , , , , , , , , , , , , , , , , , , S. No. Performance Indicators Weightage in %, , 1, Preparation of experimental set up 10, , 2. Prepare sample using different operations 30 _|, 3. Check the microstructure and hardness of the sample 30, , 4. Follow Safety measures 10, , 5. Observations and Recording 2, , 6. Interpretation of result and Conclusion 5, , 7. Answer to sample questions 5, , 8. Submission of report in time 2, , , , , , , , , , MSBTE — Updated on 11.10.2018 Page 3 of 9

Page 4 :

Mechanical Pnymeering Matervals Course Code: 224, , , , | S.No. ____ Performance Indicators i Weightage in %, Total 100, , , , The above PrOs also comprise of the following social skills/attitudes which are Affective, Domain Outcomes (ADOs) that are best developed through the laboratory/field based, experiences:, , a. Follow safety practices., , Practice good housekeeping, , c. Demonstrate working as a leader/a team member., , d. Maintain tools and equipment., , c. Follow ethical Practices., , The ADOs are not specific to any one PrO, but are embedded in many PrOs. Hence. the, acquisition of the ADOs takes place gradually in the student when s/he undertakes a series of, practical experiences over a period of time. Moreover, the level of achievement of the ADOs, according to Krathwohl’s “Affective Domain Taxonomy’ should gradually increase as planned, below:, , e ‘Valuing Level’ in 1“ year, , © ‘Organizing Level’ in 2"! year, , © ‘Characterizing Level’ in 3" year,, , a MAJOR EQUIPMENT/ INSTRUMENTS REQUIRED, The major equipment with broad specification mentioned here will usher in uniformity in, conduct of experiments. as well as aid to procure equipment by authorities concerned., , , , , , , , | s. : : ae fu a, No Equipment Name with Broad Specifications |, “1 | Metallurgical Reflected light Microscope Vv, 30W halogen’ |, rg) Pp |, , Light.200x magnification.191x126x100 mm specimen stage ,Size With 100 |, | mm travel |, 2 Slitting Machine- Slitting width- standard 300 mm or extensible. Slitting | 2.3.4. |, blade, Slitting each width at least 15 mm _ |, 3 Polishing Machine Grinding/polishing disc diameter: 200mm. Rotation | 2.3.4, speed: 0-600 rpm - aaa _ |, 4 | Digital Rockwell hardness tester- Easy-to-use Electronics Console 5,6.7, Hi/Lo Tolerance Settings, Adjustable Time @ Load Average Test Group, Results 2-9; Test Result Memory Capacity 5000 results, RS232 Output.Average Range. | |, , , , 5 Digital Brinell Hardness Machine- Hardness range HBW<125 5,6.7, 6 Laboratory box furnaces 1200°c 11.12.14, 7 __| Peel Tester 10.13, , 8. UNDERPINNING THEORY COMPONENTS, The following topics are to be taught and assessed in order to develop the sample UOs given, below for achieving the COs to attain the identified competency. More UOs could be added., , “MSBTE - Updated on 11.10.2018 Page 4 of 9

Page 5 :

Mechanical Pnginecting Materials, , Course Code: 29343, , , , , , Unit Unit Outeomes (UOs), (in cognitive domain), Unit -1 la. Interpret crystal structure, Ba of of the given material., , Engineerin | 1b., g Materials, , Interpret the structure of, specified materials at the, given level., lc. Identify microstructure of, the given material with, justification., Explain with sketches the, procedure lo prepare given, sample., le. Explain with sketches, procedure of hardness, testing for the given tester., If. Choose relevant hardness, tester based on the given, situation with justification., , Id., , Topics and Sub-topics, , 1.1 Classification of engineering, materials,, , Crystal structure, Unit cell and space, lattice, , Microstructure, types of microscopes, Sample preparation, etching process., types of etchant., , Properties of metals Physical, Properties, Mechanical Properties., Hardness testing procedure on Brinell, and Rockwell tester, , 1.2., , 1.3, 1.4, , , , , , Unit-1 | 2a., Steel and, its Alloys 2b., , Interpret the given, , equilibrium diagram., , Use the Iron —carbon, , equilibrium diagram for, , the given application., , 2c. Identify the given phase, diagrams and reactions, with justification., , 2d. Identify the given fields of, steels on [ron carbon, diagram with justification., , 2e. Select relevant steel for, , the given application with, , justification., , , , , , Unit- HI | 3a. Select the relevant cast, , , , 2.1 Concept of phase, pure metal, alloy and, solid solutions., , 2.2 lron Carbon Equilibrium diagram, various phases, , i. Critical temperatures and significance, , ii. Reactions on Iron carbon equilibrium, , diagram, , Broad Classification of steels,, , i. Plain carbon steels: Definition, Types, and Properties, Compositions and, applications of low, medium and high, carbon steels., , ii. Alloy Steels: Definition and Effects of, alloying elements on properties of alloy, steels,, , iii. Tool steels: Cold work tool steels, Hot, work tool steels, High speed steels(HSS), , iv. Stainless Steels: Types and Applications, , v. Spring Steels: Composition and, Applications, , vi. Specifications of steels and their, , equivalents, , Steels for following: Shafts, axles, Nuts,, , bolts, Levers, crank shafts, camshafts,, , Shear blades, agricultural equipments,, , house hold utensils, machine tool beds,, , car bodies, Antifriction bearings and, , 2.4, , gears., , hite, gray., , , , , , MSBTE — Updated on 14.10.2018, , Page 5 of 9