Page 1 :

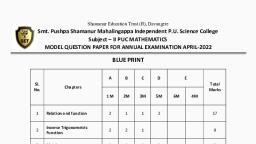

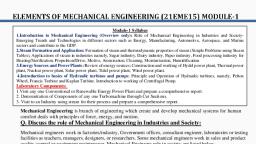

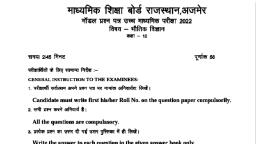

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , First Semester B.E Degree Examination, TIME: 03 Hours, , Elements of Mechanical Engineering 21EME15/25, Max. Marks: 100, , Note:, , 01. Answer any FIVE full questions, choosing at least ONE question from each MODULE., 02. Use of Steam tables are permitted to solve numerical on steam., , Module -1, Q. 1 a Discuss the role of Mechanical Engineer in the industry and Society, Role of Mechanical engineers in industries, 1.Designing, building/constructing, establishing, costing and maintaining all kinds of mechanical, tools, equipment’s, machinery, Robotics, mechatronics and electronic control of machinery., 2. To design power-producing machines, such as electric generators, IC engines, and steam and, gas turbines, as well as power-using machines, such as Refrigeration and Air-conditioning,, ventilation systems, Food processing, Farm machines, Airplanes &transportation vehicles., 3. To design the mechanical components of a building, the air and plumbing systems within a, building and all installations of machines and equipment at checking the dimensions of the, incoming material., 4. Conduct experiments methodically, analyze data and interpret results& Test and evaluate, theoretical designs, 5.Identify, formulate and produce effective solutions to emerging problems, 6.Evaluate final product’s overall performance, reliability and safety& Alter and modify design, to meet requirements and to eliminate malfunctions& Estimate budget and scope of project, , Mechanical engineers work in factories/industry, Government offices, consultant engineer,, laboratories or testing facilities as teachers, managers, designers, or researchers. Some, mechanical engineers work in sales and product quality control or equipment maintenance., Mechanical Engineers role in society are, 1. Eliminates excessive usage of resources by optimizing and improving efficiency., 2. To build things that make the world a better living place., 3. Reduces human effort and makes work easy., 4. Research and carry out projects to help the society live lives more comfortably& effectively, 5. The transportation solution. Millions of people die every year while traveling. Safety has, to be priority while designing new vehicles, , M, 10

Page 2 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , b With the help of a T-h diagram, Explain the various stages in the formation of Steam, Steam is a pure substance. Like any other pure substance, it can be converted into any of the, three states, i.e., solid, liquid and gas. A system composed of liquid and vapour phases of water, is also a pure substance. Even if some liquid is vaporized or some vapour get condensed during, a process, the system will be chemically homogeneous and unchanged in chemical composition., , Consider 1 kg of ice in a piston -cylinder arrangement as shown. it is under an Absolute Pressure, say P bar and at temperature –10C . Keeping the pressure constant, the gradual heating of the, ice leads to note the following changes in steam formation, are represented on a T-H diagram are, as explained below., , Region A-B: The heat given to ice increases its temperature from -10°C to 0°C. The volume of, ice also increases with the increase in temperature. At B the ice starts to melt which shows the, saturated solid condition., Region B-C: The ice melts into water at constant pressure and temperature. At C the melting process ends. There is a sudden decrease in volume at 0° C as the ice starts to melt. It is a peculiar, property of water due to hydrogen bonding, Region C-D: The temperature of water increases an heating from 0°C to 100°C The volume of, water first decreases with the increase in temperature, reaches to its minimum at 4°C and again, starts to increase because of thermal expansion. Point D shows the saturated liquid condition., During the process, a slight increase in volume of water (saturated water) may be noted. The, resulting volume is known as Specific volume of Saturated Water (Vf), Region D-E: The water starts boiling at D. The liquid starts to get converted into Vapour. The, boiling ends at point E. Point E shows the saturated Vapour condition at 100°C and 1 bar. The, resulting volume is known as Specific Volume of Dry Steam (vg), Region E-F: It shows the superheating of steam above saturated steam point. The volume of, Vapour increases rapidly, and it behaves as perfect gas. The difference between the superheated, temperature and the saturation temperature at a given pressure is called degree of superheat., , 10

Page 3 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , OR, Q. 2 a Enumerate the method of extracting energy from Wind with a neat sketch, The major parts are 1.The tower: most often metallic and cone shaped, it is usually white and, meets aeronautical requirements. It is 40 to 110 meters tall, with a base diameter of 4 to 7 meters., It contains an opening on the ground to allow access to variety of equipment. The rotor is located, upwards where the wind is strongest, and which allows for a lengthy blade., 2. The rotor: It is made up of three blades of composite material from 25 to 60 meters in length,, connected by a hub. The rotor pivots 360° to face the wind and to allow a maximum production, of electricity. The height at the tip of the blade varies between 90 and 150 meters for the largest, wind turbines. The blades of a wind turbine turn at an average speed of 10 to 20 rotations per, minute., 3. Gearbox: Inside the nacelle (the main body of the turbine sitting on top of the tower and, behind the blades), the gearbox converts the low-speed rotation of the drive shaft (perhaps, 16, revolutions per minute, rpm) into high-speed (perhaps, 1600 rpm) rotation fast enough to drive, the generator efficiently., 4. The pivoting nacelle: located at the peak of the tower, it houses the generator that transforms, the mechanical wind energy into electric energy. The nacelle pivots automatically depending on, the direction of the wind. Access to the nacelle is made by a ladder and/or a lift located inside, the tower. The primary characteristic of a wind turbine is its power or capacity. It is measured in, kilowatts (kW) or in megawatts (MW). Wind turbines installed today range from 850 kW to, 3,000 kW (or 3 MW). The energy produced by a wind turbine during its operation is measured, in kilowatt hours (kWh) and mainly depends on the wind speed., 5. Anemometers: is an automatic speed measuring devices and wind vanes on the back of the, nacelle provide measurements of the wind speed and direction. The Brakes are also applied, during routine maintenance., , Working Principle: To start, a windmill needs wind of at least 12 to 15 km/hr. The strength, of the wind makes the blades turn and initiates the rotor that transmits the energy received to a, generator that produces electric energy. The electricity is channeled by an underground electric, cable to the public grid. The difference in pressure between the two sides of the blade creates, an aerodynamic force that puts the rotor in motion. This motion is generally accelerated by a, gear-box and the mechanical energy transmitted by the gear-box is transformed into electrical, energy by the generator. The generator’s rotor turns at a high speed and produces an electric, charge of around 690 volts. This electricity cannot be used directly. It is handled thanks to a, converter, and then its charge is increased to 20,000 volts by a Step up transformer. The wind, turbines are set in the ground thanks to reinforced concrete foundations, often circular, covered, over with seeded soil. They are interconnected among themselves by underground electric, cables. Each wind turbine is connected to the transformer located at the foot and inside the, tower. The electric energy produced is sent towards the public distribution grid through a, delivery station., , 10

Page 4 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , b 5 kg of wet steam of dryness fraction 0.8, passes from a boiler to a superheater ata constant, pressure of 1MPa absolute. In the superheater the temperature increases to 350oC. Determine, the amount of heat supplied in the superheater., The specific heat of super-heated steam Cps = 2.25 KJ/KgK, , 10, , Given:, Wet steam = mw= (mf+mg) = 5kg ; Dryness fraction = x = 0.8, Temp.of Superheated steam = Tsup =3500c; Specific heat of Superheated steam = Cps = 2.25 KJ/KgK, Pressure = 1mg = 1 × 106 p but 1 bar = 105 pascal, So, P = 10bar, From Steam table A1 at P =10bar: Saturated steam = Tsat = 179.83oc, Specific enthalpy of saturated water = hf = 762.6 KJ/Kg, Latent heat of steam = hfg = 2013.6 KJ/Kg, Specific enthalpy of dry saturated steam = hg = 2776.2 KJ/Kg, Amount of heat added in Superheated = ( hsup – h ), we know that the steam coming out of boiler is wet steam hence h = ( hf + x hfg ) KJ/Kg, h = 762.6 + 0.8 × 2013.6 = 2373.48 KJ/Kg, After heat addition the temperature is increase to superheated temperature that Tsup = 350oc, hsup = hg + Cps ( Tsup – Tsat ) i.e. hsup = 2776.2 + 2. 25 (350 – 179.83 ) = 3159.08 KJ/Kg, Amount of heat Supply = ( hsup – h ) = 3159.08 – 2373.48 = 785.5 KJ/Kg, Therefore amount of heat added for 5Kg of Steam = 785.5 × 5Kg of Steam = 3927.5 KJ, , Module-2, Q. 3 a Classify and explain different types of Smart Materials, Smart materials: Smart materials, called also intelligent or responsive materials, are designed, materials that have one or more properties that can be significantly changed in a controlled, fashion by external stimuli, such as stress, temperature, moisture, pH, electric or magnetic, fields, light, or chemical compounds., CLASSIFICATION OF SMART MATERIALS, Nowadays, there are different types of smart materials and new ones arise every day, thanks, to investment in R+D+i. Among them, the following should be highlighted:, 1.Piezoelectric material, They can convert mechanical energy into electrical energy and vice versa. For example, they, change their shape in response to an electrical impulse or produce an electrical charge in, response to an applied mechanical stress., 2.Shape memory materials, They have the ability to change the shape, even returning to their original shape, when exposed, to a heat source, among other stimuli., 3.Chromoactive materials, They change colour when subjected to a certain variation in temperature, light, pressure, etc., Nowadays, they are used in sectors such as optics, among others., 4.Magnetorheological materials, They change their properties when exposed to a magnetic field. For example, they are currently, used in shock absorbers to prevent seismic vibrations in bridges or skyscrapers., 5.Photoactive materials, There are several types: electroluminescent emit light when they are fed with electrical impulses,, fluorescents reflect light with greater intensity and phosphorescent are able to emit light after the, initial source has ceased., EXAMPLES AND APPLICATIONS OF SMART MATERIALS, Materials science is a constant supply of news about new discoveries that could revolutionise, our future. We review some of the most amazing materials from recent years below:, , 8

Page 5 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Synthetic spider web. This material is not only five times stronger than steel, but also has great, elasticity. Its potential uses include: bulletproof clothing, artificial skin for burns or waterproof, adhesives., Shrilk. Its main component is chitin, a carbohydrate found in krill shells. It was created by, researchers from Harvard University and is considered the ideal substitute for plastic — since its, decomposition time is only two weeks and it also works as a stimulant for plant growth —., Graphene. Its potential uses are almost unlimited: batteries with more autonomy, cheaper, photovoltaic solar cells faster computers, flexible electronic devices, more resistant buildings,, bionic limbs, etc. All this is possible thanks to their multiple properties., b Differentiate between the Brazing and Soldering Process, , c What are the three modes of Heat transfer? Explain the process of Heat transferin, Automobile radiator, Heat can travel from one place to another in several ways. The different modes of heat transfer, include: 1. Conduction 2. Convection 3. Radiation, 1. Conduction: The process in which heat flows from solid objects with higher temperature to, objects with lower temperature. An area of higher kinetic energy transfers thermal energy, towards the lower kinetic energy area. Highspeed particles clash with particles moving at a slow, speed, as a result, slow speed particles increase their kinetic energy. This is a typical form of heat, transfer and takes place through physical contact, 2. Convection: The movement of fluid molecules from higher temperature regions to lower, temperature regions. In convection, bulk quantities of the fluid flow to areas of different, temperature., , 3. Radiation: Radiant heat is present in some or other form in our daily lives. All bodies, continuously emit energy if their temp is above zero absolute (0K) and energy thus, emitted is called thermal radiation. Radiation is the transfer of energy by electromagnetic, waves which carry away the energy from the emitting body. Thermal radiations are, referred to as radiant heat. Radiation takes place through a vacuum or transparent, , 4, , 8

Page 6 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , medium which can be either solid or liquid. Thermal radiation is the result of the random, motion of molecules in the matter. The movement of charged electrons, AUTOMOBILE RADIATORS: “The radiators are heat exchangers used to transfer thermal, energy from one medium to another for the purpose of cooling and heating” Radiators are, used to convert thermal energy from one mode to another for the purpose of cooling and, heating., Radiators function in automobiles, buildings as well as in electronics., It acts as a coolant source for automotive engine cooling., Radiators transfer most of their heat via convection rather than thermal radiation., If there are large temperature differences, it can cause distortion of the engine components., The radiator will do the cooling purposes because the temperature of the burning gases in the, engine cylinder reaches up to 1500 to 2000°C., If the heat is not dissipated there can be a failure of the cylinder material. Radiators can, reduce the chances of piston seizure and keep the temperature minimum., , The upper tank is connected to the water outlet or outlets from the engine jacket by a hose pipe, and, The lower tank is connected to the jacket inlet through the water pump. The core is a radiating element,, which cools the water. The core is composed of a large number of individual air cells which are, surrounded by water. Because of its appearance, the cellular type usually is known as a honeycomb, radiator, especially when the cells in front are hexagonal in form. Radiator Cap: As the coolant in the, radiator is always under pressure, which helps to keep the coolant much hotter under without boiling. In, radiator, the coolant flows from the inlet to the outlet through many tubes mounted in a parallel, arrangement. The hot water enters the radiator through the inlet port. And a fan is attached on behind, the radiator to cool down the hot water in the tubes. The fan blows the air and cools down the water. So, the water is going to come out cooler than it entered before and then go back to the engine, , OR, Q. 4 a Discuss how gas welding is different from brazing process. List the applicationsof gas, Welding, The difference between brazing and gas welding is that the melting temperature of the filler metal used, is lower than the melting temperature of the base material, but higher than or equal to the melting, temperature of the filler material. Braze welding differs from brazing is that the joint design of brazing is, similar or the same as the joint design used in gas welding. Capillary action is not a factor in bond, formation., Although gas welding usually requires acetylene gas as fuel, it can also be brazed with other fuel gases, such as propane, natural gas, propylene and acetylene. This is because during the braze welding, flux is, added to perform functions normally associated with pre-cleaning and the deoxygenation characteristics, of the acetylene-oxygen flame., Brazing is usually related to the connection of steel. In general, the filler material used is low smoke, bronze-either a bare rod immersed in the flux material, or a bare rod coated with a flux coating on the, electrode. In actual operation, the steel to be connected is heated to approximately dark red, and at this, time, the low-smoke bronze filler material is used together with the flux and flows with the steel to be, connected to form a tight bond, , 10

Page 7 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Applications of Gas Welding:, 1. For joining most ferrous and non-ferrous metals, carbon steels, alloy steels, cast iron, aluminium and, its alloys, nickel, magnesium, copper and its alloys, etc., 2. For joining thin metals., 3. For joining metals in automotive and aircraft industries., 4. For joining metals in sheet metal fabricating plants., 5. For joining materials those requires relatively slow rate of heating and cooling, etc., , b With a neat sketch explain the principle and working of MIG welding. List itsapplications, , 10, , MIG Welding:, This is similar to TIG welding. At the place of non-consumable tungsten electrode, a consumable, metal electrode is used in the form of continuously fed metal wire. The electrode wire and inert gas, are fed through welding gun. Only DC is recommended for this type of welding giving positive, polarity to electrode wire. Feeding speed of electrode wire is adjusted according to the welding speed., This is used for the welding of carbon steel, low alloys steel, stainless steel and alloys of the metal, exhibiting resistance to heat. IG may be preferable for thicker material and for fill passes in thickwall pipe welds. MIG welding can be used on all thicknesses of steels, on aluminium, nickel, and, even on stainless steel, etc., , Applications of MIG welding:, • Used for most types of sheet metal welding., • Fabrication of pressure vessels and steel structures., • Automotive industry and home improvement industry., • MIG is most commonly used to repair cars, motorbikes, recreational vehicles, vans and SUVs2, , Module-3, Q. 5 a With a suitable sketch explain the different parts of an I.C Engine, , 10

Page 8 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , 1. Cylinder: It is Heart of engine having cylindrical shape in which the fuel is burnt and the power is, developed. The primary functions of cylinder are i) To contain the working fluid under pressure and ii), To guide the piston while reciprocating inside the cylinder., 2. Piston and Piston Rings: The rings which are placed in the grooves cut towards top of the piston, are called Piston Rings. There are two set of rings inserted into the groves. (Compression rings and oil, rings.) Compression rings: The compression rings press hard with the cylinder walls forming a tight, seal between the piston and the cylinder. This prevents escaping of the high pressure gases into the, crankcase. Oil rings: The function of oil rings is to extract the lubricating oil from the cylinder walls, and send it back to oil sump through the holes provided on the piston., 3. Connecting rod: The connecting rod is a link that connects the piston and the crankshaft. Its, function is to convert the reciprocating motion of the piston into rotary motion of the crankshaft., 4. Crank: The crank is a lever with one of its end connected to the connecting rod by a pin joint with, other end connected rigidly to the crankshaft. The other end of the crank is connected to the crankshaft., The power required for any useful purpose is taken from the crankshaft., 5. Crank case: It encloses the crankshaft and serves as a sump for the lubricating oil., 6. Valves: The valves are control devices that allow the air/fuel to enter into the cylinder and also to, discharge the burnt gases to atmosphere. There are two valves and are actuated by means of cams., Inlet valve is the one through which fresh charge (air and fuel or air) enters into the cylinder., Exhaust valve through which the burnt gases are discharged out of the cylinder., 7. Cams: It is an element designed to control the movement of both the inlet and exhaust valves, 8. Flywheel: It is a heavy mass of rotating wheel mounted on the crankshaft and is used as an energy, storing device. The energy received during the power stroke & supplies the same during other strokes., 9.Bore: The inside diameter of the cylinder is called 'bore'., 10.Top dead center (TDC): The extreme position of the piston near to the cylinder head is called, 'TDC'., 11.Bottom dead center (BDC): The extreme position of the piston nearer to the crankshaft is called, 'BDC'., 12.Stroke(L): It is the linear distance travelled by the piston from the TDC to BDC or BDC to TDC., 13.Clearance volume (Vc): It is the volume of cylinder above the top of the piston, @ TDC piston, position., 14.Swept volume or Stroke volume (Vs): It is the volume swept by the piston as it moves from BDC, to TDC or TDC to BDC., 15.Compression ratio: (RC): The ratio of the total cylinder volume to the clearance volume is called, Compression ratio. Total cylinder volume = Stroke volume (Vs) + Clearance volume (Vc), Rc = Vs+VC Vc, 16.Piston Speed: The average speed of the piston is called ‘piston speed’ = 2.L.N where ,N = engine, RPM., , b Discuss the need of Electric and Hybrid vehicles. List their advantages and limitations, Need of Electric vehicles :The major benefit of electric cars is the contribution that they can make, towards improving air quality in towns and cities. EVs have no tailpipe emission as compared to ICE, vehicles. Adopting EVs will help in reducing local air pollution., Shifting to EVs will reduce Greenhouse Gas (GHG) emissions that gets emitted from running an ICE, vehicle., Hybrid vehicles: One of the biggest advantages of a hybrid car over a gasoline-powered car is that it, runs cleaner and has better gas mileage, which makes it environmentally friendly. A hybrid vehicle, runs on twin powered engine (gasoline engine and electric motor) that cuts fuel consumption and, conserves energy, Advantages of an Electric Vehicles, An electric car can be a great way for you, as a consumer, to save a lot of money on gas. However, there, are so many different reasons why you should invest in an electric car in the modern-day of technology., 1. No Gas Required: Electric cars are entirely charged by the electricity you provide, meaning you don’t, need to buy any gas ever again. Driving fuel-based cars can burn a hole in your pocket as prices of fuel, have gone alltime high. The average American pays about 15 cents a mile to drive a gas-powered vehicle,, whereas many electric cars run on five cents a mile. Electricity is largely less expensive than gasoline., 2. More Convenient: The electric vehicle is easy to recharge, and the best part is you will no longer need, to run to the fuel station to recharge your car before hitting the road! Even a normal household socket, , 10

Page 9 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , could be used for charging an electric car., 3. Savings: These cars can be fueled for very low prices, and many new cars will offer great incentives, for you to get money back from the government for going green. Electric cars can also be a great way to, save money in your own life.., 4. No Emissions: The biggest advantage of an electric vehicle is its green credential. Electric cars are 100, percent eco-friendly as they run on electrically powered engines. It does not emit toxic gases or smoke in, the environment as it runs on a clean energy source. They are even better than hybrid cars as hybrids, running on gas produce emissions. You’ll be contributing to a healthy and green climate., 5. Popularity: EV’s are growing in popularity. It is nearly three times as efficient as cars with an internal, combustion engine, according to Wikipedia. With popularity comes all new types of cars being put on the, market that are unique, providing you with a wealth of choices moving forward. 6. Safe to Drive: Electric, cars undergo the same fitness and testing procedures test as other fuel-powered cars. An electric car is, safer to use, given their lower center of gravity, which makes them much more stable on the road in case, of a collision. In case an accident occurs, one can expect airbags to open up and electricity supply to cut, from the battery. This can prevent you and other passengers in the car from serious injuries. They are, even less likely to explode in the absence of any combustible fuel or gas., 7. Cost-Effective: Earlier, owning an electric car would cost a bomb. But with more technological, advancements, both cost and maintenance have gone down. The mass production of batteries and, available tax incentives further brought down the cost, thus, making it much more cost-effective. Consult, a tax specialist to learn more about any tax credits that might be available to you on the state or federal, level., 8. Low Maintenance: Electric cars run on electrically powered engines, and hence there is no need to, lubricate the engines, anything related to the combustion engine or a ton of maintenance tasks that are, usually associated with a gas engine.Other expensive engine work is a thing of the past. Therefore, the, maintenance cost of these cars has come down. You don’t need to send it to the service station often as, you do for a standard gasoline-powered car., 9. Reduced Noise Pollution: Electric cars put a curb on noise pollution as they are much quieter. Electric, motors are capable of providing smooth drive with higher acceleration over longer distances. Many, owners of electric cars have reported positive savings of up to tens of thousands of dollars a year., 10. Battery Life & Cost: Batteries are an integral part of an electric vehicle. Most electric vehicle, batteries are lithium ones, and their costs are improving every year. The full capacity of a lithium-ion, battery cell should be good for 300 to 500 cycles. A good battery could last you up to ten years. With the, improving technologies, the cost of these batteries is expected to come down even more., , Disadvantages of an Electric Vehicles:, Although the evidence of the positives has become very clear, there are also some downsides that each, individual needs to consider before they decide to make an electric car their next big investment. These, reasons are:, 1. Recharge Points: Electric fueling stations are still in the development stages. Not a lot of places you, go to ona daily basis will have electric fueling stations for your vehicle, meaning that if you’re on a long, trip or decide tovisit family in a rural orsuburban area and run out of charge, it may be harder to find a, charging station. You maybe stuck where you are. However, until charging stations are more widespread,, be sure to have a charging station maps where you live and where you frequently go so that you’ll be able, to charge your new EV when you need to., 2. The Initial Investment is Steep: As EVs are very new, you may be surprised when you take a look at, the sticker price for EVs., 3. Electricity isn’t Free: Electric cars can also be a hassle on your energy bill if you’re not considering, the options carefully. If you haven’t done your research into the electric car you want to purchase, then, you may be making an unwise investment. Sometimes electric cars require a huge charge to function, properly – which may reflect poorly on your electricity bill each month. 4. Short Driving Range and, Speed: Electric cars are limited by range and speed. Most of these cars have a rangeof about 50-100 miles, and need to be recharged again. You just can’t use them for long journeys as of now, although it is, expected to improve in the future., 5. Longer Recharge Time: While it takes a couple of minutes to fuel your gasoline-powered car, an, electric car takes about 4-6 hours and sometimes even a day to get fully charged. Therefore, you need

Page 10 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , dedicated power stations as the time taken to recharge them is quite long. Thus, the time investment and, necessary planning do put some people off. There are some kits that can cut the charging time down. But, again, that is going to be an additional investment.So, consider that, too., 6. Silence as a Disadvantage: Silence can be a bit disadvantage as people like to hear the noise if they, are coming from behind them. An electric car is, however, silent and can lead to accidents in some cases., 7. Normally 2 Seaters: Most of the electric cars available today are small and 2 seated only. They are not, meantfor the entire family, and a third person can make a journey for the other two passengers a bit, uncomfortable., 8. Battery Replacement: Depending on the type and usage of battery, batteries of almost all electric cars, are required to be changed every 3-10 years., 9. Not Suitable for Cities, Facing Shortage of Power: As electric cars need the power to charge up, the, cities that already facing acute powershortages are notsuitable for electric cars. The consumption of more, power wouldhamper their daily power needs., 10. Lower Amount of Choices: The market today for electric cars is expanding, with no signs of slowing, down. However, the truth is that there are fewer options to customize and choose the aesthetics of your, EV, , OR, Q. 6 a Describe the working principle of Vapour Compression Refrigeration, , WORKING: The liquid refrigerant in the evaporator absorbs the heat from the medium which is to be, cooled and undergoes a change of phase form liquid to vapour. The vapour at low temperature and, pressure is drawn into the compressor where it is compressed to a high pressure and temperature. The, compressed vapour then enters the condenser. In the condenser the vapour refrigerant is cooled and, condensed by giving its latent heat to the circulating cooling medium. The high-pressure liquid refrigerant, leaves the condenser and passes through the expansion valve where it is expanded to low pressure and, temperature. The temperature of the refrigerant falls to a value less than that of the refrigerated space. The, low pressure-low temperature refrigerant again enters the evaporator where it absorbs the heat from the, medium and evaporates. The low pressure-low temperature vapour is drawn into the compressor and the, cycle repeats. Thus, heat is continuously extracted from the medium, thereby keeping the contents at the, required lower temperature., , 10

Page 11 :

Solutions to VTU Model Question Paper-2, Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, b List and explain the industrial application of Refrigeration, 10, Refrigeration and cooling systems are designed to fulfil determined requirements based on the specific, characteristics of each industry. The main industries that require refrigeration or cooling systems are:, 1. District Cooling: One of the top markets for cooling is focused on providing cooled air to urban and, touristic areas, thus keeping enclosed ambiances comfortable independently of the outside weather. In, big hotels, resorts and district areas, refrigeration production is usually delivered by District, Cooling systems., 2. Electricity Production: Electricity generation is often based on the combustion of different fuels., To achieve a higher efficiency, inlet air must be in determined conditions. If the temperature of the inlet, air is too high, its density decreases, suffering a decline in the electric production. To avoid this, problem, systems like Turbine Inlet Air Cooling System, a system in ARANER’s portfolio, are used to, cool down these air streams, 3. Chemical & Petrochemical, Although chemical and petrochemical reactions are not as strictly controlled as the reactions in the, Pharmaceutical field, control of temperature is an important factor in reaching high efficiency in their, transformations. Distillations, crystallizations or condensations are operations requiring the removal of, heat; hence refrigeration systems are necessary to obtain their products. In chemical, and petrochemical industries, large scale cooling plants are used in their processes. Due to the high flow, required and the location of the industries, river water or seawater is used as refrigerant., 4. Pharmaceutical, The Pharmaceutical industry is based around operations where fulfilment of strict conditions is essential, for the success of every process. Going further, many production procedures imply biological or, biochemical reactions that only take place in strict conditions in which microbiological species generate, chemical compounds at their maximum yield. This is why it is so important that Pharmaceutical firms, develop their products in clean disinfected rooms., 5. Food & Beverages, Maintaining the cold chain in the F&B industry is vital for preserving products and avoiding possible, microbiological contamination. Each product has its own optimal conditions for storage and preservation., In the preparation process, temperature is one of the most important parameters to assure food safety., In products like fish, poultry, meat, dairies or fruits, refrigeration systems are necessary to keep, products in low temperatures and extend the recommended consumption period. Other types of F&B, industries—like a brewery—require several refrigeration systems to finish the biological and chemical, reactions that take place during the process, and to preserve the optimal conditions of the product once, the process is finished., 6. Data Centres, Data centers store groups of servers used to process and distribute data. The servers naturally produce, heat during operation, and if the heat is not removed, the temperature rises. Unfortunately, this can, adversely affect the functioning of the servers. To prevent this problem, powerful air-cooling, systems are usually placed in these data centers, dissipating the heat produced and minimizing, maintenance operations. These cooling systems are commonly air-based or liquid-based, depending on, exterior conditions. Furthermore, new cooling systems are starting to be more environmentally friendly,, using seawater as a refrigerant., , Module-4, Q. 7 a A pinion with 120mm pitch circle diameter meshes with a gear of 400mm pitchcircle, diameter. The number of teeth on the pinion is 18 and it rotates at 1440rpm. Determine: i), Gear Ratio ii) number of teeth on gear iii) Speed of thegear, , 6

Page 12 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , b What are the different types of belt drives? With a neat sketch explain any two ofthem, Types of Belt:, , 8, , TIMING BELT is a toothed endless belt which is a part of an internal combustion, engine that synchronizes the rotation of the crankshaft and the camshaft(s) so that the engine's, valves open and close at the proper times during each cylinder's intake and exhaust strokes., Open belt drive: The driving and the driven, pulley are rotating in the same direction., The angle of lap on the smaller pulley is less, than the angle of lap on the larger pulley, No rubbing in belt, hence, wear and tear less, , Length of Open belt drive, , Cross belt drive: The driving and the driven pulley, rotate in opposite directions, The angle of lap is same on both the pulleys, At belt crosses, it rubs against each other and, there will be excessive wear and tear. Hence, shaft should be placed at a maximum distance of, 20b, where b is the width of belt and the speed of, the belt should be less than 15m/s., , Length of Cross belt drive, , c With a suitable example explain the application of linear motion mechanism, , Linear Actuators, Stationary Screws with rotating nuts, This group include machine tool traversing mechanisms, jacks, valve drives etc etc., These mechanisms essentially convert rotary motion to linear motion. High mechanical advantages, can result from components which are convenient to design and engineer. The output motions and, forces are very easy to evaluate for the input forces, Linear heads use reduction gears to reduce motor speed and increase motor torque, while a reliable, and low cost rack- and-pinion mechanism converts rotational motion into linear motion. The direction, , 6

Page 13 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , of rack movement is determined by the direction of motor rotation., Stationary Nuts with with rotating screw, This group includes power screw actuators, valve drives, jacks. The characteristics of this group is, essentially the same as the group with stationary screws and rotating nuts, Single and double acting hydraulic and pneumatic cylinders, This is a massive group including positioning cylinders, rams jacks . The motions and forces are very, easy to calculate..The motion involves convertion of potential energy in fluid to kinetic energy of the, motion of the component moved by the cylinder, , An elevator moves up and down with the help of an electrically powered pulley mechanism., The motion of the elevators is along a straight line., OR, Q. 8 a With suitable sketches explain the different types of joints used in robots, , 8, , Type of joints. :An industrial robot is a general purpose, programmable machine having certain, anthropomorphizes (i.e., human – like) characteristics, like the arm with following different, type of joints., , Rotational Joint: Rotational joint can also be represented as R –Joint. This type will allow the joints to, move in a rotary motion along the axis, which is vertical to the arm axes., Linear Joint: Linear joint can be indicated by the letter L –Joint. This type of joints can perform both, translational and sliding movements. These motions will be attained by several ways such as telescoping, mechanism and piston. The two links should be in parallel axes for achieving the linear movement., Twisting Joint: Twisting joint will be referred as V –Joint. This joint makes twisting motion among the, output and input link. During this process, the output link axis will be vertical to the rotational axis. The, output link rotates in relation to the input link., Orthogonal Joint: The O –joint is a symbol that is denoted for the orthogonal joint. This joint is, somewhat similar to the linear joint. The only difference is that the output and input links will be moving, at the right angles., Revolving Joint:Revolving joint is generally known as V –Joint. Here, the output link axis is, perpendicular to the rotational axis, and the input link is parallel to the rotational axes. As like twisting, joint, the output link spins about the input link., , b Explain the application of robot in assembly and inspections, Application of robot in assembly are:, Applications for robotic assembly include automotive components, like pumps, motors and gearboxes., Computers and consumer electronics are another excellent area, as are medical devices and household, appliances. Assembly robots are ideal for tasks demanding speed and precision like applying sealants, and adhesives. Not only can they put together parts that are too small or intricate for a human, but they, work quickly and accurately without tiring or making mistakes. They are good in applications where, cleanliness is paramount, like pharmaceuticals and medical device assembly, and they aren’t prone to, debilitating injuries, like carpal tunnel syndrome, that come with repetitive work., , Application of robot in inspection are:, Inspection applications are widely used in manufacturing to identify errors or defects that may, occur with goods produced. These processes were once only completed by humans, but the, advancement of robotic vision systems has led to the development of robot based inspection, applications. Industrial robots integrated with visions systems are able to take over inspection, tasks from workers, increasing quality control measures with the capability of microscopic, , 8

Page 14 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , detection. Robotic inspection systems can be used to flag defective parts, measure parts, or verify, that all parts are assembled correctly., , c List the advantages of gears over belt drives, , 4, , Advantages of Gear drives over the belt/chain drives:, 1)It is a positive drive and the velocity ratio remains constant., 2) The center distance between the shafts is relatively small, which results in Compact construction, 3) It can transmit very large power which is beyond the range of belt or chain drives., (4) It can transmit motion at very low velocity which is not possible with the belt drives., (5) The efficiency of gear drives is very high up to 99% in case of spur gear., (6) A provision can be made in the gearbox for the gear shifting, by just changing the velocity ratio, over, , Module-5, Q. 9 a What is taper turning? Explain the taper turning operation by swiveling thecompound, rest method., , 10, , Taper turning: The selection of method depends on length of taper to be generated on the work, piece. The different methods of taper turning are, 1. Taper turning by form tool method, 2. Taper turning by swiveling the compound rest., 3. Taper turning by offsetting the tail stock, 4. Taper turning by taper turning attachment., Taper Turning by Swiveling Compound Rest: In this method of taper the half taper angle is, calculated. The compound rest has rotating base graduated in degrees, which can be rotated to, any angle (according to the taper angle).]In this method the tool is advanced by rotating the, compound rest and hand wheel so that the tool moves according to set taper angle. This method, produces taper length larger than form tool method. Formula which is used to calculate taper, angle is tan α = ( D - d) / 2L where α = Half taper angle, D= Large diameter, d= Small diameter,, L= Length of taper, , b What is Smart Manufacturing? Discuss the role of IoT in smart manufacturing, Smart Manufacturing is a approach that utilizes Internet-connected machinery to monitor the production, process. The objective of SM is to identify opportunities for automating operations and use data analytics, to improve manufacturing performance using Industrial Internet of Things (IIoT) Then automation was, introduced, and now, with Industry 4.0, value is being added through artificial intelligence (AI),, autonomous systems, and analytics. Smart manufacturing employs these technologies to drive greater, efficiency and productivity in manufacturing across industries. The backbone of this digital, transformation consists of Industrial Internet of Things (IIoT) systems that instruct, manage and monitor, machines, equipment, processes and supply chains., Today, sensors, machine-to-machine communications, AI, machine learning, augmented reality, and, sophisticated analytics drive improvements across the industrial value chain through real-time, operational data and insights in a smart manufacturing environment., • As smart manufacturing becomes more common and more machines become networked through the, Internet of Things, they will be better able to communicate with each other, potentially supporting greater, levels of automation., o Intelligent sensors: Sensors can make sense of complex data that allows machines to perform to their, fullest capability, eliminating the need for remote processing whilst increasing productivity and efficiency, of smart machines., o Connectivity: The connectivity will need to manage, aggregate, buffer, and process data, and that too, in a secure manner. Manufacturing processes can be connected by a Personal Area Network (PAN), Local, Area Network (LAN), Wide Area Network (WAN), Virtual Private Network (VPN) or Metropolitan Area, , 10

Page 15 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Network (MAN). Each network has different strengths and ideal use cases and a strong partner with, experience in connecting smart manufacturing systems can help decide which connectivity solution is, best., o Automation: Robotics and artificial intelligence (AI) is expected to play a major role in the growth of, smart manufacturing. AI will assist manufacturers inject next-level automation into their processes., Software based on AI can be leveraged in several areas of a smart factory, including planning, scheduling,, and predictive maintenance., o Tracking: Keeping track of asset locations is an important Cloud computing: Cloud computing, facilitates the development of new products as it allows regular collaboration throughout the design, process. It enables employees to prioritize important tasks. In turn, cloud computing allows smart, manufacturers to connect to global locations and track the status of the product in a seamless manner. o, Security: Security is a constant threat to manufacturers in India and elsewhere. Smart manufacturing, envisages the use of Deep Neural Networks to secure communication, preventing frauds. Of course, there, are many other ways of ensuring cyber security as well

Page 16 :

Solutions to VTU Model Question Paper-2, , Q.10, , a, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , OR, Describe the Construction and working of upright Drilling Machine, , 10, , The upright drilling machine is designed for handling medium sized workpieces., Though it looks like a sensitive drilling machine, it is larger and heavier than a, sensitive drilling machine. Holes of diameter upto 50mm can be made with this, type of machine. Besides, it is supplied with power feed arrangement. For drilling, different types of work, the machine is provided with a number of spindle speeds, and feed., Construction of a drilling machine The basic parts of a drilling machine are a base,, column, drill head and spindle. The base made of cast iron may rest on a bench, pedestal, or floor depending upon the design. Larger and heavy duty machines are grounded on the, floor. The column is mounted vertically upon the base. It is accurately machined and the, table can be moved up and down on it. The drill spindle, an electric motor and the, mechanism meant for driving the spindle at different speeds are mounted on the top of, the column. Power is transmitted from the electric motor to the spindle through a flat belt, or a ‘V’ belt, Working: Drill head is mounted on the top side of the column. The drill spindle and the, driving motor are connected by means of a V-belt and cone pulleys. The motion is, transmitted to the spindle from the motor by the belt. The pinion attached to the handle, meshes with the rack on the sleeve of the spindle for providing the drill the required, down feed. There is no power feed arrangement in this machine. The spindle rotates at a, speed ranging from 50 to 2000 r.p.m., , b, , With Suitable Example explain the concept of open and Closed loop System, , 10

Page 17 :

Solutions to VTU Model Question Paper-2, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , S.N, , Open-Loop Control System, , Closed-Loop Control System, , 1, , The controlled action is free, from the output in the case of an, open-loop control system., , Here the output relies on the controlled, act of the system., , 2, , It is also known as a nonfeedback control system., , It is also known as a feedback control, system, , 3, , The segments of the open-loop, control system hold a controlled, process and controller., , The segments of the closed-loop control, system contain a controlled process,, controller, amplifier and feedback., , 4, , It is simple to build this system., , It is complex to construct this system., , 5, , It is unreliable., , It is reliable, , 6, , The precision exactness of this, system mostly relies on, calibration., , The accuracy depends on the feedback., , 7, , These systems are stable., , These are less stable as compared to the, open-loop control system., , 8, , Here optimization is not, allowed., , Optimization is allowed here., , 9, , It provides a quick response., , It is sluggish in terms of providing the;, response., , 10, , The calibration of this system is, hard., , The calibration of this system is simple., , 12, , Open-loop control systems are, nonlinear, , These are linear., , 13, , Some of the examples of these, types of systems are TV remote,, automatic washing machine,, immersion rod, traffic light, etc., , Some of the examples of these types of, systems are pressure and speed, AC,, control systems, toaster, and refrigerator.