Page 1 :

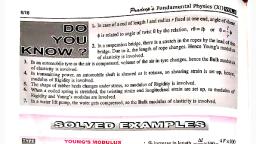

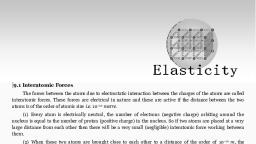

Elasticity - Elastic, plastic materials, stress, strain and their units and, young’s modulus, Exercise 2.5.10, Elastic material, , 11 Rubber Epichlorohydrin, , The Elastic materials are those materials that have the, ability to resist a distorting or deforming influence or force,, and then return to their original shape and size when the, same force is removed., , 12 Nylon, , Linear elasticity is widely used in the design and analysis, of structures such as beams, plates and sheets., , 15 Poilbutadiene, , Elastic materials are of great importance to society since, many of them are used to make clothes, tires, automotive, spare parts, etc., , 17 Vinyl stretch, , Characteristics of elastic materials, , 13 Terpene, 14 Isoprene Rubber, 16 Nitrile Rubber, 18 Thermoplastic elastomer, 19 Silicone rubber, 20 Ethylene-propylene-diene rubber (EPDM), , When an elastic material is deformed with an external, force, it experiences an internal resistance to the, deformation and restores it to its original state if the, external force is no longer applied., , 21 Ethylvinylacetate (EVA or foamy gum), , To a certain extent, most solid materials exhibit elastic, behavior, but there is a limit of the magnitude of the force, and the accompanying deformation within this elastic, recovery., , Plastic Material, , A material is considered as elastic if it can be stretched, up to 300% of its original length., For this reason there is an elastic limit, which is the, greatest force or tension per unit area of a solid material, that can withstand permanent deformation., For these materials, the elasticity limit marks the end of, their elastic behavior and the beginning of their plastic, behavior. For weaker materials, the stress or stress on, its elasticity limit results in its fracture., The elasticity limit depends on the type of solid considered., For example, a metal bar can be extended elastically up, to 1% of its original length., However, fragments of certain gummy materials may, undergo extensions of up to 1000%. The elastic properties, of most solid intentions tend to fall between these two, extremes., Maybe you might be interested How to Synthesize an, Elastolic Material?, , 22 Halogenated butyl rubbers (CIIR, BIIR), 23 Neoprene, Plastic Material Classification, “Plastic material” is a term that refers to a large class of, polymers, separated into various groups and sub-groups., Before starting the chapter on the uses and subsequent, recycling of plastic, let us establish a general classification, of these thermosetting resins or thermo-plastics (the two, big groups into which we include elastomers) by detailing, their properties, their make-up, their aspect, and their, final uses, while explaining which ones are recyclable., Thermoplastics, Remember that thermoplastic is a material whose, structure and viscosity can be modified both ways through, heating or cooling. This large family of materials is, commonly used by many industries and is easily, integrated into France’s recycling cycles., The following polymers are some examples of plastic, material:, 1 Polyolefins, 2 Vinyl polymers, 3 Polystyrenes, , Examples of elastic materials, , 4 Acrylate and methacrymate polymers, , 1 Natural gum, , 5 Polyamide, , 2 Spandex or lycra, , 6 Polycarbonates, , 3 Butyl Rubber (GDP), , 7 Celluloid, , 4 Fluoroelastomer, , 8 Linear polyesters, , 5 Elastomers, 6 Ethylene-propylene rubber (EPR), 7 Resilin, 8 Styrene-butadiene rubber (SBR), 9 Chloroprene, 10 Elastin, 42, , 9 Polyfluorethane, 10 Polyacetal, 11 Polysulfone, 12 Polyphenylene sulfide, 13 Modified polyphenylene oxide (PPO), , Copyright free, under CC BY Licence

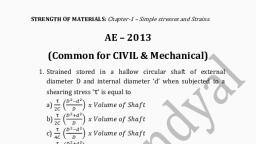

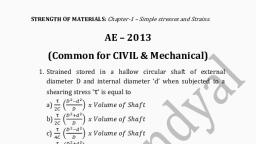

Page 2 :

Thermosetting plastic, , Poisson's ratio, , Thermosetting plastic is a compound that, during, condensation polymerisation (and/or implementation), when, submitted to a catalyst or a temperature increase, irreversibly, cures. the structure, shape, or rigidity of the manufactured, plastic object can not be modified again, and the material is, rarely recycled., , It is a ratio between lateral strain and linear strain., , This type of plastic includes the following types of, compounds:, , 1 Calculate the tensile strain when a force of 3.2 kN, is applied to a bar of original length 280 cm, extends the bar by 0.5 mm (Fig 1 & Fig 2), , 1, , Unsaturated polyster, , 2, , Phenol formaldehyde resins, , 3, , Melamine resins, , 4, , Polyepoxides, , 5, , Polyimide, , 6, , Polyurethane, , 7, , Polyorganosiloxanes, , Poisson’s ratio =, , Lateral strain, Linear strain, , =, , 1, m, , Examples, , Generally in any industry the material used are elastic in, nature. Hence if a material is subjected to an external, load, it undergoes deformation. During the deformation, process the material will offer a resistance against the, deformation. In case if the material fails to put up full, resistance to the external load, the deformation continues, until rupture takes place. Hence it is important to have a, considerable knowledge about the materials and their, properties for designing and fabricating., Strain, When an external forces acting on a material, there is a, change in its dimension and shape. The deformation is, called strain. Thus, strain is the ratio between the change, in dimension of a material to its original dimension. It has, no unit. It is represented by e (Epsilon), Strain =, , Change in dimension ( ), Original dimension ( ), , Linear or Longitudinal strain, It is the ratio between the change in length of the material, to its original length., Linear Strain =, , Change in length ( ), Original length ( ), , Lateral Strain, It is the ratio between change in cross sectional area of, material to its original area., Change in area, , Lateral Strain =, , Original Area, , Volumetric Strain, It is the ratio between change in volume of material to its, original volume., Volumetric Strain =, , Force, , = 3.2 kN, , Change in volume, , Original length (L), , = 280 cm, , Original Volume, , Increased length( ) = 0.5 mm = 0.05 cm, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 43

Page 3 :

Tensile Strain =, , Increased length, , = 400 /18, , Original Length, , = 22.22 Newton / mm, , =, , Force required to, compress the, spring into 6 mm, Load required, , 0.05, 280, , = 0.0001786, , =, , = 22.22 6, = 133.32 N, , 2 A steel rod used for brake operation is 1.50 m long., When it is subjected to a tensile force the extension, produced is 0.5 mm. Find the strain in the rod., Tensile strain =, , = Spring stiffness Deflection, , Extension, , 5 Calculate the tensile strain when a force of 3.2, KN is applied to a bar of original length 2.8 m, extends the bar by 0.5 mm., Force F, , = 3.2 KN, , Original length, , Original length L, , = 280 cm, , ⎛ mm ⎞, ⎜, ⎟, 1.5 x 1000 ⎝ mm ⎠, , Increased length( ) = 0.5 mm = 0.05 cm, , 0.5, , Tensile strain, , Strain in the brake rod = 0.0003, , =?, Strain, , 3 A helical spring is loaded with a force of 600, Newton and is compressed by 30mm. What would, be the load required to compress it to 10 mm (Fig3), , =, , =, , , L, , 0.05, 280, , = 0.0001786, 6 A metal bar is 2m long. When 5.5 tonne is applied, its length becomes 1.995 m. Find the compressive, strain?, Force F, , = 5.5 KN, , Original length L1, , =2m, , Final length L2, , = 1.995 m, , Increased length( ) = 2 - 1.995 = 0.005 m, Compressive strain, , =, , Solution, Spring stiffness =, , Deflection, , Load required to compress the spring by 10 mm, = spring stiffness x deflection, = 25 (N/mm) x 10(mm), Load required = 250 N, 4 Helical spring is loaded with a force of 400 Newton and it is compressed by 18 mm. What would, be the load required to compress it to 6 mm?, Given force, , = 400 Newton, , Deflection, , = 18 mm, , Spring Stiffness, , = Force / Compressed length, , , L, , 0.005, , 2, = 0.0025, , Applied load, , 600 ⎛ N ⎞, ⎛ N ⎞, ⎜ mm ⎟ = 25⎜ mm ⎟, =, 30 ⎝, ⎠, ⎝, ⎠, , 44, , =, , 7 When a steel rod of 4mm diameter experienced, the load of 200 Kg. It is found to be elongated by, 1.5 mm from the original length of 1500 mm., Calculate the strain., Force F, , = 200 Kg., , Original length L1, , = 1500 mm, , , Strain, Compressive strain, , = 1.5 mm, =?, =, , =, , , L, , 0.005, , = 0.001, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 2

Page 4 :

8 An iron rod of length 1 metre and 1 cm diameter, gets elongated by 1 cm. When a force of 100 Kg, is applied at one end. Calculate the strain, developed in the rod., Force F, , = 100 Kg., , Original length L1, , = 1 m = 100 cm, , , , 2 Compressive stress: When a material is subjected to, two equal and opposite axial pushes, the material tends, to decrease in length. The resistance offered against, the decrease in length is called compressive stress., The corresponding strain is called compressive strain., (Fig 5), , = 1 cm, , Strain, , =?, , Compressive strain, , =, , =, , , L, , 1, , Compressiv e stress , , 100, , = 0.01, , Compressive stress , , Axial push, Area of cross section, , Decrease in length, Original length, , Stress, The internal opposite force to the external load per unit, area is known as stress. The unit of stress depends upon, the force applied and area of original cross-section of, material. It is represented by (Sigma), Stress , , =, , Forced applied, , Shear stress (τ ) =, , F, A, , ⎛ N, Kg, ⎜, or, ⎜, 2, cm 2, ⎝ mm, , ⎛ N, Kg, ⎜, or, ⎜, cm2, ⎝ cm2, , 1 Compressive stress on connecting rod on the first part, of power stroke, 2 Compressive stress on push rod during valve opening, 3 Clutch lining when the clutch is engaged, , Area of original cross section, , Load (or) Force, Area, , Eg., , ⎞, ⎟, ⎟, ⎠, , ⎞, ⎟, ⎟, ⎠, , 3 Shear stress: When a material is subjected to two, equal and opposite forces acting tangentially across, the resisting section, the body tends to be sheared off, across the cross section. The stress included is called, shear stress. It is represented by . The corresponding, strain is called shear strain. (Fig 6), , Types of Stress, 1 Tensile stress, 2 Compressive stress, 3 Shear stress, 4 Torsional Stress, 1 Tensile stress: When a material is subjected to two, equal and opposite axial pulls, the material tends to, increase in length. The resistance offered against this, increase in length is called tensile stress. The, corresponding strain is called tensile strain. (Fig 4), , Shear stress (τ ) =, , F, A, , ⎛ N, Kg, ⎜, or, ⎜, 2, cm2, ⎝ cm, , ⎞, ⎟, ⎟, ⎠, , Eg., 1 Rivets, 2 Gudgeon Pin, 3 Spring shackle pin, 4 Brake rod rivets, E.g.:, , 5 Chassis rivets, , 1 When brake is applied the brake rod is under tensile, stress., , 6 Fly wheel holding bolts, , 2 During tightening of bolt or nut., 3 Belt driving the fan., 4 Crane rope (When rope is pulling), , 7 Swivel pins, 8 Gear box shaft, 9 Axle shaft, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 45

Page 5 :

4 Torsional stress: When a shaft is subjected to the, action of two equal and opposite couples acting in, parallel planes, then the shaft is said to in torsion. The, stress set up by the torsion is known as torsional shear, stress., , 3 A load of 600 kg is placed on a hollow cast iron, cylinder of 200 mm outer diameter and 100 mm, internal diameter. Find the stress on the cylinder., Hollow cylinder, , Eg., , Outer diameter (D) = 200 mm = 20 cm, , 1 Rear axle, , Outer radius (R), , 2 Crank shaft, , Internal diameter (d) = 100 mm = 10 cm, , 3 Coil springs, , Inner radius (r), , = 5 cm, , 4 Propeller shaft, , Weight, , = 600 kg, , 5 Starter motor armature shaft, Examples, 1 A steel wire 3 mm dia. is loaded in tension with a, weight of 50 kg. Find out the stress developed., Diameter of the steel wire, , = 1.5 mm, , Weight, , = 50 kg, , Stress, , =, , =, , Area, , = π (R + r) (R − r), 22, × (10 + 5) × (10 − 5), 7, 22, =, × 15 × 5, 7, 1650, =, = 235.7cm 2, 7, , Area(A), , Stress, , 22, × 1.5 × 1.5, 7, 49.5, =, = 7.07 mm2, 7, , =, , =, , 50, 7.07, = 7.072 Kg/mm2, , Stress, , =, , 2 A force of 500 N is applied on a metallic wire of, 5mm diameter. Find the stress., Diameter of the wire, , = 2.5 mm, , Force, , = 500 Newton, , 600, kg/cm2, 235.7, , = 2.546 kg/cm2, 4 Calculate the minimum cross section area of a, M.S. bar to withstand a load 6720 kg. Take the, maximum stress of the material as 698.2 kg/cm2., Weight, , = 6720 kg, , Maximum stress, , = 698.2 kg/cm2, , Stress, , =, , Area(A), , =, , = 5 mm, , Radius, , Area(A), , =, , Force(F), , = r2, , Force(F), , Stress, , = 3 mm, , Radius, , Area of circular wire (A), , = 10 cm, , Force(F), Area(A), , 6720, 698.2, , = 9.625 cm2, Stress, , =, , Area of circular wire (A), , Force(F), Area(A), , = r2, , To calculate diameter, , Area, , 22, × 2.5 × 2.5, 7, 137.5, =, = 19.64mm2, 7, , =, , πd 2, 4, , =, , Stress, , =, , 500, 19.64, , = 25.46 N/mm2, 46, , d2, , = 4 x 9.625 x, , =, , 134.75, 11, , d2, , = 12.25, , d, , = 3.5 cm, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 7, 22

Page 6 :

5 A load of 300 kg hanging from a rod of 3 metre, length and 5 mm diameter extends it by 4 mm., Find the stress in the material and the strain it, causes., , Thickness of the plate = 5 mm = 0.5 cm, Diameter of the punch = 30 mm = 3 cm, Shear stress, , = 400 kg/cm2, , Length of the rod, , = 3 m = 3000 mm, , Force, , = Shear stress x area, , Increased length, , = 4 mm, , Shear area, , = Circumference x thickness, , Diameter, , = 5 mm;, , Radius, , = 2.5 mm, , Weight, , = 300 kg, , Strain, , =, , =, , =, , Change in length, Original length, , ==, Stress, , = Dt, , 4, = 0.00133, 3000, , Force(F), Area(A), , Area of circular rod (A) = r2, , 22, =, × 2.5 × 2.5, 7, 137.5, =, 7, , =, Required force, , 22, 7, , x 3 x 0.5, , 33, 7, , = 4.71 mm2, , = 400 x 4.71, = 1885.71 kg, , 8 What force will be required to shear off a bar of, 30 mm dia. if the ultimate shear stress of the, material is 35 kg/mm2., Diameter of the bar, , = 30 mm, , Shear stress, , = 35 kg/mm2, , Stress(), , Force(F), , =, , Area(A), , = 19.643 mm2, 35, , 300, =, 19.643, , Stress, , Thickness of the plate= 1 mm, , = 24750 kg, 9 A Hole of 2 cm dia is to be punched out of a plate, of 1.4 cm thick. If the force applied to the punching, die is 12 KN. Calculate the shear stress., Dia. of the hole, , = 2cm, , Thickness, , = 1.4 cm, , Force, , = 12 KN, , Shear stress, , =?, , Dia. of the punch, , = 10 mm, , Shear stress, , = 50 Newton/mm2, , Force, , = Shear stress x area, , Shear area, , = Circumference x thickness, , Punched out area, , =, =, , =, , dt, 22, 7, , F, π × 15 × 15, , = 35 x x 15 x 15 kg, , F, , = 15.273 kg/mm2, 6 Find the force required to punch a hole of 10 mm, dia. in a 1 mm thick plate, if the allowable shear, stress is 50 N/mm2., , =, , = Circumference of the hole, Thickness, = 2 r t unit2, = 2 1 1.4, , x 10 x 1, , = 2.8 cm2, , 220, , = 31.43 mm2, 7, Force = 50 x 31.43, , Shear stress ( ) =, , = 1571.5 Newton, 7 A hole of 30 mm diameter is punched in a plate of, 5 mm thickness. If the shear stress is 400 kg/cm2., Find the force required to punch the hole., , =, , F, A, 12KN, 2.8 π cm2, , = 1.364 KN/cm2, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 47

Page 7 :

10 A square rod of 10 mm side is tested for a tensile, load of 1016 kg. Calculate the tensile stress?, Side of square rod a, , = 10 mm, , Tensile force F, , = 1016 kg, , Tensile stress , , =?, , Stress(), , =, , =, , =, , Force(F), Area(A), , 2, , 1016, 10x10, , = 10.16 Kg/mm2, 11 A M.S. tie bar 3.5 cm dia. is under a state of stress, which carries a load of 6720 kg. Find the intensity, of stress in the material., , If the external force is so large that the stress exceeds the, limit, the material loses to some extent its property of, elasticity. If now the force is removed, the material will not, return to its original shape and size and there will be a, residual deformation in material., , d = 3.5 cm, , Yield point, , r = 1.75 cm, , The yeild point of a material is the point at which there is, a marked increase in elongation without increase in load., , F = 6720 kg, Stress(), , When an external force acts on a body, the body tends to, under go some deformation. If the external force is removed, and the body comes back to its original shape and size, (Which means the deformation disappers completely)., The body is known as elastic body. This property by virtue, of which certains materials return back to their original, position after the removal of the external force is called, elasticity., The body will regain its previous shape and size only when, the deformation caused by the external force is with in a, certain limit. Thus there is a limiting value of force up to and, within which the deformation completely disapperas on the, removal of the force. The value of stress corresponding to, this limiting force is known as elastic limit of the material., , Force, a, , Elasticity and Elastic limit, , =, , =, , Hooke’s law, , Force(F), , Robert Hooke discovered a relationship between stress, and strain. According to Hooke’s law stress is proportional, to strain within elastic limit., , Area(A), Force, , πr, , Young’s Modulus or Modulus of Elasticity, , 2, , 6720, , =, , 3.14 x 1.75 x 1.75, , =, , 6720, , The ratio of stress to strain within elastic limit is known as, young’s modulus or modulus of elasticity. This is expressed by a symbol “E”. The unit of Young’s modulus is, same that of stress., , , 9.616, , = 698.8 Kg/cm, , 2, , 12 A rivet of 10 mm dia. is subjected to a double shear, force of 1.5 KN. Find the shear stress in the rivet., , Double shear force is acting on the rivet, consider, the area as double., Stress, , =, , F, 2Area, , =, , 1.5, , Modulus of Rigidity (N) , , Shear stress, Shear strain, , Bulk Modulus, When a body is subjected to three mutually perpendicular, forces of the same intensity, the ratio of volumetric stress, to the volumetric strain is known as Bulk Modulus. It is, usually represented by the letter K., , , Bulk Modulus (K) , , Volumetric stress, , 2x3.14x5x5, = 0.00955 KN/mm2, , 48, , Strain, , The ratio of shear stress to shear strain is known as, “modulus of rigidity” represented by symbol “N”., , , Shear stress = ?, , Stress, , Modulus of Rigidity, , dia. of the rivet = 10 mm, r = 5 mm, , Young' s modulus (E) , , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , Volumetric strain

Page 8 :

Relationship between three moduli for a given, material, , ==, , The relationship between three moduli for a given material, is as follows :, , ⎛ 2⎞, ⎛ 1⎞, E = 2N⎜1+ ⎟ = 3 K ⎜1− ⎟., m, ⎝ m⎠, ⎝, ⎠, , =, , , , 2, π, × 2.5, 4, , π × 6.25, , cm2, 4, Force applied, Stress =, Area of original cross section, , Where, , 4500, π × 6.25, =, 4, , E = Young’s modulus of elasticity, N = Modulus of rigidity, K = Bulk modulus, , 4500× 4, = π, × 6.25, , 1, = Poisson’s ratio, m, , =, , Example, 1 A steel rod of 10 mm diameter and 175 mm long, is subjected to a tensile load of 15 kN. If E = 2 x105, N/mm2, calculate the change in length., Tensile load, , = 15 kN = 15000 N, 22, , Area of cross section = (r2) =, , , , Stress =, , 15000N, , , , Strain, , =, , Change in length =, , 2880, Kg/cm2, π, , , , Strain, , =, , Change in length, Original length, , =, , 0.008 8 1000, =, 20, 20, , =, , 8, 4, =, 20×1000 10000, , =, , 4, 10000, , Stress, , , , Strain, , E = 2 105 N/mm2 =, , Stress =, , = 191 N/mm2, , 0.785×100mm2, , Young's modulus E =, , , , 5 5 mm2 = 78.57, , 7, , 191N/mm2, Strain, , Strain, , Young’s modulus, , 2 ×105, , 2 ×105, , mm, , 2 A bar of steel 2.5 cm diameter was subjected to, compressive load of 4500 kg. The compression in, a length of 20 cm was found to be 0.008 cm. Find, the Young’s modulus of elasticity of bar., Solution, = 2.5 cm, , Force applied i.e. compressive load = 4500 kg, , 2880, 4, ÷, π, 10000, , =, , 2880 10000, ×, π, 4, , =, , 7200000, π, , = 2292000 Kg/cm2, = 2.292 x 106 Kg/cm2, 3 A force of 10 tonnes is applied axially on a rod of, 12 cm dia. the original length is 100 mm.If modulus, of elasticity is 2 x 1012 kg/cm2. Calculate stress, and strain developed in the rod., Force applied = 10 tonnes, , = 0.008 cm, , Area of original cross-section =, , =, , Solution, , Original length of bar = 20 cm, Change in length, , Stress, Strain, , = 0.167 mm., , Diameter of bar d, , =, , 191, , 175 ×191, , 2880, π, , π, 4, , = 10 x 1000 kg, = 104 kg, , d2, , Diameter (d) = 12 mm, , = 1.2 cm, , Young’s modulus (E), , = 2 x 1012 kg/cm2, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 49

Page 9 :

Stress =, , Force applied, Area of original cross section, , =, , =, , Strain, , 104, π 12 12, × ×, 4 10 10, , 104 × 4 × 10 × 10, π × 12× 12, , =, , = 0.0136, , = 8841 kg/cm2, , We know, Stress, , = Young’s modulus, , Strain, , Strain x Young’s modulus, Strain, , = Stress, =, , =, , Stress, Young's Modulus, , 8841, , E, , =, , Stress, , = 8841 kg/cm2, , Strain, , = 4420.5 x 10-12, , 4 A bar of 100 cm elongates to 101.36 cm when a, load of 15000 kg is applied to it. Take the area of, cross section of bar as 10 cm2. Find the stress,, strain and youngs modulus., L2, , = 101.36 cm, , = 110300 kg/cm2, 5 What force is required to stretch a steel wire of 10, mm long and 10 mm dia. to double its length. E, of steel is 205 KN/cm2., d, , = 10 mm = 1 cm, , r, , = 0.5 cm, , L1, , = 1 cm, , L2, , = 2 cm, , , , = L2 - L1 = 2 - 1 = 1 cm, , E, , = 205 KN/cm2, =, , E, , =, , 205, , =, , Stress, , = 1 x 205 = 205 KN/cm2, , Stress, , =, , 205, , =, , A, , = 10 cm2, , Stress, , =, , =, , Strain, , Stress, , 1, , Force(F), Area(A), Force, , Force, , = 205 x 3.14 x 0.5 x 0.5, = 161 KN, , 6 A wire of 1.6 cm diameter is subjected to a tensile, load of 2000 Kg. Find the stress and strain if, youngs modulus = 2 x 106 kg/cm2., , Force(F), Area(A), , F, , = 2000 kg, , 15000, , d, , = 1.6 cm, , 10, , r, , = 0.8 cm, , E, , = 2 x 106 Kg/cm2, , = 1500 kg/cm2, 50, , Stress, , 3.14 x 0.5 x 0.5, , = 101.36 - 100 = 1.36 cm, = 15000 kg, , =, , 1, =1, 1, , Strain, , = L2 - L1, F, , 1500, , 2 ×1012, , = 4420.5 x 10-12, , = 100 cm, , Strain, , 0.0136, , =4420.5, 12, 10, , L1, , Stress, , Youngs modulus =, , = 8841 kg/cm2, Stress, , 1.36, 100, , 106, =, 36 π, , , , =, , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence

Page 10 :

Stress, , =, , E, , F, , Rectangular rod length = 2 cm, , A, , =, , = 2 x 106 kg/cm2, , Breadth = 1 cm, , 2000, Stress() =, , πr 2, 2000, , =, , =, , 3.14 x 0.8 x 0.8, , =, , E, , = 995.2 kg/cm2, , 2 x 106, , =, , lxb, , 2000, , =, , Stress, Strain, 1000, Strain, , 995.2, , Strain, , Strain, , Strain, , =, , Stress, Strain, , =, , Force, , = 1000 kg/cm2, , 2.0096, , 2 x 106, , Area(A), , =, , 2 x1, , 2000, , Youngs modulus =, , Force(F), , =, , 1000, 6, 2 x 10, , = 0.0005, , 995.2, 6, 2 x 10, , = Strain, , = 0.0005, 7 A tensile load of 2000 kg is applied on a, rectangular rod of 2 cm x 1 cm whose length is 2, metres. Calculate the elongation in length as E =, 2 x 106 Kg/cm2., F, , = 2000 Kg., , L1, , = 2 m = 200 cm, , , 200, , = 0.0005, , = 200 x 0.0005, , = 0.1 cm, , Elongated length = 0.1 cm, , Assignment, Strain, 1 Find the compressive strain if a metal bar is 150 cm, long. When 2.5 KN is applied, its length becomes, 148.6 cm., , 2 Calculate the intensity of stress if a mild steel rod having, a cross sectional area of 40 mm2 is subjected to the, load of 1000 kg., , 2 Calculate the strain if a metallic bar is 150 cm long., When 2500 kg is applied its length becomes 150.5, cm., , 3 Calculate the tensile stress if a square rod of 10 mm, side is tested for a tensile load of 1000 kg., , 3 Find the strain it causes if a load of 300 kg hanging, from a rod of 3 metres length and 5 mm diameter, extends it by 4 mm., 4 A tensile force of 10 kg is applied on a copper wire of, diameter 1 cm. So that the length of wire increases by, 5 mm. If the original length of wire was 2 metres, findout, the strain., , 4 Calculate the maximum stress if a bar of 9 cm2 cross, sectional area 300 cm long carries a tensile load of, 3500 kg., 5 Find out the stress on the rod. if a load of 500 kg is, placed on a M.S.rod of dia. 35 mm., 6 A metallic bar of 8 cm diameter is under stress carrying, a load of 8620 N. Calculate the intensity of stress., 7 A steel wire 2 mm diameter is loaded in tension with a, weight of 20 kg. Find out the stress developed., , Stress, 1 Calculate the intensity of stress in the material if a, copper rod of 40 mm diameter is subjected by tensile, load of 4000 Newtons., , 8 A rod having a cross sectional area of 25 mm2 is, subjected to a load of 1500 kg. Find out stress on the, rod., , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence, , 51

Page 11 :

9 A square rod of 10 mm side is tested for a tensile load, of 2500 kg. Calculate the tensile stress of the rod., Youngs modulus, 1 A piece of wire 2 m long, 0.8 mm2 in cross section, increases its length by 1.6 mm on suspension of 8 kg, weight from it. Calculate the stress, strain and youngs, modulus., 2 A wire of 16 mm dia. is subjected to a tensile load of, 2000 kg. Find the stress and strain if young’s modulus, E = 2 x 1016 kg/cm2., 3 A wire is of 2 metres long and its area of cross section, is 0.78 mm2. If 78 kg weight is suspended on this, wire, then the length of the wire is increased by, 1.4 mm. Find out stress, strain and youngs modulus, of elasticity., , 52, , 4 A wire 2800 mm long is stretched by 0.5 mm, when a, weight of 9 kg is hung on it, its diameter is 2 mm., Calculate stress and youngs modulus for the substance, of the wire., 5 A force of 1000 kg is applied axially on rod of 12 mm, diameter the original length is 100 mm. If modulus of, elasticity is 2 x 1012 kg/cm2. Calculate the stress and, strain developed in the rod., 6 A steel wire 3.2 mm diameter and 3.65 metre long, stretches by 2.03 mm under the load of 115 kg., Calculate the stress and youngs modulus of elasticity., 7 A mass of 10 kg is hung from a vertical wire 300.25 cm, long and 0.0005 sq. cm cross section. When the load, is removed the wire is found to be 300 cm long. Find, the modulus of elasticity for the wire material., , Workshop Calculation & Science : (NSQF) Exercise 2.5.10, , Copyright free, under CC BY Licence

Page 12 :

Elasticity - Ultimate stress and working stress, Ultimate stress and Working stress, The minimium load at which a material develops failure is, called as ultimate load or breaking load. The stress, produced in a material at ultimate load is called as ultimate, stress or breaking stress., Ultimate stress =, , Ultimate load, Area of original cross section, , The load which is considered safe for the machine element, is known as safe load or working load and the, corresponding stress at this load is called as safe stress, or working stress., Safe stress =, , Safe load, Area of original cross section, , Factor of safety (Fig 1), , Exercise 2.5.11, , A metal (say mild steel) is subjected to increasing load and, the extensions are measured with an extensometer. On, plotting a graph between the loads and elongations produced,, in the beginning, there is a straight-line relationship. It, continues up to ‘a’ which is called the limit of proportionality,, i.e. up to ‘a’ in Fig 2 ‘Stress is proportional to strain’., Point b denotes the elastic limit. Below this point, the body, regains its original shape, if the load is removed. Beyond, this point the body does not recover its original shape, completely, even if the load is removed., Upto a point beyond the elastic limit, a considerable, amount of elongation takes place even with a slight, increase in load. The point C where it occurs, is called the, yield point., At ‘d’ the maximum or the ultimate load is reached. After, this, a waist or local contraction is formed in the specimen,, and fracture occurs as illustrated in Figure., Example, A standard steel bar of 30 mm square cross section is, subjected to tensile stress. If the factor of safety is 4 and, ultimate stress is 370 N/mm2 determine the load to which, the bar is subjected. (Fig 3), , The ratio of ultimate stress to working stress (i.e. safe, stress) is known as factor of safety. The ratio of ultimate, load to the safe load may also be termed as factor of, safety. It has no unit. Hence it is expressed in a number., , Factory of safety =, , Ultimate stress, Working stress, , Ultimate stress, = Factor of safety = 4, Working stress, , or, Ultimate load, Factor of safety =, Safe load, , Working stress =, , N/mm2, 4, Area of cross section = 900 mm2, (a2 = 302 = 900, a =, , Stress-Strain graph, Load-extension graph (Fig 2), , 370, , =30), , Load = Working tensile stress x area, = 900 mm2 x, , 370, , N/mm2, , 4, , = 83250 N, Example, 1 A rod of 60 mm is subjected to a maximum, tensile load of 1600 kg. Calculate the stress and, strength of the material. If the factory of safety is, 5., Dia. of rod, , = 60 mm, , Tensile load F, , = 1600 kg, , Copyright free, under CC BY Licence, , 53

Page 13 :

i, , Stress, , Factor of safety (FS) = 4, , F, 1600, =, A π × 30 × 30, , =, , = 0.5658 kg/mm2 Ans., ii Factor of safety, Factor of safety, , 5=, Ultimate stress, , =, , Ultimate stress, Working stress, , 4, , =, , 25 kg/mm 2, W.S, , WS, , =, , 25, kg/mm2, 4, , =5, =, , Ultimate stress, Working stress, , Ultimate stress, , = 6.25 kg/mm2, , 0.5685 kg/mm 2, = 5 0.5658 kg/mm2, , Stress, , Strength of the material = 2.829 kg/mm2, 2 Find the safe load which can be suspended from, a 4.2 mm dia. wire. If the ultimate stress is 25 kg/, mm2 and the factor of safety is 4., Dia. of wire d, , FS., , =, , 6.25 kg/mm2, F, , = 4.2 mm, , Safe load F, , Ultimate stress U.S = 25 kg/mm2, , =, , F, A, F kg, π × 2.1 × 2.1mm2, , = 6.25 2.1 2.1 kg, = 86.6 kg, , Assignment, 1, , A = 60 x 15 mm2, Rm = 370 N/mm, , F = 19000 N, Rm = 420 N/mm2, , F = ______ N, , Factor of safety = 5, , Rm = Ultimate, stress, , d = ______ mm, , F = Breaking Force, 2, , 4, , 2, , 5, , F = 35000 N, , A = 25 x 6 mm2, , Working shear, stress = 110 N/mm2, , F = 63000 N, , b = 10 mm, , Rm = ______ N/mm2, , l = ______ mm, , 6, , Ultimate tensile, stress = 420 N/mm2, d = 10 mm, , 3, , A = 490.87 mm, , 2, , Shear force Max, = ______ N, , F = 206.22 kN, d = ______ mm, Rm = ______ N/mm2, , 7, , F = 140 kN (Tensile), Factor of safety = 4, Ultimate tensile, stress = 500 N/mm2, Ultimate shear, stress = 400 N/mm2, d = ______ mm, , 54, , Workshop Calculation & Science : (NSQF) Exercise 2.5.11, , Copyright free, under CC BY Licence

Page 14 :

8, , 9, , Ultimate tensile, strength, = 370 N/mm2, Shear force, = 380 kN, R = 30 mm, Thickness of plate, punched, = ______ mm, Ultimate tensile, strength = 330 N/mm2, s = 3 mm, F = 60 kN, (Shear force), , 10, , 15 A steel rod of 1.5 cm diameter and 8 metres long pulled, by a forced of 80 kg at both ends. Find out the, expansion and strain on the rod. The coefficient of, elasticityE=2.10106 kg/cm2., 16 Find out the load which can be suspended from a 3.2, mm dia wire taking the factor of safety as 2. Ultimate, stress is 25 kg/mm2., 17 A rod of 60 mm dia is subjected to a maximum tensile, load of 1600kg. Calculate the stress and strength of the, material if the factor of safety is 5., , F = 43180 N, , 18 A wire of length 3.5 m and diameter 0.35 mm is, stretched by a force of 2kg weight. If the elongation is, 4 mm. Calculate the young's modulus of the material of, wire., , Ultimate tensile, strength, = 220 N/mm2, d = ______ mm, , d = 12 mm, F = 36.2 kN, Ultimate tensile, strength = ____ N/mm2, , 12, , 14 A steel rod 1.5 metres long and of 30 mm diameter is, pulled at both ends by a force of 1500 kg. If modulus of, elasticity of steel is 2.4 106 kg/cm2, determine increase, in length of rod and strain produced in it., , d = ______ mm, , s = 2.5 mm, , 11, , 13 A steel rod whose diameter is 1 cm and 60 cm in length., This rod is pulled at both ends by a force of 700 kg. If, modulus of elasticity of steel is 2.1 106 kg/cm2, find out, increase in length of rod and strain produced in it., , Tensile load, = 15000 N, Ultimate tensile, strength, = 9.5 N/mm2, , 19 A mass of 1kg is suspended from a metal wire 100 cm, long and 0.5 mm diameter. An increase in length of wire, equal to 2 mm is observed. Calculate the young's, modulus of wire., 20 A 4 metre long copper wire of diameter 3 mm is used to, support a mass of 50kg. What will be the elongation of, the wire. Young's modulus of elasticity for copper is, 7x1010 N/mm2., 21 Calculate the change in length of a rod of dia 16 mm and, 160 mm long when it carries a load of 40KN. Take E =, 200000 N/mm2., 22 A hollow C.I. column with a wall thickness of 2 cm is, subjected to an axial compressive load of 80 tonnes. If, the maximum stress is not to be exceeded 1 tonne per, cm2, determine the internal diameter of column. Calculate, compressive strain, if E = 950 tonnes per cm2., , s = 20 mm, Width `b' = ______ mm, , Workshop Calculation & Science : (NSQF) Exercise 2.5.11, , Copyright free, under CC BY Licence, , 55