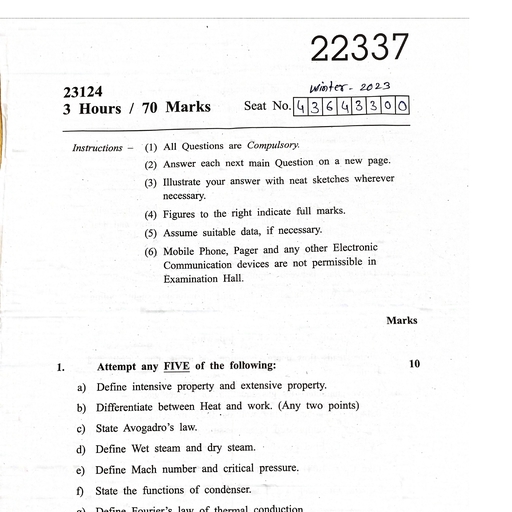

Page 1 :

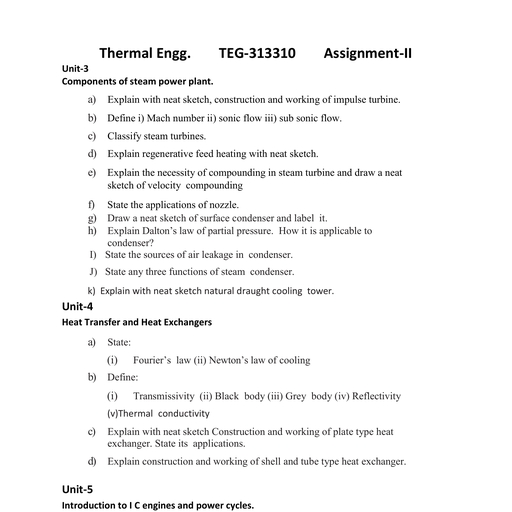

Exhaust steam, , Condenser, , , , Feed water, pump <2 heater, , , , Pe, om, , =, , Cooling water out, , Cooling water in

Page 2 :

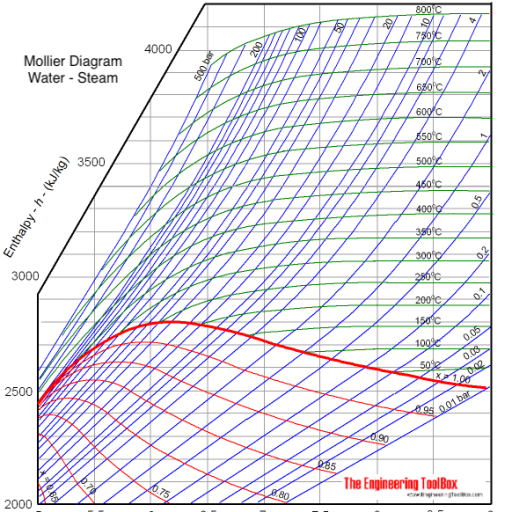

The process of draining steam from the certain section, of turbine during its expansion and using this steam, for heating feed water supplied to boiler is known *, bleeding and this process of heating feed water !s, known as regenerative feed heating., , , , Feed heating system are of two types :, , i), , When the bleed steam does not mix with feed water, or cascade system : In this condensate of condenser, passes through the coil of the feed water heater which, is surrounded by bleed steam from the turbine. This, , bleed steam heat the condensate flowing through the, coil and heats it., , When bleed steam is mixed with feed water or drain, pump system : In this case feed water and bleed, , steam comes in direct contact with each other is then, supplied to boiler., , Advantages, , 1) The thermal efficiency of boiler increases as heat input, , decreases., , | 2) Stress produce in boiler is reduced.

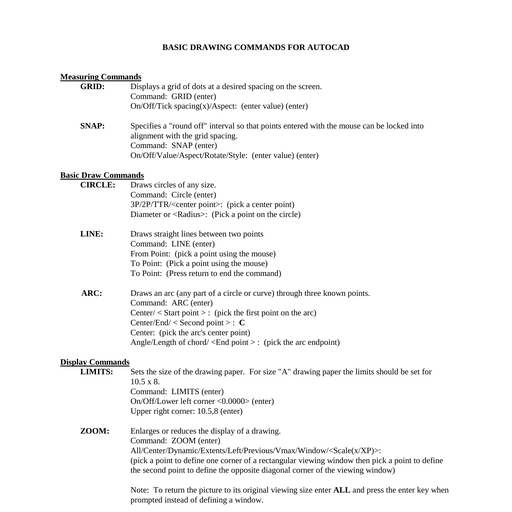

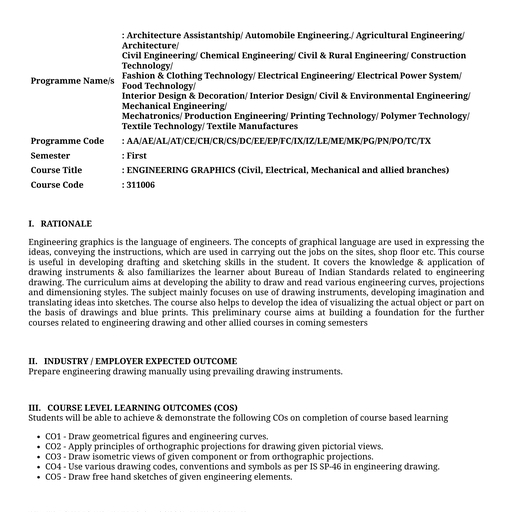

Page 4 :

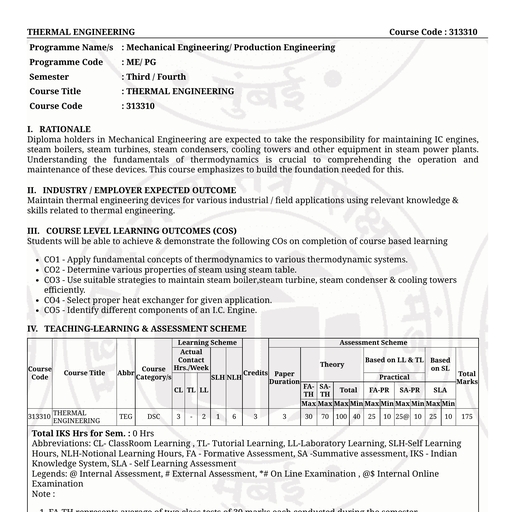

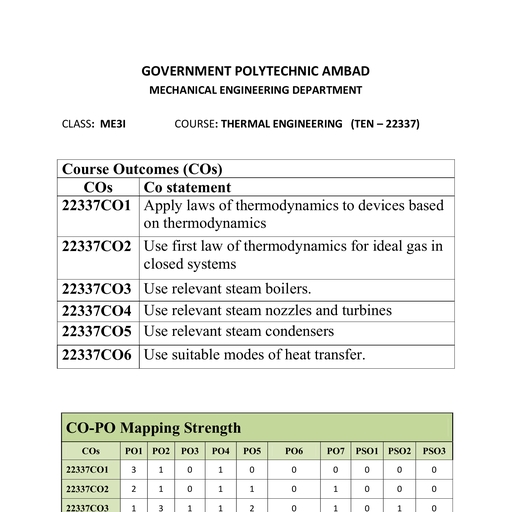

4.3.3 Losses in Steam Turbines ., , , , MOSHHY (MOB IE), , (MSBTE - W-14, W-15, S-16, S-17, W-18, $-19), , , , Any turbo machine extracts energy from high-pressure, steam and converts it into shaft work. The total energy, content available in steam supplied to the steam turbine is, not completely converted in the form of mechanical and, , electrical energy. There are certain losses in energy of, steam which occur inside a turbine., , Losses in Steam Turbines, , , , , , , , , , 1. Admission losses, 2. Leakage losses, 3. Friction losses, | 4. Exhaust loss, 5. Radiation and convection losses, 6. Losses due to moisture, , 7. Carry over losses, , Fig C4.3 : Losses in steam turbines, , , , ut, , Admission losses, , In practice the flow of steam through nozzle is not, isentropic, but accompanied with losses which, decrease the kinetic energy of steam.coming out of, , the nozzle. The decrease in kinetic energy is due to the, , following reasons, — Viscous forces between steam particles, , Heat loss from steam before entering the nozzle, , — Deflection of flow in the nozzle, Boundary layer development in the nozzle, , — Turbulence in the nozzle, , The friction in the nozzle which reduces available, , enthalpy drop and hence actual velocity leaving the, , nozzle is less than that obtained with isentropic, , expansion., , , , 4., , 5., , Leakage losses, , es the condenser, regulating, ozzies and, , haft etc., , Steam leaves the boiler and reach, after passing through the main valve,, valves, nozzles, clearance spaces between Nn, moving blades, diaphragm and rotating S$, Further there is large pressure difference between, inside of steam turbine and the ambient and also from, one location to another location across these devices., Therefore steam leakage takes place through, , — Main valve and regulating valve, , - Seals and glands, — Spaces between nozzles and moving blades, , — Spaces between diaphragm and shaft of turbine, , — Space between moving blade rings and turbine, casing, , — Leakage of steam through these is a direct loss of, energy., , Friction losses, , Frictional resistance is offered during flow of steam, through nozzles on moving and stationary blades. In, most of the turbines the blade wheels rotate in a, space full of steam. The viscous friction at the wheel, surface causes admission losses as steam passes from, nozzle to wheel. The effect of partial admission creates, eddies in the blade channels., , The surface of curved moving blades and stationary, blades offers resistance, which increases with increase, in roughness of blade surface and relative velocity, between steam and rotating blade., , The energy loss also takes place when the steam jets, , turns along the curvature of the blade surface. The, turning losses depend on the angle of turning., , Exhaust loss, , The energy content of steam is not fully utilized in the, turbine. Despite of being at very low pressure the, exhaust coming out of the turbine and entering the, condenser carries some of kinetic energy and useful, enthalpy, which is direct energy loss. :, , Radiation and convection losses, , The steam turbine operates at a relatively high, temperature; therefore some of the heat energy of.

Page 5 :

steam is radiated and convected from the body of the, turbine to its surrounding. These direct losses and are, minimized by proper insulation's., , 6. Losses due to moisture, , The steam passing through the last stage of turbine, has high velocity and large moisture content. The, liquid particles have lesser velocity than that of vapour, particles and hence the liquid particles obstruct the, flow of vapour particles in the last stage of turbine and, therefore, a part of kinetic energy of steam is lost. If, the dryness fraction of steam falls below 0.88, the, erosion and corrosion of blades can also take place., , 7. Carry over losses |, , ~- When steam passes from one stage to another, through the diaphragm, some energy losses takes, place, which are referred to as carry over losses, and therefore, the kinetic energy of steam, available at succeeding stage of moving blades for |, utilization is less than that of the exit at preceding, stage. This is due to formation of eddies in, , annular space between the nozzle and moving, blades., , - Due to moist air life of fan blade is decreased due |, to erosion.