Page 1 :

Combustion in C.I. Engines, 6:1 to 11 : 1 of S.I. engines) the heavy forces act on the parts of the engine and, 6.1. Introduction. 6.2. Combustion phenomenon in C.I. engines. 6.3. Fundamentals of the, combustion process in diesel engines. 6.4. Delay period (or ignition lag) in C.I. Engines, 6.5. Diesel knock. 6.6. C.I. engine combustion chambers-Primary considerations in the design, of combustion chambers for C.I. engines-Basic methods of generating air swirl in C.I. engines, combustion chambers-Types of combustion chambers. 6.7. Cold starting of C.I engines, Highlights-Objective Types Questions-Theoretical Questions., 6.1. INTRODUCTION, The compression ignition (C.I.) engine was developed by Dr. Rudol Diesel, he got a patent of, his engine in 1892., It is a very important prime mover these days and is finding wide applications in :, buses trucks, tractors;, locomotives,, pumping sets;, stationary industrial applications ;, small and medium electric power generation ;, marine propulsion., The following points are worth noting about C.I. engines :, Its thermal efficiency is higher than S.I. engines., C.I. engine fuels (diesel cil5) are less expensive than S.I. engine fuels (petrol or gaso-, line). Furthermore, since C.I. engines fuels have a higher specific gravity than petrol,, and since fuel is sold on the volume basis (litres) and not on mass basis (kg), more kg of, fuel per litre are obtained in purchasing C.I. engine fuel., Due to the above mentioned factors the running cost of C.I. engines is much less than S.l., engines and as a consequence these engines find wide application in industrial, transport and, other applications., A C.I. engine is not much favoured in passenger cars due to the following reasons :, (i) Heavier weight;, (ii) Noise and vibration ;, (iii) Smoke ;, (iv) Odour., In view of the utilisation of heavier compression ratios (12 :1 to 22 : 1 compared, therefore heavier parts are required., 226, Scanned by CamScanner

Page 2 :

227, COMBUSTION IN C.I. ENGINES, Also, because of heterogeneous mixture, lean mixture is used., These factors make the engine heavier., The incomplete combustion of heterogeneous mixture, and droplet combustion, result in the smoke and odour., • C.I. engines are manufactured in the following range of speeds, speeds and power out-, puts :, Particulars, Range, 50 mm to 900 mm, 1. Piston diameters, 2. Speeds, 100 r.p.m. to 4400 r.p.m, 3. Power output, 2 В.Р. to 40000 В.Р., 6.2. COMBUSTION PHENOMENON IN C.I. ENGINES, The process of combustion in the compression ignition (C.I.) engine is fundamentally, different from that in a spark-ignition engine. In C.I. engine combustion occurs by the, high temperature produced by the compression of the air, i.e. it is an auto-ignition. For, this a minimum compression ratio of 12 is required. The efficiency of the cycle increases, with higher values of compression ratio but the maximum pressure reached in the cyl-, inder also increases. This requires heavier construction. The upper limit of compres-, sion ratio in a C.I. engine is due to mechanical factor and is a compromise between high, efficiency and low weight and cost. The normal compression ratios are in the range of 14, to 17, but may be upto 23. The air-fuel ratios used in the C.I. engine lie between 18 and, 25 as against about 14 in the S.I. engine, and hence C.I. engines are bigger and heavier, for the same power than S.I. engines., • In the C.I. engine, the intake is air alone and the fuel is injected at high pressure in the, form of fine droplets near the end of compression. This leads to delay period in the C.I., engine, is greater than that in the S.I. engine. The exact phenomenon of combustion in, the C.I. engine is explained below., Each minute droplet of fuel as it enters the highly heated air of engine cylinder is, quickly surrounded by an envelope of its own vapour and this, in turn and at an, appreciable interval is inflamed at the surface of the envelope. To evaporate the, liquid, latent heat is abstracted from the surrounding air which reduces the tem-, perature of the thin layer of air surrounding the droplet, and some time must elapse, before this temperature can be raised again by abstracting heat from the main, bulk of air in this vicinity. As soon as this vapour and the air in actual contact with, it reach a certain temperature, ignition will take place. Once ignition has been, started and a flame established the heat required for further evaporation will be, supplied from that released by combustion. The vapour would be burning as fast as, it can find fresh oxygen, i.e., it will depend upon the rate at which it is moving, through the air or the air is moving past it., In the C.I. engine, the fuel is not fed in at once but is spread over a definite period., The first arrivals meet air whose temperature is only a little above their self-, ignition temperature and the delay is more or less prolonged. The later arrivals, find air already heated to a far higher temperature by the burning of their, predecessors and therefore light up much more quickly, almost as they issue from, the injector nozzle, but their subsequert progress is handicapped for there is less, oxygen to find., If the air within the cylinder were motionless, only a small proportion of the fuel, would find sufficient oxygen, for it is impossible to distribute the droplets uniformly, throughout the combustion space. Therefore some air movement is absolutely, essential, as in the S.I. engine. But there is a fundamental difference between the, Scanned by CamScanner

Page 3 :

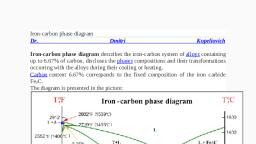

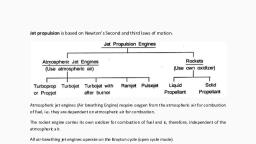

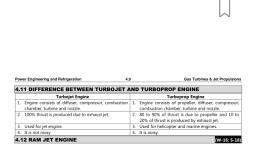

and mean a confusion of whirls and eddies with no general direction of flow, (to, air movements in the two types of engines. In the S.I. engine we call it turbulence, INTERNAL COMBUSTION ENGINES, break up the surface of the flame front, and to distribute the shreds of flame, it air swirl and mean an orderly movement of the whole body of the air, with or, 228, throughout an externally prepared combustible mixture). In the C.I. engine ame, without some eddying or turbulence, so as to bring a continuous supply of fn or, to each burning droplet and sweep away the products of combustion which othe air, tend to suffocate it., Three phases of C.I. engine combustion :, In the C.I. engine, combustion may be considered in three distinct stages as shown in Fir o., 1. Ignition delay period., 2. Period of rapid or uncontrolled combustion., 3. Period of controlled combustion., The third phase is followed by after burning (or burning on the expansion stroke), which, may be called the fourth phase of combustion., 1. Ignition delay period, The delay period is counted from the start of injection to the point where the p-8 com., bustion curve departs from air compression (or no ignition or motoring) curve., • The delay period can be roughly sub-divided into physical delay and chemical de., lay. The period of physical delay is the time between the beginning of injection, and the attainment of chemical reaction conditions. In the physical delay period,, the fuel is atomized, vaporized, mixed with air, and raised in temperature. In the, chemical delay period reaction starts slowly and then accelerates until inflammation, or ignition takes place (it may be noted that the ignition delay in the S.I. engine is, essentially equivalent to the chemical delay in the C.I. engine)., 90, 80, Start of, combustion, 70F, Compression, pressure, 60, Injection, starts, 50, 40, 0.001 sec., 30, 1+2+3-4-, 20, Injection, 10F, Atmospheric, 120, 100, 80, 60, 40, 20 T.D.C. 20, 40, 60, 80, 100 120, Time, degrees of crankshaft rotation (0), Fig. 6.1. Combustion phenomenon of C.I. engine., Scanned by CamScanner, p(bar)

Page 4 :

229, COMBUSTION IN C.I. ENGINES, The delay period exerts a great influence in the C.I. engine combustion phenomenon. It, is clear that the pressure reached during the second stage will depend upon the dura-, tion of the delay period ; the longer the delay, the more rapid and higher the pressure, rise, since more fuel will be present in the cylinder before the rate of burning comes, under control. This causes rough running and may cause diesel knock. Therefore we, must aim to keep the delay period as short as possible, both for the sake of smooth run-, ning and in order to maintain control over the pressure changes. But some delay period is, necessary otherwise the droplet would not be dispersed in the air for complete com-, bustion. However, the delay period imposed upon is greater than what is needed and, the designer's efforts are to shorten it as much as possible., 2. Period of rapid or uncontrolled combustion. The second stage of combustion in, C.I. engines, after the delay period, is the period of rapid or uncontrolled combustion. This period, is counted from the end of the delay period to the point of maximum pressure on the indicator, diagram. In this second stage of combustion, the rise of pressure is rapid because during the delay, period the droplets of fuel have had time to spread themselves out over a wide area and they have, Gresh air all around them. About one-third of heat is evolved during this process., The rate of pressure rise depends on the amount of fuel present at the end of delay period,, degree of turbulence, fineness of atomization and spray pattern., 3. Period of controlled combustion. At the end of second stage of combustion, the, temperature and pressure, are so high that the fuel droplets injected in the third stage burn, almost as they enter and any further pressure rise can be controlled by purely mechanical means,, i.e. by the injection rate. The period of controlled combustion is assumed to end at maximum cycle, temperature.The heat evolved by the end of controlled combustion is about 70 to 80 per cent., 4. After burning, a . The combustion continues even after the fuel injection is over, because of poor distribution, of fuel particles. This burning may continue in the expansion stroke upto 70° to 80° of, crank travel from T.D.C. This continued burning, called the after burning, may be, considered as the fourth stage of the combustion. The total heat evolved by the end of, entire combustion process is 95 to 97% ; 3 to 5% of heat goes as unburned fuel in, exhaust., • In the p-V diagram, the stages of combustion are not seen because of little movement of, piston with crank angle at the end and reversal of stroke. So for studying the combus-, tion stages, therefore, a pressure-crank angle or time, p-0 or p-t diagram is invariably, used. In the actual diagram, the various stages of combustion look merged, yet the, individual stage is distinguishable., Factors affecting combustion in C.I. engine :, The factors affecting combustion in C.I. engine are as follows:, (1) Ignition quality of fuel (cetane number), (2) Injection pressure of droplet size, (3) Injection advance angle, (4) Compression ratio, (5) Intake temperature, (6) Jacket water temperature, (7) Intake pressure, supercharging, (8) Engine speed, (9) Load and Air to fuel ratio, (10) Engine size, (11) Type of combustion chamber., Scanned by CamScanner

Page 5 :

• The power output of a diesel engine is controlled by varying the amount of fuel s, The pressure and temperature reached at the end of the compression stroke will depend, Effect of Compression Ratio and Engine Speed on Cylinder Pressure and Tem-, It has been observed that injection usually commences 15° to 20° before T.D.C., Further it can be seen that the pressure and temperature rise in the cylinder with, injected into a cylinder filled with compressed and heated air whereas the petrol engine, 15 :1 compression ratio engine would have something like 600°C maximum tem-, when both cylinder pressures and temperatures are much lower. As an example, a, are established, this being known as the ignition and the temperature at which it, occurs is called the self-ignition temperature of the fuel under these condition. The, heat required for further evaporation of the fuel droplets will thus be provided from, INTERNAL COMBUSTION ENGINES, 230, perature, spray, is controlled by throttling the pre-mixed charge entering the cylinder., primarily upon the compression ratio, intake temperature and speed of the en de, perature at T.D.C. but at 15° before T.D.C. this would only amount to 530, increased speed is largely due to the reduced time available for compressed ci, escape past the piston rings and heat to be lost through the cylinder walls and h, Diesel Engine Heterogeneous Charge Mixing, The air-fuel mixture formation, in the diesel engine, is of a heterogeneous natures, that is it, is locally concentrated at various sites and is therefore unevenly distributed throughout the cylin., der and combustion chamber., Injected fuel spray penetrates the highly compressed and heated air mass where it is, pulverised into many very small droplets in a localised formation. The mixing of the, localised spray of fuel droplets in the hot air charge causes stoichiometeric (14.7:1 by, weight) air-fuel ratio combustion zones to be established which are completely surrounded, by pure air only. Thus the overall (averaged out) air-fuel mixture ratio range may vary, from a rich, full load, 20 : 1, to a weak no-load, 100 1, air-fuel ratio., Most engines operate with at least 20% excess air due to difficulty of introducing, sufficient exposed oxygen to the fuel vapour in the given time available so that the, combustion process can be completed before the exhaust valve opens. If the oxygen, supply is partially prevented from getting to the fuel vapour early enough during the, power stroke then incomplete combustion, polluted exhaust gas and dark smoke will, result., Diesel Engine Injected Spray Combustion Process, Towards the end of the compression stroke when injection of the fuel into the combus-, tion chamber commences, the quantity of fuel discharged is spread out over a predeter-, mined period., • The fuel spray enters the hot combustion chamber but does not immediately ignite,, instead it breaks up into very small droplets (Fig. 6.2) and once these liquid droplets, are formed, their outer surfaces will immediately start to evaporate so there will oe, liquid core surrounded with a layer of vapour. At this point it should be explained that, the burning of a hydrocarbon fuel in air is purely an oxidation process. Thus, inida, heat liberated from the oxidation of the fuel vapour is less than the rate at which heur, extracted by convection and conduction, but eventually a critical temperature 1s reace, when the rate of heat generated by oxidation exceeds the heat being dissipated 0y con he, tion and radiation. As a result, the temperature rises which, in turn, speeds up tes, oxidation process thus further increasing the heat released until a flame site orh it, heat released by the oxidation process, which is referred to as combustion., Scanned by CamScanner