Page 1 :

TERMS AND CONDITIONS, , These PowerPoint slides are a tool for lecturers, and as such:, YOU MAY add content to the slides, delete content from the slides, print out the slides, and save the slides onto your computer or server., YOU MAY NOT resell, reproduce or redistribute the content in any form whatsoever, without prior written permission from the copyright holder., , © Troupant Publishers (Pty) Ltd, 2016, Selected images used under licence from Shutterstock.com

Page 3 :

Safety measures relating to different engineering systems, Module 6

Page 4 :

Electrical and electronic�systems, Unit 6.1

Page 5 :

Safety procedures, When to write safety procedures:, Designing a new job or task., Changing a job or task., Installing new equipment in the workplace., Reviewing a procedure.

Page 6 :

Safety procedures, Safety procedure should identify:, The supervisor and the employees., The tasks that pose risks., The equipment that is used in these tasks., The control measures., Any training or qualification needed., The PPE to be worn., Actions to be undertaken to address safety issues that may arise.

Page 7 :

VIDEO: Personal protective equipment

Page 8 :

Electrical systems, Dangers of , electricity, Figure 6.2 ‘Beware of high voltage’ sign

Page 9 :

Types of injuries associated with electricity, The four main types of electrical injuries:, Electrocution., Electric shock., Burns., Falls.

Page 10 :

Electrical accidents, Common causes:, Inattention and carelessness., Poor housekeeping., Taking chances., Overloading of electrical circuits., Not complying with sound work practices.

Page 11 :

Bypassing or ignoring safety procedures., Lack of knowledge., Fatigue., Faulty or unguarded machinery., Electrical accidents, Common causes:

Page 12 :

Electrical safeguards, Examples of electrical safeguards:, Circuit-breakers., Direct earthing., Isolating transformers., Double-insulated appliances., Earth leakage units.

Page 13 :

Safety precautions when working with or near electricity, Do not use power tools with faulty cords., Do not use outlets or cords that have exposed wiring., Use only cords or tools that are rated for the level of amperage or wattage that you are using., Wet or damp areas have a greater risk of electric shock., Know where the distribution board is.

Page 14 :

Safety precautions when working with or near electricity, Ensure that all circuit-breakers are labelled., Do not block access to circuit-breakers., Do not use metallic ladders near power lines., Lock out an isolator in the off position and place a tag on it., Electrical accident: always disconnect the current first before attending to the accident.

Page 15 :

Electric power tools, Basic safety measures for power tools

Page 16 :

Electric power tools, Basic safety measures for power tools (continued), Figure 6.4 Damaged cables

Page 17 :

Electric power tools, Basic safety measures for power tools (continued)

Page 18 :

Electric power tools, Basic safety measures for power tools (continued)

Page 19 :

Electric power tools, Basic safety measures for power tools (continued)

Page 20 :

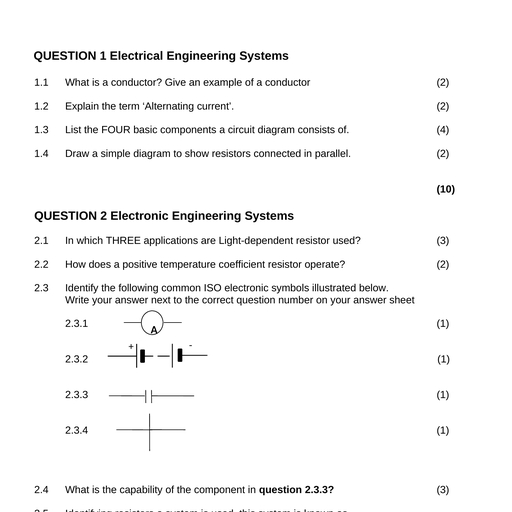

Electronic systems, Basic safety measures for electronic systems

Page 21 :

Electronic systems, Basic safety measures for electronic systems (continued)

Page 22 :

Electrostatic charges, Handling semiconductor devices

Page 23 :

Electrostatic charges, Handling semiconductor devices (continued)

Page 24 :

Mechanical, hydraulic and pneumatic systems, Unit 6.2

Page 25 :

Mechanical systems, Figure 6.11 Clothing can get caught in machinery

Page 26 :

Mechanical hazards include:, Movement of parts – rotating, sliding or reciprocating., Entanglement or catching hair, clothing or jewellery., Friction and abrasion., Cutting and shearing., Mechanical systems

Page 27 :

Mechanical hazards include:, Puncturing., Impact., Crushing., Drawing in., Compressed air or high-pressure fluids., Mechanical systems

Page 28 :

Non-mechanical hazards include:, Access problems. , Handling and lifting., Electrical., Chemical., Fire and explosion., Noise and vibration., Temperature., Radiation., Mechanical systems

Page 29 :

Machine guards, Figure 6.12 A guard fitted to prevent accidents

Page 30 :

Types of machine guards, Fixed guards., Interlocking guards., Adjustable guards., Self-adjusting guards.

Page 31 :

VIDEO: Machine guard

Page 32 :

Safety devices, The two main safety devices are:, Trip devices., Two-handed controls.

Page 33 :

Machine guards and safety devices, Table 6.1 Guards and safety devices

Page 34 :

Machine guards and safety devices, Table 6.1 Guards and safety devices (continued)

Page 35 :

Why and how workers are injured by machinery, Why and how workers are injured by machinery

Page 36 :

Why and how workers are injured by machinery, Why and how workers are injured by machinery (continued)

Page 37 :

Where mechanical hazards occur, The point of operation., The power transmission components., Other moving parts.

Page 38 :

General safety precautions relating to the use of machinery, Check the machine guards and safety devices regularly., Ensure that control switches are clearly marked to indicate which machine they control., Ensure that you are trained to work safely on machinery and that you wear appropriate protective clothing., Make sure you know how to stop the machine before you even start it.

Page 39 :

General safety precautions relating to the use of machinery, Inform your team leader if you think a machine is not working properly., A dusty workplace can be dangerous. , Machines that are poorly located or that are too close together may not be safe, even if guarded., With some machines, wear gloves to protect your hands from the sharp edges of the material being processed.

Page 40 :

General safety precautions relating to the use of machinery, Never attempt to clean a machine in motion; �switch it off or use a lock-out procedure., Never use a machine that has a danger tag attached to it., Do not wear jewellery, loose clothing or long hair as it may get caught in moving parts., Adequate lighting is needed for the operation of machinery.

Page 41 :

Hydraulic systems and tools, Do not operate a hydraulic system or tool unless thoroughly trained or under the supervision of an instructor., Always wear safety equipment such as goggles, ear and head protection, as well as safety shoes when operating the tool., Do not inspect or clean the tool while the hydraulic power source is connected.

Page 42 :

Ensure that all hose connections are tight., Do not operate a damaged, improperly adjusted or incompletely assembled hydraulic system., Do not exceed the rated limits of the tool or use the tool for applications beyond its design capacity., Figure 6.16 Ensure that all hose connections are tight, Hydraulic systems and tools

Page 43 :

Hydraulic systems and tools, Always keep critical hydraulic system markings legible/visible., Keep in mind that hydraulic power tools can produce an extreme amount of pressure., Ensure that the surfaces are free of any oil., Figure 6.17 A warning sticker on a hydraulic valve

Page 44 :

Pneumatic systems and tools, Dangers associated with the use of pneumatic systems and tools

Page 45 :

Pneumatic systems and tools, Dangers associated with the use of pneumatic systems and tools (continued)

Page 46 :

Pneumatic systems and tools, Dangers associated with the use of pneumatic systems and tools (continued)

Page 47 :

Pneumatic systems and tools, Dangers associated with the use of pneumatic systems and tools (continued)

Page 48 :

Pneumatic systems and tools, Dangers associated with the use of pneumatic systems and tools (continued)

Page 49 :

The implications of non-adherence to safety measures as stipulated by the manufacturers, Severe bodily injury or loss of life., Damage to or failure of the equipment., Voiding of the warranty of the equipment.

Page 50 :

Summative assessment, Test your knowledge of this section by completing the�Summative assessment�(page 99 of your Student’s Book)

Learn better on this topic

Learn better on this topic

Learn better on this topic

Learn better on this topic