Page 1 :

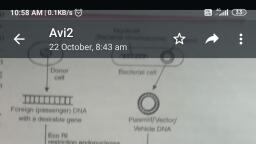

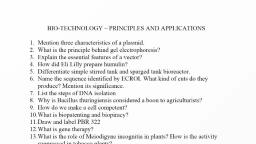

inciples and Processes, , both foreign | DNa ENZYME cut; , 4,, at Specific 6. vector DNA ‘NAY, , ooo”, , —<——>, , DOCOOC ¢, Ligases 1910 foreign ’, NA to Plasmid, , yond, , te,, , Os, , — nt, 2G, , | Transformation, E. coli, , if Celis divide \, , Figure 11.5 Diagrammatic representation of, recombinant DONA technology, , , , 1? Bioreactors, , hese are the large volume (100-1000 L) vessels in, hich raw materials are biologically converted, , to specific products, individual enzymes, etc.,, sing microbial plant, animal or human cells., , , , , , , , , , , N ’ Motor, Acia;Base ——f T, ) 5» ker, for oH. control C2 Foam brea, stig 6, , \, , Flat bladed impeller, , , , (®D ", Steari for, -_— Culture broth, ( Dy, . 3 — alee — Sterile ait, | | ctor, Figure 11.6 Simple stirred-tank piored, , , , a) Ht Provides the optima conditions for, ac jevin @ the desired eihiaes ete, powils ctindiittiens io meen by providing, , , , substrate, salt, vitamins ana Saygen 7, surface, area for, , oxygen transfer, , Bubbles/dramaticalty, increase the, oxygen, transfer area, , Figure 11.7 Sparged stirred-tank bioreactor through which, , sterile air bubbles ore sparged, , (ii) The stirred-tank reactor is usually, cylindrical or with a curved base to facilitate, the mixing of the reactor contents., , (a) The stirrer facilitates mixing and oxygen, availability throughout the bioreactor., , (b) The most commonly used bioreactors, are of stirring type., , (iii) In the sparged stirred-tank bioreactor,, sterile air bubbles are sparged to imcrease, the surface area for oxygen transfer., , (iv) The components of a bioreactor are, (a) An agitator system, (b) An oxygen delivery system, (c) A foam control system, (d) A temperature control system, (e) pH control system, , (f) Sampling ports to withdraw culture, periodically., , Downstream Processing, After the product formatio, subjecte ies of processe, they are subjected to a series © pe ae, collectively referred to as downstream processing,, These include, , (i) Separation of desired product., (il) purification of products. 4, (itt) Formulation with preservative : —, , 7 oducts undergo strict 4, , inally, these Pf . ae, ae testing before being marke, , finished product., , Ss,, , , , , , n in biosynthetic stage,