Page 1 :

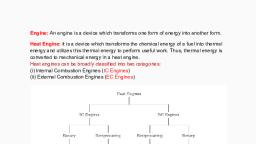

Air Pollution from I.C. Engines, 18, Air Pollution from I.C. Engines, and Its Control, 18.1. Introduction. 18.2. Pollutants-Pollution derived from combustion products-Mixture, strength and combustion product characteristics. 18.3. Spark ignition (S.I.) engine emissions, Crankcase emission-Evaporative emission-Exhaust emission. 18.4. S.I. engine emission, control-Modification in the engine design and operating parameters-Exhaust gas oxidation-, Exhaust emission control by fuel variation-Blow-by control-Evaporation emission control device, (EECD)-Control of oxides of nitrogen (NO,) –Total emission control packages. 18.5. Diesel, engine emissions. 18.6. Diesel smoke and control-Exhaust smoke-Causes of smoke, Measurement of smoke-Control of smoke-Diesel odour and control. 18.7. Comparison of, gasoline and diesel emissions. 18.8. Zero emission. 18.9. Air pollution from gas turbines and its, control. 18.10. Effects of engine emissions on human health-Highlights-Objective Type, Questions-Theoretical Questions., 18.1. INTRODUCTION, Air pollution can be defined as an addition to our atmosphere of any material which will, have a deleterious effect on life upon our planet. Besides I.C. engines other sources such, as electric power stations, industrial and domestic fuel consumers also add pollution., • There has been a great concern, in recent years, that the internal combustion engines is, responsible for too much atmospheric pollution, which is detrimental to human health, and the environment. Thus concerted efforts are being made to reduce the responsible, pollutants emitted from the exhaust system without sacrificing power and fuel consump-, tion., 18.2. POLLUTANTS, 18.2.1. Pollution Derived from Combustion Products, Pollutants are produced by the incomplete burning of the air-fuel mixture in the combustion, chamber. The major pollutants emitted from the exhaust due to incomplete combustion are:, 1. Carbon monoxide (CO), 2. Hydrocarbons (HC), 3. Oxides of nitrogen (NO,)., Other products produced are acetylene, aldehydes etc. If, however, combustion is complete, the only products being expelled from the exhaust would be water vapour which is harmless, and, carbon dioxide, which is an inert gas and, as such it is not directly harmful to humans., 1. Carbon monoxide (CO) :, • It is a colourless gas of about the same density as air., It is a poisonous gas which, when inhaled, replaces the oxygen in the blood stream s0, that the body's metabolism can not function correctly., Small amounts of CO concentrations, when breathed in, slow down physical and nievar, activity and produces headaches, while large concentration will kill., Scanned by CamScanner

Page 2 :

and vapour escaping from the carburettor are also harmful to health., A significant portion of this unburnt hydrocarbon may burn during expansion and exhaust, As the products cool down to exhaust temperature, major part of CO reacts with oxygen to, combustion chambers, unburnt hydrocarbons may appear in the exhaust., • derived from unburnt fuel emitted by exhausts, engine crankcase fumes, Due to existence of local very rich mixture pockets at much lower temperatures than the, (Ois generally formed when the mixture is rich in fuel. The amount of CO formed increases (as, 613, unstable, and the following reactions take place before the equilib-, 21,0 + 0,-, →2(1- y) H,0 + 2yH, + yO,, is, C+ O2, →CO2, (1-х)СО, + хСО +, O2, a, 2. Hydrocarbons (HC):, Mechanism of formation of HC, mhe hydrocarbons also appear due to flame quenching near the metallic walls., 3. Oxides of nitrogen (NO,):, - Ovides of nitrogen and other obnoxious substances are produced in very small quantities, and, in certain environments, can cause pollution ; while prolonged exposure is danger-, ous to health., Mechanism of formation of nitric oxide (NO), At high combustion temperatures, the following chemical reactions take place behind, the flame :, N2 + O2-, →2NO, N2, + 2H,0, → 2NO + 2H2, Chemical equilibrium calculations show that a significant amount of NO will be formed at, the end of combustion. The majority of NO formed will however decompose at the low temperatures, of exhaust. But due to very low reaction rate at the exhaust temperature a part of NO formed, remains in exhaust. It is far in excess of the equilibrium composition at that temperature as the, formation of NO freezes at low exhaust temperatures., The NO formation will be less in rich mixtures than in lean mixtures., Smoke or particulate, ond particles are usually formed by dehydrogenation, polymerisation and agglomera-, tion., intte combustion process of different hydrocarbons, acetylene (C,H,) is formed as ar, Scanned by CamScanner

Page 3 :

are formed as intermediate products. In some parts of the spray the aldehydes will be left, 614, - INTERNAL COMBUSTION ENGINES, Aldehydes, Due to very slow chemical reaction during delay period in the diesel engines, aldebua, after the initial reactions. These aldehydes may be oxidised in the later part of the et, if the mixture temperature is high, and if there is sufficient oxygen., • At heavy loads, due to lack of oxygen, an increase in aldehyde emission in the exhauet :, observed., Following points are worth noting :, 1. If the air-fuel mixture is too rich there is insufficient air for complete combustion ond, some of the fuel will not be burnt or at least only partly burnt. Since hydrogen has a greater affini, for oxygen, hydrogen will take all the oxygen it needs leaving the carbon with a deficiency of oxvg, As a result of the shortage of oxygen a percentage of the carbon will be converted to carbon monoride, as well as carbon dioxide, and, with very rich mixtures, particles of pure unburnt carbon, expelled from the exhaust as "black smoke"., may be, Incomplete combustion due to partial oxidation of the hydrocarbon fuel also produces other, products such as acetylene and aldehyde. These products, when expelled from the exhaust, leave an, unpleasant smell and are particularly noticeable during engine warm-up when a rich mixture is, provided., 2. If the mixture is made too weak it is unlikely that the atomised liquid fuel will be thor-, oughly mixed throughout the combustion chamber so that slow burning, incomplete combustion and, misfiring may result., 18.5, en, A further characteristic of weak mixtures is that the excess oxygen (which has not taken part, in the combustion process) at very high temperature is able to combine with some of the nitrogen, that constitutes about three-quarters of air, to form oxides of nitrogen such as nitrogen peroxide, (NO,). The amount of nitrogen peroxide produced will increase as the mixture weakens until it peaks, at just over an air-fuel ratio of 15.5: 1, beyond this point the temperature of combustion begins to fall, below that necessary for formation of nitrogen peroxide so that with further reduction in mixture, strength the amount of nitrogen peroxide progressively decreases., ir, 18.2.2. Mixture Strength and Combustion Product Characteristics, The chemically correct air-fuel ratio by mass for complete combustion is known as, stoichiometric ratio., Refer Fig. 18.1. It shows how the three main exhaust pollutants products (CO, HC, NO), vary from different air-fuel ratio operating on either side of the stoichiometric ratio for a, very rich mixture (11: 1) to a very lean mixture (18 : 1)., The amount of CO produced in the exhaust is about 8% for an 11:1 air-fuel, ratio,, but this percentage steadily decreases to zero as the mixture is reduced to just, beyond the stoichiometric ratio (on the lean side)., HC produced in the exhaust gases amounts to about 1100 parts per million (ppm), with a rich 11 : 1 air-fuel ratio and, as the mixture strength approaches the, stoichiometric ratio, it progressively falls to around 500 ppm. A further weakening, of the mixture to 18:1 air-fuel ratio only reduces HC content to approximately, 350 рpm., -, Oxides of nitrogen products formed during combustion are very low at 100 ppm with, a rich air-fuel ratio of 11: 1. As the mixture strength approaches the stoichiometric, ratio it rises fairly rapidly to 2000 ppm, and a further reduction of the mixture, strength to 15:1 peaks the oxides of nitrogen to something like 2,300 ppm, weake, ing the mixture beyond this point rapidly reduces it until, at an 18:1 air-fuel ratio,, it is 1000 ppm., Scanned by CamScanner

Page 4 :

The following are the three main sources from which pollutants are emitted from the S.I., 615, 2400, 2000, 10, Carbon.monoxide, 1600, 8, 1200, 6., 800, Hydrocarbons, 400, 11, 12, 13, 14, 15, 16, 18, Air-fuel ratio +, 191. Effects of mixture strength on exhaust composition of a petrol engine., engine :, mhe crankcase. Where piston blow-by fumes and oil mist are vented to the atmosphere., nhe fuel system. Where evaporative emissions from the carburettor or petrol injection air, o The exhaust system. Where the products of incomplete combustion are expelled from the, tail pipe into the atmosphere., Evaporative, emission, Crankcase, emission, (HC), CO, Evaporative, emission·, (HC), Exhaust, emissions, rco, HC, Crankcase, emission, THCT, LCO., NO2, LPB., Fig. 18.2. Spark ignition engine emissions., Scanned by CamScanner, Hydrocarbon or oxides, of nitrogen (ppm), / Stoichiometric, itrogen, 17, 2., Carbon monoxide (%)

Page 5 :

18.3.1. Crankcase Emission, Piston ring blow-by :, The piston and its rings are designed to form a gas-tight seal between the sliding piston, spirt and the cylinder walls. However, in practice there will always be some compressed, charge and burnt fumes which manage to escape past the compression and oil control, piston rings and therefore enter the crankcase (Fig. 18.3). These gases which find their, way past the piston ring belt may be unburnt air-fuel mixture hydrocarbons, or burnt (or, partially burnt) products of combustion, CO, H,0 (steam) or CO., a) Blow-by during, the compression, (b) Blow-by during, the power stroke, stroke, Escaping-, charge, Escaping, exhaust, gases, Fig. 18.3. Piston ring blow-by., • Piston blow-by increases with engine speed, and, in particular, as the piston rings and, cylinder bore wears (Fig. 18.4), the blow-by, becomes more noticeable in the upper speed, 1.0, 0.08, range., • Blow-by takes place between the piston ring, gap, piston-ring to piston-groove clearance, and in the T.D.C. region where the piston, ring circumferential shape can not accu-, rately follow the contour of an oval or bell, mounter cylinder wall., • Besides effectively reducing the engine com-, pression ratio and the power developed, the, effects of piston blow-by are two-fold :, (i) It can lead to a high concentration of, combustible air-fuel mixture which could, cause an explosion in the crankcase., E 0.06, 0.04, 0.02, Bedded in piston and rings, 2000, 4000, 6000, Engine speed (rev/min), Fig. 18.4. Effect of engine speed on, piston and ring blow-by., Scanned by CamScanner, Engine blow-by (m°/min)