Page 1 :

Mechanical Properties of Solids, , 1. Introduction, , A rigid body generally means a hard solid, object having a definite shape and size. But, in reality, bodies can be stretched,, compressed and bent. Even the appreciably, rigid steel bar can be deformed when a, sufficiently large external force is applied on, it. This means that solid bodies are not, perfectly rigid. A solid has definite shape, and size. In order to change (or deform) the, shape or size of a body, a force is required., , 2. Deforming Force, , A force which produces a change in, configuration (size or shape) of the object, on applying it, is called a deforming force., , 3. Elasticity, , Elasticity is that property of the object by, virtue of which it regains its original, configuration after the removal of the, deforming force., , For example, if we stretch a rubber band, and release it, it snaps back to its original, length., , 4. Perfectly Elastic Body, , Those bodies which regain its original, configuration immediately and completely, after the removal of deforming force are, called perfectly elastic bodies. The nearest, approach to a perfectly elastic body is, quartz fibre., , 5. Plasticity, , If a body does not regains its original size, and shape completely and immediately, after the removal of deforming force, it is, said to be a plastic body and this property is, called plasticity., , 6. Perfectly plastic body, , That body which does not regain its original, configuration at all on the removal of, deforming force are called perfectly plastic, bodies.Putty and paraffin wax are nearly, perfectly plastic bodies., , 7. Stress, , If a body gets deformed under the action of, an external force, then at each section of, the body an internal force of reaction is set, up which tends to restore the body into its, original state., , 7.1 Definition, , The internal restoring force set up per unit, area of cross section of the deformed body, is called stress., , 7.2 Mathematical Form, , Applied Force, , Stress =, Area, , Its unit is N/m2 or Pascal., , Its dimensional formula is [ML*T ? ]., 7.3 Types of stress, , There are three different types of stress, , 1. Longitudinal Stress

Page 2 :

Mechanical Properties of Solids, , If deforming force is applied normal to the area, of cross section, then the stress is called, longitudinal stress. It is further categorized in, two types, , (a) Tensile stress If there is an increase, in length of the object under the effect, of applied force, then stress is called, tensile stress., , (b) Compressional stress If there is a, decrease in length of the object under, the effect of applied force, then stress is, called compression stress., , L, , 7! [Compressive Stress], , 2. Tangential or Shearing Stress, , If deforming force acts tangentially to, the surface of a body, it produces a, change in the shape of the body. The, tangential force applied per unit area is, called tangential stress., , 3. Normal Stress, , If a body is subjected to a uniform force, from all sides, then the corresponding, stress is called hydrostatic stress., , 8.Strain, , When a deforming force acts on a body,, the body undergoes a change in its, shape and size. The fractional change in, configuration is called strain., , 8.1 Mathematical Equation, , change in dimension, , Strain = —_—__.._—_._, original dimension, , It has no unit and it is a dimensionless, quantity., , According to the change in, configuration, the strain is of three, , types, , change in length, , (1) longitudinal strain= crigital length, , change in volume, , (2) Volumetric strain = Original Volume, , tangential applied force, , (3) Shearing strain S7#="= spre, , 9. Hooke’s Law, , Robert Hook found that within the, elastic limit, the stress is directly, proportional to strain. Thus we have, , stress « strain, , or, stress = K.strain, , where K_ is the constant of, proportionality called “Elastic Modulus”, of the material., , There are some materials that do not, obey Hooke’s law like rubber, human’s, muscle., , 9.1 Types of Modulus of rigidity, , 9.1.1 Young’s Modulus of rigidity (Y)

Page 3 :

or, , Mechanical Properties of Solids, , It is defined as the ratio of normal stress, to the longitudinal strain within the, elastic limit., , _ longitudinal stress, ~~ Longitudinal strain, , It has same units as stress because, strain does not have any unit. Y is, measured in N/m? or Pa., , Metals generally have large values of, Young’s modulus compare to other, materials. In scientific terms, the higher, the Young’s modulus of the material the, more elastic it is., , 9.1.2 Bulk Modulus of Rigidity, , normal stress, Se, Volumetric strain, , a eA., ie pV/AV, , The SI unit of bulk modulus is N/m?, , F, , , , Compressibility, , Compressibility of a material is the, reciprocal of its bulk modulus of elasticity., Compressibility (C) = 1/k, , Its SI unit is N-1m 2 and CGS unit is dyne*, , cm?., , 9.1.3 Modulus of rigidity or shear, Modulus (77), , tangential stress, , , , , , 1 ~Shear strain, = F, =A 2., AY, 2 F, 1 ay, —.F, Ea, , The SI unit of shear modulus is N/m?, , The shear modulus of a material is, always considerably smaller than the, Young’s modulus for it., , 10. Limit of elasticity, , The maximum value of deforming force for, which elasticity is present in the body is, called its limit of elasticity.

Page 4 :

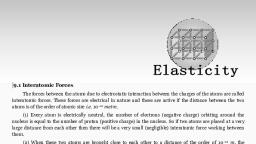

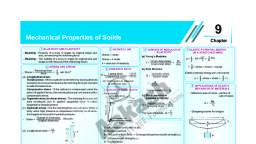

Mechanical Properties of Solids, , 11.Stress- strain Curve, , Elastic limit, Proportional, limit, , , , , , , or, yield point, , , , Fracture point, , . Plastic behaviour, , oe behaviour, , , , am Permanent set, , 0, t E Strain —> 30%, 1%, , Figure shows the stress-strain curve for a, metal wire which is gradually being loaded., , (a) The initial part OA of the graph is a, straight line indicating that stress is, proportional to strain. Upto the point A,, Hooke’s law is obeyed. The point A is called, the proportional limit. In this region, the, wire is perfectly elastic., , (b) After the point A, the stress is not, proportional to strain and a curved portion, AB is obtained. However, if the load is, removed at any point between O and B, the, curve is retraced along BAO and the wire, attains its original length. The portion OB of, the graph is called elastic region and the, point B is called elastic limit or yield point., The stress corresponding to B is called yield, strength., , (c) Beyond the point B, the strain increases, more rapidly than stress. If the load is, removed at any point C, the wire does not, come back to its original length but traces, dashed line. Even on reducing the stress to, , zero, a residual strain equal to OE is left in, the wire. The material is said to have, acquired a permanent set. The fact that, stress-strain curve is not retraced on, reversing the strain is called elastic, hysteresis., , (d) If the load is increased beyond the point, C, there is large increase in the strain or the, length of the wire. In this region, the, constrictions ( called necks and waists), develop at few points along the length of, the wire and the wire breaks ultimately at, the point D, called the fracture point., , In the region between B and D, the length, of the wire goes on increasing even without, any addition of load. This region is called, plastic region and material is said to, undergo plastic flow or plastic deformation., The stress corresponding to the braking, point is called ultimate strength or tensile, strength of the material., , 12. Elastic after Effect, , The bodies return to their original state on, the removal of the deforming force. Some, bodies return to their original state, immediately after the removal of the, deforming force while some bodies take, longer time to do so. The delay in regaining, the original state by a body on the removal, of the deforming force is called elastic after, effect.

Page 5 :

‘SUMMARY, See tes rose SS Pes eee nay Ber ee onl Cae ee, , In general there three of stresses (a) tensile stress — longitudinal stress, tssoctied with siehing) er compressive ste aneceinlodl eette compaaa nde,, , Fol deformations, stress ety proportional othe stan or many mater, , This ts known as Hooke's law. The constant of of, , Sloot Taree oes mere AAEM GEA cies a endl lulus, , to describe the elastic behaviour of objects as they respond to, , that act on them., , Acclass of solids called elastomers does not obey Hooke's law., , ‘When an object ts under tension or compression, the Hooke's 1a, F/A = YAL/L, , where AL/LIs the tensile or com, , , , , , , , where AL Is the displacen tn the direction of the applied force F,, wien eeay i exestedby, , 5. an due toa stress ‘a surrounding, fluid, the takes the form, , 7., , where p ts Se eee Hee Reena, volume strain) Is change in the object's volume due to that, pressure and Bits the lus of the object., , POINTS TO PONDER, , 1, , In the case of a wire, suspended from celing and stretched under the action of a weight (F), suspended from its other end, the force exerted by the ceiling on it 1s equal and opposite, to the weight. However, the tension at any cross-section A of the wire is just F and not, 2F, Hence, tensile stress which 1s equal to the tension per unit area ts equal to F/A., Hooke’s law ts valid only in the linear part of stress-strain curve., , The Young’s modulus and shear modulus are relevant only for solids since only solids, have lengths and shapes., , Bulk modulus ts relevant for solids, liquid and gases. It refers to the change in volume, when every part of the body is under the uniform stress so that the shape of the body, , remains unchanged., , Metals have larger values of Young's modulus than alloys and elastomers. A material, with large value of Young's modulus requires a large force to produce small changes in, its length., , In dally life, we feel that a material which stretches more Is more elastic, but ft a Is, misnomer. In fact material which stretches to a lesser extent for a given load ts considered, to be more elastic., , In general, a deforming force in one direction can produce strains in other directions, also. The proportionality between stress and strain in such situations cannot be described, by Just one elastic constant. For example, for a wire under longitudinal strain, the, lateral dimensions (radius of cross section) will undergo a small change. which is described, by another elastic constant of the material (called Potsson ratto)., , . Stress is not a vector quantity since, unlike a force, the stress cannot be assigned a, , specific direction. Force acting on the portion of a body on a specified side of a section, has a definite direction.