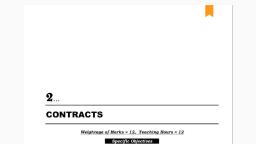

Page 1 :

Chapter 1, GENERAL, Syllabus, Reinforced Cement Concrete Concept of Composite Material - Purpose of Providing Reinforcement, Materials used in R.C.C and their Requirement - Different Grades of Cement and Steel Characteristic, Strength and Grades of Concrete Modular Ratio, Types of Loads on Structures as Per (IS: 875),, Analysis, Design and Detailing: Methods of Design Working Stress Method, Limit State Method-, Introduction of IS 456 and SP-16. I.S., About This Chapter, At the end of this chapter students will be able to:, Understand Reinforced concrete and its constitute materials, Know Grades and properties of concrete, Define Limit state and its types., State characteristic values, partial safety factors., Know types of loads to be considered in R.C.C. design., Describe I.S. specifications regarding types of steels and their modification factors., 1.1 INTRODUCTION TO CONCRETE, In old times stone, bricks and timber were the popular building materials. Later cement was, Invented and cement concrete was prepared as a very good building material. Structures In, concrete have become very common in civil engineering construction., Concrete has the advantage of being moulded into any desired shape most conveniently. It is, an artificial stone like mass òbtained by mixing aggregates, cement and water., The product thus produced is allowed to cure for hardening. Its essential ingredients are, cement and water, which react with each other chemically to form another material having, useful strength., The strength of concrete depends upon the quality of Its ingredients, their relative quantitles, and the manner in which they are mixed, compacted and cured., It is possible to produce concrete of different specifications for various purposes by suitably, adjusting the proportions of cement, aggregate and water., There are two states of concrete:, (1) plastic state, and, (II) hardened state., Plastic state refers to the state of concrete before It has set and hardened. During this state,, concrete is placed in a form work and compacted. It should be workable so that It can be easily, mixed, placed, compacted and finished at the surface., After concrete has been placed in the form work, it hardens and galns strength. Hardened, concrete should be durable, Impermeable and should have adequate strength., (1-1), 1

Page 2 :

1-2, General, RCC Design, Table 1.1: Important Properties of Concrete, In Hardened State, In Plastic State, 1. Strength, 2. Durability, 3. Impermeability, 4. Creep, 5. Shrinkage, 6. Thermal expansion, 1. Workability, 2. Segregation, 3. Bleeding, JAR, The concrete is mainly categorised as:, 1. Plain Cement Concrete., 2. Reinforced Cement Concrete., 1.2 DEFINITION OF R.C.C, Reinforced Cement Concrete (R.C.C.) is a composite material made of concrete and steel. Plain, cement concrete possesses high compressive strength but is weak in tension. This low tensile, strength is compensated by the use of steel reinforcement. Thus, the concrete is strengthened, (1.e. reinforced) by steel and the resultant composite mass is known as Reinforced Cement, Concrete (R.C.C.)., 1.3 CONCEPT OF COMPOSITE MATERIAL, A composite is a material made by combining two or more other materials. The component, materials have very different properties. They do not dissolve or blend into each other., The success of reinforced concrete as a composite material is mainly attributed to the excellent, bond between concrete and reinforcements. The external loads are shared by steel and, concrete without disruption of the composite material due to its strain compatibility., 1.4 PURPOSE OF PROVIDING REINFORCEMENT MATERIALS, 1. To carry direct or bending tension: In case of slabs, beams and walls of water tanks,, reinforcement is mainly provided to carry direct or bending tensile stresses and hence, it is, called main steel. It is provided on tension face of the member and away from the neutral, axis., 2. To strengthen the concrete to resist compression: In case of columns the steel is, provided to resist the direct compressive stresses as well as bending stresses if any. The, steel provided for this purpose is known as main or longitudinal steel., 3. To resist diagonal tension due to shear: In case of beams stirrups are provided to resist, the diagonal tension due to shear and to hold the main steel in position., 4. To prevent buckling of main bars in columns: The steel is provided in the form of, rectangular, circular lateral ties or spirals to prevent buckling of main bars in columns., 5. To resist spiral cracking due to torsion. The box type mesh of reinforcement is provided, to resist torsion., 6. To distribute concentrated loads and effects of temperature and shrinkage: It is, provided in the form of distribution steel. The function of this steel is to distribute the, concentrated loads and to reduce the effects of temperature and shrinkage and to hold main, bars in position., 1.5 ADVANTAGES OF REINFORCED CONCRETE, 1. The constituents of R.C.C. are easily available., 2. Concrete can be easily moulded to any desired shape., 3. It is possible to make the concrete of desired strength byY proper proportioning of mixture., 2

Page 3 :

RCC Design, 1-3, General, 4. It can be made water tight., 5. It is durable., 6. It is fire resisting., 7. Its maintenance cost is practically nil., 8. It is chemical resistant., 1.6 CONSTITUENT MATERIALS OF R.C.C, The main constituent materials in R.C.C. are:, (a) Cement,, (b) Aggregates,, (c) Water,, (d) Admixtures and, (e) Steel reinforcement., 1.7 GRADES OF CEMENT, The following are the different grades of cement:, 1.7.1 33 Grade Ordinary Portland Cement, These grades of cement are conforming to IS 269. The various other types of these cements, are:, Low heat Portland Cement (IS: 269), (i), Portland Pozzolana Cement (IS: 1489), (ii), (a) (fly ash based) conforming to IS: 1489 (Part I), (b) (calcined clay based) conforming to IS: 1489 (Part II), (iii), apid hardening Portland cement (IS: 8041), 1.7.2 43 Grade Ordinary Portland Cement, These grades of cement are conforming to IS: 8112. The various other types of there cements, are:, Portland slay cement (IS: 455), (i), (ii) Hydrophobic cement (IS: 8043), (ii) White and coloured Portland cements (IS: 8042), (iv) High Alumina Cement (IS: 6452), (v) Low heat Portland cement (IS: 12600), (vi) Sulphate resisting Portland cement (IS: 12330), 1.7.3 53 Grade Ordinary Portland Cement, There grades of cement are conforming to IS: 12269.53 Grade cement is used for fast paced, construction where initial strength is to be achieved quickly. It is used in RCC and prestressed, concrete of higher grades, cement grouts, instant plugging mortars etc. where initial higher, strength is the criteria., 1.8 GRADES OF STEEL, The following types of steel are used in present RCC practice:, (1) Mild Steel Grade Fe250 conforming to IS 432 (Part I). These bars have well defined yield, point., (il) High Yield Strength Deformed bars of grade Fe415, Fe500 conforming to IS 1786-2008., These bars are cold twisted., (1ii) Thermo Mechanically Treated (TMT) bars conforming to IS 1786-2008. These are high, strength bars hot rolled of grade Fe415, Fe500., 3

Page 4 :

RCC Design, 1-4, General, In all these cases Fe refers to ferrous material and the number following it refers to specified, yield stress in N/mm2. The high strength bars do not show well defined yield point. In such a, case yleld strength is determined at 0.2% (I.e. 0.002 strain) proof stress as shown in Fig. 1.1., Characteristic curve, 1,-, 0.8 f,, 1, 0.0, 0.001, 0.002 0.003, 0.004, Strain, Fig. 1.1: Determination of Yield Stress in HYSD Bars, 1.8.1 Advantages of Steel as a Reinforcement, 1. Its tensile strength is high., 2. It can develop good band with concrete., 3. Its coefficient of thermal expansion is nearly equal to that of concrete., 4. It is freely available., 1.8.2 Requirements, 1. All reinforcement shall be free from loose mill scales, loose rust and coats of paints, oil, mud, or any other substances which may destroy or reduce bond. Sand blasting or other, treatment is recommended to clean reinforcement., 2. Special precautions like coating of reinforcement may be required for reinforced concrete, elements in exceptional cases and for rehabilitation of structures. Specialist Iiterature may, be referred to in such cases., 3. The modulus of elasticity of steel shall be taken as 200 kN/mm2. The characteristic yield, strength of different steel shall be assumed as the minimum yield stress/0.2 percent proof, stress specified in the relevant Indian standard., In addition to above requirements, the reinforcing bars (re-bars) must comply with the, requirements of dimensions and weight. The maximum tolerance permitted in respect of weight, and diameter of bars are given below:, In weight,, ± 4%, + 2.5%, diameter s 8 mm, diameter > 8 mm, In diameter,, diameter s 25 mm, + 0.5%, 1.9 GRADES OF CONCRETE, IS: 456-2000, the code of practice for plain and reinforced concrete specifies that the concrete, mix proportion should be selected so as to ensure the workability of fresh concrete and, durability of hardened concrete. The properties of cement, aggregates and water to achieve the, desired strength may be determined by design mix or nominal mix., 4, Stress

Page 5 :

General, RCC Design, 1-5, The concrete should be designated as per table 1.2., Table 1.2: Grades of Concrete, Specified Characteristic, Compressive Strength of 150 mm, Cube at 28 Days in N/mm², (3), Group, Grade, Designation, (1), (2), M 10, 10, Ordinary concrete, M 15, 15, M 20, 20, Standard concrete, M 25, 25, M 30, 30, M 35, 35, M 40, 40, M 45, 45, M 50, 50, M 55, 55, High strength, M 60, 60, concrete, M 65, 65, M 70, 70, M 75, 75, M 80, 80, Notes:, 1. In the designation of concrete mix, M refers to the mix and the number to the specified compressive strength of, 150 mm size cube at 28 days, expressed in N/mm., For concrete of compressive strength greater than M 55, design parameters glven in the standard may not be, applicable and the values may be obtained from specialised literatures and experimental results., 2., The minimum grade of concrete for plain and reinforced concrete shall be as per Table 1.2., Concrete of grades lower than those given in Table 1.2 may be used for plain concrete, constructions, lean concrete, simple foundations, foundation for masonry walls and other simple, or temporary reinforced concrete construction., 1.10 CHARACTERISTIC STRENGTH OF CONCRETE, The characteristic strength is defined as the strength of material below which not more than 5, per cent of the test results are expected to fall., The concrete mix should be designed for the target strength given by,, Target strength, charActeristic strength + 1.65 x Standard Devlatlon, %3D, IS:456-2000 specifies the characteristic compressive strength of 150 mm cubes at the age of, 28 days as grades of concrete varying from 15 to 55 N/mm? designated as M15 to M55. For, RCC, the minimum grade of concrete to be used is M20., 1.11 MODULAR RATIO (m), The modular ratio in R.C.C. is defined as the ratio of modulus of elasticity of steel (Es) to, modulus of elasticity of concrete (Ec)., Es, Thus, modular ratio, m =, Ec, 280, 3 Ochc, As per I.S.: 456-2000 modular ratio is given as m, Where is ocbc = permissible bending compressive stress in concrete (N/mm')