Page 1 :

ELECTRICIAN, NSQF (LEVEL - 5), , 3rd Semester, TRADE THEORY, SECTOR: Electrical, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright @ NIMI Not to be Republished

Page 2 : Sector, , : Electrical, , Duration : 2 - Years, Trade, , : Electrician 3rd Semester - Trade Theory - NSQF (LEVEL - 5), , Copyright© 2018 National Instructional Media Institute, Chennai, First Edition :, First Reprint :, , October 2018, December 2018, , Copies : 1,000, Copies : 5,000, , Rs.250/-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical, including, photocopy, recording or any information storage and retrieval system, without permission in writing from the National, Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone : 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected],

[email protected], Website: www.nimi.gov.in, , (ii), , Copyright @ NIMI Not to be Republished

Page 3 :

FOREWORD, The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of, every four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy., Industrial Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled, manpower. Keeping this in mind, and for providing the current industry relevant skill training to Trainees,, ITI syllabus has been recently updated with the help of Mentor Councils comprising of various stakeholder's, viz. Industries, Entrepreneurs, Academicians and representatives from ITIs., National Instructional Media Institute (NIMI), Chennai has come up with instructional material to suit the, revised curriculum for Electrician 3rd Semester Trade Theory NSQF (LEVEL - 5) in Electrical sector, under Semester Pattern required for ITIs and related institutions imparting skill development. The, NSQF (LEVEL - 5) will help the trainees to get an international equivalency standard where their skill, proficiency and competency will be duly recognized across the globe and this will also increase the, scope of recognition of prior learning. NSQF (LEVEL - 5) trainees will also get the opportunities to promote, life long learning and skill development. I have no doubt that with NSQF (LEVEL - 5) the trainers and, trainees of ITIs, and all stakeholders will derive maximum benefits from these IMPs and that NIMI's effort, will go a long way in improving the quality of Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, , Director General / Addl. Secretary,, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright @ NIMI Not to be Republished

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Training (D.G.T), Ministry of Labour and Employment, (now under Directorate General of Training, (D.G.T), Ministry of Skill Development and Entrepreneurship) (MSDE) Government of India, with technical, assistance from the Govt. of the Federal Republic of Germany. The prime objective of this institute is to, develop and provide instructional materials for various trades as per the prescribed syllabi (NSQF) under, the Craftsman and Apprenticeship Training Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials, are generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book,, Practical book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and, Transparencies) and other supporting materials., The trade theory book provides related theoretical knowledge required to enable the trainee to do a job., The test and assignments will enable the instructor to give assignments for the evaluation of the performance, of a trainee. The wall charts and transparencies are unique, as they not only help the instructor to effectively, present a topic but also help him to assess the trainee's understanding. The instructor guide enables the, instructor to plan his schedule of instruction, plan the raw material requirements, day to day lessons and, demonstrations., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the Media, Development Committees specially drawn from Public and Private sector industries, various training institutes, under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment &, Training of various State Governments, Training Departments of Industries both in the Public and Private, sectors, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators,, but for whose active support NIMI would not have been able to bring out this materials., , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Chennai - 600 032, , (iv), , Copyright @ NIMI Not to be Republished

Page 5 :

ACKNOWLEDGEMENT, National Instructional Media Institute (NIMI) sincerely acknowledges with thanks for the co-operation and, contribution extended by the following Media Developers and their sponsoring organisations to bring out this, Instructional Material (Trade Theory) for the trade of Electrician NSQF (LEVEL - 5) under Electrical Sector for, ITIs., MEDIA DEVELOPMENT COMMITTEE MEMBERS, Shri. D.S. Varadarajulu, , -, , DD/Principal, (Retd.,),, Govt. I.T.I, Ambattur,, Chennai - 98., , Shri. G.Ethirajulu, , -, , Principal (Retd.),, Govt. I.T.I, Guindy,, Chennai - 32., , Shri. M.H. Nagesh, , -, , Junior Training Officer, Govt. I.T.I,, Mysuru - 570 007., , Smt. S.Chandrakala, , -, , Junior Training Officer, Govt. I.T.I,, Mysuru - 570 007., , Smt. D.Vinutha, , -, , Junior Training Officer, Govt. I.T.I,, Bangalore - 560 029., , Shri P. Natarajan, , -, , Assistant Training Officer, Govt. ITI, Anaikatti,, Coimbatore (Dist), , Shri K. Mohandass, , -, , Assistant Training Officer, Govt. ITI, North Chennai, Chennai - 21., , NIMI CO-ORDINATORS, Shri. K. Srinivasa Rao, , -, , Joint Director, NIMI, Chennai - 32., , Shri. Subhankar Bhowmik, , -, , Assistant Manager,, NIMI, Chennai - 32., , NIMI records its appreciation for the Data Entry, CAD, DTP operators for their excellent and devoted services in the, process of development of this Instructional Material., NIMI also acknowledges with thanks the invaluable efforts rendered by all other NIMI staff who have contributed, towards the development of this Instructional Material., NIMI is also grateful to everyone who has directly or indirectly helped in developing this Instructional Material., , (v), , Copyright @ NIMI Not to be Republished

Page 6 :

INTRODUCTION, This manual for trade Theory is intended for use in the ITI workshop. It consists of a series of practical exercises, that are to be completed by the trainees during the Third semester of course is the Electrician trade under, Electrical Sector. It is National Skills Qualifications Framework NSQF (LEVEL - 5), supplemented and, supported by instructions/information to assist the trainees in performing the exercises. The syllabus for the, 3rd Semester Electrician NSQF (LEVEL - 5) Trade under Electrical Sector Trade Practical is divided into, six modules.The allocation of time for the various modules is given below:, Module 1 - DC Generator, , 7 Exercises, , 78 Hrs, , Module 2 - DC Motor, , 9 Exercises, , 122 Hrs, , Module 3 - AC Three Phase Motor, , 11 Exercises, , 125 Hrs, , Module 4 - AC Single Phase Motor, , 9 Exercises, , 100 Hrs, , Module 5 - Alternator, , 5 Exercises, , 50 Hrs, , Module 6 - Synchronous Motor and MG Set, , 4 Exercises, , 50 Hrs, , 45 Exercises, , 525 Hrs, , Total, , The syllabus and the content in the modules are interlinked. As the number of workstations available in the, electrical section is limited by the machinery and equipment, it is necessary to interpolate the exercises in the, modules to form a proper teaching and learning sequence. The sequence of instruction is given in the schedule, of instruction which is incorporated in the Instructor's Guide. With 25 practical hours a week of 5 working days, 100 hours of practical per month is available., The procedure for working through the 45 exercises for the 3rd semester with the specific objectives to be achieved, as the learning out comes at the end of each exercise is given in this book., The symbols used in the diagrams comply with the Bureau of Indian Standards (BIS) specifications., This manual on trade Theory forms part of the Written Instructional Material (WIM), which includes manual on trade, practical and assignment/test., , (vi), , Copyright @ NIMI Not to be Republished

Page 7 :

CONTENTS, Lesson No., , Title of the Lesson, , Page No., , Module 1 : DC Generator, 3.1.115 & 3.1.116, , DC Generator - principle - parts - types - function - e.m.f. equation, , 1, , 3.1.117, , Building up of a DC shunt generator, , 16, , 3.1.118, , Test a DC machine for continuity and insulation resistance, , 19, , 3.1.120 to 3.1.123, , Characteristics of DC generator, , 21, , Module 2 : DC Motor, 3.2.119 & 3.2.124, to 3.2.127, , 3.2.128, , 3.2.129, , 3.2.130, , DC motor - principle and types, , 36, , The relation between applied voltage, back emf, armature voltage drop, speed, and flux of DC motor - method of changing direction of rotation, , 37, , DC motor starters, , 39, , Relation between torque, flux and armature current in a DC motor, , 40, , Service and maintenance of DC motor starters, , 42, , Characteristics and applications of a DC series motor, , 44, , Characteristic and applications of a DC shunt motor, , 46, , DC compound motor - load characteristics, , 48, , Speed control methods of a DC motor and their applications, , 51, , Method of calculation of control resistance and new speed, , 54, , Troubleshooting in DC machines, , 56, , Maintenance procedure for DC machines, , 59, , DC motor control system (drives) AC-DC and DC-AC control, , 63, , Materials used for winding - field coil winding, , 64, , Winding wires, , 66, , Armature winding - terms - types - rewinding of mixer/liquidizer, , 70, , Simplex lap and wave winding - developed diagram, , 74, , Preparation of armature for rewinding, , 77, , Rewinding of mixer/liquidizer, , 80, , Method of rewinding and balancing the armature, , 83, , Testing of armature winding, , 86, , Module 3 : AC Three Phase Motor, 3.3.131 to 3.3.139, , Principle of induction motor, , 89, , Construction of a 3-phase squirrel cage induction motor - relation between, slip, speed, rotor frequency, copper loss and torque, , 91, , Classification of squirrel cage motors, , 95, , (vii), , Copyright @ NIMI Not to be Republished

Page 8 :

Lesson No., , 3.3.140, , Title of the Lesson, , Page No., , Insulation test on 3 phase induction motors, , 96, , Starter for 3-phase induction motor - power control circuits - D.O.L starter, , 99, , B.I.S. symbols pertaining to contactor and machines, , 103, , D.O.L. starter, , 119, , Numerical problems in ac 3-phase induction motors, , 120, , Jogging (inching) control circuits for motors, , 121, , Rotary type switches, , 123, , Manual star-delta starter, , 125, , Semi-automatic star-delta starter, , 128, , Automatic star-delta starter, , 129, , Three-phase, slip-ring induction motor, , 130, , Resistance starter for 3-phase, slip-ring induction motor, , 132, , Method of measurement of slip in induction motor, , 133, , Efficiency - characteristics of induction motor- no load test blocked rotor test, , 134, , Characteristics of squirrel cage induction motor, , 136, , No-load test of induction motor, , 137, , Blocked rotor test, , 138, , Efficiency from no-load and blocked rotor test, , 139, , Effect of external resistance in slip ring motor rotor circuit, , 140, , Auto-transformer starter, , 140, , Single phasing preventer / phase failure relay, , 141, , Braking system of motors, , 144, , Method of speed control of 3 phase induction motor, , 145, , Fundamental terms used in AC winding, , 147, , Hand winding process, , 151, , 3 phase squirrel cage induction motor winding (single layer, distributed winding), , 152, , Method of placing coils in a basket or distributed winding, , 154, , Three-phase induction motor winding (single layer - concentric type, - half coil connection), , 158, , 3 phase squirrel cage induction motor - double layer distributed type winding, , 161, , Testing of windings, , 164, , Insulating varnish and varnishing process in electric machines, , 167, , Method of connecting end connection, group connection, terminal leads,, binding and forming the overhangs, , 169, , (viii), , Copyright @ NIMI Not to be Republished

Page 9 :

CONTENTS, Lesson No., 3.3.141, , Title of the Lesson, , Page No., , Maintenance, service and troubleshooting in AC 3 phase squirrel cage, induction motor and starters, , 172, , Troubleshooting of motor starters, , 180, , Module 4 : AC Single Phase Motor, 3.4.142 to 3.4.150, , Single phase motors - split phase induction motor - induction-start,, induction-run motor, , 183, , Centrifugal switch, , 185, , Single phase, split phase type motor winding (concentric coil winding), , 188, , Capacitor-start, induction-run motor, , 191, , Capacitors used in single phase capacitor motors, , 192, , Permanent capacitor motor - capacitor-start, capacitor-run motor and, shaded pole motor, , 194, , The shaded pole motor, , 195, , Universal motor, , 197, , Troubleshooting of universal motor, , 199, , Repulsion motor, , 200, , Stepper motor, , 202, , Hysteresis motor, , 204, , Reluctance motor, , 206, , Module 5 : Alternator, 3.5.151 to 3.5.153, , Alternator - principle - relation between poles, speed and frequency, , 207, , Types and construction of alternators, , 209, , Generation of 3-phase voltage and general test on alternator, , 211, , Emf equation of the alternator, , 214, , 3.5.154, , Characteristic and voltage regulation of the alternator, , 217, , 3.5.155, , Parallel operation and synchronisation of three phase alternators brushless alternator, , 220, , Synchroscope method, , 222, , Brushless alternator, , 224, , Module 6: Synchronous Motor and MG Set, 3.6.156 & 3.6.157, , Synchronous motor, , 226, , 3.6.158 & 3.6.159, , MG set and rotary converter and inverter, , 230, , Maintenance of MG set, , 231, , Project work, , 233, , (ix), , Copyright @ NIMI Not to be Republished

Page 10 :

ASSESSABLE / LEARNING OUTCOME, On completion of this book you shall be able to, • Plan, execute commissioning and evaluate performance of DC, machines., • Execute testing and maintenance of DC machines and motor starters., • Plan, execute commissioning and evaluate performance of AC, motors., • Execute testing and maintenance of AC motors and starters., • Plan, execute testing, evaluate performance and carry out, maintenance of Alternator/MG set., • Execute parallel operation of Alternators., • Distinguish organize and perform motor winding., , (x), , Copyright @ NIMI Not to be Republished

Page 11 :

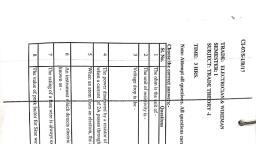

SYLLABUS, Third Semester, , Duration: Six Month, , Week Ref. Learning, No. Outcome, , Professional Skills(Trade Practical), with Indicative hours, , Professional Knowledge, (Trade Theory), , 53 - 54, , •, , Plan,, Execute, commis, -sioning, and, evaluate, performance, of, DC, machines, , 115. Identify terminals, parts, and connections of, different types of DC, machines. (10 Hrs), 116. Measure field and, armature resistance of DC, machines. (10 Hrs), 117. Determine build up voltage, of DC shunt generator with, varying field excitation and, performance analysis on, load. (15 Hrs), 118. Test for continuity and, insulation resistance of DC, machine. (5 Hrs), 119. Start, run and reverse, direction of rotation of DC, series, shunt and, compound motors. (10, Hrs), , General concept of rotating, electrical machines., Principle of DC generator., Use of Armature, Field Coil,, Polarity, Yoke, Cooling Fan,, Commutator, slip ring and, Brushes, Laminated core, etc., E.M.F. equation, Separately excited and self, excited generators., Series, shunt and, compound, generators, , 55 - 56, , •, , Plan, Execute, commissioning, and evaluate, performance of, DC machines., Execute, testing,, and, maintenanceof, DC machines, and, motor starters, , 120.Perform no load and load, test and determine, characteristics of series, and shunt generators. (12, Hrs), 121.Perform no load and load, test and determine, characteristics of, compound generators, (cumulative and, differential). (13 Hrs), 122.Practice dismantling and, assembling in DC shunt, motor. (12 Hrs), 123.Practice dismantling and, assembling in DC, compound generator. (13 Hrs), , Armature reaction,, Commutation, inter poles and, connection of inter poles., Parallel Operation of DC, Generators., Load characteristics of DC, generators., Application, losses & efficiency, of, DC Generators., Routine & maintenance, , Plan, Execute, commissioning, and evaluate, performance of, DC machines., Execute, testing,, and, maintenance of, DC machines, and, motor starters, , 124.Conduct performance, analysis of DC series, shunt, and compound motors. (15, Hrs), 125.Dismantle and identify, parts of three point and, four point DC motor, starters. (10 Hrs), 126.Assemble, Service and, repair three point and four, point DC motor starters., (15 Hrs), , Principle and types of DC, motor., Relation between applied, voltage, back e.m.f., armature voltage, drop, speed and flux of DC, motor., DC motor Starters, relation, between torque, flux and, armature current., Changing the direction of, rotation., , •, , 57 - 58, , •, , •, , Copyright @ NIMI Not to be Republished

Page 12 :

127.Practice maintenance of, carbon brushes, brush, holders, Commutator and, slip-rings. (10 Hrs), , Characteristics, Losses &, Efficiency of DC motors., Routine and maintenance, , 59 - 60, , •, , Execute, testing,, and, maintenance, of DC, machines, and, motor, starters., • Distinguish,, organise and, perform, motor, winding, , 128.Perform speed control of, DC motors - field and, armature control method., (10 Hrs), 129.Carry out overhauling of, DC machines. (15 Hrs), 130.Perform DC machine, winding by developing, connection diagram, test, on growler and assemble., (25 Hrs), , 61 - 62, , •, , Plan, Execute, commissioning, and evaluate, performance of, AC motors., Execute, testing,, and, maintenanceof, AC motors, and, starters, , 131.Identify parts and, terminals of three phase, AC motors. (5 Hrs), 132.Make an internal, connection of automatic, star-delta starter with, three contactors. (10 Hrs), 133.Connect, start and run, three phase induction, motors by using DOL, stardelta, and auto-transformer, starters. (20 Hrs), 134.Connect, start, run and, reverse direction of, rotation of slip-ring motor, through rotor resistance starter, and determine, performance, characteristic. (15 Hrs), , Working principle of three, phase, induction motor., Squirrel Cage Induction, motor,, Slip-ring induction motor;, construction, characteristics,, Slip, and Torque., Different types of starters for, three phase induction, motors, its, necessity, basic contactor, circuit,, parts and their functions, , Plan, Execute, commi, -ssioning, and evaluate, performance, of, AC motors., Execute, testing,, and, maintenance, of, AC motors, and, starters, , 135.Determine the efficiency of, squirrel cage induction, motor by brake test. (8, Hrs), 136.Determine the efficiency of, three phase squirrel cage, induction motor by no load, test and blocked rotor test., (8 Hrs), 137.Measure slip and power, factor to draw speedtorque, (slip/torque), characteristics. (14 Hrs), 138.Test for continuity and, insulation resistance of, three phase induction, motors. (5 Hrs), , Single phasing prevention., No load test and blocked rotor, test of induction motor., Losses & efficiency., Various methods of speed, control., Braking system of motor., Maintenance and repair, , •, , 63 - 64, , •, , •, , Methods of speed control of, DC, motors., Lap and wave winding and, related terms, , Copyright @ NIMI Not to be Republished

Page 13 :

139.Perform speed control of, three phase induction, motors by various methods, like rheostatic control,, autotransformer etc. (15, Hrs), 140.Perform winding of three, phase AC motor by, developing connection, diagram, test and, assemble. (20 Hrs), 141.Maintain, service and, troubleshoot the AC motor, starter. (05 Hrs), , 65, , •, , Distinguish, organise, and, perform, motor, winding, , 66 - 67, , •, , 142. Identify parts and, Plan, Execute, terminals of different types, commissioning, of single phase AC, and evaluate, motors.(5 Hrs), performance of, 143.Install,, connect and, AC motors., determine, performance, Execute testing,, single, phase, AC motors.(15 Hrs), and, 144.Start,, run, and, reverse the, maintenance of, direction, of, rotation, of single phase AC, AC motors and, motors.(10, Hrs), starters, 145.Practice on speed, control of single phase AC, motors.(10 Hrs), 146.Compare starting and, running winding currents, of a capacitor run motor at, various loads and measure, the speed. (10 Hrs), , •, , 68 - 69, , •, , Distinguish, organise and, perform motor, winding, , 147.Carry out maintenance,, service and repair of single, phase AC motors. (10 Hrs), 148.Practice on single/double, layer and concentric, winding for AC motors,, testing and assembling. (25, Hrs), 149.Connect, start, run and, reverse the direction of, rotation of universal, motor. (10 Hrs), 150.Carry out maintenance and, servicing of universal, motor. (05 Hrs), , Concentric/ distributed, single/, double layer winding and, related, terms, , Working principle, different, method of starting and, running, of various single phase AC, motors., Domestic and industrial, applications of different single, phase AC motors., Characteristics, losses and, efficiency, , Concentric/ distributed, single/, double layer winding and, related, terms., Troubleshooting of single, phase, AC induction motors and, universal motor, , Copyright @ NIMI Not to be Republished

Page 14 :

70 - 71 •, , Plan, execute, testing,, evaluate, performance, and, carry out, maintenance of, Alternator / MG, set., Execute, parallel, operation of, alternators, , •, , 151.Install an alternator,, identify parts and, terminals of alternator. (10, Hrs), 152.Test for continuity and, insulation resistance of, alternator. (5 Hrs), 153.Connect, start and run an, alternator and build up the, voltage. (10 Hrs), 154.Determine the load, performance and voltage, regulation of three phase, alternator. (10 Hrs), 155.Parallel operation and, synchronization of three, phase alternators. (15 Hrs), , Principle of alternator, e.m.f., equation, relation between, poles, speed and frequency., Types and construction., Efficiency, characteristics,, regulation, phase sequence, and, parallel operation., Effect of changing the field, excitation and power factor, correction, , 72, , •, , Plan, execute, testing,, evaluate, performance, and, carry out, maintenance of, Alternator / MG, set, , 156.Install a synchronous, motor, identify its parts, and terminals. (10 Hrs), 157.Connect, start and plot, Vcurves, for synchronous, motor under different, excitation and load, conditions. (15 Hrs), , Working principle of, synchronous, motor., Effect of change of excitation, and, load., V and anti V curve., Power factor improvement, , 73, , •, , Plan, execute, testing,, evaluate, performance, and, carry out, maintenanceof, Alternator /, MG, set, , 158.Identify parts and, terminals of MG set. (5, Hrs), 159.Start and load MG set with, 3 phase induction motor, coupled to DC shunt, generator. (20 Hrs), , Rotary Converter, MG Set, description and, Maintenance, , 74 - 75, , 76 - 77, 78, , Project work/Industrial visit (optional), Broad Areas:, a) Phase sequence checker for 3 phase, supply, b) Induction motor protection system, c) Motor starters with protection, d) Solar/wind power generation, Revision, Examination, , Copyright @ NIMI Not to be Republished

Page 15 :

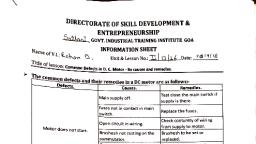

Electrical, Electrician - DC Generator, , Related Theory for Exercise 3.1.115 & 3.1.116, , DC generator - principle - parts - types - function - e.m.f. equation, Objectives: At the end of this lesson you shall be able to, • state the general concepts of rotating electrical machine, • state the principle of the DC generator, • explain the faraday's of laws of electro magnetic induction, • explain the production of dynamically induced e.m.f., its magnitude and direction, • describe the parts of a DC generator and their function, • classify and identify the different type of generators and their terminal markings, • explain the armature circuit resistance and its relation, • derive the emf equation and calculation of a DC generator, • explain about separately excited DC generator with different types of windings., General concept of rotating electrical machine, In rotating machines, there are two parts, the stator and, rotor. Rotating electrical machines are also of two types DC and AC machines. Electrical machines are widely, used. In DC machines the stator is used as a field and, the rotor is used as an armature, while reverse is the, case for AC machines. That is synchronous generators, and synchronous motors. The induction motor is another, kind of AC machine, which is singly excited; that is AC, supply voltage is only given to the stator and no supply is, given to the rotor. In DC machines and synchronous, machines, the field is always excited., Generator:An electrical generator is a machine which, converts mechanical energy into electrical energy., Principle of the generator:To facilitate this energy, conversion, the generator works on the principle of Faraday's, Laws of Electromagnetic Induction., Faraday's Laws of Electromagnetic Induction: There, are two laws., The first law states:, First law: Whenever the flux linking to a conductor or, circuit changes, an emf will be induced., The second law states: The magnitude of such induced, emf depends upon the rate of change of the flux linkage., emf ∝, , Change of flux, ., Time taken for change, , Types of emf: According to Faraday's Laws, an emf can, be induced, either by the relative movement of the conductor, and the magnetic field or by the change of flux linking on, a stationary conductor., Dynamically induced emf: In case, the induced emf is, due to the movement of the conductor in a stationary, magnetic field as shown in Fig 1a or by the movement of, the magnetic field on a stationary conductor as shown in, Fig 1b, the induced emf is called dynamically induced emf., , As shown in Figs 1a & 1b, the conductor cuts the lines of, force in both cases to induce an emf, and the presence of, the emf could be found by the deflection of the needle of, the galvanometer `G'. This principle is used in DC and AC, generators to produce electricity., Statically induced emf: In case, the induced emf is due, to change of flux linkage over a stationary conductor as, shown in Fig 2, the emf thus induced is termed as, statically induced emf. The coils 1 and 2 shown in Fig 2 are, not touching each other, and there is no electrical, connection between them., According to Fig 2, when the battery (DC) supply is used, in coil 1, an emf will be induced in coil 2 only at the time, of closing or opening of the switch S. If the switch is, permanently closed or opened, the flux produced by coil, 1 becomes static or zero respectively and no emf will be, induced in coil 2. EMF will be induced only when there is, a change in flux which happens during the closing or, opening of the circuit of coil 1 by the switch in a DC circuit., , Copyright @ NIMI Not to be Republished, , 1

Page 16 :

Conductor B = BLV Sin 30°, = 100 x 0.50, = 50 volts., , Alternatively the battery and switch could be removed and, coil 1 can be connected to an AC supply as shown in, Fig 2. Then an emf will be induced in coil 2 continuously, as long as coil 1 is connected to an AC source which, produces alternating magnetic flux in coil 1 and links with, coil 2. This principle is used in transformers., Production of dynamically induced emf: Whenever a, conductor cuts the magnetic flux, a dynamically induced, emf is produced in it. This emf causes a current to flow if, the circuit of the conductor is closed., For producing dynamically induced emf, the requirements, are:, •, , magnetic field, , •, , conductor, , •, , relative motion between the conductor and the magnetic, field., , E = BLV Sinθ Volts, B = magnetic flux density, measured in tesla, L = effective length of the conductor in the field in, metres, relative velocity between field and conductor in, metre/second, , θ = the angle at which the conductor cuts the magnetic, field., Let us consider Fig 3a in which conductors A to I are, placed on the periphery of the armature under magnetic, poles. Assume for this particular generator shown in, Fig 3a, the value of BLV = 100V., Accordingly the conductor A induces an emf, = BLV Sin θ where θ = zero and Sin zero is equal to, zero, emf induced in, 2, , = 100 x 1, = 100 V., emf induced in, Conductor D = BLV Sin 135°, = BLV Sin 45°, = 70.7 volts., emf induced in, Conductor E = BLV Sin 180°, = Sin 180°= 0, = 100 x 0, , where, , = 100 x 0 = zero., , Conductor C = BLV Sin 90°, , = 100 x 0.707, , If the conductor moves with a relative velocity 'v' with, respect to the field, then the induced emf `E' will be, , V =, , emf induced in, , = zero., Likewise for every position of the remaining conductors in, the periphery, the emf induced could be calculated. If, these values are plotted on a graph, it will represent the, sine wave pattern of induced emf in a conductor when it, rotates under N and S poles of uniform magnetic field., As in Fig 3b the emf induced by this process is basically, alternating in nature, and this alternating current is converted, into direct current in a DC generator by the commutator., Fleming's right hand rule: The direction of dynamically, induced emf can be identified by this rule. Hold the thumb,, forefinger and middle finger of the right hand at right angles, to each other as shown in Fig 4 such that the forefinger is, in the direction of flux and the thumb is in the direction of, the motion of the conductor, then the middle finger, indicates the direction of emf induced, i.e. towards the, observer or away from the observer., Imagine a conductor moving in between north and south, poles in an anticlockwise direction as shown in Fig 5a., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 17 :

Applying Fleming's right hand rule, we find that the, conductor 1 which is moving upwards under the north pole, will induce an emf in the direction towards the observer, indicated by the dot sign and the conductor 2 which is, moving down under the south pole will induce an emf in the, direction away from the observer indicated by the plus, sign., Fig 5b indicates the current direction in the form of an, arrow. The dot sign indicates the pointed head of the arrow, showing the current direction towards the observer and the, plus sign indicates the cross-feather of the arrow showing, the current direction away from the observer., Parts of DC generator, A DC generator consists of the following essential parts as, shown in Fig 6., 1 Frame or yoke, 2 Field poles and pole-shoes (Figs 8,9 & 10), 3 Field coils or field winding (Fig 11), 4 Armature core, 5 Armature windings or armature conductors, 6 Commutator, 7 Brushes, 8 Bearings and end plates, 9 Air filter for fan, 10 Shaft, , The yoke, the pole cores, the armature core and the air, gaps between the poles and the armature core form the, magnetic circuit, whereas the armature conductors, field, coils, commutators, and brushes form the electrical circuit., Yoke: The outer frame or yoke serves a dual purpose., Firstly, it provides mechanical support for the poles and, acts as a protecting cover for the whole machine as shown, in Fig 6. Secondly, it allows the magnetic circuit to, complete through it., In small generators where cheapness rather than weight is, the main consideration, yokes are made of cast iron. But, for large machines usually cast steel or rolled steel is, used. The modern process of forming the yoke consists of, rolling a steel slab round a cylindrical mandrel, and then, welding it at the seams. The feet, the terminal box etc. are, welded to the frame afterwards as shown in Fig 7. Such, yokes possess sufficient mechanical strength and have, high permeability., Poles cores and pole shoes (Fig 8): The field magnets, consist of pole cores and pole shoes. The pole shoes, serve two purposes; (i) they spread out the flux in the air, gap uniformly and also, being of a larger cross-section,, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 3

Page 18 :

reduce the reluctance of the magnetic path, and (ii) they, also support the field coils., , There are two main types of pole construction., The pole core itself may be a solid piece made out of either, cast iron or cast steel but the pole shoe is laminated and, is fastened to the pole face by means of countersunk, screws as shown in Fig 8., In modern designs, the complete pole cores and pole, shoes are built of thin laminations of annealed steel which, are riveted together under hydraulic pressure. The thickness, of laminations varies from 1mm to 0.25mm. The laminated, poles may be secured to the yoke in any of the following, two ways., Either the pole is secured to the yoke by means of screws, bolted through the yoke and into the pole body as in, Fig 9 or holding screws are bolted into a steel bar which, passes through the pole across the plane of laminations, as in Fig 10., , Both thick gauge wire winding (series) and thin gauge, winding (shunt) are wound, one over the other with separate, insulations, and the terminals are brought out separately., , Pole coils (Field coils): The field coils or pole coils, which, consist of copper wire or strip are former-wound for the, correct dimension. Then the former is removed and the, wound coils are put into place over the core as shown in, Fig 11., , Armature core: The armature core houses the armature, conductors and rotate in the magnetic field so as to make, the conductors to cut the magnetic flux. In addition to this,, its most important function is to provide a path of very low, reluctance to the field flux, thereby allowing the magnetic, circuit to complete through the yoke and the poles., , When a current is passed through the coils, they magnetise, the poles which produce the necessary flux that is cut by, revolving armature conductors., 4, , The armature core is cylindrical or drum-shaped as shown, in Fig 12, and build up of circular sheet steel discs or, laminations approximately 0.5mm thick as shown in, Fig 13., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 19 :

Armature windings: The armature windings are usually, former-wound. These are first wound in the form of flat, rectangular coils and are then pulled into their proper, shape with a coil puller. Various conductors of the coils, are insulated from each other. The conductors are placed, in the armature slots which are lined with tough insulating, material. After placing the conductors in the slot, this slot, insulation is folded over the armature conductors, and is, secured in place by special, hard, wooden or fibre wedges., Commutator: The function of the commutator is to, facilitate collection of current from the armature conductors., It rectifies i.e. converts the alternating current induced in, the armature conductors into uni-directional current for the, external load circuit. It is of cylindrical structure and is, built up of wedge-shaped segments of high conductivity,, hard-drawn or drop-forged copper. These segments are, insulated from each other by thin layers of mica. The, number of segments is equal to the number of armature, coils., , The slots are either die-cut or punched on the outer, periphery of the disc and the keyway is located on the, inner diameter as shown. In small machines, the armature, stampings are keyed directly to the shaft. Usually these, laminations are perforated for air ducts which permit axial, flow of air through the armature for cooling purposes. Such, ventilating holes are clearly visible in the laminations, shown in Figs 12,13 and 14., , Each commutator segment is connected to the armature, conductor by means of a copper lug or riser. To prevent, them from flying out under the action of centrifugal forces,, the segments have V-grooves, these grooves being, insulated by conical micanite rings. A sectional view of a, commutator is shown in Fig 15, whose general appearance, when assembled is shown in Fig 16., , Up to armature diameters of about one metre, the circular, stampings are cut out in one piece as shown in Fig 13. But, above this size, these circles, especially of very thin, sections, are difficult to handle because they tend to, distort and become wavy when assembled together., Hence, the circular laminations, instead of being cut out, in one piece, are cut in a number of suitable sections of, segments which form part of a complete ring., A complete circular lamination is made up of four or six or, even eight segmental laminations. Usually, two keyways, are notched in each segment and are dovetailed or, wedge-shaped to make the laminations self-locking in, position as shown in Fig 14., , Brushes: The brushes whose function is to collect current, from the commutator are usually made of carbon and, graphite and are in the shape of a rectangular block., The purpose of using lamination is to reduce the loss due, to eddy currents. Thinner the laminations are, greater the, resistance offered against eddy current loss., , These brushes are housed in brush-holders, shown in, Fig 17, which have a box-holder for the brush, a spring to, maintain the brush tension and a hole to fix the holder to, the rocker arm. The brushes can slide in the rectangular, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 5

Page 20 :

box, open at both ends. The brushes are made to bear, down on the commutator by a spring whose tension can, be adjusted by changing the position of the tension lever, in the notches. A flexible, copper pigtail mounted at the, top of the brush conveys the current from the brushes to, the holder. The number of brushes per spindle depends on, the magnitude of the current to be collected from the, commutator., , Brush-rocker: The spindle is used to have a number of, brushes connected in a large machine. There may be only, two brushes for a small machine. All the spindles are, insulated and attached to the brush rocker., The brush-rocker may either be supported by a bearing, cover in a small machine or by brackets attached to the, yoke as shown in Fig 18. The brush position to the neutral, axis can be set by changing the position of the brushrocker., , Cooling fan, DC Machines are often selected based upon a particular, work or load requirement. In most cases, heat dissipation, is achieved through a cooling fan fitted on the DC Machine, shaft. Another method to remove heat from DC machine, is by providing forced air cooling. This is commonly done, by providing an electric fan externally to blow air over the, DC machine. Forced air cooling can reduce the amount, of heat transferred into the machine structure and allow, the machine to be operated at a higher load., Types of DC generators: The type of a DC generator is, determined by the manner in which the field excitation is, provided. In general, the methods employed to connect, the field and armature windings, fall into the following, groups.(Fig 21), , Bearings (Fig 19): Because of their reliability, half-bearings, are frequently employed, though for heavy duties roller, bearings are preferable. The ball and rollers are generally, filled with hard oil for quieter operation and for reduced, bearing wear. When sleeve bearings are used, these are, lubricated by ring oilers fed from an oil reservoir in the, bearing bracket., End plates (Fig 20): The bearings are housed in these end, plates, and they are fixed to the yoke. They help the, armature for frictionless rotation and to position the armature, in the air gap of the field poles., 6, , Separately excited generator: The field excitation for a, separately excited generator, shown in Fig 22, is supplied, from an independent source, such as storage battery,, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 21 :

separate DC generator or rectified DC supply from an AC, source., The field excitation voltage may be the same as that of, generated (armature) voltage or may differ. Generally, the, excitation voltage will be of low voltage, say 24, 36 or 48V, DC., , Long-shunt compound generator: This is a generator in, which the shunt field is connected after the series field as, shown in Fig 26., , Self-excited generator: The field excitation is provided, by its own armature. In this type of generators, initially the, voltage is built up by residual magnetism retained in the, field poles. Self-excited generators may be further classified, as shunt, series and compound generators., Shunt generator: The field winding is connected to the, armature terminals as shown in Fig 23. (i.e. shunt field, winding is connected in parallel with armature winding)., The shunt field contains many turns of relatively fine wire, and carries a comparatively small current only which is a, small percentage of the rated current of the generator., , Differential and cumulative compound generator:, The compound generators can also be further classified as, cumulative and differential. In cumulative compound, generators the magnetising forces of the shunt and the, series field ampere-turns are cumulative, i.e. they both, tend to set up flux in the air gap in the same direction., However, in case the ampere turns of the shunt widning, oppose those of the series winding, the machine is said to, be differentially compound wound generator. Both the, types are shown in Fig 27., , Series generator: The field winding is connected in, series with the armature winding as shown in Fig 24. The, series field winding has a few turns of heavy wire. Since it, is in series with the armature it carries the load current., , Compound generator: The field excitation is provided by, a combination of shunt and series field windings., Short-shunt compound generator: This is a generator, in which the shunt field is directly across the armature as, shown in Fig 25., , Terminal markings : As per BIS 4718-1975 the terminal, markings for DC commutator machines shall be according, to the marking principles stated below., •, , Windings are distinguished by capital letters., , •, , End points and intermediate points of windings are, distinguished by a numerical suffix., , •, , Winding letters for DC windings are chosen from the, earlier part of the alphabet.(Fig 28), , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 7

Page 22 :

Fleming's right hand rule. Similarly the direction of the, induced voltage and the resulting current under the south, pole is to be directed from C to D making the slip- ring 1, as positive. When the conductor AB moves from the north, pole to the south pole, the direction of induced emf in it will, reverse, so that the current will now flow from B to A, making the slip-ring 2 positive. At the same time coil side, CD has moved into the north pole region and its induced, emf is reversed and current will flow from D to C making the, slip-ring 1 negative., Thus for one half of a revolution (for a two-pole generator), the emf is directed around the coils A to B & C to D. For, the other half of the revolution the emf is directed around, the coil D to C and B to A. The current in the externally, connected load resistor via the stationary brushes in, contact with the pair of slip rings `1'and `2' will be, alternating (AC) in nature., Wave-shape of the induced voltage: When the output, voltage is plotted against electrical degrees we get the, output wave-form., , Commutator (Split rings), A generator produces electrical power with the help of the, rotation of a group of conductors in a magnetic field. It uses, the principle of electromagnetic induction to convert the, input mechanical power into electrical power., , The output wave-form obtained across the load, according, to the pole shape shown in Fig 29, will not be of sinusoidal, shape due to un-uniform magnetic field but of rectangular, shape as shown in Fig 30., , Slip rings: Let us consider a simple AC generator having, a single loop of wire and rotated within a fixed magnetic, field, as shown in Fig 29., , However, if the magnetic field is uniform, the output waveform will be of sinusoidal shape as shown in Fig 31., , Let each end of the single loop coil be connected to copper, or brass rings called slip rings. These slip-rings are, insulated from each other, insulated and mounted on the, shaft. In a broader sense this rotating assembly (coil,shaft, & slip-ring) is called armature. The wire loop (armature, coil) is connected to an external circuit by means of two, brushes which are positioned to rub against the slip-rings., As the armature is rotated at a uniform angular velocity,, the generated voltage in the loop conductor will actually be, of alternating voltage., For the clockwise rotation indicated, the direction of, generated voltage and the resulting current in the coil side, under the north pole will be directed from A to B making the, slip-ring 2 negative. This is readily confirmed by using, 8, , Simple generator with split-rings: A direct current, generator is simply an AC generator provided with split, rings instead of slip-rings., The split ring is a ring made up of hard drawn copper cut, into two segments, insulated from each other and the shaft, in which it is mounted. A commercial generator uses a, number of split rings called commutators. The split ring is, a device for reversing the brush contact with the armature, coil terminals, every time the induced current in the coil, reverses, so that the output current taken by the brushes, remains always in the same direction., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 23 :

As shown in Fig 32a, if the armature rotates clockwise the, split ring rotates with it, and the brushes and the poles are, stationary in their position. As shown in Fig 4a, when the, moving coil is in the horizontal position, the induced, current will flow through the coil from ABCD to the segment, `B' via the positive brush and load to the negative brush and, segment A. The direction of current flow in the external, circuit is shown in Figures 32a and 32c., When the armature rotates so that the coil just assumes, a vertical position as in Fig 32b, the brushes will shortcircuit both the segments. The induced emf is zero and no, current flows through the load circuit for a short moment., When the armature rotates and the coil assumes the, position as indicated in Fig 32c, the coil side AB will enter, the south pole region and its induced emf will reverse,, compared to the direction it had while moving under the, north pole region as shown in Fig 32a., , But when this happens the split ring segments `A' and `B', will also have exchanged their positions since they rotate, along with the coil., As the emfs in the coil sides AB and CD reverse their, polarity, the split ring segments to which they are connected, simultaneously change their positions under the stationary, brushes. As a result, the polarity of the brushes remains, fixed and the current direction through the load remains as, shown in Fig 32c which is the same as shown in Fig 32a., Figure 33 represents the generated voltage of a simple DC, generator. The voltage is uni-directional due to the split, ring action., The induced emf by a single loop (one turn) coil is very, small in magnitude and pulsating in nature as shown in, Fig 33. Coils, having a number of turns in series, multiply, the generated emf by the same number. However to get a, steady (DC) current it is necessary to increase the pulses, produced in the armature; thereby their average value is, constant., , There are two ways to increase the number of pulses, during each rotation of the armature., •, , Increase the number of field poles., , •, , Increase the number of separate coils (multi-coil) in the, armature., , The multi-coils necessitate a multiple segment split-rings, which is called a commutator., Fig 34 represents the generated voltages and their wave, shapes when the armature has different number of split, rings, i.e. commutator segments. The practical generator, will have more number of commutator segments as shown, in Fig 34c, and the induced emf will be as shown in the, adjoining graph., Armature circuit resistance and its relation with, different types of windings and brush resistance, Armature windings ( Fig 35 Lap winding, Fig 36 wave, winding): We have seen earlier, when a single loop, conductor is rotated through a magnetic field, an alternating, voltage is induced in it. This alternating voltage can be, changed into direct voltage (rectified) by the commutator., In practice, there are several coils in the armature, each, with a large number of turns laid in the slots of the armature, core. This arrangement of the coil is called armature, winding. The ends of the coils are soldered to the, Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 9

Page 24 :

commutator raisers, depending on the kind of winding i.e., lap or wave, which decides the number of parallel paths in, the armature., , Lap and wave windings could readily be identified by the, manner in which the coil ends are connected to the, commutator bars. As shown in Fig 35, in a simplex lap, winding, the ends of a coil are connected to adjacent, commutator segments. Fig 36 shows the simplex wave, winding in which the coil ends are connected to the, commutator segments almost equal to the distance, between poles of the same polarity., , i.e. lap or wave, which decides the numbers of parallel, paths in the armature., A preliminary knowledge about the different types of, winding is essential to tackle problems related to the, calculation of induced voltage in various types of generators., , Table 1 shows the main differences between lap and, wave winding., , Table 1, Lap winding, The two ends of each armature coil are connected to, adjacent commutator segments in the case of simplex,, two segments apart in duplex and three segments apart, in triplex., , The two ends of each coil connect to the commutator, segments placed between adjacent poles of the same, polarity., , There are many parallel paths for current as there, are field poles in the case of lap winding, , There are two parallel paths regardless of the number, of field poles in the case of simplex wave winding., , No. of parallel paths = Number of poles x plex of the, winding, , Number of parallel paths in wave windings = 2 x plex of, the winding where plex for-simplex is 1, duplex is 2, and triplex is 3., , The number of brush positions is equal to the number of, poles., , Only two brush positions are required regardless of, the number of field poles., , Used for machines having low voltage and high current, capacity., , Used in machines having low current and high voltage, capacity., , DC armature circuit - voltage drop and its importance:, One of the major reasons for the drop in voltage at the, terminals of a loaded generator is due to armature voltage, 10, , Wave winding, , drop. This depends on the armature circuit resistance and, the armature current. A thorough understanding of the, armature resistance, apart from helping an electrician to, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 25 :

calculate the efficiency of a DC machine, is of great help, to check the correctness of the rewind armature without, physically checking the number of turns and the size of the, winding wire. This is done in all established factories,, where a record is maintained to indicate voltage drop, across the armature of each DC machine, at a specified, armature current. Any variation from this recorded value to, the value obtained from the rewind armature (having the, same grade of brushes), clearly indicates either the size, of the winding wire or the number of turns has changed,, and the performance of the machine will not be the same, as earlier. Normally armature circuit resistance will be in, the order of one ohm or below., Voltage drop: This could be calculated by finding the, total resistance of the armature conductors in series per, parallel path and dividing it by the number of parallel paths,, but in actual practice it is calculated by the voltage drop, method., Refer to the circuit shown in Fig 37., , Therefore, No. of parallel paths = 4., Conductors per, parallel path =, , Total No. of conductors, 48, =, = 12., No.of parallel paths, 4, , Resistance per parallel path = 12 x 0.1 = 1.2 ohms., Therefore the total armature resistance for 4 parallel paths, = 1.2/4 = 0.3 ohms., In addition to this, the total armature circuit resistance, includes brush resistance and brush contact resistance., Hence the value measured will be more than 0.3 ohms in, the above example., Brushes: The main function of the brushes is to transfer, the energy present at the armature to the external circuit., Brushes are usually made from a compound of carbon and, graphite. Graphite content provides a self-lubricating action, as the brushes rub against the commutator., The most important characteristics of brushes are specific, resistance, friction coefficient, current-carrying capacity,, maximum operating speed and abrasiveness., Specific resistance is the resistivity of the brush material., , Let 'r' be the specific resistance of the armature conductors,, 'a' be the area of the cross-section of the armature, conductor in sq. cm., 'L' be the length of the conductor in cms., 'Ra' - armature resistance in ohms., 'Rp' - resistance per parallel path in ohms., Method of calculating the armature resistance: Let P, be the number of parallel paths in the armature,, Z be the total conductors in armature., Then the number of conductors per parallel path = Z/P., Resistance per parallel path R p =, , Z ρL, ×, P a, , Armature resistance in ohms = Ra, , Ra =, , RP, No. of parallel paths, , Example: In a DC 4-pole lap-wound machine the resistance, of one conductor is 0.1 ohm; there are 48 conductors., Calculate the armature resistance., Since it is lap-wound,, No. of parallel paths=No.of poles (assuming simplex, winding)., , Friction coefficient is the ratio of the force on the surface, to the force required to slide another surface over it, and, is influenced by the brush temperature, pressure, current,, atmospheric condition, mechanical condition, commutator, material, surface films and speed. The resulting high brush, friction often causes the brush to chatter and chip. Since, friction serves no useful purpose, low brush friction is, preferred. Low brush friction will have a friction coefficient, in the order 0.22 or below whereas a high brush friction will, have a friction coefficient above 0.4., Current-carrying capacity: It depends on the brush, material, operating conditions, type of ventilation and, operating temperature. If the temperature is high due to, high current density, the brush life will be shortened., Speed: The allowable speed depends upon the, characteristics of the brush material, spring pressure,, current density, types of brush-holders, brush angle and, the area of contact of the commutator., Abrasiveness: The ability of the brush to prevent excessive, build up of film usually caused by corrosive or oily, atmosphere is called the abrasiveness or polishing action., Grade and types of brushes: There are four major brush, families classified according to the manufacturing, process., •, , Graphite, , •, , Carbon and carbon graphite, , •, , Electro-graphite, , •, , Metal graphite, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 11

Page 26 :

Graphite: Graphite brushes are usually made of natural, or artificial graphite. Natural graphite contains impurities., Artificial graphite is usually pure. It is used in fractional HP, machines., , where high current and low voltages are involved. Its, typical applications are for electroplating generators,, battery chargers, welding generators and other high current, equipment., , Carbon and carbon graphite: It has high hardness, high, mechanical strength, cleaning action and long brush life., , Whenever the brushes are to be changed, the same grade, of brushes is to be procured and used to get the same, performance characteristics from the machine., , Electro-graphite:It consists of various forms of amorphous, carbon. These brushes usually have higher current density,, lower strength, lower hardness and lower specific, resistance. They generally have good commutating, characteristic but may not always be used because of the, lesser requirement of high current, and the requirement of, severe mechanical conditions., Metal graphite: It is generally made from natural graphite,, and finally divided into metal powders. Copper is the most, common metal constituent, but silver, tin, lead and other, metals are sometimes used. The metal content ranges, from approximately 10 to 95% by weight. A high metal, content provides greater current capacity, higher, mechanical strength and also certain combined, characteristics of contact drop and friction. It is used, , As an accepted procedure, every electrician should identify, the brush grade of each machine, either from service, manuals or by visual inspection, and record it in the, maintenance card of the machine for proper selection of, replacement at a later date., Brush contact resistance is the resistance offered between, the brush and the commutator for the current flow. This, resistance value depends upon the grade of brushes,, material used for the commutator, contact area between, the brush and commutator, and the brush tension. Normally, the brush contact resistance is measured in terms of, voltage drop at specific current ratings., Table 2 shows the different grades of brushes and, their characteristics., , Table 2, Characteristics of brushes, Grade of, carbon, , Max. current, density A/cm2, , Soft graphite, , 9 to 9.5 A/cm2, , Copper carbon, , 15 to 16 A/cm2, , Carbon, , 5.5 to 6.5A/cm, , Electro-graphite, , 8.5 to 9 A/cm2, , Max.contact, resistance, ohms/cm2, –, , 2, , Pressure on, commutator, kg/cm2, , Voltage, drop, in volts, , 0.12, , 1.6, , 0.00000465, , 0.15-0.18, , 0.25-0.35, , 0.000062, , 0.22-0.27, , 2, , 0.000031, , 0.22, , 1.7-1.8, , EMF equation of DC generator, When the armature of a DC generator, containing a, number of conductors in the form of a winding, rotates at, a specific speed in the magnetic field, emf is induced in the, armature winding and is available across the brushes. The, equation and the numerical problems given as examples, will help an electrician to better his understanding about, the construction of a DC machine., Induced emf in a DC generator can be calculated as, explained below., Figure 38 is given for your reference., LetØ = flux/pole in weber, Z = total number of armature conductors = No. of slots x, No.of conductors/slot, P = No. of poles in the generator, A = No. of parallel paths in armature, N = armature revolution per minute (r.p.m.), 12, , E = emf induced in the generator., Average emf generated = Rate of change of flux, per conductor in one, (Faraday's Laws of, revolution, Electromagnetic induction, d∅, volt (since N = 1), dt, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 27 :

Now, flux cut/conductor in one revolution, (dØ) = PØ Wb, , (ii) Simplex wave winding, , No. of revolutions/second = N/60, Time for one revolution, (dt) = 60/N second, According to Faraday's Laws of Electromagnetic Induction,, we have emf generated/conductor/second, d∅, P∅N, =, =, volts, dt, 60, , emf generated in `Z'conductors in the armature assuming, they are all in series =, , P∅ZN, volts., 60, , The emf generated in the armature, of the DC generator when there are, `A' parallel paths in the armature, =, , Could be written as =, , P∅ZN, volts., 60 A, , ∅ZN P, x, volts., 60, A, , E =, , 20 × 10, , −3, , × 960 × 500, 8, × = 640V., 60, 2, , Separately excited DC generator, Introduction, A DC generator is the most commonly used separately, excited generator, used for electroplating and battery, charging. A separately excited generator is one in which, the magnetic field is excited from an external DC source., The DC source may be a DC generator or a battery or a, metal rectifier connected to an AC supply. Generally a, potential divider is connected across the DC source, and, the required DC voltage is supplied to the field as shown, in Fig 39., An ammeter is connected in the field circuit to measure, the field current. The shaft of the generator is coupled to, a prime mover. (Not shown in Fig 39), , A = 2 - for simplex wave winding, = P - for simplex lap winding., Example: A four-pole generator, having a simplex, wave-wound armature has 51 slots, each slot containing, 20 conductors. What will be the voltage generated in the, machine, when driven at 1500 r.p.m assuming the flux per, pole to be 7.0 mWb?, ∅ZN P, x, volts., Solution: E =, 60, A, , Here, Ø= 7x 10-3 Wb, Z = 51 x 20 = 1020, P=4, N = 1500, r.p.m., A = 2 as the winding is simplex wave., , E=, , 7 × 10 -3 × 1020 × 1500 4, ×, = 357V., 2, 60, , An 8-pole DC generator has 960 armature conductors and, a flux per pole of 20mWb running at 500 r.p.m. Calculate, the emf generated when the armature is connected as (i), a simplex lap-winding, (ii) a simplex wave winding., Solution, (i) Simplex lap winding, E, , =, , E=, , Magnetisation characteristic: This characteristic gives, the relation between the field flux and the induced voltage, in a generator. However, it is difficult to measure the field, flux, and, hence, the field current is taken instead of the, field flux. The characteristic curve is drawn by keeping the, field current in the `X' axis and the induced emf in the `Y', axis. To draw the characteristic curve, the connections are, made as shown in Fig 39, and then, the prime mover is, started and made to run at its rated speed, keeping the, field switch `s' open. The terminal voltage which appears, at the armature terminals is measured and recorded. This, small voltage Er is known as residual voltage which is due, to the residual magnetism available in the field cores., Throughout the experiment, the speed of the generator is, held constant. Next, the field switch `S' is closed keeping, the potential divider at its minimum position, and gradually, the field current is increased in steps. For each step, the, field current and the corresponding voltage at the armature, terminals are noted. The readings are tabulated in Table 3., , ∅ZN P, x, 60, A, , 20 × 10 −3 × 960 × 500 8, ×, = 160V., 60, 8, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 13

Page 28 :

Table 3, Sl.No. Field current, , As the poles are in the process of saturation, the relation, between the terminal voltage and the field current no longer, stands in direct proportion as indicated by the knee portion, of the curve., , Terminal voltage, , Finally when the poles get fully saturated the induced emf, ceases to increase even at the increased field current, which is indicated by the last portion of the curve and, named as saturation region., If a graph is plotted between the field current and the, terminal voltage, the curve will be as shown in Fig 40. The, field current is taken on the X-axis and the emf E on the, Y-axis. The curve drawn is known as the magnetisation, characteristic of a separately excited generator., , Reasons for not building up of voltage in a separately, excited generator and their remedies, Sometimes a separately excited generator may not build, up voltage. The probable reasons and remedies thereof are, given in Table 4., Load characteristic of a separately excited generator:, The load characteristic shows the relation between the, load current and the terminal voltage. Through this, characteristic curve, we can determine the behaviour of, the generator on load., , A study of the curve indicates that it starts just above, the origin, travels straight in the linear region indicating, that the emf induced is directly proportional to the field, current If., , Fig 41 shows the method of connecting the separately, excited DC generator to obtain the load characteristic. The, generator speed should be brought to the rated value with, the help of the prime mover and the voltage is built up to, its normal rated voltage. Then the load switch is closed., Gradually the load is increased in steps. Each time, the, load current IL in amps and the corresponding terminal, voltage `V' in volts are noted. The readings are tabulated, in Table 5., , Table 4, Reasons, , Remedies, , A break or opening in the armature or field circuit., , Test the field and armature circuits for open circuit., Locate the fault and rectify., , A short circuit in the armature or field., , Test the field and armature for short circuit. Locate, the fault and rectify., , Loose brush connections or loose brush contact., , Tighten the brush connections. Check up the brush, tension. Adjust, if necessary. If the brushes are worn, out, replace them., , A dirty or severely pitted commutator., , Clean the commutator for dirt, dust and greasy, material. Use trichloroethylene. If the segments are, pitted, dress them up., , The speed is too low., , Increase the speed of the generator to its rated speed., , The DC supply for excitation is absent., , Check the DC supply across the field winding, terminals. If the supply is not there, check the supply, source and rectify the fault Where AC main supply is, converted as DC supply through rectifiers, the fault, may be located in the rectifier circuit., Table 5, , Sl.No., , 14, , Load current IL in amps, , Terminal voltage in volts, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished

Page 29 :

It is observed from the graph that a slight voltage drop, occurs when the generator is loaded. This is due to the, armature voltage drop (IaRa) and armature reaction., If the voltage drop from no load to full load is very small, the, separately excited DC generator can be regarded as a, constant voltage generator., Advantages of a separately excited generator, The graph shown in Fig 42 is the load characteristic or, external characteristic of a separately excited generator, having load current in the X axis and terminal voltage in the, Y axis., , The terminal voltage remains almost stable when compared, to the self-excited generators because the field circuit is, independent of the induced voltage., As the field is independent, the IaRa drop in the armature, will not affect the field flux., This generator can be used where a wide range of terminal, voltage is required., Disadvantage, 1 The disadvantage of a separately excited generator is, the inconvenience of providing a separate DC source, for excitation., 2 Besides it is expensive., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.115 & 3.1.116, , Copyright @ NIMI Not to be Republished, , 15

Page 30 :

Electrical, Electrician - DC Generator, , Related Theory for Exercise 3.1.117, , Building up of a DC shunt generator, Objectives: At the end of this lesson you shall be able to, • explain the conditions and method of building up of voltage in a DC shunt generator, • explain the method of creating residual magnetism in the poles of a DC generator, • determine the magnetization characteristic of a DC shunt generator, • estimate the value of field critical resistance in the DC shunt generator., Condition for a self-excited DC generator to build up, voltage: For a self-excited DC generator to build up, voltage, the following conditions should be fulfilled,, assuming the generator is in sound condition., , The polarity of the induced voltage must be in such a, direction as to produce the field current to assist the, residual magnetism., , •, , There must be residual magnetism in the field cores., , •, , The field resistance should be below the field critical, resistance value., , The polarity of the induced emf depends upon the direction, of rotation and the polarity of the field poles depends upon, the field current direction., , •, , The generator should run at the rated speed., , •, , There must be a proper relation between the direction, of rotation and the direction of field current. It could be, explained as stated below., , Even after fulfilling the above conditions, if the self-excited, DC shunt generator fails to build up voltage, there may be, other reasons as listed in Table 1., , Table 1, Sl.No., 1, , Causes, , Reasons, , A break or opening in, the field or armature, circuit., , Remedies, , Break or loose connection, in the field or in the, armature winding/circuit., , Locate the open circuit and rectify., , High resistance in the field, circuit beyond the field critical, resistance value., , Reduce the resistance of the, field regulator., , 2, , Loose brush connections, or contacts., , Improper brush, contact/loose brush, connections., , Check the brushes for excessive, wear, and replace them, if, necessary. Check the commutator, for pitting. If necessary, turn down, the commutator. Always clean the, commutator when poor brush contact, is discovered. Check the brush, tension and readjust it, if necessary, Tighten any loose connections., , 3, , A dirty or severely, pitted commutator., , Severe sparking due, to overload., , In this case, follow the same, procedure as outlined above., , 4, , A short circuit in, the armature or field, , Overload or excess, heating., , Do a resistance check, ascertain,, locate and remove the fault., , Method of building up voltage in a DC shunt generator:, Fig 1 shows the circuit diagram for building up voltage in, a DC shunt generator. When the generator is made to run, at its rated speed initially, the voltmeter reads a small, amount of voltage say, 4 to 10 volts. It is due to the residual, magnetism. Since the field coils are connected across, the armature terminals, this voltage causes a small, amount of current to flow through the field coil. If the current, flow in the field coils is in the correct direction, it will, 16, , strengthen the residual magnetism and induce more, voltage., As such, the generated voltage will rise marginally. This, rise in voltage, in turn, will further strengthen the increasing, field current and induce more voltage. This rise in voltage,, in turn, will further strengthen the increasing field current., This cumulative action will build up voltage until saturation, is reached. After saturation, any increase in the field, current will not increase the induced voltage. However, the, , Copyright @ NIMI Not to be Republished

Page 31 :

whole procedure of building up of voltage takes a few, seconds only., , Method of creating residual magnetism: Without, residual magnetism, a self-excited generator will not build, up its voltage. A generator may lose its residual magnetism, due to any one of the following reasons., – The generator is kept idle for a long time., , gives the relation between the field current and the induced, voltage. Referring to the emf equation, the induced emf in, a generator is proportional to the flux per pole and the, revolutions per minute of the generator. At a constant, speed, the generated emf becomes directly proportional, to the field flux. In a given machine, the flux depends upon, the field current. The graph (Fig 3) illustrates this feature., Because of the residual magnetism, the curved part below, point `a' does not start at zero. Between the points `ab',, the curve is in almost a straight line indicating that the, voltage in the area is proportional to the field current., Between points `b' and `c' a large increase in field current, causes only a slight increase in the voltage. It indicates, that the field cores are reaching saturation and this part of, the curve is called the `knee' of the curve. Between points, `c' and `d', the curve is flat indicating that the increased, field current is not able to increase the induced voltage., This is due to saturation of the field cores. Because of, saturation, the field flux becomes constant, and the, induced voltage will not be in a position to increase further., This curve is also called a no-load or open-circuit, characteristic curve., , – Heavy short circuit., – Heavy overloading., – The generator is subjected to too much heat., When the generator loses its residual magnetism, it can, be re-created as stated below., Flashing of field: One of the methods to create residual, magnetism is called the flashing of the `field'. This can be, done by connecting the shunt field across a battery or any, DC source for a few minutes as shown in Fig 2., , While flashing the field, the polarity of the magnetic field,, now created, should be the same as that of the residual, magnetic field it lost earlier., , Critical resistance: If the shunt field circuit resistance is, too large, it does not allow sufficient current to flow into the, field to build up its voltage. In other words, it acts like an, open field. Therefore, the field circuit resistance should be, smaller than a value called critical field resistance. Critical, field resistance is the highest value of resistance of the, shunt field circuit with which a DC shunt generator can, build up voltage. Beyond this value of resistance, the, generator fails to build up voltage. The value of the critical, resistance can be determined by drawing a tangential line, to the open circuit characteristic curve as shown in, Fig 4., , In practice, this checking may not be possible., Alternatively note the polarity of the DC supply used for, flashing the field and the corresponding field terminals., Run the generator in the specified direction at its rated, speed. Measure the residual voltage induced and its, polarity. Check whether the polarity of the residual voltage, is the same as that of the DC generator. If found reversed,, flash the field again by connecting the supply voltage in, reverse polarity., Magnetisation characteristic of a DC shunt generator:, The magnetisation characteristic curve shown in Fig 3, Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.117, , Copyright @ NIMI Not to be Republished, , 17

Page 32 :

For example, by drawing the tangent on the open-circuit, characteristic curve as shown by line OR of Fig 4, we find, the tangent is parting at point `b' from the curve. By drawing, ordinates from point `b' to x and y axis, the value of critical, resistance (Rc) can be determined as below., Rc = Field critical resistance, , Field circuit resistance is the sum of the field resistance, and field rheostat resistance. This value should be less, than, say 1000 ohms (field circuit resistance) to enable the, generator to build up voltage, if the generator is intended, to self-excite. Normally this happens when the field, regulator resistance is set at a high value., , voltage represented by the tangent, current represented by the tangent, OF, 200 V, = 1000 ohms., =, =, OH, 0.2 A, =, , 18, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 3.1.117, , Copyright @ NIMI Not to be Republished

Page 33 :