Page 1 :

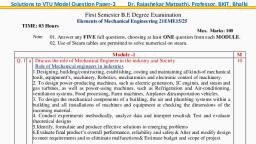

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , First Semester B.E Degree Examination(21 Scheme), Elements of Mechanical Engineering 21EME15/25, TIME: 03 Hours, Max. Marks: 100, Note: 01. Answer any FIVE full questions, choosing at least ONE question from each MODULE., 02. Use of Steam tables are permitted to solve numerical on steam., Module -1, Q. 1 a Briefly explain the emerging trends of mechanical Engineering in Manufacturing & Energy Sector, , Emerging trends of Mechanical Engineering in Manufacturing Sector are, 1.Industrial Internet of Things (IIOT). where interconnected devices are used in manufacturing, and industrial settings to collect data – data that can then be used to enhance the manufacturing, process. Sensors are a prime example of these interconnected IIoT devices. Data gathered from, sensors on factory machines can help manufacturers understand how machines are performing,, optimize the maintenance process, reduce machine downtime, and even predict when things will, go wrong., 2. 5G & Edge computing: The fifth generation of mobile data network technology (5G) will, enable manufacturers to easily connect their IIoT technology and leverage the data collection and, data processing within devices such as smart machines and sensors (what we refer to as edge, computing). Manufacturers can create a private 5G network on their premises which will give them, superfast data speeds without the need for cables and much-improved data security., 3. Predictive maintenance: In a manufacturing context, predictive maintenance refers to the use, of sensor data and Artificial intelligence (AI) to detect failure patterns in machinery and, components. The idea is that by understanding when a machine or part is likely to fail,, manufacturers can take preventative action and maintain their equipment more effectively., 4. Digital twins: can be used to simulate any physical process or object. For example, in a, manufacturing setting, a digital twin could be used to simulate a new product's dimensions or, create a digital replica of the equipment on the factory floor to see how the machinery operates, under certain conditions. Digital twin technology can even be used to visualize and simulate an, entire supply chain. By 2022, as many as 70 percent of manufacturers may be using digital twins to, conduct simulations and evaluations – which gives you an idea of just how transformative this, trend could be., 5. Automation and dark factories & Robots : Thanks to AI, machines are now capable of, carrying out more and more tasks that were previously reserved for humans. So it makes sense that, machines can take on more and more manufacturing tasks using intelligent robots – or “cobots” –, that are specifically designed to work alongside humans., 6. 3D printing: As 3D printing becomes more cost-effective, efficient, and scalable, manufacturers, will increasingly be able to make products using 3D printing methods – which use fewer materials, and create less waste than traditional manufacturing methods. I believe 3D printing will also drive, a new era of personalization because individually personalized products can be made without, worrying about economies of scale. Plus, 3D printing can help to drive innovation by allowing, rapid prototyping., Emerging trends of Mechanical Engineering in Energy Sector are, 1) Renewable Energies, Renewable is one of the emerging trends in energy sector. This Renewable energy trend helps to, safeguard the environment by emitting little to no harmful pollutants. The fundamental premise of, renewable energy is to obtain it from a consistent source in the environment, such as the sun, wind, or, geothermal sources. The source is then converted into useful power or fuel., A variety of technologies that address various facets of generating power and heat from renewable, sources is one of the latest technology trends in renewable energy. This involves lowering the cost of, building renewable infrastructure and enhancing the efficiency of power generation., 2) Internet of Energy (IoE), In the traditional method, during the time of construction, the electric power system uses the central, architecture, and this poses a number of obstacles to the industry. And here IoE comes into the frame., It helps to recognize some of the challenges and accordingly propose the best efficiency and optimal, Page 01 of 02, , M, 10

Page 2 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , design to build an energy system., Technology trends in the energy industry refer to automate the power infrastructure in order to, manufacture and produce energy. Benefits are:, • Reduce insufficiency, • Make the transmission of energy more productive, • Reduce the expenses, • Decrease in the wastage of energy, 3) Energy Storage Methods, Energy storage is one of the effective energy industry emerging trends. Energy storage permits steady, pricing by proactively maintaining demand from consumers., In response to shifting energy demands and technological advancements, the energy storage business, has evolved, adapted, and innovated during the last century. Energy storage systems offer a diverse set, of technological solutions for improving our power supply to build more resilient energy infrastructure, and save money for utilities and customers. The 5 types of Energy Storage based on their technology:, 1. Batteries, 2. Thermal, 3. Mechanical, 4. Pumped hydro, 5.Hydrogen,, It has the potential to save consumers money while also improving dependability and resilience,, integrating power sources, and reducing environmental impacts., 4) Blockchain Technology, Blockchains or distributed ledgers are emerging technology trends in the energy industry that has, drawn significant interest from energy supply firms, startups, financial institutions, governments,, technology developers, and the academic community., Blockchain technology proposes to combine all energy stakeholders under a single decentralized, system. Electricity producers, metering operators, distribution network operators, and traders, potentially avail from utilizing smart contracts. These agreements ensure that all energy-related, transactions are routed through a safe and immutable network, reducing the risk of losses. Blockchain, also can achieve some degree of equity between energy generators and consumers. Therefore, we, could say that Blockchain has the potential to transform the energy sector., b Define the following terms with respect to steam:, 10, Saturation temperature: The temperature at which vaporization (boiling) starts to occur for a given, pressure is called the saturation temperature or boiling point The temperature of water increases an, heating from 0°C to 100°C, Latent heat of vaporization: It is the quantity of heat required to convert 1 kg of water at saturation, temperature for a given pressure to one kg of dry saturated steam, at that pressure. It is denoted as ‘hfg’, Quality of the steam: It is the representation of dryness fraction in %: Quality of Steam = (x X 100 ), 𝒎𝒈, Dryness Fraction of Saturated Steam (x)=, 𝒎𝒈+𝒎𝒇, , It is the ratio of the mass of dry steam (mg) to the mass of total wet steam (mg +mf), where mf is the, mass of water vapor., Sensible heat: It is the quantity of heat in kJ required to raise the temperature of 1 kg of water from 0°C, to the saturation temperature at which water begins to boil at the given pressure P. If is denoted as ‘hf’, Degree of superheat: The Degree of Superheat can be defined as the amount by which the temperature, of a superheated vapor/steam exceeds the temperature of the saturated vapor/steam at the same, pressure. i.e., Degree of superheated = Tsup - Ts, OR, Q. 2 a What is solar Energy? Apply the Solar energy conversion technic into electrical energy in a solar, , cell, , Solar Energy:, , solar energy, radiation from the Sun capable of producing heat, causing chemical, reactions, or generating electricity. Solar constant the total radiation energy received from the Sun per, , unit of time per unit of area on a theoretical surface perpendicular to the Sun’s rays and, at Earth’s mean distance from the Sun. It is most accurately measured from satellites where, atmospheric effects are absent. Its value for earth is 1366w/m2, There are 2 types of solar energy used to generate power., 1. Solar Photovoltaic Power Plant & 2. Solar Thermal Power Plant, Page 01 of 02, , 10

Page 3 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , The photovoltaic technology will directly convert the sunlight into electricity, while the solar thermal, technology will capture the heat of the sun. When photons, or particles of light, hit the thin layer of, silicon on the top of a solar panel, they knock electrons off the silicon atoms. This PV charge, creates an electric current (specifically, direct current or DC), which is captured by the wiring in solar, panels, Working Principle of Solar Cell:, , Fig. Construction of Solar Cell, When light reaches the p-n junction, electron is excited to the valance band under the condition that, light energy is higher than the band gap energy, it generates the electron and holes which are equal in, number in the valance and conduction band respectively. These electron hole pairs move in opposite, directions to the barrier field. Electrons move towards the n-side and the hole is moved towards the pside. So a voltage is set up which is known as photo voltage and when a load is connected, the current, flows., b With a neat sketch explain the working principle of a Pelton Turbine, 10, The pelton wheel is the most commonly used type of impulse turbine. It works under a high head and, requires small quantity of water. Fig. shows a schematic sketch of a Pelton Wheel. The water from a, high head source is supplied to the nozzle provided with a needle, which controls the quantity of, water flowing out of the nozzle., , The pressure energy of water is converted into velocity energy as it flows through the nozzle. The jet, of water issuing out of the nozzle at high velocity impinges on the curved blades known as pelton, cups, at the centre as shown in the adjoining figure. The impulsive force of the jet striking on the, Pelton cups sets up the pelton wheel to rotate in the direction of the impinging jet. Thus the pressure, energy of the water is converted into mechanical energy. The pressure inside the casing of the turbine, will be at atmospheric pressure., Page 01 of 02

Page 4 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Module-2, Q. 3 a What are polymers? What are its characteristics?, 6, A polymer is a large molecule made up of chains or rings of linked repeating subunits, which are called, monomers. Polymer comes from the Greek word poly-means "many" and mer means "parts" Ex. many synthetic, organic materials used as plastics and resins., Characteristics of polymers, 1. Low specific gravity and high specific strength, 2. Thermal and electrical insulations, 3. Corrosion and weather resistances, 4. Ease in design and manufacturing of complicated structures, 5. Outstanding aesthetic appeal due to ease in adoption of permanent colours, 6. Mass production with low energy intensive manufacturing techniques, 7. Ease in printability and adhesion, 8. Ease in handling and cleanliness, 9. Offering tremendous scope of physical and chemical modification to meet industrial and consumer, requirement, 10. Tremendous adaptability to low-cost production, b State the application of Composites related to Aircraft and Automobile industry, 4, Applications: Aerospace, 1. A wide range of load-bearing and non-load-bearing components are used in both fixed-wing and rotary, wing aircraft., 2. Air frames, wing spars, spoilers, tail-plane structures, fuel tanks, drop tanks, bulkheads, flooring,, helicopter rotor blades, propellers, and structural component., 3. Pressured gas containers, domes, nose and landing gear doors, fairings, engine nacelles., 4. Air distribution ducts, seat components, access panels., 5. Modern light aircraft., 6. Rocket nozzles and re-entry shields., 7. Rocket motor casings and rocket launchers., Automotive Engineering, 1. Increasing interest in weight reduction in order to improvement in fuel economy, majority of automotive, applications involve glass-reinforced plastics for vehicle body moldings, panels and doors., 2. Selective reinforcement of aluminum alloy components for pistons and connecting rods., 3. Fuel tanks, disc brakes, brake parts, clutch plates, steering wheel, bumpers, radiator tanks support etc., Sports: Tennis rackets, cricket bats, golf clubs, fishing rods, boats, oars, archery equipment, canoes and canoeing, gear, surf boards, wind-surfers, skateboards, skis, ski-poles, bicycles, and protective equipment., General applications: Kitchen equipment, electrical equipment, motor-cycle crash helmets, television and, computer casings, and furniture., c What is gas welding? Explain with neat sketch principle of operation of oxy-acetylene gaswelding., Gas welding is a fusion welding process. Here the heat is generated by the combustion of oxygen or air and a, gas (such as acetylene, hydrogen, butane, methane petroleum gas, etc) is used to join metals. A strong flame, is produced when the mixture of gases are ignited. This flame has a very high temperature which melts and, fuses the metal parts. The quantities of gases are to be regulated for controlling the weld flame. A filler, metal rod is used to supply molten metal at the joint. It is used for repair work, for joining thin walled parts of, steel and non-ferrous alloys., , Oxy-acetylene Gas welding: When the acetylene is mixed with oxygen in correct proportion and ignited a, Page 01 of 02, , 10

Page 5 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , flame is produced. The flame will have a temperature of about 3200oC. A gas torch is used for the purpose., Acetylene gas is let out through the torch and ignited first. The gas catches fire and a flame is produced., Oxygen is then let out to sustain the flame. By regulating the control valves the quantities of both the gases, can be adjusted, so that the desired flame is produced., Acetylene gas has more available carbon (92.3 %) and hydrogen (7.7 %) by weight. The heat is released, when the carbon breaks away from hydrogen to combine with O2 and burn. The chemical reaction involved, in burning of acetylene is 2C2H2 + 5O2 = 4CO2 + 2H2O + Heat, Operation: The equipment consists of two large cylinders: one containing oxygen at high pressure and the, other containing acetylene gas. Pressure regulators are fitted on the respective cylinders to control the, pressure of the gas to the welding torch. A welding torch having controlling knobs which mixes both oxygen, and acetylene in proper proportions and burn the mixture. A spark ignites the mixture at its tip. The resulting, flame at the tip having a temperature of 3200oC which is sufficient enough to melt the work piece. A slight, gap usually exists between the two work piece, a filler metal is used to supply the additional material to fill, the gap., OR, Q. 4 a Give the differences between thermoplastics and thermosetting plastics., , 10, , b With a neat sketch explain the principle and working of TIG welding. List its applications, 10, TIG Welding :This is similar to arc welding. Additionally, it requires a cylinder of inert gas, valve, pressure, regulator and hose pipe with sprayer to spray inert gas in the welding pool. A non-consumable tungsten, electrode is used to establish arc. Sometimes inert gas sprayer is also mounted in the electrode holder. As per the, requirement additional filler metal can be provided from the outside to make up the joint. This is suitable for, welding of most of the metal and alloys except lead and zinc due to their very low melting point. TIG welding is, suitable for high quality welding., , Page 01 of 02

Page 6 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Tungsten electrodes are commonly available from 0.5 mm to 6.4 mm diameter and 150 - 200 mm length. The, current carrying capacity of each size of electrode depends on whether it is connected to negative or positive, termin.al of DC power source. The power source required to maintain the TIG arc has a drooping or constant, current characteristic which provides an essentially constant current output when the arc length is varied over, several millimetres. Hence, the natural variations in the arc length which occur in manual welding have little, effect on welding current. The capacity to limit the current to the set value is equally crucial when the electrode, is short circuited to the work piece, otherwise excessively high current will flow, damaging the electrode. Open, circuit voltage of power source ranges from 60 to 80 V., TIG welding Applications used in the so-called high-tech industry applications such as, • Nuclear industry, • Aircraft, • Food processing industry, • Maintenance and repair work, • Precision manufacturing industry, • Automobile industry, Module-3, Q. 5 a With the help of a P-V diagram explain the working of a four-stroke diesel engine, , 10, , A 4-stroke diesel engine performs four different strokes to complete one cycle of operation., , Suction stroke: At the beginning of the stroke piston is in TOC and during the stroke, piston moves from TDC., to BDC. The inlet valve opens and the exhaust valve will be closed. The downward movement of the piston, creates suction in the cylinder and as a result, fresh air is drawn into the cylinder through the inlet valve. When, the piston reaches the BDC, the suction stroke completes and this is represented by the line AS on P-V diagram, as shown in the figure., Compression stroke: At the beginning of the stroke piston is in BDC and during the stroke piston, moves from BDC to TDC. Both inlet and the exhaust valves are closed. As the piston moves upwards, air inthe, cylinder is compressed to a high pressure and temperature. The compression process is adiabatic innature, and is shown by the curve BC in P-V diagram. At the end of the stroke, the fuel (diesel) is sprayed into the, cylinder by fuel injector. As the fuel comes in contact with the hot compressed air, it gets ignited and undergoes, combustion at constant pressure. This process is shown by the line CD on PV diagram. At the point D fuel, supply is cutoff. The compression ratio ranges from 16:1 to 20:1., Power stroke / Expansion stroke: At the beginning of this stroke, piston is in TDC and during the stroke,, piston moves from TDC to BDC. Both inlet and the exhaust valve remain closed. As combustion of fuel takes, place, the burnt gases expand and exert a large force on the piston. Due to this, piston is pushed from TDC the, BDC. The power impulse is transmitted down through the piston to the crankshaft through the connecting rod., This causes the crankshaft to rotate at high speeds. Thus work is obtained in this stroke. The expansion of gases, is adiabatic in nature and this is shown by the curve DE on P- V diagram. When the piston reaches the BDC, the, exhaust valve opens. A part of burnt gases escapes through the exhaust valve out of the cylinder due to self, expansion. The drop in pressure at constant volume is shown by the line EB on P- V diagram., Exhaust stroke: At the beginning of the stroke piston is in BDC and during this stroke, piston moves from BDC, to TDC. The inlet valve is closed and the exhaust valve is opened. As the piston moves upward, it forces the, remaining burnt gases out of the cylinder through the exhaust valve. This is shown by the line SA on P- V, Page 01 of 02

Page 7 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , diagram. When the piston reaches the TDC the exhaust valve closes. This completes the cycle. In the next cycle, the piston which is at the TDC moves to BDC thereby allowing fresh air to enter into the cylinder and the, process continues., b With help a line diagram describe the working principle of Electric vehicle, , 10, , Electric vehicle:A vehicle that works on an electric motor instead of an internal combustion engine is called, an Electric Vehicle. It uses one or more electric motors or traction motors for propulsion. An electric vehicle, maybe powered through a collector system by electricity from off-vehicle sources, or may be self-contained, with a battery, solar panels or a generator to convert fuel to electricity. EVs include road and rail vehicles,, surface and underwater vessels, electric aircraft and electric spacecraft., Inner parts of an EV: EVs have 90% fewer moving parts than an ICE (Internal Combustion Engine), car. Here's a breakdown of the parts that keep an EV moving:, 1. Electric Engine/Motor - Provides power to rotate the wheels. It can be DC/AC type, however, AC, motorsare more common., 2. Inverter - Converts the electric current in the form of Direct Current (DC) into Alternating Current (AC), 3. Drive train - EVs have a single-speed transmission which sends power from the motor to the wheels., 4. Batteries - Store the electricity required to run an EV. The higher the kW of the battery, the higher the range., 5. Charging - Plug into an outlet or EV charging point to charge your battery., , OR, Q. 6 a With Suitable example enumerate the application of refrigeration in Food Processing Industry, , 10, , 1. Storage of Raw Fruits and Vegetables: It is well-known that some bacteria are responsible for, degradation of food, and enzymatic processing cause ripening of the fruits and vegetables. The, growth of bacteria and the rate of enzymatic processes are reduced at low temperature. This helps in, reducing the spoilage and improving the shelf life of the food. It can be seen that the storage, temperature affects the useful storage life significantly. In general, the storage life of most of the food, products depends upon water activity, which essentially depends upon the presence of water in liquid, form in the food product and its temperature. Hence, it is possible to preserve various food products, for much longer periods under frozen conditions., In case of fruits and vegetables, the use of refrigeration starts right after harvesting to remove the postharvest heat, transport in refrigerated transport to the cold storage or the processing plant. A part of it, may be stored in cold storage to maintain its sensory qualities and a part may be distributed to, retail shops, where again refrigeration is used for short time storage. Depending upon the size, the, required capacity of refrigeration plants for cold storages can be very high. Ammonia is one of the, Page 01 of 02

Page 8 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , common refrigerants used in cold storages., 2. Fish: Icing of fish according to ASHRAE Handbook on Applications, started way back in 1938. In, India, iced fish is still transported by rail and road, and retail stores store it for short periods by, this method. Freezing of fish aboard the ship right after catch results in better quality than freezing it, after the ship docks. In some ships, it is frozen along with seawater since it takes months before the, ships return to dock. Long-term preservation of fish requires cleaning, processing and freezing., 3. Meat and poultry: These items also require refrigeration right after slaughter during processing,, packaging. Short-term storage is done at 0°C. Long-term storage requires freezing and storage at 25°C., 4. Dairy Products: The important dairy products are milk, butter, buttermilk and ice cream. To, maintain good quality, the milk is cooled in bulk milk coolers immediately after being taken from, cow. Bulk milk cooler is a large refrigerated tank that cools it between 10 to 15°C. Then it is, transported to dairy farms, where it is pasteurized. Pasteurization involves heating it to 73°C and, holding it at this temperature for 20 seconds. Thereafter, it is cooled to 3 to 4°C. The dairies have to, have a very large cooling capacity, since a large quantity of milk has to be immediately cooled after, arrival. During the lean period, the refrigeration plants of dairies are used to produce ice that is used, during peak periods to provide cooling by melting. This reduces the required peak capacity of the, refrigeration plant., Ice cream manufacture requires pasteurization, thorough mixing, emulsification and stabilization, and subsequently cooling to 4 to 5°C. Then it is cooled to temperature of about – 5 °C in a freezer, where it stiffens but still remains in liquid state. It is packaged and hardened at –30 to –25°C until it, becomes solid; and then it is stored at same temperature., Buttermilk, curd and cottage cheese are stored at 4 to 10°C for increase of shelf life. Use of, refrigeration during manufacture of these items also increases their shelf life. There are many, varieties of cheese available these days. Adding cheese starter like lactic acid and several substances, to the milk makes all of these. The whey is separated and solid part is cured for a long time at about, 10°C to make good quality cheese., 5. Beverages: Production of beer, wine and concentrated fruit juices require refrigeration. The taste, of many drinks can be improved by serving them cold or by adding ice to them. This has been one of, the favorite past time of aristocracy in all the countries. Natural or man-made ice for this purpose has, been made available since a very long time. Fruit juice concentrates have been very popular because, of low cost, good taste and nutritional qualities. Juices can be preserved for a longer period of time, than the fruits. Also, fruit juice concentrates when frozen can be more easily shipped and transported, by road. Orange and other citrus juices, apple juice, grape juice and pineapple juice are very popular., To preserve the taste and flavour of juice, the water is driven out of it by boiling it at low temperature, under reduced pressure. The concentrate is frozen and transported at –20°C., Brewing and wine making requires fermentation reaction at controlled temperature, for example lager-type, of beer requires 8 to 12°C while wine requires 27- 30°C. Fermentation is an exothermic process; hence heat, has to be rejected at controlled temperature., 6. Candy: Use of chocolate in candy or its coating with chocolate requires setting at 5-10°C, otherwise it becomes sticky. Further, it is recommended that it be stored at low temp. for best taste., 7. Processing and distribution of frozen food: Many vegetables, meat, fish and poultry are frozen to, sustain the taste, which nearly duplicates that of the fresh product. Freezing retains the sensory qualities, of colour, texture and taste apart from nutritional qualities. The refrigeration systems for frozen food, applications are very liberally designed since the food items are frozen in shortest period of time. The, sharp freezing with temperature often below –30°C, is done so that the ice crystals formed during, freezing do not get sufficient time to grow and remain small and do not pierce the cell boundaries and, damage them. Ready-to-eat frozen foods, packed dinners and bakery items are also frozen by this, method and stored at temperatures of –25 to -20°C for distribution to retail stores during peak demands, or off-season demands., Page 01 of 02

Page 9 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , b Write a short note on Centralized Air Conditioning and enumerate how it is differedfrom the comfort, , room air conditioner, Providing a cool indoor atmosphere at all times regardless of weather conditions needed either for human, comfortor industrial purposes by artificially cooling, humidifying or dehumidifying, cleaning and recirculation, the surrounding air is called air conditioning. Central air conditioning (or central A/C) is a system in which, air is cooled at a central location and distributed to and from rooms by one or more fans and ductwork. The, work of the air conditioner compressor is what makes the whole process of air conditioning possible. The, compression of the refrigerant gas enables it to discharge heat out of the house, which is how the cool air is, created., Principle: An air conditioner draws air from an indoor space to be cooled, cools it by the refrigeration, principlesand discharges back into the same indoor space that needs to be cooled., WORKING: The Room conditioner unit consists of a vapour compression refrigeration system, an air filter, anddouble motor shaft that drives a fan at one end and a blower at the other end. The room side and the outside, of the unit are separated by an insulation partition wall within the casing. The blower sucks the warm air from, , the room to be cooled through the air filter and an evaporator. The refrigerant inside the evaporator coil gets, vaporized by absorbing the heat from the warm air. The motor runs the blower to deliver the cooled air into the, room. This air mixes with the air present in the room, thereby bringing down the temperature and humidity, levelso as to maintain comfortable conditions., The refrigerant vapour from the evaporator is compressed in the compressor to high pressure and temperature., The high pressure vapour then enters the condenser where it is cooled by the outside atmospheric air circulated, by a fan. The high pressure refrigerant is reduced to low pressure by passing it through an expansion valve., The low pressure ad temperature refrigerant again enters the evaporator where it absorbs heat from the, room to be cooled and cycle continues. Desired temperature in the room can be maintained by controlling, the operator of the compressor with the help of a thermostat. The heater and humidifiers may also be provided, in theunit to achieve the required temperature and humidity level., Comfort air conditioning is the controlling of, humidity and temperature of air to give, maximum comfort to the human beings., Example: Office restaurant, building etc, , Industrial air conditioning is required in, controlling the humidity and temperature in, processing and manufacturing industries., Example: Textile industries chemical plant,, photographic industry etc., The temperature and RH are maintain which is, suitable for Industrial process., , Temperature and R.H. maintain which are suitable, for human comfort which vary from person to, person, The main purpose to provide comfort to human, The main purpose is to improve the quality and, beings, efficiency of product, In general, the conditions are 22 to 25°C DBT, 30, The condition very from process to process., to 60 % RH. and 5 to 8 m/min air motion, Module-4, , Page 01 of 02, , 10

Page 10 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Q. 7 a Give the classifications of Gear Drives. Enlist each of their applications\, 6, A gear is a toothed component within a transmission device that transmits rotational force to another gear or, device, TYPES OF GEARS: 1. According to the position of axes of the shafts. a. Parallel, b. Intersecting & c. nonintersecting and non-parallel, a. Parallel, 1. Spur Gear: Teeth is parallel to axis of rotation.Transmit power from one shaft to another parallel shaft. They, are used widely in Electric screwdriver, oscillating sprinkler, windup alarm clock, washing machine and clothes, dryer, 2. Helical Gear: The teeth on helical gears are cut at an angle to the face of the gear.This gradual engagement, makes helical gears operate much more smoothly and quietly than spur gears., Herringbone gears (Double Helical): To avoid axial thrust, two helical gears of opposite hand can be mounted, side by side, to cancel resulting thrust forces.Herringbone gears are mostly used on heavy machinery., 3. Rack and Pinion: Rack and pinion gears are used to convert rotation (From the pinion) into linear motion (of, the rack).A perfect example of this is the steering system on many cars., b. Intersecting, Bevel Gear: Bevel gears are useful when the direction of a shaft's rotation needs to be changed.They are usually, mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The teeth on, bevel gears can be straight, spiral or hypoid. They are used widely in locomotives, marine applications,, automobiles, printing presses, cooling towers, power plants, steel plants, railway track inspection machines, etc, c. Non-intersecting and Non-parallel, Worm and worm gears: Worm gears are used when large gear reductions are needed. It is common for worm, gears to have reductions of 20:1, and even up to 300:1 or greater. Many worm gears have an interesting property, that no other gear set has: the worm can easily turn the gear, but the gear cannot turn the worm.Worm gears are, used widely in material handling and transportation machinery, machine tools, automobiles etc., b A belt drive is used to transmit 20kw power from an electric motor to an exhaust fan. The diameter of motor, and fan pulley are 250mm and 1000mm respectively. The speed of motor shaft is 750 rpm and thickness of, belt is 6mm. Determine, i), Speed of the exhaust fan pulley, ii), Velocity of the belt, iii), Torque required to transmit the power, Data: P=20kW=20000W d1=250mm =0.25m d2= 1000mm N1=750rpm ; t=6mm; N2=? V=? T=?, , 6, , Taking t = 6 mm. Velocity ratio, (V.R.) N2/N1 = (D1 + t)/ (D2 + t), i), Speed of the exhaust fan pulley N2=750*256/1006= 190.854rpm, ii), , Velocity of the belt, , =3.142*0.25*750/60 = 9.8174 m/s, , considering thickness of belt V = 3.142*0.256*750/60 = 10.053m/s, iii), , Torque required to transmit the power P =(T1-T2)*v Net Torque =20000/10.053= 1,989.45N-m, , c Classify the robots on the basis of physical configurations, Robot Physical Configuration Control System : Industrial robots come in a variety of shapes and sizes., They are capable of various arm manipulations, and they possess different motion systems. There are four, basic configurations, 1.Cartesian configuration: A robot which is constructed around this configuration consists of three, orthogonal slides, as shown in fig. the three slides are parallel to the x, y, and z axes of the Cartesian, coordinate system. By appropriate movements of these slides, the robot is capable of moving its arm at any, point within its three-dimensional rectangular spaced work space., Advantages: • Highly accurate & speed, • Fewer cost, • Simple operating procedures,& • High payloads., Disadvantages: • Less work envelope, Reduced flexibility, 2. Cylindrical configuration: in this configuration, the robot body is a vertical column that swivels about a, vertical axis. The arm consists of several orthogonal slides which allow the arm to be moved up or down and, in and out with respect to the body., Advantages: • Increased flexibility, • Huge work volume, and • Quick operation., Disadvantages: • Very expensive, • Difficult operating procedures, and • Plenty of components., 3. Polar configuration: this configuration also goes by the name “spherical coordinate” because the, Page 01 of 02, , 8

Page 11 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , workspace within which it can move its arm is a partial sphere as shown in figure. The robot has a rotary base, and a pivot that can be used to raise and lower a telescoping arm., Advantages: Low weight and minimal structural complexity., Short joint travel for many motions., Good, accuracy and resolution.,, 1 linear + 2 rotational axes, Disadvantages: Large variable torque on second joint creating counterbalance problem., Position error is, large due to rotary joints., 4. Jointed-arm configuration: is combination of cylindrical and articulated configurations. This is similar in, appearance to the human arm, as shown in fig. the arm consists of several straight members connected by, joints which are analogous to the human shoulder, elbow, and wrist. The robot arm is mounted to a base, which can be rotated to provide the robot with the capacity to work within a quasi-spherical space., Advantages:• Flexibility to reach over or under an object., Good workspace.,3 rotational axes can reach, above or below obstacles., Disadvantages: Counterbalance problem., ,Poor resolution and accuracy due to rotary joints., High, moment of inertia and dynamic instability (i.e. vibrations)., , OR, Q. 8 a With Suitable example explain the working principle Rack & pinion and Gear & Bevelgear., Rack and Pinion: Rack and pinion gears are used to convert rotation (From the pinion) into linear motion, (of the rack).A perfect example of this is the steering system on many cars, , Bevel Gear: Bevel gears are useful when the direction of a shaft's rotation needs to be changed.They are usually, mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The teeth on, bevel gears can be straight, spiral or hypoid. They are used widely in locomotives, marine applications,, automobiles, printing presses, cooling towers, power plants, steel plants, railway track inspection machines, etc, , Page 01 of 02, , 8

Page 12 :

Solutions to EME Model Question paper 1, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , b Explain the Industrial application of robots specific to material handling and Assembly, Industrial Robot Applications can be divided into following categories, Material Handling: Material handling robots can automate some of the most tedious, dull, and, unsafe tasks in a production line and is one of the easiest ways to add automation. Material handling, robots enhance the efficiency of your production line and increase customer satisfaction by providing, quality products in a timely manner., The term material handling encompasses a wide variety of product movements. Part selection and, transferring, palletizing, packing, and machine loading are just a few of the applications that are, considered material handling., When picking material handling equipment for your facility, you should consider payload and, speed requirements, end-of-arm tooling or grippers needed, facility layout and floor-space, the type, of material being handled and any additional possible production problems., • Part transfer, a dull and tedious process, can also be injury-inducing to human workers. By, adding robots to this job, human workers are kept free of the hazardous environment., • Packaging robots are extremely flexible and easy to integrate into a workspace. Some of the, advantages of packaging robots include reduced part package time, ability to lift larger packages and, labor cost reduction . With the right end of arm tooling, a robot can complete any packaging, process. There is a large variety of robot sizes, mounting options, payload and reach available to, choose from. • Palletizing robots can be seen in many industries including food processing,, manufacturing, and shipping. • Machine loading robots not only increase production speeds, it also, protects workers from injury., • Involve the movement of material or parts from one location to another., • It includes part placement, palletizing and/or depalletizing, machine loading and unloading., , 8, , Robots in Assembly: Assembly robots are used for lean industrial processes and have expanded, production capabilities in the manufacturing world. An assembly line robot can dramatically increase, production speed and consistency. They also save workers from tedious and dull assembly line jobs., End of arm tooling can be customized for each assembly robot to cater to the manufacturing, requirements. Additional options, like robotic vision, can also be incorporated to improve efficiency, and accuracy of part orientation or sorting identifiers., • Involve part-handling manipulations of a special tools and other automatic tasks and operations., c Differentiate between Mechanics and Machines, , 4, , Mechanics is one branch of physics — and some mathematicians are also focused on mechanics., You can divide this field of study into classical mechanics and quantum mechanics, but in either case, it involves the study of motion and the forces that cause or result from motion., A machine is a physical system using power to apply forces and control movement to perform an action., The term is commonly applied to artificial devices, such as those employing engines or motors,. Machines, can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal,, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific, application of output forces and movement. They can also include computers and sensors that monitor, performance and plan movement, often called mechanical systems., , Page 01 of 02

Page 13 :

Solutions to Model Question Paper-I, Q. 9, , a, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Module-5, Explain with neat diagrams, any two metal cutting operations performed on a lathe, machine., Facing is the process of removing metal from the end of a work piece to produce a flat, end surface. The work piece rotates about its axis and the facing tool is fed perpendicular, to the axis of lathe, , 8, , Knurling is the process of embossing a required diamond shaped pattern on the surface, of the work piece for better gripping. This diagram shows the knurling tool pressed, against a piece of circular work piece., , b, , With the help of a block diagram, explain the basic elements of CNC machines, Computer Numerical Control (CNC) machine Block Diagram : The CNC machine, works with the execution of the programs at the machine tool. The program is customized, with CNC machining language called G-codes or M codes. Using these codes the description, of the operation that is to be perform is written. The description of coordinates, the location, of the machine tool, speed and feed rates,, , The MCU consists of the following components: (1) CPU, (2) Memory, (3) Input/output, Interface, (4) Controls for Machine Tool Axes and Spindle Speed, and (5) Sequence, Controls for Other Machine Tool Functions. These are interconnected by means of a system, bus, which communicates data and signals among the components of a network., Central Processing Unit: The CPU is the brain of the MCU. It manages the other, components in the MCU based on software contained in main memory., Memory: The immediate access memory in the CPU is not intended for storing CNC, software. A much greater storage capacity is required for the various programs and data, needed to operate the CNC system., Input/output Interface: The I/O interface provides communication software between the, various components of the CNC system, other computer systems, and the machine operator., Controls for Machine Tool Axes and Spindle Speed: These are hardware components that, control the position and velocity (feed rate) of each machine axis as well as the rotational, speed of the machine tool spindle. The control signals generated by MCU must be converted, to a form and power level suited to the particular position control systems used to drive the, machine axes., , 8

Page 14 :

Solutions to Model Question Paper-I, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Sequence Controls for Other Machine Tool Functions: In addition to control of table, position, feed rate, and spindle speed, several additional functions are accomplished under, part program control., c, , Q.10, , a, , Differentiate between open loop and close loop System, , 4, , S.N, o., , Open-Loop Control System, , Closed-Loop Control System, , 1, , The controlled action is free from, the output in the case of an openloop control system., , Here the output relies on the controlled, act of the system., , 2, , It is also known as a non-feedback, control system., , It is also known as a feedback control, system, , 3, , The segments of the open-loop, control system hold a controlled, process and controller., , The segments of the closed-loop control, system contain a controlled process,, controller, amplifier and feedback., , 4, , It is simple to build this system., , It is complex to construct this system., , 5, , It is unreliable., , It is reliable, , 6, , The precision exactness of this, system mostly relies on, calibration., , The accuracy depends on the feedback., , 7, , These systems are stable., , These are less stable as compared to the open-loop control, system., , 8, , Here optimization is not allowed., , Optimization is allowed here., , 9, , It provides a quick response., , It is sluggish in terms of providing the;, response., , 10, , The calibration of this system is, hard., , The calibration of this system is simple., , 12, , Open-loop control systems are, nonlinear, , These are linear., , 13, , Some of the examples of these, types of systems are TV remote,, automatic washing machine,, immersion rod, traffic light, etc., , Some of the examples of these types of, systems are pressure and speed, AC,, control systems, toaster, and refrigerator., , OR, Explain the principle of working of horizontal milling machine, In this the spindle is horizontal. The base, which supports the other components. The, column, which contains the spindle and its driving mechanism. The over arm, which, provides support for arbor – mounted cutters. The knee, a separate section attached to the, column and can move vertically over the column. The saddle, which is supported by and, moves horizontally on the knee. The table, which supports the work piece and can move, horizontally at right angles to the saddle movement., Working Principle of Milling Machine: Depending upon relative feed direction of, worktable and rotation of cutter two different methods of milling is possible 1.Up milling, (Conventional milling) 2.Down milling (Climb milling), , 6

Page 15 :

Solutions to Model Question Paper-I, , B, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , Illustrate the working of an automated washing machine to demonstrate the, mechatronic system, Mechatronics is the synergistic integration of mechanical engineering, with electronics and, intelligent computer control in the design and manufacturing of industrial products and, processes. Mechatronics brings together areas of technology involving sensors and, measurement systems, drive and actuation systems, analysis of the behavior of systems,, control systems and microprocessor system., Consider an automatic washing machine. It is good example for a mechatronics system., Its actions are strictly ordered in time or in an event driven sequence. Its operation is, controlled by a control unit which comprises of the microcontroller or a microprocessor., In a washing machine sensors are used to estimate the water level, water temperature,, drum speed and whether the door is closed etc. These sensors provide data regarding the, above mentioned parameters to the control unit. This data is used by the control unit to, calculate the next setting of the washing process. In order to control the washing process, the control unit sends signals to the correction elements such as pumps, valves, heaters, or motors. This process is repeated until the process is complete, The washing machines use inverter control for both washing and spin-drying. Inverter, control helps reduce wash/spin noise and vibration and enables a washing machine to, adjust the amount of water and motor torque to suit the washload. IGBTs are used for, , 8

Page 16 :

Solutions to Model Question Paper-I, , Dr. Rajashekar Matpathi. Professor, BKIT, Bhalki, , motor drive, and microcontrollers for overall control. Additionally, an intelligent power, device (IPD) is used to drive a water circulating pump of a spin dryer. Power factor, correction (PFC) ICs or IGBTs are used in the power supply circuit to keep harmonics in, the input current below the IEC limit., , Advantages: 1. Time Saving 2. Effective 3. Consume less power 4. Save water, c, , Enlist the advantages of CNC machine in mechanical Industry, Advantages of CNC Machine:, 1. Increased productivity. & Greater flexibility., 2. High accuracy and repeatability., 3. Reduced production costs & indirect operating costs, 4. Facilitation of complex machining operations., 5. Improved production planning and control., 6. Lower operator skill requirement. 7. Facilitation of flexible automation., Limitations/Disadvantages of CNC, . 1.Relatively high initial cost of the equipment., 2. The need and cost for programming and computer time., 3. Special maintenance with trained personnel., 4. High preventative maintenance since breakdowns is costly, , 6