Page 1 :

PRODUCTION TECHNOLOGY-1, , GOVT. TOOL ROOM AND TRAINING CENTRE, KARNATAKA, , REFERENCE NOTES, , PRODCUTION TECHNOLOGY -1, , FOR, : DIPLOMA IN TOOL AND DIE MAKING, : DIPLOMA IN PRECISION MANUFACTURING, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 1 of 96

Page 2 :

PRODUCTION TECHNOLOGY-1, , SYLLABUS: General safety, , -, , Safety precautions, , 1Hrs, , Bench layout, , -, , Work bench, Basic, machine, Arrangement of tools, shop practice, & instruments, , 1Hrs, , -, , Vices, Files, Hacksaws, Chisels, Hammers, Scrapers, Screw drivers, Wrenches & Spanners, Pliers, , Hand tools, , 18Hrs, Basic, , machine, , shop practice, Work, , shop, , technology, Vol 1&2, Drills, , &, , Drilling, , machines, , Marking & layout tools, , -, , Drills, Drilling operations, Drill geometry, Different types of, drilling machines, Work holding devices, Speeds, Basic machine, Feeds, Coolants, shop practice, Reamers, , -, , Scribers, Surface gauges, Dividers, Angle plates, Surface plates, , Work shop, , 10Hrs, , 6Hrs, , technology, Vol 1&2, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 2 of 96

Page 3 :

PRODUCTION TECHNOLOGY-1, , Measuring instruments, , Threads, , -, , Tapes, Rulers, Vernier’s, Micrometers, Depth gauges, Height gauges, Bevel protractors, Try squares, , Basic machine shop, , -, , Taps, Dies, Thread terms, IS standards, , Basic machine shop, , 4Hrs, , practice, Work shop, technology, Vol 1&2, , 1Hrs, , practice, Work shop, technology, Vol 1&2, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 3 of 96

Page 4 :

PRODUCTION TECHNOLOGY-1, , UNIT1: GENERAL SAFETY, 1. Always wear shoes in the workshop., 2. Always maintain discipline and do not indulge in mischief with co-workers., 3. Do not walk below the load carried by a crane., 4. Do not run in the workshop while going for an urgent call., 5. Do not work alone in the workshop., 6. Do not keep long hair., 7. Do not play with the machines., 8. Do not work during ill health., 9. Do not lift heavy jobs without the uses of cranes., 10. Protect yourself from welding arcs., 11. Report to the doctor in case of any injury and learn first aid treatment., 12. Take care of moving machines and walk within the prescribed work belt., 13. Wear a helmet in a big fabrication shop., 14. Wear proper workshop dress., 15. Wear safety goggles while working in a machine shop., 16. Wear gloves while moving sheet metal or stock with sharp edges., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 4 of 96

Page 5 :

PRODUCTION TECHNOLOGY-1, , UNIT 2. BENCH LAYOUT/WORK BENCH, Bench layout/Work bench:, The work bench is the main kind of work place equipment used for Bench work. It is essentially, a special table on which fitting jobs are carried out. It is strong and stable shown in fig.1 is the sketch of, a commonly used Work Bench. The bench frame is a welded made up of steel or iron tubing or angles., The bench top is made of hard wood boards 50 – 60mm thick depending upon the operating conditions., The top is covered by a steel 1-2mm thick. Fitter’s benches are normally 1000-1200mm in length, 700 –, 800mm wide and 800 – 900mm in height., , 1. Frame, , 2. Bench top, , 3. Vice, , 4. Protective screen, , 5. Blueprint holder, , 6. Lamp, , 7. Tool tray, , 8. Tool rack, , 9. Drawers, , 10. Shelves., , 11. Seat, , As shown in the figure, marking instruments, filing tools and other accessories required for work on, the bench are segregated and kept in order. A bench Vice is fitted on the work bench, which is at a distance, of approximately 1/4 th the length of the table from one edge., Also, shown in is the adjustment of a bench vice according to the height of the work- man., The height is correct, if the fingers of the workman touch the chin, with the elbow placed on top of the, vice jaws as shown., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 5 of 96

Page 6 :

PRODUCTION TECHNOLOGY-1, , UNIT 3: VICES, Objectives:, - Vice, - Bench vice, - Parts of a fixed parallel bench vice, Designation of a vice, -, , Hand vice, Leg vice, Machine vice, Machine vice with swivel base, Pipe vice, Shapers vice, Tool makers vice, , Safety precautions while using a vice, VICES, VICE:, Vices are holding devices extensively used for clamping of work pieces in a work shop. Most, 0f the manual operations like sawing, filing, tapping, reaming etc. are done by holding the work pieces in, the vice., TYPES OF VICES:, 1. BENCH VICE, , Fig, i, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Fig, ii, , Page 6 of 96

Page 7 :

PRODUCTION TECHNOLOGY-1, , (i) Swiveling Bench Vice, , (ii) Fixed Parallel Bench Vice, , 1.Stationary support disc, , 2.Turning lever, , 3.Swivel plate, , 4. Base plate, , 5.Handle, , 6.Movable jaw, , 7.Jaw plates, , 8. Fixed jaw, , 9.Box nut, , 10.Clamping screw, , 11.Circular slot, , 12.Anvil, , 13.Base, , 14.Coupling plate, , It is the most commonly used vice. The bench vice is firmly fixed on the bench. The vice, consists of a cast iron body, a fixed jaw and a movable jaw, both made of cast steel. Other parts of the, vice include a handle, a square threaded screw and a nut, all made of mild steel. Separate cast steel plates, called as jaw plates, are fixed to the jaw by means of a screw and they can be replaced when worn out., The holding faces of the jaw plates have teeth for holding the work firmly, but this has some disadvantages, for clamping of soft metals as they may get damaged. Protective grips made of Fiber, Tin plates, Lead or, Aluminum, must be fitted over the jaws to prevent the serration’s from damaging the finished surface of, the work piece., Bench vices may be either of the fixed type or the Swiveling type. Both types are shown in, the figure. The movement of the vice is caused by the movement of the screw through the box nut fixed, under the movable jaw., PARTS OF A FIXED PARALLEL BENCH VICE:, A Bench vice consists of the following main parts:, FIXED JAW:, The fixed jaw as the name indicates is fixed to the base or cast along with the base of the vice., The top portion of the fixed jaw are fitted with jaw plates to help in gripping the job. The bottom portion, of the Fixed jaw extends to form three lugs which help in fastening the vice to the bench. The Fixed jaw, is made from Grey cast iron., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 7 of 96

Page 8 :

PRODUCTION TECHNOLOGY-1, , MOVABLE JAW: It is a hollow inverted channel section that slides in the body of the fixed jaw and, is shaped to form a jaw at its outer end. It is also made from Grey cast iron., BASE: The base is cost along with the body of the fixed jaw. The three lugs extended on the base help, to fix the vice on the bench., SCREW ROD OR SPINDLE:, Vice Spindles or Screw rods usually have square or acme threads but a quick grip vice has, buttress threads. It is located in the movable jaw and engages with the fixed nut or box nut, which is, housed in the body of the fixed jaw. The screw rods or Spindle is made of Mild steel., BOX NUT OR FIXED NUT:, The box nut is located in the base and holds the spindle. Box nuts are made of phosphorous, bronze or Grey cast iron., JAW PLATES:, They are made from tool steel and hardened to 50-52HRC. The jaw plates are serrated, suitably to hold the work., HANDLE:, A Handle is used to rotate the spindle. Generally, the length of the handle is 2.5 times the, normal size of the vice. This slides freely in the spindle hole and does not come out because of the collar, fitted at the two ends. This is made from Mild steel., DESIGNATION OF A VICE:, The designation of a vice indicates:, 1. The commonly used name., 2. The nominal size., Ex: Bench vice 100mm, Leg vice, , 125mm etc., , The size of the vice is known by the width of its jaws. The width suitable for common, work varies from 80-140mm, the maximum opening being 95mm and 180mm., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 8 of 96

Page 9 :

PRODUCTION TECHNOLOGY-1, , 1. HAND VICE, , 1. Jaws, , 2. Jaw plates 3. Spindle, , 4. Handle, , 5. Wing nut., , The hand vice is used for gripping screws, rivets, keys, small drills and other small objects that are, difficult to hold by hand. This is a very common tool used by key smiths., , 1., 2., 3., 4., 5., 6., 7., 8., , 2. LEG VICE, Fixed jaw, Hinged jaw, Handle, Spring, Pivot pin, leg, Lugs on base., Clamp, This kind vice is usually used for forging and hammering works. The vice is secured to the top of the, , bench by a stop fastened to a plate bolted to the bench top. The leg of the vice is fastened to the bench, leg with staples and its end fits into a hole in the floor. Therefore, the name leg vice. The construction of, the vice makes it suitable for heavy work., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 9 of 96

Page 10 :

PRODUCTION TECHNOLOGY-1, , 3. MACHINE VICE, 1. Handle, 2. Screw, 3. Movable Jaw, 4. Jaw plates, 5. Fixed jaw, 6. Clamping bolt, 7. Base plate, 8. Bracket, 9. Guide way, 10. Swivel base, Machine vices are designed for machining of precision work on Milling and Drilling machines to meet, strenuous production requirements. The body of a machine vice is made of Grey cast iron. The body is, well proportioned to absorb stresses uniformly and gives a rigid base for clamping any kind of work to, the table of the machines., 4. MACHINE VICE WITH SWIVEL BASE, The parts are commonly mentioned in the above figure., , This is a special type of vice made with a swelling base. The job, after mounting in the jaws can be, adjusted in any angle horizontally or vertically. The base is graduated for a full circle of 3600., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 10 of 96

Page 11 :

PRODUCTION TECHNOLOGY-1, , 5. PIPE VICE, i. Fixed type, ii. Open type, 1., 2., 3., 4., , Handle, Spindle with square thread, V Jaws, Base, Pipe vices are used for clamping pipes, mostly for, , threading, fitting and removing of joints. Two types of pipe, vices are commonly used. The open type and the fixed type., , 6. SHAPER’S VICE, , 1. Fixed jaw, , 3. Job seating space, , 2. Movable jaw, , 4. Screw, , 5. Swivel base, , As the name suggests this vice is used to hold jobs on a Shaping machine. This vice is strong and, rigid in construction and hence permits the use of heavy depths of cut and faster of feed to be given of the, job., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 11 of 96

Page 12 :

PRODUCTION TECHNOLOGY-1, , 7. TOOL MAKER’S VICE, , 1. Clamping grooves, , 2. Screw, , The Tool Makers vice is commonly used by the Tool Maker for tool room work. It is, similar to a machine vice but it is less rigid. It helps in holding and machining of small precision jobs., SAFETY PRECAUTION WHILE USING A VICE:, 1. The bench vice should never be used as an Anvil. If the cast iron body cracks up, it becomes difficult, to weld and be used again., 2. A hammer and other such means should never be used for extra tightening of the vice jaws as this may, result in the breaking of the screw of wear out of threads., 3. Wherever possible the work should be held in the center of the jaws. This results in better gripping of, the job., 4. Use soft jaws for clamping of finished components or softer materials to avoid serration marks of the, jaws from falling on the work piece., 5. Always leave a small gap in between the jaw plates when the vice is not in use. The eliminates the, force which would otherwise be acting on the jaw plates as well as on the spindle when the vice jaws, are kept tightly joined., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 12 of 96

Page 13 :

PRODUCTION TECHNOLOGY-1, , Assignment:, 1., 2., 3., 4., 5., 6., 7., 8., 9., , What is a vice? Mention the different types of vices?, Write a brief note on bench vice?, Neatly draw the sketch of bench vice and mention its different parts?, Briefly explain each part of bench vice?, How vices are designated? Give two examples?, Neatly sketch hand vice and explain briefly?, Explain briefly leg vice with a neat sketch?, Write a brief note on machine vice?, Write a brief note on machine vice with swivel base?, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 13 of 96

Page 14 :

PRODUCTION TECHNOLOGY-1, , UNIT 4. FILES, Objectives:, Parts of a file, Types of a file, Cross section of a file, Elements of a file, Methods of filing, Safety while filing, Parts of file, a., b., c., d., e., f., g., , Tang, Shoulder, Heel, Edge, Face, Belly, Tip or point, , Types of files, a., b., c., d., e., f., g., h., , Flat file, Half round file, Hand file, Knife edge file, Round file, Square file, Triangular file, Warding file, , - Cross section of file, -Elements of a file, a. Safe edge, b. Convexity of files, c. Taper of the file, -Methods of filing, a. Cross filling, b. Straight filing, c. Draw filing, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 14 of 96

Page 15 :

PRODUCTION TECHNOLOGY-1, , Safety precaution., A File is a hand cutting tool used to remove excess material and to produce a finished, surface. It is made up of High Carbon Steel (HCS)and has teeth cut on its face in slanting rows. It is, hardened to about 60-62 HRC and the tang portion is left soft. The tang portion of the file fits into handle, made of plastic or wood., PARTS OF A FILE, , 1. Tang, , 3. Heel, , 5. Face, , 2. Shoulder 4. Edge, , 6. Belly, , 1-Taper portion, , 7. Tip or Point, , 2-Length of the file, , 1. TANG: The narrow portion of the file where the handle is fixed., 2. SHOULDER: The radius portion adjacent to the face formed between the edge of the file and the, , tang is called as Shoulder., 3. HEEL: The uncut portion on the face near the shoulder of the shoulder of the file is termed as the, , Heel., 4. EDGE: It is the perpendicular side of the face. The edge is always single cut. Sometimes the teeth, , are not cut on the edge and are called as Safe edge files., 5. FACE: It is the surface of the file where the teeth are cut., 6. BELLY: Some files are tapered on both the width and thickness. This is for 1/3rd of the length and, , this portion is called as Belly., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 15 of 96

Page 16 :

PRODUCTION TECHNOLOGY-1, , 7. TIP: The taper of the file ends towards the length of the file and forms a sharp portion is called as tip., , It is used to remove the scale., a) FLAT FILE, It is rectangular in cross section and is tapered towards the tip in both width and thickness., Teeth are cut on both faces of the file and also on its edges. It is widely used for general purpose work., b) HAND FILE, These are similar to flat files but are parallel in width and thickness. They are sometimes, tapered in thickness only. One of its edges do not have teeth cut on them. This file is used for filing flat, surfaces, the safe edge being useful when filing up to the shoulder., c) HALF ROUND FILE, This file is flat on one side and curved on the other side. So, it can be used on both flat, and curved surfaces., d) KNIFE EDGE FILE This file is shaped like a knife and is tapered in width and thickness with two, faces at 150 angle each. It is mainly used by lock smiths for filing acute angles more than 150., e) ROUND FILE It has a round cross section and is tapered diametrically from the tip to the shoulder., Small round files are also called as Rat Tail Files and files without taper are called as parallel round, files. This is used for the filing of circular openings, curved surfaces and for making concave surfaces., f) SQUARE FILE It has got four filing sides and is used to make key ways, grooves and slots., g) TRIANGULAR FILE It has Triangular cross section with each face at 60 degrees. It is used for, filing acute angles more than 60 degrees. It is used for cleaning square corners and repairing damaged, screw threads providing notches etc., h) WARDING FILE It is rectangular in cross section but it is thinner than the flat file. It is mainly used, by Lock smith for filing notches in keys., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 16 of 96

Page 17 :

PRODUCTION TECHNOLOGY-1, , a. Hand file, , e. Round file, , b. Flat file, , f. Half round file, , c. Square file, d. Triangular file, , g. Lozenge file, h. Knife edge File, , The figure above shows the application of the different file types., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 17 of 96

Page 18 :

PRODUCTION TECHNOLOGY-1, , 4. CROSS SECTION OF FILES, , a) Flat, b) Hand, c) Half-round, d) Round, , e) Triangle, f) Square, g) Warding, h) Knife, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 18 of 96

Page 19 :

PRODUCTION TECHNOLOGY-1, , ELEMENTS OF THE FILE:, 1. SAFE EDGE:, The flat file will have single cut teeth on its edges. Hand files usually have teeth cut on, one of its edges. The other end is ground and left uncut or safe. This uncut edge of a file is termed as safe, edge., 2. CONVEXITY OF FILES:, All the files are made with the face slightly convex on the thickness and along the length., It is done so because, while filing a broad surface, the application of pressure will be on both the ends of, the file. There is a tendency of the file to bend towards the pressure exerted and hence flatness of the job, may not be achieved., 3. TAPER OF THE FILE:, The reduction in width of the file from the tip portion towards the belly is called as the, Taper of the file., METHODS OF FILING, A. CROSS FILING, B. STRAIGHT FILING, C. DRAW FILING, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 19 of 96

Page 20 :

PRODUCTION TECHNOLOGY-1, , 1. CROSS FILING: In Cross filing the filing strokes run alternatively from left to right and right to left, at an angle of 40-600 to horizontal. This is a common method adopted in the workshop to remove, excess material and to get a fine surface finish. Also in this method, the possibility of rounding off of, the edge of the job is minimized and the score marks made in the work by the file teeth are, crisscrossing. Due to the increased contact area maximum amount of material can be removed., 2. DRAW FILING: When it is desired to file a piece of work length wise, it may done by draw filing., In this method the handle of the file is not held. Instead, both ends are placed close together on the, file as shown in the figure. The file is placed at right angles across the work piece while the hands, and especially the thumbs grip the file and move it up and down the length of the material. It does not, remove much material, but a smoother cutting action is achieved than with a cross or straight file., This method is mainly used to remove the material from thin sheets very lightly. Single cut files are, used for Draw filing., 3. STRAIGHT FILING: In straight filing, the file is removed at right angles to the length of the job., On the back stroke, the pressure on the file is lifted clear of the work in order not to blunt the teeth., Straight filing is especially useful on long and narrow pieces of work whose width is less than that of, the file. The filing speed varies from 30-40 strokes per minute for mild steel., SAFETY WHILE FILING:, 1. Apply pressure while filing only in the forward direction as retaining the pressure on the reverse, direction causes the teeth to become blunt., 2. After filing, clean the file using a file brush. This enables the clogged material to clear off the cutting, edges of the file., 3. Do not apply excessive pressure while working with a smooth file., 4. Do not use one kind of file for all types of work., 5. Do not use a file without a handle as this may result in injury to the hands., 6. Use a new file gently on metals like gun metal, bronze, aluminum etc. the first few strokes., , 1., 2., 3., 4., 5., 6., 7., , Assignment:, What is a file? Mention the different parts of file and explain each part briefly?, Draw a neat sketch of flat file and mention the parts?, Mention different types of files? Explain each in brief?, Neatly sketch the different types of files with their cross section?, Explain briefly the elements of a file?, Briefly explain methods of filing?, Mention some important safety precautions while filing., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 20 of 96

Page 21 :

PRODUCTION TECHNOLOGY-1, , UNIT 5. HACKSAW, Objectives:, Parts of a hand hacksaw, Parts of the frame, Types of blades, Classification of blades, Saw- setting, Material of the blade, Safety precautions while sawing, Parts of a hand hacksaw., a. Wing nut, b. Frame, c. Adjustable blade holder, d. Hacksaw blade, e. Fixed blade holder, f. Handle, g. Pins, h. Slits., Frame, -Parts of a frame, a. Body, b. Tension screws, c. Wing nut, d. Pins, Blades, -Parts of a blade, a. Pin holes, b. Teeth, c. Toothed edge, 1.Cutting edge, 2.Face, 3.Flank, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 21 of 96

Page 22 :

PRODUCTION TECHNOLOGY-1, , 4.Nominal length, 5.Pitch, 6.Tooth radius, 7.Width, Types of blades, a. All hard blades, b. Flexible blade, c. Flexible center blade, d. Spring back blade, Classification of a blade, Saw setting, -Types of saw setting, a. Alternative saw set, b. Staggered or raker saw set, c. Wavy saw set, Material of blade, a. High carbon steel blades, b. High speed steel blades, c. Low tungsten alloy steel blades, Safety precautions while sawing, HACKSAW, The Hand Hacksaw is a hand cutting tool generally used for cutting materials like, thick, metal sheets, round bar stock and other sections, and to cut slots, contours etc., PARTS OF A HAND HACKSAW: The Hacksaw mainly consists of two parts. They are:, 1. Frame, , 2. Blade, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 22 of 96

Page 23 :

PRODUCTION TECHNOLOGY-1, , 1., 2., 3., 4., 5., 6., 7., 8., , Wing nut, Frame, Adjustable blade Holder, Hacksaw Blade, Fixed Blade Holder, Handle, Pins, Slits, , The above figure shows the Fixed and Adjustable Hacksaw with parts., 1. FRAME: The Frame is that part is the Hacksaw, which holds the blade. The Frame is available as a, Flat type, Tubular type or Deep cutting type. Among all these three types, Fixed and Adjustable, varieties can also be found. The parts of an Adjustable Flat Frame are explained below., PARTS OF THE FRAME, a) BODY: The body of the frame is made from either a tube, a solid flat strip or a round bar and may be, of the fixed type or adjustable type. Wooden handles are generally used. Pistol grip steel frame handles, are also used for the frame., b) TENSION SCREW: As the name suggests this screw is used to adjust the tension of the blade. It is, present opposite to the handle. The wing nut tightens on the tension screw., c) WING NUT: It is so named because it has the appearance of a housefly wing. This is driven by the, thumb on the tension screw and this pressure is enough to keep the blade in tension. No extra leverage, is necessary., d) PINS: Two pins are provided at the ends of the frame. These pins enable the blade to be fixed to the, frame., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 23 of 96

Page 24 :

PRODUCTION TECHNOLOGY-1, , BLADE, A blade consists of the following parts., , a) PIN HOLES:, The blade has two holes made at the ends to enable the blade to be fitted to the frame. A, clearance is provided on the holes as the blade can be freely inserted on to the pins and then tightened, with the help of tension screws., b) TEETH:, The serrations cut across the thickness of the blade, generally on one of its edges, are, called as the teeth of the blade. The teeth provide the cutting edges of the blade. There are different types, arrangements or placement of the teeth on the blade and are called as saw settings. These are explained, later in this chapter., c) TOOTHED EDGE, The longitudinal edge along with the teeth is called as the toothed edge., (i), , CUTTING EDGE:, The edge of the blade where the teeth, , are cut is called as the Cutting edge of the blade., 1. Pitch, 4. Root Radius, ii), iii), , 2. Face, , 3. Cutting Edge, , 5. Flank, , FACE: The surface of the tooth adjacent to the, cutting edge is called as the, Face., FLANK: The surface behind the cutting edge upto the root radius is called as the Flank., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 24 of 96

Page 25 :

PRODUCTION TECHNOLOGY-1, , iv), , NOMINAL LENGTH: The length between the outer edges of the pin holes measured along the, center line of the blade is the blade’s nominal length., , v), , PITCH: The distance between the two adjacent cutting edges of the teeth is called as the pitch., , vi), , ROOT RADIUS: The radius connecting the face and the flank in the root of the teeth space is, called as the Root radius., , vii), , WIDTH: It is the distance between one edge to the other edge of the blade., , TYPES OF BLADES:, Blades may be of the following types:, 1. All hard blade: It is fully hard except near the pin holes., 2. Flexible blade: It is hardened at the teeth portion only., 3. Flexible center blade: It is hardened at the back and at the teeth only., 4. Spring back blade: It is hardened at the teeth and the remaining portion is spring tempered., , CLASSIFICATION OF A BLADE:, Hacksaw blades are classified according to the following:, 1. The commonly used name whether hand or machine operated, 2. The nominal length, width and thickness., 3. The pitch or teeth per inch., 4. The material whether H.S.S (High speed steel), H.C.S (High carbon steel) or L.S.S (Low alloy steel)., 5. The type of blade; whether All hard, Flexible, Flexible center or Spring back., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 25 of 96

Page 26 :

PRODUCTION TECHNOLOGY-1, , EXAMPLE:, The hacksaw blade for hand operation having a length of 300mm, a width of 13mm, thickness of 0.63mm, and a pitch of 0.8mm of Low alloy steel and All hard, shall be specified as:, ‘Hand saw blade 250 X 13 X 0.63/0.8-L.A. All hard’., ‘hand saw 12” x ½” x 1mm x 18 T.P.I (H.S.S)’, SAW SETTING:, The arrangement of the saw teeth in a regular fashion is called as Saw setting. Setting the, teeth of the Saw blade is done in order that the width of the slot cut may be slightly larger than the blade, thickness. This provide a clearance between the blade and the slot and thus prevents the jamming of the, blade. This makes cutting much easier. According to the pitch of the blade, there are different types of, Saw settings:, There are three different types of saw setting, 1. Staggered set (fig-A), 2. Alternative Saw set (fig-B), 3. Wavy Saw set (fig-C), , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 26 of 96

Page 27 :

PRODUCTION TECHNOLOGY-1, , SAW SETTING:, 1. STAGGERED OR RAKER SAW SET: This type of setting is used in blades having a pitch of 1to, 1.25mm. Here, one teeth is bent to one side, the next teeth is straight and unset, the third teeth is bent, to the opposite side of the first teeth and the fourth teeth is again straight and unset. The same pattern, is found along the entire length of the blade barring 30mm from either edge of the blade. Raker set, blades are used for general purpose sawing., 2. ALTERNATIVE SAW SET: This type of setting is generally used on blades having a pitch of 1.6, mm. In this type, the teeth are set alternatively that is 1 tooth is bent on one side and the next teeth on, the opposite side., 3. WAVY SAW SET: Hack saw blades with a pitch of 0.8mm are wavy set that is two or three, consecutive teeth are bent alternatively to opposite sides by 0.25 to 0.6mm. The teeth of the blade, look like a wave and hence the name wavy set. This type of set is used on blades to cut thin sheet, metal sections., MATERIAL OF THE BLADE: Blades are made by different materials, depending upon the cutting, surface or the job to be cut., 1. HIGH CARBON STEEL BLADES: These blades have a hardness of 60to62 HRC. It is used to, cut mild steel, brass, copper, aluminum etc. A cutting sped of 35 strokes per minute is specified for these, blades., 2. HIGH SPEED STEEL BLADES: These blades have a very high wear resistance and an ability to, cut harder material. These blades have an HRC of 62 to 65. It is used to cut alloy steels and tool steels., A cutting speed of 65 strokes per minute is specified for these blades., 3. LOW TUNGTEN ALLOY STEELS BLADES: These blades have a hardness of 61-65 HRC and, is used to cut mild steel and carbon steel. These blades are wear resistant, cut faster and last longer. Hence, they are much economical than carbon steel blades. A cutting speed of 40 to 55 strokes per minute is, specified for these blades., POINTS FOR SAWING., 1. Hold the work rigidly before cutting and keep the cutting line nearer to the grip to avoid spring action., 2. Before starting the cut, check that the blade is fixed properly., 3. File a ‘V’ shaped nick at the starting point with a triangular file or with the help of thumb and blade., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 27 of 96

Page 28 :

PRODUCTION TECHNOLOGY-1, , 4., 5., 6., 7., , Hold the work rigidly before cutting and keep the cutting line nearer to the grip to avoid spring action., Before starting the cut, check that the blade is fixed properly., File a ‘V’ shaped nick at the starting point with a triangular file or with the help of thumb and blade., While starting, keep the blade at an angle, as it shall engage at least three teeth. While selecting a, blade, follow the ‘three- teeth rule’ which requires that during cutting, a minimum of three teeth be, continuously in contact with the work., 8. Start the cut with a light, steady and forward stroke., 9. After starting the cut, use long strokes but not at a higher speed than prescribed., 10. As the cut is nearing finish, relieve the pressure. The pressure should be applied on the return stroke., 11. Thin sheets are neatly cut when held in a piece of board made of wood., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 28 of 96

Page 29 :

PRODUCTION TECHNOLOGY-1, , SAFETY PRECAUTIONS WHILE SAWING:, 1. Before sawing, make a groove or notch with a triangular file to position the blade on the marked for, cutting the slot., 2. Ensure that the blade is properly tightened, and the job is held securely in the vice., 3. Fine pitch blades should be used while cutting hard materials and coarse pitch blades for soft materials., 4. Relieve the cutting pressure on the return stroke., 5. Reduce the cutting pressure when the blade is almost about to cut the job., 6. Start cutting from a new edge if the blade breaks in the middle., 7., , To prevent chattering, cut as close as possible to vice jaws., , 8. Use full length of the blade during sawing., 9. While sawing, make continuous strokes., 10. While sawing thin sheets, keep wooden boards as support., 11. While sawing, ensure that at least three teeth are in contact with the job., Assignment:, 1., 2., 3., 4., 5., 6., 7., 8., 9., , What is a hacksaw? Draw a neat sketch of hand hacksaw and mention the different parts?, Briefly explain the parts of the frame of the hacksaw?, Briefly explain the parts of the blade that is used while hacksawing?, Mention the types of blades?, How blades are classified. Explain with an example?, Explain briefly saw setting?, What are the different types of saw setting? Explain briefly each with a neat sketch?, What are the different types of materials used to manufacture the blade? Explain each in brief?, Mention some important safety precautions while sawing?, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 29 of 96

Page 30 :

PRODUCTION TECHNOLOGY-1, , UNIT 6. CHISELS, A chisel is a hand cutting tool used to chip off excess layers of stock from the surfaces of work pieces, by using a hammer. The chisel is considered outdated today, due to the advent of modern machine tools., However, there are occasions when a chisel becomes indispensable., Chipping is resorted to when machining is impractical and high accuracies are not required. Typical, chipping applications include removal of large surface irregularities, hard skins, burrs, sharp edges from, castings and stampings, cutting key ways, oil grooves, preparing the edges of cracks for welding up,, cutting of the heads of rivets for their removal, making holes in sheet metal and so on., COMMON TYPES OF CHISELS:, The following are the common types of chisels that we can come across in a machine shop:, 1., 2., 3., 4., 5., 6., , Flat, Cross-cut (cape), Diamond point, Round nose, Cow mouth (Gouge), Side cut, , 1. FLAT CHISELS:, 1. Cutting angle, 2.Taper head, 3.Length of the taper portion, 4.Cutting edge, 5.Width of the cutting edge (Nominal size), 6.Dia of the head, 7.Size of chisel body, 8.Length, 9.Body, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 30 of 96

Page 31 :

PRODUCTION TECHNOLOGY-1, , The diamond point chisel has a cutting edge like a diamond. It is used for making sharp corners,, removing metal from corners, cutting oil grooves, etc., , 2. CROSS CUT CHISEL:, 1.Width of cutting edge, , 2. Dia. of head, , 3. Size of body, , 4. Size of the chisel body, , 4. Length, , 5.Cutting angle, This chisel is normally used to cut key ways, Channels and grooves. The cutting edge is, narrow in this chisel., , 3. DIAMOND POINT CHISEL, 1.Width of cutting edge, 2.Dia. Of head, 3.Length of the taper portion, 4.Size of chisel body, 5.Length, 6.Cutting angle, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 31 of 96

Page 32 :

PRODUCTION TECHNOLOGY-1, , The diamond point chisel has cutting edge like a diamond. It is used for making sharp, corners, removes metal from corners, cutting oil grooves, etc., , 4. HALF ROUND NOSE CHISEL, 1. Width of cutting edge, 2. Dia. Of head, 3. Size of body, 4. Length, 5. Cutting angle, It is used for cutting grooves, forming flutes, bringing drill holes in the correct position, when set out inaccurately, etc., 5. COW MOUTH CHISEL, cross-section of cutting point, 1. Cross section of cutting point, 2. Body, 3. Taper hand, 4. Convex portion of head, This chisel is used for removing the, material from hollow jobs, cutting circular, blanks from sheets, etc., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 32 of 96

Page 33 :

PRODUCTION TECHNOLOGY-1, , 6. SIDE CUT CHISEL, 1. Cutting angles, 2. Head, 3. Cutting Edge, 4. Body, This chisel is specially made, for removing the metal from, cotter ways or slots which are, to be cut by hand after, drilling. They are also used for removing excess material from the sides of the casting formed by a runner, and a raiser on the surface., DESIGNATION OF A CHISEL: The chisel is designed by the width of the cutting edge, length and, the commonly used name. For example, a Flat chisel having a cutting edge width of ‘Flat chisel 20 x, 250mm’, The figure below shows a chisel with it is various angles., 1.Rake angle, 2.Cutting angle, 3.Forging angle, 4.Chip torn cut, 5.Holding angle, 6. Clearance angle, SAFETY WHILE CHISELLING:, 1. Always chip towards the fixed jaw of the vice., 2. Before chipping, it is necessary to file a chamfer on the job to give seating to the chisel., 3. Chamfer the job from both the sides in case of a cast iron block, if the chipping to run up to the other, end. Otherwise, due to the brittle quality of the metal, the corner of the job will be rooted out in the, end., 4. Do not take too deep a cut. A cut approximately 1 ½ mm deep is enough., 5. For heavy chipping, use a leg vice., 6. To cut off the heavy rivet head, cut a groove in the head with a hacksaw frame or a cross cut chisel, and then remove the excess metal with a Flat or side cut chisel., Assignment:, 1., 2., 3., 4., , What is a chisel? Why it is used?, Mention the common types of chisel. Explain each in brief with a neat sketch and name the parts?, How chisels are designated?, Mention some safety precautions while chiseling, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 33 of 96

Page 34 :

PRODUCTION TECHNOLOGY-1, , UNIT 7: HAMMERS, HAMMER:, Hammers are one of the most primitive tools that are in use today. They have a metallic head with a, wooden handle. They are used for punching, bending, striking, riveting and forging., They are made of alloy steel having 0.6 percent of carbon and are usually drop forged. Hammers have, hardness 43 – 51 HRC., TYPES OF HAMMERS, 1. Ball pein hammer, 2. Cross-pein hammer, 3. Straight pein hammer, , The following are the common types of hammers in use:, 4. Claw hammer, 5. Soft hammer, 6. Mallet hammer, , Types of hammers., A. Ball peen hammer, , F. Soft faced hammer, , B. Cross peen hammer, , G. Mallet, , C. Straight peen hammer, , H. Cross peen sledge-hammer, , D. Claw hammer, , I. Ripping hammer, , E. Sledge- hammer (double faced), , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 34 of 96

Page 35 :

PRODUCTION TECHNOLOGY-1, , BALL PEEN HAMMER, The Ball peen hammer is a common type of hammer used for striking while doing general, work in the shop or at home. The peen or the head of the hammer is ball shaped and hence the name. It, is used for forming the rivet head by spreading the shank of the rivet., , 1. Ball peen, 2. peen neck, , 4. Eye hole, 5. Pole neck, , 7. Face, 8. Handle, , 3. Cheek, , 6. Pole, , 9. Length of handle, , The following are the main parts of a hammer., PARTS OF A BALL PEEN HAMMER, CHEEK: The flat portions on both sides in the middle of the hammer head are called as cheeks. Here, the manufacturer’s name, weight etc. is stamped., 1. EYE HOLE: The hole provided for fixing, the handle is called as the Eye hole. It is oval and tapered, from both the ends to the middle. The hole is oval so that the hammer should not rotate in the handle, and it is tapered for better grip., 2. FACE: The flat portion in the front which strikes the job is called as the Face. This is hardened and, tempered to 41 to 53HRC to a maximum of 13mm length. The face has a small curve that helps in, striking at the exact position., 3. HANDLE: It is the holding portion and is made of wood and is introduced in to the eye hole and is, secured firmly with the help of the handle wedges., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 35 of 96

Page 36 :

PRODUCTION TECHNOLOGY-1, , 4. PEIN: It is that part of the hammer which is opposite to the face. The peen is used for riveting, and, peening., 5. PEIN NECK: It is the radius portion joining the peen and the center of the metallic head., 6. POLE NECK: It is the radius portion joining the pole and the center body of the metallic head., 7. POLE: The cylindrical portion adjacent to the face is called the pole. It is hardened near the face., , 1. CROSS PEIN HAMMER: The peen of this hammer is flat and is perpendicular to the handle. It is, used for bending sheet, binding, providing collars etc., 2. CLAW HAMMER: This hammer head has a cut in the center and is bent to a sharp curve. It is used, for pulling nails out of wood with the help of the head while the face is same as that of a ball pein, hammer. This is mostly used by cobblers and carpenters. Sometimes the peen has a small curve on, the claw and is called as a Ripping hammer., 3. MALLET HAMMER: A wooden hammer is called a mallet. It is used by carpenters to drive their, tools and by sheet metal workers for bending thin sheets., 4. STRAIGHT PEIN HAMMER: The peen of this hammer is parallel to the handle. It is used for, stretching of metal, working of corners etc., 5. SLEDGE HAMMER: Sledge hammer are used by black smiths, wood cutters, stone breakers,, fabricators, etc. For heavy jobs. There are Three types of sledge hammer. They are:, 1. Double faced, 2. Cross peen, 3. Straight peen, 6. SOFT HAMMER: It is made up of soft metals like copper, aluminum, lead etc. It is used for, hammering finished jobs specially in an assembly shop., DESIGNATION OF A HAMMER:, Hammers are designated according to the following:, a) Type of hammer, b) Weight of hammer and, c) peen, E.g. ‘0.5 kg. Straight peen hammer’, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 36 of 96

Page 37 :

PRODUCTION TECHNOLOGY-1, , Hammers are available in various weights like 0.25kg, 0.5kg and 1kg for common, hammers and 2-10kg for sledge hammer., SAFETY PRECAUTIONS WHILE HAMMERING:, 1. Handle should be properly fixed., 2. Select a hammer of correct weight for a suitable job., 3. Check the handle head for cracks., 4. The face of the hammer should be free from oil., , Assignment:, 1. What is hammer? Why it is used?, 2. What is the percentage of carbon present in the hammer and mention its hardness?, 3. What are the different types of hammer? Explain each in brief with a neat sketch?, 4. Draw a neat sketch of ball peen hammer and explain its parts in brief?, 5. How hammers are designated?, 6. Mention some safety precautions while hammering?, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 37 of 96

Page 38 :

PRODUCTION TECHNOLOGY-1, , UNIT: SCRAPERS, Scraping is the process of removing small chips from metal surfaces by means of a sharp-edged, tool called the scraper., Producing flat surfaces by manual scraping requires a high degree of skill, normally done to, provide good sliding surface and accurate gauging etc. Scraping leaves plenty of cavities which allow oil, to collect and reduce the contact surface., Types of Scraper, Most commonly used scrapers are, , , , , , Flat scraper, Hook scraper, Half-round bearing scraper, Triangular scraper, , Flat Scraper: It is also named as ‘end scraper’. It is the most frequently used. It is used for removing, metal from flat surfaces. The modern flat scrapers have tungsten carbide tip brazed or held with a, holder. The blade must have slight curvature on the cutting edge and the corners are rounded which, helps to scrape exactly the high spots., , Hook Scraper: It is used for frosting, flanking and producing various designs on the end plates,, surface plates, machine columns and other jobs. It looks like flat scraper except its cutting end is bent to, form a cutting edge., Half round Bearing Scraper: It is used for scraping curved and cylindrical surfaces-split bearing,, big bush bearing etc. It is also called as half-round because the body is curved., Triangular Scraper: It is used for scraping curved surfaces and scraping holes and bores., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 38 of 96

Page 39 :

PRODUCTION TECHNOLOGY-1, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 39 of 96

Page 40 :

PRODUCTION TECHNOLOGY-1, , UNIT: SCREW DRIVERS, The screwdriver is one of the most commonly used tools in the workshop and at, home. It is used to loosen and tighten screws which have slots in their heads., Sizes of the Screwdriver: The size of screwdriver is measured by the length of the shank and is, available in a variety of sizes. Sizes of 50-500 mm are very common., Types of Screwdriver: The commonly used types are listed below, , , , , , , , , , , , , Standard, Cabinet, Standard with a square shank, Flat blade (London pattern), Electrician’s screwdriver, Motor, Off-set, Phillips, Ratchet type screwdriver, Stubby or close-quarter, Watchmaker’s screwdriver, , Standard Screwdriver: This is used for general work. Some screwdrivers of standard makes are, equipped with stronger shanks and heavy-duty handles, and are used for heavy duty work., Cabinet: This is used for driving wood screws. The handle is made flat on two sides to get an extra, grip to drive the screws in wood. Carpenters and cabinet makers use such type., Standard with a square shank: Its shank is square. The wrench is sometimes used for turning the, shank to get a greater force. Otherwise this screwdriver has the same parts as a standard screwdriver., Flat blade (London Pattern): This is also used by cabinet makers and carpenters. The blade is, made from a flat strip to make it stronger. The width of the point in such a blade is more than the length, of the screw slot so that a greater driving force while fitting the screws inn wood is achieved., Electrician’s Screwdriver: It is like the standard screwdriver but has a long thin shank and is, insulated. It is very useful for driving small screws and some are equipped with a small mechanism for, testing live wires. The handle of this is generally made from cellulose acetate moulds., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 40 of 96

Page 41 :

PRODUCTION TECHNOLOGY-1, , Motor Screwdriver: This has short shank and used where there is a limited space. The shank is flat, throughout., Off-Screwdriver: These have a bent shank with points on both ends. It is used for driving screws, that cannot be reached with a straight shank screwdriver. One of the points is forged from an octagonal, bar in line with the shank and the other is at 900, making it easy to drive even where the space is limited., Phillips Screwdriver: The tip of these have slots and is cross-shaped. The blade suits the head of a, Phillips head screw and gives better grip and also prevents damage to the head., Ratchet Screwdriver: This type is used for fast motion screw driving. The ratchet is fitted in the, handle. The hand is not lifted for fresh motion to turn the screw clockwise or anti-clockwise. The most, common type us ratchet type off-set screwdriver. This can be adjusted quickly for right and left-hand, drive., Stubby Screwdriver: This has a very short shank and is used where there is limited space. This is, commonly used by electricians and motor mechanics., Watch-maker’s Screwdriver: These are small, fully metallic screwdrivers coming in sets of four or, six. Some screwdrivers are made with detachable handles which are used for all shanks., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 41 of 96

Page 42 :

PRODUCTION TECHNOLOGY-1, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 42 of 96

Page 43 :

PRODUCTION TECHNOLOGY-1, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 43 of 96

Page 44 :

PRODUCTION TECHNOLOGY-1, , UNIT: WRENCHES AND SPANNERS, Wrenches or spanners are used mainly for fastening purpose. They are used for tightening and, loosening of nuts and bolts, pipes etc. There is different type of wrenches. Some wrenches are also called, spanners. Spanners are made from Chrome Vanadium steel and are usually dropped forged. They are, specified by their type and the size of the jaw opening. This differs for fixed and adjustable wrenches., Spanners are of the following type:, OPEN END WRENCH, The open end spanner has its head positioned straight or angular to the axis of the center line. It is, used where there is sufficient space for its insertion and where the nuts and bolts are freely accessible, SOCKET WRENCH, These have detachable parts such as the, head and its shafts of different sizes., , This, , wrench is used where it is difficult to use an, open end wrench. It is generally inserted into, the parts where it is to be used. Hence the necessity of lengthier shafts arise. It is used in assembly shop,, automobile shop etc., , 1. Close end wrench., 2. Shaft, 3. Head, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 44 of 96

Page 45 :

PRODUCTION TECHNOLOGY-1, , PIPE WRENCH, It is used for fastening or unfastening of pipes, pipe fittings round bars etc. it is commonly used, by the plumber. The jaws of the pipe wrench have serrations to have a better grip on the job. The pipe, wrench can be adjusted to various openings by means of an adjusting screw and tightened on the job., 1., 2., 3., 4., 5., 6., , Pivot, Spring, Handle or Lever, Spring, Adjusting Nut, Movable Jaw, MONKEY WRENCH The jaw of this wrench open parallel and can be moved using a screw and, , hence can be adjusted to a range of openings. The jaws being flat, do not damage the sides of the nut., , 1. Fixed jaw, , 2. Knurled nut on screw, , 3. Movable jaw, , CLOSE END WRENCH, , This is similar to single end wrench but it encloses the nut entirely. It is also called as a box, wrench., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 45 of 96

Page 46 :

PRODUCTION TECHNOLOGY-1, , TWELVE-POINT BOX WRENCH OR RING SPANNER, The ring spanner has twelve notches in the hole. The point of the nut may be gripped by six, notches in case of hexagonal nut and four notches in case of a square nut. This is commonly known as a, ring spanner. It can be used where a very little turn of the spanner is only possible and is easy to handle., , TEE-SOCKET WRENCH, This wrench has the appearance of the letter ‘T’. It has a socket opening which, helps for applying greater force for driving the nut. It is used at all places where single, end and double end wrenches are difficult to use., 1. Handle, 2. Shank, 3. Head, , OFF-SET SOCKET WRENCH, This is similar to a ‘T’ socket wrench but is used for light duty work., , ADJUSTABLE WRENCH: This type of wrench can be used where, the nut size is having an odd dimension. Here one end of the wrench, can be adjusted with the help of a screw., 1. Knurled nut on screw, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 46 of 96

Page 47 :

PRODUCTION TECHNOLOGY-1, , ALLEN WRENCH, It is an extruded hexagonal bar of a standard size which fits into the socket of a standard Allen head, screw. It is commonly known as an Allen key. It is bent to drive an Allen head screw., , PIN HOOK SPANNER, It is used to drive round nuts having holes or notches in a cylindrical or a flat surface., a. For flat surfaces, b. For cylindrical surfaces, , 1. Pin, A, , SAFETY WHILE USING WRENCHES:, 1. If the wrench has got burrs, grind off the rough spots to avoid injury to the hands., 2. It is safer to pull the wrench towards the worker than to push it away., 3. Select an open end wrench or a socket wrench where ever possible. Avoid the use of a adjustable, wrench., 4. To get an extra force, never strike the wrench with a hammer. Use a mallet or a soft hammer if needed., 5. When the nut is not coming out due to rusting, etc with a normal pull, give sudden but controlled jerks., Assignment:, 1. From what material are the wrenches made up of? What is the purpose of using a wrench?, 2. How are spanners specified?, 3. What are the types of wrenches, explain briefly each with a neat sketch?, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 47 of 96

Page 48 :

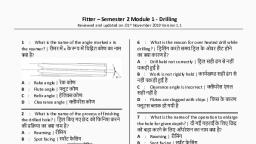

PRODUCTION TECHNOLOGY-1, , UNIT: DRILLS AND DRILLING MACHINES, DRILLING:, Drilling is an operation of producing a hole in a solid material by means of a cutting tool called as, a drill. Twist drills and flat drills are commonly used for producing holes. Drills are normally made of, High Speed Steel. Tungsten carbide drills are also available., , TYPES OF DRILLS, The following are three main types of drills:, A. Flat drill, B. Straight fluted drill, C. Twist drill, The other types of drills are, 1., 2., 3., 4., 5., 6., 7., 8., , Carbide tip drills, Counter sink drills, Counter bore drills, 3 or 4 fluted drills, Long series drills, Oil hole drills, Stub series drills, Sub land or step drills, , A. FLAT DRILL, , A Flat drill has the cutting lips ground at an included angle of 900 – 1200., The relief for the clearance at the cutting edges is 30 – 60. Flat drills do not have flutes cut along the, body and hence pose difficulty for chip removal. Hence deep holes cannot be drilled by using these drills., A flat drill is preferred for drilling of Brass as it does not dig into the material. The flat drill is shown in, the figure., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 48 of 96

Page 49 :

PRODUCTION TECHNOLOGY-1, , B. STRAIGHT FLUTED DRILL:, , A straight fluted drill is a drill having its flutes running parallel to its axis. A straight fluted drill, has a Zero rake. Chip removal is affected due to the straight nature of the flutes. The drill has to be often, removed for clearing the chips during drilling. In drilling of soft materials like Brass, the drill tends to, advance faster than the rate of feed and the drill digs into the material. Such problems are not encountered, when using a Straight fluted drill. When drilling sheet metal, the straight fluted drill does not tend to lift, the sheet from the table as in the case of a twist drill., C. TWIST DRILL, , These drills are the most commonly used drills for general purpose drilling., The parts of a Twist drill are explained below:, The Twist drill is typically a Two flute cutting tool having two main parts:, 1. The Body, 2. The Shank, 1. THE BODY: The body consists of the cutting point and the cylinder and with two opposite helical, grooves, or flutes. The flutes have a special profile forming the cutting edges and providing the, necessary space for the flow of chips, which come up along the flutes from the hole being drilled., Two narrow margins running along the flutes on the cylinder of the body guide the drill in the hole, and reduces its friction against the hole surface. The body consists of the following parts:, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 49 of 96

Page 50 :

PRODUCTION TECHNOLOGY-1, , a. DEAD CENTER and POINT, , The point is the conical portion at one end of the drill opposite to the shank. Normally this point, is ground at 1180 with each cutting lip or edge sharped at an angle of 590 with the axis af the drill. The, point tapers down to a sharp edge and is the extreme point of the drill. This is called as the Dead center, of the drill. The dead center is usually 1/3rd the diameter of the drill. The dead center should always lie, in the exact center of the drill axis., b. FLUTES:, The helical grooves provided throughout the entire length of the body are called as the flutes of the drill., They provide a pathway for the chips to escape from the hole during the drilling process. Drills for cutting, hard materials are sometimes providing with three of four flutes. An increase in the helix angle of the, drill flutes tend to weaken the drill body particularly so in smaller drills., , c. LIPS or CUTTING EDGES:, It is that part which actually cuts the material when drilling a hole. Lips are formed by the, intersection of the flutes and the point. The length of the lips should be ground always equal, as otherwise, only one lip will take the cut causing a rough hole and damage to the drill., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 50 of 96

Page 51 :

PRODUCTION TECHNOLOGY-1, , The figure shows the nomenclature of a twist drill in detail., A lip clearance is often provided on the lips. Lip clearance is that surface of the point that is ground away, or relieved just back of the cutting lip of the drill. The lip clearance allows the drill to enter the metal with, less friction and resistance., d. BODY CLEARANCE:, The portion of the land that has been cut away so that it does not rub the walls of the hole being drilled, is called as the Body clearance., e. MARGIN or LAND:, The margin is the narrow strip shown in Fig. 53 and Fig. 54. It ensures the finish, Diameter of the drill and extends along the ensure length of the flute., f. WEB:, Web is the central portion of the drill body that joins the lands of the drill. It runs throughout the length, of the flutes. The web is thicker at the ends than at the point to give enough strength to the drill., 2. SHANK:, Most taper shank drills are provided with a groove like neck between the shank and the body. The neck, is utilized for stamping the size, material of the drill and the manufacturer’s name or trade mark. There, are three types of shanks in common use. They are straight, taper and square shanks. The drill is held at, the shank and rotated. Taper shanks, generally in Morse tapers are made in drills from 6 to 80mm in, diameter and Straight shanks in those up to 20mm in diameter. Taper shank drills are placed directly into, the bore of the drilling machine spindle of through taper sleeves and held in the spindle by a drill chuck., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 51 of 96

Page 52 :

PRODUCTION TECHNOLOGY-1, , 1., , CARBIDE DRILL, , a. Carbide tipped twist drill with a taper shank, b. Carbide tipped Straight fluted drill, The drill has a straight flutes and a straight shank. The drill is used for making holes in hardened, steel in range of 48-62 HRC. It has a brazed carbide tip on the point, ., 2. CENTER DRILL: Combined drill and countersink commonly referred to as a Center drill, is used, to produce both a short drilled hole and a countersunk hole in one operation. The angles on these drills, are always 600. This is used for drilling of center holes in work to be turned between centers in a lathe, and for starting holes in the correct location on the drilling machine., , 3. COUNTER SINK DRILL, , This drill is used for making cones shaped enlargement of hole mouth for counter sunk screw heads to, seat. The point comes with different angles. The common angles are 600 , 900 , and 120 ., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 52 of 96

Page 53 :

PRODUCTION TECHNOLOGY-1, , 4. COUNTER BORE DRILL, , 1. Tang, 2. Shank, 3. Neck, , 4. Flute, 5. Pilot, , This drill is used for enlarging predrilled holes for the seating pf Allen screw heads. The drill is, equipped with integral pilots which helps in proper alignment of the drill., 5. THREE OR FOUR FLUTED DRILLS, , 1.Tang, 3. Neck, , 2. Shank, 4. Lip, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 53 of 96

Page 54 :

PRODUCTION TECHNOLOGY-1, , These drills are used for enlarging core and punched holes. The advantage of more flute is proper location,, improved finish, increased accuracy in the hole size and increased rate of metal removal. These are also, called core drills or multi-fluted drills., 6. LONG SERIES TWIST DRILL, , The fluted part of this drill is more than the length of a twist drill. This drill is used for drilling, deep holes. This drill comes in straight shanks only., 7.OIL HOLE DRILL, , The oil hole drill is used in large scale production units. There are holes in the flutes through which oil is, forced to the cutting edges. This helps in efficient cooling of the point and also forces the chips out of the, drilled hole., 9. STUB SERIES DRILL:, , 1. Straight shank 2. Short flute length, This drill has a short body. Therefore, it does not wobble or vibrate. This drill is used for centering work, and so is called centering drill. They come in parallel shank only., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 54 of 96

Page 55 :

PRODUCTION TECHNOLOGY-1, , 1. SUBLAND or STEP DRILL, , A Step Drill may have two or more diameters, produced by grinding various successive steps on the lands, of the drill. These steps are usually separated by square or angular cutting edges, as the individual jobs, may require. The step drill is useful for most of the jobs requiring multiple-diameter drilling. It is, extensively used because it can be made by grinding down and stepping an ordinary drill. Some thinning, of the web is usually required when so made., Sub land drills, perform the same function as the step drill, while its construction is somewhat, different. The step drill has its steps or different diameters on the same land, while the Subland drill has, two distinct lands running substantially to the entire length of the flutes. This is shown in the figure., DRILLING MACHINES:, A Drilling machine is one in which the following operations can be performed:, 1. Drilling of through or blind holes., 2. Boring with a single point tool, counter-boring and countersinking., 3. Reaming for high grade accuracy and surface finish., 4. Cutting of internal threads with Taps., 5. Spot facing on external and internal bosses, lugs etc., The different types of drilling machines are:, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 55 of 96

Page 56 :

PRODUCTION TECHNOLOGY-1, , 1. Gang Drilling Machine, 2. Hand Drilling Machine, a. Hand Grip Drilling Machine, b. Pistol Grip Drilling Machine, 3. Hand Drilling Machine, , 4. Multi Spindle drilling Machine, 5. Radial Drilling Machine, 6. Sensitive Drilling Machine, 7. Upright Drilling Machine., , 1. GANG DRILLING MACHINE, A number of drilling machine heads along with the pillars are mounted on the same table. This, machine is used for large scale production work where different sizes are done on the same job. It is done, without removing the job from the table. Such machines are called Gang Drilling Machines., Gang-type, six spindle drilling machine with both hand and power-feed., 2. HAND DRILLING MACHINE, This machine is held manually there are two types of hand drilling machine., 1. Pistol Grip drilling machine, 2. Heavy Grip drilling machine, , a. PISTOL GRIP DRILLING MACHINE:, They are used for drilling holes less than diameter 6mm., b. HAND GRIP DRILLING MACHINE:, They are used for drilling holes between diameter 6mm-diameter 13mm. The pistol grip drilling, machine is held in one hand and this machine has a finger press retaining button switch, while heavy duty, hand grip drilling machines are held in two hands., Fig. 66 shows the common types of hand drilling machines., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 56 of 96

Page 57 :

PRODUCTION TECHNOLOGY-1, , Hand Drilling machines, A. Hand drilling machine – Light duty, B. Hand drilling machine - Heavy duty, C. Hand drilling machine – Manually operated, , 1., 2., 3., 4., 5., , Switch, 6. Knurled grip, 11. Body, Handle, 7. Chuck, 12. Bevel gear wheel, Cable, 8. Drill, 13. Chuck mounting threads, Air holes 9. Handle, 14. Chuck, Motor, 10. Hand wheel, 15. Drill, , 3. MULTI SPINDLE MACHINE:, This machine has number of spindles run by a motor mounted on it. This drilling machine is used, when a number of holes of the same size or of different sizes are to be drilled on the same surface., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 57 of 96

Page 58 :

PRODUCTION TECHNOLOGY-1, , 4. RADIAL DRILLING MACHINE, This machine is used for working on heavy and large components. The arm of the machine is, capable of moving in the radius of its column. This machine has the following special features., 1. High capacities of drilling large holes., , 2. Large clamping surface and a wide range of heights between spindle and base., 3. A wide range of spindle feeds which enables to drill large and small holes as well as to perform, reaming and tapping., 4. Mostly the elevation of the arm is carried with the help of motor., 5. Ample rigidity which avoids vibration. A few radial drill machines have universal head movements., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 58 of 96

Page 59 :

PRODUCTION TECHNOLOGY-1, , 6. SENSITIVE DRILLING MACHINE, , A Sensitive Drilling Machine is a belt driven general purpose drilling machine used to produce a, range of small holes. These drilling machines are made in the Floor model, Bench model and Multiple, spindle models. It is called as a sensitive drilling machine because of its accurately balanced spindle., 7. UPRIGHT DRILLING MACHINE, This is a heavy structured machine and therefore larger sized holes than that are possible on a sensitive, drilling machine are drilled on this machine. They are equipped with slower speeds than sensitive drilling, machines and the spindle is driven by stepped pulley through “V” belt or a flat belt. This has both manual, and automatic feed mechanism., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 59 of 96

Page 60 :

PRODUCTION TECHNOLOGY-1, , SPECIFICATIONS OF A DRILLING MACHINE:, 1. Column diameter: E.g. 100 mm, 2. Capacity-maximum size of drill that can be drilled on the machine, say, 18mm., 3. Capacity swing- The maximum diameter of the job can be held on the machine table while drilling,, E.g. 250mm., 4. Distance from the center of the spindle to the center of the column., 5. Feed- whether manually operated or automatic, feed range E.g.0.05-0.18., 6. Height of the machine. E.g.2100mm, 7. Maximum vertical traverse of the spindle E.g.150mm, 8. Maximum distance from the table to the highest point of the spindle E.g. 218mm, 9. Motor capacity E.g. H.P. of motor, R.P.M-1200, A.C. or D.c. and voltage-440v., 10 Speeds-Range of rpm. E.g. 50, 75, 100, 215, 400, 600, 750, 800,1000, rpm., 11.Spindle hole taper- type and number of taper holes. E.g. M.T.3., (Morse Taper 3)., 12.Table size. E.g. 300x350mm., 13.T-slots in the table.E.g.6 slots x 14H7, 14.Type of starter, whether supplied with drill chuck and key are coolant, pump., 15.Type-whether Sensitive, Upright, Radial etc., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 60 of 96

Page 61 :

PRODUCTION TECHNOLOGY-1, , DRILLING ACCESSORIES:, The common types of drilling accessories are mentioned below:, 1. Drill chuck, 2. Sleeves, 3. Drill drift, , DRILL CHUCK, , The drill chuck is the most common accessory used in drilling machines for holding of mostly, drills and reamers with straight shanks. These chucks come in two varieties, The keyless chuck and the, keyed chuck. Both these types are illustrated in the, Three jaw self-centering keyless drill chuck, a. Construction, b. Setting, 1. Shank, 4. Jaws, 2. Sleeve, 5. Body, 3. Spring, Three jaw self-centering Key type drill chuck, 1. Jaw nut, 2. Sleeve, 3. Key hole, 4. Key, SLEEVES, According to the type of shank, Twist drills, Reamer, Counter bores etc., are held in the drilling, machine spindle by three methods. Directly in the taper bore of the spindle, in Taper sleeves and in the, drill chucks. The placement of the drill in the, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 61 of 96

Page 62 :

PRODUCTION TECHNOLOGY-1, , Spindle bore directly is shown in the fig.72. Morse taper is the most commonly used taper in the drilling, machine spindle. Morse tapers are designated in numbers 0-6., Taper sleeves are used when the taper diameter of the drill or reamer is less than the bore diameter of the, machine spindle. The sleeve with the drill is inserted into the spindle bore and held there by the selflocking Morse taper. This is illustrated in the Fig.72.Sleeves are available in sets according to the increase, in the taper bore diameter., a. Directly in spindle hole taper, Tool holding methods set of taper sleeve, b. Setting a drill in a sleeve, , DRILL DRIFTS, Usage of drifts to remove a tool from the spindle, , a. Using plane Drift, b. Using a Safety drift, The drill drift is an accessory on the drilling, machine used to remove the taper shank drills or, sleeves from the spindle. The drill drift is, introduced into the slot provided in the spindle and, a light tap is given to push out the drill or sleeve thus, releasing the self locking. shows the drill drift in, use., , Cutting fluids (Coolant):, The purpose of using coolant is to minimize the wear & tear of cutting tools, which increases the, life of cutting tools by reducing the heat generation. To obtain smooth cutting action without much friction., To get good surface finish., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 62 of 96

Page 63 :

PRODUCTION TECHNOLOGY-1, , Cutting fluids play an important role in reducing the wear of cutting tools., They help to carry away the heat generated during cutting operations., Flush away the chips from the cutting points., Maintain the accurate dimensions., Produce good quality finish., Prevent corrosion., Operate machines on a high speed and feed., Cutting fluids of different types are available, but only those commonly used are explained here., Soluble oil: - soluble oil is most popular variety of cutting fluids., Soluble oil of different types is available., This is an emulsified oil, which, when mixed with water, is an excellent cutting fluids., Soluble oil is comparatively cheap, and can be used for a number of machining operations., Soluble oil should be mixed correctly and the proportions of oil and water is recommended by the, manufacturer should be strictly followed., It may be noted that for preparing a stable emulsion, oil should always be added to the water and not vice, versa., While mixing, it should be continuously stirred., Indian oil corporation produces three types of soluble cutting oils, SERVO CUT ‘S’, SERVO CUT XL, and SERVO CUT CLEAR., Servo cut ‘s’ oil when mixed with water, forms a milky emulsion., This oil has high cooling and lubricating properties. It is capable of minimizing tool wear and improving, surface finish. This oil is recommended for a variety of cutting operations of ferrous and nom ferrous, metals. It is used in concentration of 5% for general machining operations, and for grinding, more dilute, emulsions are prepared., Servo cut XL is a superior quality soluble oil. This, when mixed with water, forms an opaque emulsion., This oil gives good performance in hard water., Servo cut clear oil, when mixed with water and used, will give clear visibility during machining. This has, excellent cooling and lubricating properties, and is capable of ensuring long tool life and improved surface, finish., Oil cutting fluids can cause metal cutting to ‘clog’ in operations like fine grinding where fine particles of, metals are removed. To overcome this, non-oily synthetic soluble cutting oils (chemical solutions) are, used., Using the correct cutting fluids while machining is important for maintaining tool life, efficiency in cutting, and for obtaining good quality surface finish., Synthetic soluble cutting oils: - this oils consist basically of mixture of chemicals which are soluble in, water and are mainly used as grinding coolants. These oils have high anti rust properties. The cutting, fluids of this type are servo synthetic 2 and servo synthetic 5., Servo synthetic 2 is recommended for grinding ferrous metals, high nickel and titanium alloys only., Servo synthetic 5 is suitable for grinding iron, steel, non-alloyed and nickel chrome steel., These oils are not recommended for machining of non-ferrous metals., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 63 of 96

Page 64 :

PRODUCTION TECHNOLOGY-1, , SAFETY WHILE DRILLING:, 1. clean the machine spindle thoroughly before mounting the drill chuck to ensure proper seating., 2. Clamp the job rigidly to the vice or table before starting to drill., 3. Do not leave the drift in the machine spindle after removing the sleeve or drill chuck., 4. Do not force the drill into the work. Use optimum cutting speeds and feeds., 5. Do not change gears while the machine is in the running condition., 6. Never try to hold the work in hand., 7. Never remove the clips by hand. Always use a brush for cleaning the chips., Use a proper coolant while drilling, otherwise the hot chips may cause injury., TROUBLE SHOOTING IN DRILLING:, SYMPTOMS, 1.Breaking of the drill., , PROBABLE CAUSES, 1.Blunt drill, 8. Less clearance, 9. Less cutting speed, 10. Chip blocking in the, flutes, , REMEDIES, 1. Resharpen the drill, 2. Provide, proper, clearence, 3. Use correct speed., 4. Lift the drill more, oftenly during work., , 2.Burning marks in the, cutting edge., 3. Drill refuses to enter, work., , 1. Dry drilling, 2. Higher feed rate., 1.Dull drill., 2. Too little lip clearance., , 1., 2., 1., 2., , 4. Hole larger than the drill 1. Unequal lip length., size., , use coolant, use optimum feeds., Sharpen the drill, Provide proper lip, clearance, 1. Grind the lip length, equally., , Assignment:, 1. What is drilling?, 2. Mention different types of drills?, 3. Write a note on, (a) Flat drill., (b) Straight fluted drill, (c) Twist drill., 4.With a neat sketch?, 4. Briefly explain the body of the drill?, 5. Mention the different parts of the body of the drill?, 6. Briefly explain the dead center and point in the body of the drill with a neat sketch?, 7. Write a note on, (a) Flutes, (b) Lips or cutting edges, (c) Body clearance, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 64 of 96

Page 65 :

PRODUCTION TECHNOLOGY-1, , (d) Margin or land, (e) Web., 8. Write a note on shank of the drill?, 9. Write a note on carbide drill, center drill, counter sink drill, center bore drill with a neat sketch?, 10. Write a note on, Three or four fluted drills, long series twist drills, oil hole drills, stub series drills with, a neat sketch?, 11. Write a brief note on sub land or step drill with a neat sketch?, 12. What are the different operations that can be performed in a drilling machine?, 13. What are the different types of drilling machines?, 14. Explain gang and hand drilling machines?, 15. Explain with a neat sketch with sensitive drilling machine?, 16. How are drilling machines specified?, 17. Mention the different drilling accessories and explain?, 18. Mention some safety while drilling?, 19. Mention some symptoms, probable causes and remedies in drilling?, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 65 of 96

Page 66 :

PRODUCTION TECHNOLOGY-1, , REAMERS:, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 66 of 96

Page 67 :

PRODUCTION TECHNOLOGY-1, , These are finishing tools used when a hole must be finished to a high degree of accuracy and finish. A, square shank allows the wrench to be used for rotating the reamer in the hole. The teeth on one end of the, reamer are tapered slightly for a certain distance, so that it can enter the hole and act as a guide whereas, in machine reamers this taper is absent, but a chamfer at the tip is provided for easy entry. Hand reamers, should never be turned back wards while reaming as this may damage the cutting edges. Both roughing, and finishing tapered hand reamers are available for all standard sizes. Since the chip does not fall readily,, tapered hand reamers should be removed from the hole and the flute should be cleaned frequently., MACHINE REAMERS OR CHUCKING REAMERS, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 67 of 96

Page 68 :

PRODUCTION TECHNOLOGY-1, , These reamers may be used in drilling and milling machines for both roughing and finishing of, holes. Machine reamers normally have taper shanks, but straight shank reamers are also available. They, are also called as chucking reamers because of the method used to hold them. Machine reamers are, available in a wide variety of types. Some of the types are straight shank helical flute reamer, expansion, reamer, rose reamer, stub screw machine reamer, jobber reamer, taper finishing reamer, taper shank bridge, reamer, die maker’s reamers with high spiral flutes, taper shank combination drill and reamer etc. these, reamers are illustrated in the FIG., , SPEEDS FOR REAMING:, The speed or R.P.M. for reaming is normally 1/3 rd the speed used for drilling., SAFETY WHILE REAMING:, 1. always store reamer in separate boxes or containers to prevent the cutting edges from nicking and, burning., 2. Cutting fluids should be used while reaming to improve hole finish., 3. Do not turn the reamer backwards while taking it out of the hole for cleaning the chips. This may, damage the cutting edges., 4. Do not use a hand reamer as a machine reamer and vice-versa., 5. Never rotate the reamer backwards. This will damage the cutting edge., 6. Never roll or drop the reamer on a metal surface., 7. When it is not in use keep it oiled to prevent it from rusting., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 68 of 96

Page 69 :

PRODUCTION TECHNOLOGY-1, , UNIT: MARKING AND LAYOUT TOOLS, MARKING AND LAYOUT TOOLS:, The following are the common types of marking and layout tools in a workshop that is of relevance to, a toolmaker., 1., 2., 3., 4., 5., 6., 7., 8., , Calipers and Dividers., Punches., Surface plates., Scribers., Try squares., Angle Plate., V Block., Surface gauges, 1. CALIPERS and DIVIDERS: Dividers are used to mark out circles, arcs for dividing straight and, , curvilinear lines and for plotting geometrical figures. They are also used to transfer dimensions from the, rulers to the work pieces. Calipers are used as checking instruments and to measure the inside and outside, diameters of generally. These instruments are finding less usage in the present days. The different types, of calipers are shown in the figure below., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 69 of 96

Page 70 :

PRODUCTION TECHNOLOGY-1, , 2. PUNCHES:, , As the name suggests these are used for punching on marked lines, hole centers, boundaries etc., Punches are classified into three types depending on the included angle of the point., 1.Prick punch (300), 2.Dot punch (600), 3.Center punch (900), Prick punches are used to make small indent marks on layout lines. The dot punch is used to enlarge, the mark made by the prick punch and enable it to last longer. Center punches further enlarge the mark, made by the dot punches and are used to guide the drill bits. Fig. 78 shows the three different types of, punches., 1. Taper Head, 2. Knurled length of body, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 70 of 96

Page 71 :

PRODUCTION TECHNOLOGY-1, , 3. SURFACE PLATE:, , The surface plate is usually a Seasoned Cast iron block, which is scraped to a high degree of accuracy, and flatness. The surface plate is mainly used for marking purposes. Angle plates, Vernier height gauges, etc. are used on the surface plate for marking purposes. Surface plate are also made of granite are hardened, steel. The fig shows a surface plate., 4. Scribers :, Scribers are used for marking lines, on work surfaces with the aid of steel, rules, squares and templates. Scribers, are made of Tool steel. To layout on, well-finished sheet surfaces, scribers, made of brass are usually used., Scribers come in three main varieties., Single, , point,, , double, , point, , and, , removable point type. The single, point scriber is a steel rod of 150 to 250mm in length and 4 – 5mm in diameter. One end is hardened to a, length of 20 – 30mm from the tip and sharpened at an angle of 15 0. The other end bent to form an eye 25, – 30mm in diameter., The double point scriber is a steel rod with both the ends pointed; one point is bent at right angles to, the shank. The shank is greater in diameter and knurled to provide a better grip. The bent end is used in, reaching through holes etc. The scriber with removable point is similar to a watchmaker’s screwdriver;, the point is a ground and a sharpened steel rod. The Fig. indicates the above mentioned scribers., , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 71 of 96

Page 72 :

PRODUCTION TECHNOLOGY-1, , 5. TRY SQUARES: Try squares are precision tools made of stabilized hardened steel, which are, normally made of two pieces and riveted to each other. Perfect right angle is maintained between the Beam, and the Blade. The try square is mainly used for checking the right angles of machined jobs and also for, setting jobs on the machine. The blade is thinner than the beam and is lengthier than the beam. Try squares, are of the following types:, 1.Fixed try square., 2.Adjustable try square., 3.Bevel edge try square., 4.Tool and die makers square., , Fixed try squares, as the name suggests, have the blade and the beam fixed to each other by means of, rivets. Adjustable try squares have an adjusting screw by which the length of the blade can be varied, forward or backwards depending as per requirements. Bevel edge try squares have their edges beveled at, 450 and as such provide an improved perfect line contact with the job. Tool and die maker’s try squares, are mostly used by toolmakers. They have detachable blades and are useful for measuring small angles, and slots on inserts and precision job surfaces. The four types of try squares mentioned above are shown, in fig, , GOVT. TOOL ROOM AND TRAINING CENTRE, , Page 72 of 96

Page 73 :