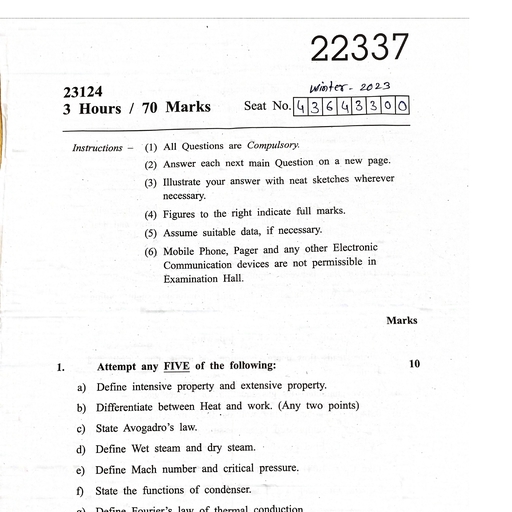

Page 1 :

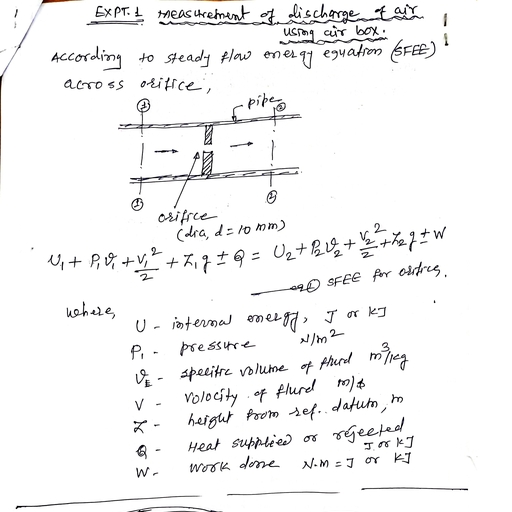

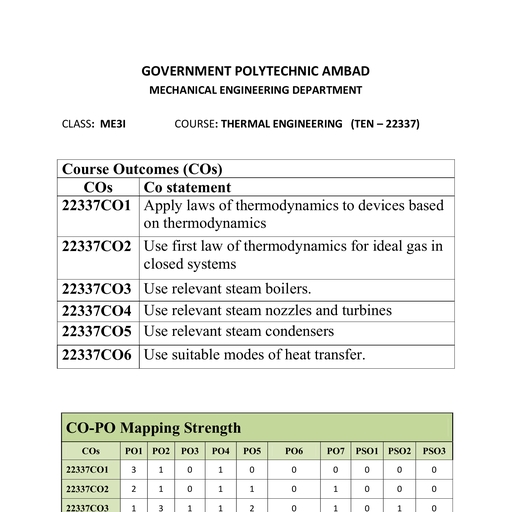

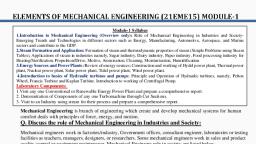

I., , Til., , FV., , VI., , Vil., , Practical No. 6: Determination of dryness fraction of steam, , Practical Significance Pr te, In industries who use steam for various purposes need to find out dryn, , i i F i reater impact on, determining condition of steam. Particles of water in steam can eG 2 a, a, various devices. In steam turbines the presence of water particle ain Wee, well as corrosion of blades of turbine. Wet steam is economical in ce! ., , Relevant Program Outcomes (POs) ‘, , PO2 - Discipline knowledge: Apply Mechanical engineering knowled;, based mechanical engineering related problems. ., PO3 - Experiments Sal practice: Plan to perform experiments and practices to use the, results to solve broad-based Mechanical engineering problems. f ;, , PO6 - Environment and sustainability: Apply Mechanical engineering solutions also, for sustainable development practices in societal and environmental contexts., , ge to solve broad, Competency and Skills , i, This practical is expected to develop the following skills for the industry identified, competency ‘Use principles of thermal engineering to maintain thermal related, equipment. ’:, , e Follow safety practices., , e Practice energy conservation., , Relevant Course Outcome(s), , “.e Use relevant steam boilers., , we, , Practical Outcome, , Determination of dryness fraction of a given sample of steam by using separating, * calorimeter., , Minimum Theoretical Background id, The steam containing water particles is called as wet steam: Steam calorimeters are, devices used to find dryness fraction of the steam. In separating calorimeters, water, particle are separated mechanically. The steam is allowed to strike on hard surface due to, which water particles falls down. The steam is separately collected in another chamber., The weight s of water particles and steam are measured. rien, Ge., ,, , ; } 'y re, Setup (Models) - i coafeg } ey, (Label the sketch), , , , , , , , Figure — Seperating Calorimeter, , , , Maharashtra state Board of Technical Education, , 29

Page 2 :

VILL. Resources Required, , , , ee enn, S.No. | Name of Resource Suggested Broad Specification : Quant, \ Experimental setup to find | Steam generator with —- 0., dryness fraction of steam. calorimeter. Steam generator equippe!, with pressure and temperature gauges., , , , , , , , , , , , , , , , 2 eine eee, 3, , 1X. _ Precautions to be Followed ., 1. Use safety shoes., 2. Monitor pressure gauge for safe operation of steam generator., , , , X. Procedure, 1. Start the steam generator., 2. Note the pressure and temperature of steam generator., 3. Open the steam valve for few seconds and send the sample to calorimeter., 4. Measure mass of condensate collected., 5. Measure mass of dry steam separately. ¢, , , , XI. Resources Used, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , |. Name of Broad Specifications Quantity Remarks, No. | Resource Make Details (if any), 1. | Seperats. gel SpHale phase AX, 2. | calosiMmert [ag 7 Ul, 3. To LP &@ JEL, ‘ Or, XII., , XIE., , , , XIV. Observations and Calculations, , , , , , , , , , , , , , , , , , Press| Mass of | Mass of, ce] Pome | aa MERND | moe, a 1% kg kg fraction, : : St) AA | 81s OTe.), 2 Aro r su, S| 5s] eres oe

Page 3 :

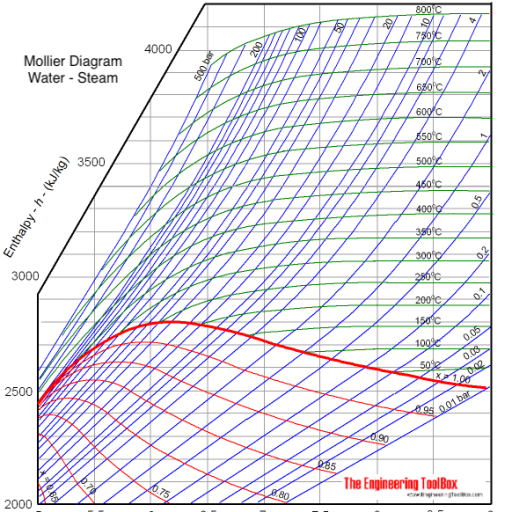

Thermal Engineering (22337), , Dryness fraction is calculated by formula (Calculate at different pressures), , X = M,/(M, + Mw) pose 6°76,, ' $10 =, XV. Results Ae BBY rach 1 FD, , , , , , , , a “e poten Sr O<7 6,, , XVI. Interpretation of Results (Giving meaning to results), , , , XVII. Conclusions (Actions to be taken based on the interpretations.) _, , lg sepia Cad, , opine pots, , , , , , , , XVIII. Practical Related Questions, , Note: Below given are few sample questions for reference. Teachers must design moresuch questions so as to ensure the achievement of identified CO., , 1. State limitation of separating calorimeter. :, , 2a Explain principle of separating and throttling calorimeter., , State formula to determine enthalpy of steam when it contain water particles., 4. List applications where wet steam is used. , 5. Calculate dryness fraction for different pressures., , (Space for Answer)