Page 1 :

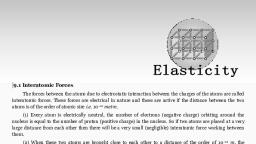

Estes, , The reaction force per unit area of the body due, to the action of the applied force is called stress, , , , , , , TANGENTIAL STRESS, , Pulling force per unit area Tangential force per unit area, Increase in length or volume It causes shearing of bodies, , , , , , ae) nN ] iN The ratio of the change in size or shape . Change in size or shape, to the original size or shape of the body, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , cr, Far a ‘ene, length - AL, a — (um,, —, ~, \, PUTO ly ‘, ACT Te) Cr || ll a 1 Vox, beeraU rm ity z > L\45, J, @ a, , Angle th h hich a li iginall, SHEAR STRAIN: ataweten atin sates —, , Deformation AX, RT ee ad OT ee, beet ry

Page 2 :

r, THERMAL STRESS (RE Sao tre, Y — Modulus of Elasticity 4), , a — Coefficient of Linear Expansion, /.t — Change in Temperature, , =, , { WORK DONE IN STRETCHING A WIRE |, W=- . Fx/L= ; load x elongation, , \ J, , , , , , , , , , , , , , , , , , , , , , g >), HOOKE'S LAW Within the elastic limit, the stress developed in a, body is proportional to the strain produced in it,, ee eketa a Ptiitai sie em thus the ratio of stress to strain is a constant.This, Se constant is called the modulus of elasticity, a (- >, STRESS STRAIN CURVE P c VE, a a 3 \ Breaking Point, If we increase the load gradually on a vertically z B Vield Point, , suspended metal wire: A, , °, , Strain, , , , , , Strain is small (<2%), Stress cc Strain—> Hook's law is valid, , IN REGION OA, , , , Stress isnot proportional to strain, but wire will still regain, , aoe its original length after removal of stretching force, , , , Wire yields — strain increases rapidly with small change in stress., This behavior is shown up to point C known as yield point, , eile) Bie, , , , Point D corresponds to maximum stress, which is called point of, breaking or tensile strength., , IN REGION CD, , MA, , , , The wire literally flows. The maximum stress corresponding to D, after, Tesiaei8)\ mala which wire begins to flow., , In this region, strain increase even if wire is unloaded and ruptures at E., , , , , , sl

Page 3 :

YOUNG'S MODULUS, , Young's modulus is defined as the ratio of the linear, stress to linear strain, provided the elastic limit is, not exceeded., , , , , , BULK MODULUS MODULUS OF RIGIDITY, , Volume Stress VAP, , p= ————_--, Tangential Stress, Volume Strain 1, , , , v, of, %, , =, , Tangential Strain, , ee ) THERMAL EXPANSION, , LINEAR EXPANSION, , ', ', ', 1, ', Lp =L;)(1+ a AT) eee =, ', ', ', ', ', ', 1, , , , , , (= coefficient of linear expansion, , AT = Change in temperature, , , , , , — After heating —>, , [ SUPERFICIAL OR AREAL EXPANSION, , !, !, !, A; = Ai (1+ BAT) §, {, !, ', !, , — Before heating >}, , , , , , , , Initial Length, Y = coefficient of Volume Expansion pene, , , , [3 = coefficient of Areal Expansion |, , id ' fer eee, VOLUME OR CUBICAL EXPANSION {0 fo-n-m--==---9""!, { yt, , ==> :, , —__——>, Length After Heating