Page 2 :

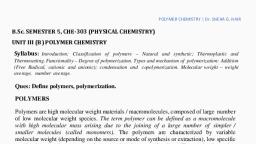

Outline, • Introduction, , • Classification of Polymers, • Kinetics of Polymerization, • Number-average Concept, • Weight-average Concept, • Methods of Molecular mass determination

Page 3 :

Polymers - What are they?, • Polymers are a special kind of macromolecules., • The word polymer comes from the Greek words, “poly,” meaning “many”, and “meres,” meaning, “parts” or “repeating units”, • A Polymer consists of a large chain of repeating, molecules (monomers) that are attached in an end to, end fashion.

Page 4 :

• Well known examples of Polymers include plastics, DNA and, proteins. E.g.- Polyethylene (PE), Poly vinyl chloride (PVC), Polypropylene whose repeating unit structures are shown below., “Poly”, , “mer”, , many, , repeat unit, , repeat, unit, , repeat, unit, , repeat, unit, , H, , H, , H, , H, , H, , H, , H H H H H H, , H, , H, , H, , H, , H, , H, , C, , C, , C, , C, , C, , C, , C C C C C C, , C, , C, , C, , C, , C, , C, , H, , H, , H, , H, , H, , H, , H Cl H Cl H Cl, , H, , CH3 H, , Polyethylene (PE), , Poly(vinyl chloride) (PVC), , CH3 H, , CH3, , Polypropylene (PP), , 4

Page 6 :

Classification of Polymers, Polymers are classified in a number of ways:, , (1) On the basis of source or origin, , (2) On the basis of structure, (3)On the basis of mode of synthesis, (4) On the basis of interparticle forces

Page 7 :

(1) Classification of Polymers Based upon Origin or, Source, On the basis of origin or source, the polymers are classified, into three types:, (a) Natural Polymers, (b) Semi-synthetic Polymers, (c) Synthetic Polymers, (a) Natural Polymers: The polymers, which are isolated, , from natural materials, mostly plants and animal sources,, are called natural polymers. The classification of natural, polymers are:

Page 9 :

(i) Polysaccharides, , , Starch and cellulose are very common examples of polysaccharides. They, are the polymers of glucose. Starch is a chief food reserve of plants while, cellulose is chief structural material of plants., , Structure of Starch, , Structure of Cellulose

Page 10 :

(ii), , , , , Polypeptides and Proteins, Amino acids are the building blocks for proteins. All amino acids contain, an amino or NH2 group and a carboxyl (acid) or COOH group. There are, 20 different amino acids commonly found in proteins and often 300 or, more amino acids per protein molecule., To form polypeptides and proteins, amino acids are joined together by, peptide bonds, in which the amino or NH2 of one amino acid bonds to the, carboxyl (acid) or COOH group of another amino acid .

Page 11 :

(iii) Polynucleotides, A polynucleotide molecule is a biopolymer composed of 13 or more, , nucleotide, monomers, covalently, bonded, in, a, chain. DNA (deoxyribonucleic acid) and RNA (ribonucleic acid) are, examples of polynucleotides with distinct biological function., Polynucleotides occur naturally in all living organisms.

Page 12 :

(iv) Polyesters, , , , Polyester is a synthetic polymer made of purified terephthalic acid (PTA), or its dimethyl ester dimethyl terephthalate (DMT) and monoethylene, , glycol (MEG). With 18% market share of all plastic materials produced,, it ranges third after polyethylene (33.5%) and polypropylene (19.5%).

Page 13 :

(b) Semi-synthetic Polymers

Page 14 :

(c) Synthetic Polymers: The polymers which are prepared in the, laboratory are referred to as synthetic polymers or man-made polymers. Some, examples of synthetic polymers are Polyethylene, Polystyrene, Teflon, PVC,, , Synthetic Rubber, Nylon, Bakelite, Orlon, Polyester, Terylene etc., , Polyethylene, , Polystyrene, , Polytetrafluoroethylene (PTFE)

Page 15 :

Polyvinylchloride, (PVC), Synthetic Rubber, , Bakelite, , Nylon

Page 17 :

(2) Classification of Polymers Based on Structure, • This classification of polymers is based upon how the monomeric, units are linked together. Based on their structure, the polymers, are classified as :, (a) Linear Polymers, (b) Branched Chain Polymers, (c) Cross-linked Polymers or Network Polymers

Page 18 :

(a) Linear Polymers, A polymer is a general term for any molecule that is a long, string of smaller repeating parts formed by carbon-carbon bonds., The bonds can form long straight chains known as linear, polymers.

Page 19 :

Properties of Linear Polymers, 1) High melting point, 2) High density, 3) High tensile strength due to close packing of polymer chains., , Applications, Food packaging, shampoo bottles, Milk, water, and juice containers, grocery, , bags, toys, liquid detergent bottles, Soft drink based cups, flower pots, drain, pipes, signs, stadium seats, trash cans, re-cycling bins, traffic barrier cones, golf, bag liners etc., , Food packaging, , Bag, , Toys, , Liquid detergent bottles

Page 20 :

(b) Branched Chain Polymers

Page 21 :

(c) Cross-linked Polymers or Network Polymers, In this type of polymers, the monomeric units are linked together to, constitute a three dimensional network. The links involved are called, cross links. Cross-linked polymers are hard, rigid and brittle because, of their network structure. Common examples of this type of Crosslinked polymers are bakelite, formaldehyde resin, melamine, etc.

Page 22 :

Bakelite, , Melamine Formaldehyde Resin

Page 23 :

(3) Classification of Polymers Based on Synthesis, • On the basis of the mode of synthesis, the polymers are, classified as :, (a) Addition Polymers, , (b) Condensation Polymers, , (a) Addition Polymers: When the monomer units are repeatedly, added to form long chains without the elimination of any byproduct molecules, the product formed is called addition polymer, and the process involved is called addition polymerization.

Page 24 :

A few examples of addition polymerisation are:

Page 25 :

(b) Condensation Polymers:, , In this type of polymers, the monomers, , react together with the elimination of a simple molecule like H2O, NH3 or ROH,, etc. The reaction is called condensation and the product formed is called, , condensation polymer., • As the process involves the elimination of by-product molecules, the, molecular mass of the polymer is not the integral multiple of the monomer, units.

Page 26 :

Dacron, , Bakelite

Page 27 :

(4) Classification of Polymers Based on Inter Particle, Forces:, On the basis of the magnitude of intermolecular forces,, the polymers have been classified into the following, four categories:, (a) Elastomers, (b) Fibers, (c) Thermoplastics, (d) Thermosetting Polymers

Page 28 :

(a) Elastomers:, •, , These are the polymers in which the polymer chains are held up, by weakest attractive forces. They are amorphous polymers, having high degree of elasticity., , •, , The weak forces permit the polymer to be stretched out about, ten times their normal length but they return to their original, position when the stretching forces is withdrawn., , •, , These polymers consist of randomly coiled molecular chains, having few cross links.

Page 29 :

•, , When the stress is applied, these randomly cross chains, straighten out and the polymer gets stretched. As soon as the, stretching force is released, the polymer regain the original, shape, , •, , because weak forces do not allow the polymer to remain in, , the stretched form.

Page 30 :

(b) Fibers, These are the polymers which have quite strong interparticle, forces such as Hydrogen-bonds. They have high modulus and, high tensile strength., These are thread-like polymers and can be woven into, , fabrics. Silk, terylene, nylon, etc., are some common, examples of such types of polymers. The H-bonds in nylon66 are shown below:

Page 31 :

(c) Thermoplastics: These are the polymers in which the, interparticle forces of attraction are in between those of, Elastomers and fibers., • The polymers can be easily molded into desired shapes by, heating and subsequent cooling to room temperature. There, is no cross-linking between the polymer chains., • Thermoplastics polymers soften on heating and becomes, fluids, but on cooling they become hard. They are capable, of undergoing such reversible changes on heating and, cooling repeatedly., A few examples of Thermoplastics are:, • polyethylene, polystyrene, PVC etc.

Page 32 :

(d) Thermosetting Polymers:, • These are the polymers which become hard and, , infusible on heating., • They are normally made from semi-fluid substances, with low molecular masses, by heating in mould., Heating results in excessive cross-linking between the, , chains forming three dimensional network of bonds as a, consequence of which a non-fusible and insoluble hard, , material is produced

Page 33 :

Polymerization, • Polymerization is a process which allows simple low molecular, weight compounds to combine and forms a complex high molecular, , weight compound. For this process, each molecule of the compound, should have the capability to react at least with two other molecules of, the same or some other compound., • The functionality of a compound depends on the number of its, , reactive sites. Due to the presence of the reactive functional groups, a, compound assumes its functionality. These groups are such as -OH, COOH, -NH2, -SH, -NCO, etc. The number of these functional, groups per molecule of the compound defines its functionality.

Page 35 :

(A) Free-Radical Addition Polymerisation, The polymer chain is initiated by free radicals produced by the, , decomposition of compounds called initiators:, , R, , R, , ., , ., , R +R, , Free radicals, , • The initiators can also be decomposed by using ultraviolet light, and form the same free radicals as those formed by its thermal, decomposition., • The polymerisation reactions initiated by UV light are known as, 'photo initiated polymerization' .

Page 36 :

• Free-radicals are also formed when initiators are induced by, suitable catalysts. The decomposition of hydrogen peroxide, by a ferrous ion and hydro peroxide by a cobaltous ion are, the examples of initiators, decomposed by reductionoxidation (redox) reaction., , H2O2 +, , Fe2+, , -, , HO + HO· + Fe3+, , Hydrogen peroxide, , R-O-OH + Co2+, Hydroperoxide, , RO· + HO- + Co3+

Page 37 :

Kinetics of Polymerization, • Stepwise polymerization: Any two monomers, present in the reaction mixture can link together at any, time. The growth of the polymer is not confined to chains, , that are already formed., , • Chain polymerization: an activated monomer attacks, another monomer, links to it, then that unit attacks, another monomer, and so on.

Page 39 :

• HO-M-COOH + HO-M-COOH → HO-M-COO-M-COOH, , • Because the condensation reaction can occur between, molecules containing any number of monomer units, chains of, , many different lengths can grow in the reaction mixture.

Page 40 :

Stepwise polymerization, • The rate law can be expressed as, d [ A], k [ A]2, dt, , • Assuming that the rate constant k is independent of, the chain length, then k remains constant throughout, the reaction., [ A]0, [ A] , 1 kt[ A]0, , p, , [ A]0 [ A], kt[ A]0, , [ A]0, 1 kt[ A]0, , • The degree of polymerization: The average number of, monomers per polymer molecule, <n>, n, , [ A]0, 1, , [ A] 1 p

Page 41 :

Chain polymerization, • Occurs by addition of monomers to a growing polymer, often, by a radical chain process., • Rapid growth of an individual polymer chain for each activated, monomer., • The addition polymerizations of ethene, methyl methacrylate,, and styrene., , • The rate of polymerization is proportional to the square root of, the initiator concentration.

Page 42 :

Three basic types of reaction step in a Chain, polymerization, I → R. + R. vi = ki[I], M + R. → .M1, (fast), (b) Propagation: M + .M1→ .M2, M + .M2→ .M3, ░ vp = kp[M][.M], M + .Mn-1→ .Mn, (c) Termination:, Mutual termination: .Mn + .Mm→ Mn+m, Disproportionation: .Mn + .Mm→ Mn + Mm, Chain transfer:, M + .Mn→ Mn + .M, (a) Initiation:

Page 43 :

Influences of termination step on the, polymerization, •, , Mutual termination: two growing radical chains, combine. vt = kt ([.M])2, , •, , Disproportionation: Such as the transfer of a, hydrogen atom from one chain to another, which, corresponds to the oxidation of the donor and the, reduction of acceptor., vt = kt ([.M])2, , •, , Chain transfer: vt = ?

Page 44 :

• the net rate of change of radical concentration is calculated as, d[.M ] , , , 2 fki [ I ] 2kt [.M ]2, dt , , production, , • Using steady-state approximation (the rate of production of, , radicals equals the termination rate), 1/ 2, , fk , [.M ] i , kt , , [ I ]1 / 2, , • The rate of polymerization, vp = kp[.M][M] = kp[M], , fk i , , , k, t , , 1/ 2, , [I ]1 / 2

Page 45 :

The above equation states that the rate of polymerization is, proportional to the square root of the concentration of the initiator., , Kinetic chain length, v,, , number of monomer units consumed, k[ M ][I ]1/ 2, number of activated centres produced, 1, where k k p ( fki kt ) 1/ 2, 2, , v, , <n> = 2v, , (for mutual termination)

Page 46 :

• Example: For a free radical addition polymerization with ki =, 5.0x10-5 s-1 , f = 0.5, kt = 2.0 x107 dm3 mol-1 s-1, and kp = 2640, dm3 mol-1 s-1 , and with initial concentrations of [M] = 2.0 M, and [I] = 8x10-3 M. Assume the termination is by combination., (a) The steady-state concentration of free radicals., (b) The average kinetic chain length., (c) The production rate of polymer., Solution: (a), , 1/ 2, , fk , [.M ] i , kt , , (b) v k[ M ][ I ], , [ I ]1 / 2, , 1 / 2, , 1, where k k p ( fki kt ) 1/ 2, 2, , (c) The production rate of polymer corresponds to the rate, vp = kp[.M][M], of polymerization is vp:

Page 47 :

Generalization of the Foregoing Concepts, • The number-average molecular weight is designated as Mn and, the weight-average molecular weight is designated as Mw., • To calculate the molecular weight of a polymer one can also use, , either the number-fraction or the weight-fraction of the, molecules present in the polymer., • With the help of ordinary mathematics, one can be easily, generalised the method of working out Mn and Mw.

Page 48 :

• Suppose that there are n number of molecules are present in a, polymer sample and nl of them have Ml molecular weight, and, n2 have M2 molecular weight and so on till one get ni having, Mi molecular weight;

Page 51 :

NUMBER-AVERAGE CONCEPT, The number-average molecular weight of a polymer can be, calculated by the following ways:, , Suppose, a bag containing four different types of fruits: apples,, papayas, pine apples and watermelons. To clarify and just for, , understanding, let each apple of the apple lot weight the same, and, similarly also each of the other fruits. Suppose that the number of, each fruit and its weight are as given below:

Page 52 :

Now, we have to find out the average weight of the fruits present in, the bag. It is assumed that the individual fruit contributes to the, average weight in the ratio of its numbers. Then we get the number-, , average weight as follows:

Page 53 :

Total number of fruits in the bag = 15, Total number of the apples in the bag = 6, Therefore,, , Number fraction of fruits (to the total number of fruits) = 6/15, In the same manner, Number fraction of papayas = 4/15, Number fraction of pine apples = 3/15, Number fraction of watermelons = 2/15, Contribution made by 6 apples towards average weight of fruits in the, , bag;, Number fraction of apples x weight of each apple, = 6/15 x 10 = 4.0 g

Page 54 :

• Similarly, contribution made by 4 papayas to the average weight, of fruits in the bag = 4/15 x 50 = 13.30 g, , • Similarly, contribution made by 3 pine apples to the average, weight of fruits in the bag = 3/15 x 100 = 20.0 g, • Similarly, contribution made by 2 watermelons to the average, weight of fruits in the bag = 2 x 200 = 26.60 g, By summing up the contributions made by each fruits variety, we, get the number-average weight of the total fruits as the :, 4.0 + 13.30 + 20.0 + 26.60 = 63.90 g

Page 55 :

WEIGHT-AVERAGE CONCEPT, The weight-average can be calculated by the other method, which is based on the assumption that the individual fruit variety, contribute to the total weight in the proportion not of its number, , but its weight. The weight-average can be get as :, , Total weight of all the fruits present in the bag = 960 g, , Weight of apples present in the bag = 60 g, , Therefore, Weight fraction of apples = 60/960

Page 56 :

• Similarly, weight fractions of papayas, pine apples, and, watermelons are 200/960, 300/960 and 400/960 respectively., , Next, contribution made by apples towards average-weight of, fruits in the bag =, , Weight fraction of apples x Average weight of apples, 60/960 x10 = 0.62 g

Page 57 :

Similarly,, Corresponding contribution by papayas = 200/960 x 50 = 1.41 g, , Corresponding contribution by pine apples = 300/960 x 100 = 31.2 g, Corresponding contribution by watermelons = 400/960 x 200 = 83.3 g, , Summing up the contributions made by each fruit variety, we get the, weight-average weight of the total fruits as :, 0.62 + 1.41 + 31.2 + 83.3 = 116.53 g

Page 58 :

Methods of Molecular mass determination, (1) OSMOMETRY, The osmometry technique is a very widely used, method to determine the molecular weight of polymers., It is of two types :, (i) Membrane osmometry, (ii) Vapour phase osmometry

Page 59 :

1. Membrane Osmometry, • It is used to determine the number-average molecular weight of, polymers. It is based on the principle of osmosis. In the, phenomenon of osmosis a semipermeable membrane is used,, which allows only one species to pass through but not the others., • In osmometry, a semipermeable membrane is placed between a, pure solvent and a solution. The solvent molecules diffuse into, the solution through the membrane till the solution gets dilute., An osmotic pressure is then applied on the solution.

Page 60 :

• The osmotic pressure is that pressure which is applied on, the solution so as to totally prevent the flow of the, , solvent through the semipermeable membrane., , • The osmotic pressure is related to the number-average, molecular weight of the polymer as :

Page 64 :

• The osmometer consists of two metallic chambers. These are, made of stainless steal. The face of the chamber possesses a, series of the concentric grooves, which are interconnected by, vertical horizontal channels. In between of these grooves of the, two metallic chambers, a semipermeable membrane is placed., • The two internal grooved faces of the metallic chambers are, interconnected on bolting the apparatus. These chambers are, separated by only a semipermeable membrane. In between the, grooves of the two chambers, the solvent and solution are placed.

Page 65 :

• The glass capillaries are inserted through a bore-drill into the, metallic chambers of the solvent and solution compartments., Both the two metallic chambers are filled with solvent one of, , the chamber is then emptied of the solvent and filled with the, solution of known concentration., • The osmometer is maintained at constant temperature. Due to, the osmotic pressure, the solvent passes to the solution, , compartment through the membrane. It causes rise in liquid, level in glass capillary tube.

Page 66 :

• The process is continue until the hydrostatic pressure developed in, the capillary tube due to the increased level of the solution., • Once the osmotic equilibrium, , is achieved, the solvent stops, , entering the solution side. When this state is achieved, the height, , difference between the solution and the solvent levels in the two, capillaries is measured with the help of a cathetometer. For that, particular concentration, the height provides the 'osmotic head' of, the solution., , • This procedure is repeated with solution of, concentrations and the 'osmotic heads' are measured., , different

Page 68 :

The osmometry possesses following drawbacks :, (a) The above method is simple but takes several hours to few, , days in diffusion of solvent through the semipermeable, membrane. It is a very slow process and the time taken to attain, equilibrium is extremely high., , (b) The non-availability of the true semipermeable membranes,, , made this technique obsolete these days.

Page 69 :

(c) Commercially available membranes such as 'gel-cellophane', membrane, 'bacterial-cellulose' membrane, and 'denitratedcollodion' membranes are permeable to very low molecular, weight polymers and, hence, the average-molecular weight, measured will always be higher than actual weight., , (d) Membrane osmometry is useful in the molecular weight range, of 30,000 to 1,000,00.

Page 70 :

2. Vapour Phase Osmometry, • The vapour phase osmometry is based on the fact that at a, , given temperature the vapour pressure of a solution is less, than a pure solvent., •, , For an experiment, place a drop each of a pure solvent and, the solution in an atmosphere saturated with the solvent, , vapour. Since vapour pressure of a pure solvent is more, than a solution hence, condensation of the solvent takes, place from the saturated vapour phase on to the solution, droplet.

Page 71 :

• The solution droplet starts getting diluted and also heated up by, the latent heat of condensation of the solvent condensing on it., Meanwhile,, , the, , temperature, , rises,, , and, , increases, , the, , concentration of the solvent, the vapour pressure of the solution, droplet also increases steadily., • The process of condensation and rise in the temperature, continues till the vapour pressure of the solution droplet at the, new elevated temperature gets equal to the pure solvent at the, original temperature.

Page 74 :

• In vapour phase osmometer a vessel is available which contains, solvent. This vessel is made up of glass. It is placed in an anodised, aluminium block. It is sealed by a stainless steel lid through teflon, gasket., , • This vessel provides the space for the atmosphere of solvent, vapour. In this vessel thermistors are placed., • The stainless steel lid is covered by another metal block through, which several syringes for placing the solution and solvent drops, , on the thermistors are inserted. This apparatus is maintained at a, constant temperature by a thermostat.

Page 75 :

• At the time of operation, the solvent is added to the solventvessel through a syringe and solvent drops are also placed on, , each thermistor. Since, there will not be any condensation on the, thermistors, there is no temperature difference, and now the, instrument reading should be zero., • The next step is to calibrate the instrument with a standard, , sample of a known molecular weight. Solutions of a standard, sample of four or five known concentrations are prepared.

Page 76 :

• One of the thermistors should be used with the solution of one, concentration and a drop of the same solution is placed on the, thermistor, while the other thermistor still consist of a drop of the, , pure solvent., • The solvent starts condensing on the solution droplet and the rise, in temperature is directly measured as the bridge imbalance, output voltage, ΔV, when a output attains steady state., • This, , process, , is, , repeated, , with, , solutions, , of, , different, , concentrations, and ΔV values for each concentration is noted.

Page 81 :

Measurement of Molecular Weight by Viscosity: Determination, of molecular weight of polymers by viscosity measurement method, is the most convenient and least complex method. The viscosity of, the polymer solution is measured by viscometer., , For the determination of viscosity two viscometers are generally, used :, , (a) Ostwald viscometer, (b) Ubbelohde suspended level viscometer

Page 82 :

• The viscometers are simple glass capillary instruments. In, Ostwald viscometer all measurements should be taken using, a constant volume of the solution; while in ubbelohde, suspended level viscometer, a single solution of known, , concentration is required and it is unaffected by the volume, of the solution taken.

Page 84 :

Experimental Technique:, • A known volume of the solution is taken in the viscometer and, the time of flow is measured., • In Ubbelohde suspended level viscometer, known volumes of, , pure solvent is taken and mixed inside the viscometer itself. Thus, subsequent concentrations can be achieved. This provides, sufficient data of flow times at different concentrations., • In Ostwald viscometer one has to empty, clean and refill the, , viscometer at each time with fresh solution before measuring the, flow time.

Page 85 :

Precautions:, 1. Viscosity is a temperature dependant property, therefore, all the, measurements must be taken at constant temperature., , 2. Viscometer should be hold in vertical and straight direction in all, the time, otherwise the pressure head will change in each, measurements., 3. All solutions should be free from impurities, otherwise the, capillary tube may choked and the flow of the solution may be, , obstructed., 4. The flow time of a solution or solvent must be sufficiently long., The difference in flow time between two successive concentrations, should be atleast of 3 to 5 seconds.

Page 86 :

LIGHT SCATTERING METHOD, • The light scattering phenomenon is used to determine the, weight-average molecular weight Mw , of polymers. It is, possible because solute molecules in a solution can scatter a, light beam. The scattering of the light occurs due to changes in, density or refractive index within the system arising from, composional vibrations., • The light scattering technique is a convenient method for, measuring the molecular weight of polymers in the range of, 10,000 to 10,000,000. This technique requires a light-scattering, photometer to determining Rθ or 𝜏 experimentally. To determine, n or dn/ dc,this method needs a differential refractometer.

Page 87 :

Experimental set-up for light-scattering measurements

Page 88 :

• In an experiment for light-scattering measurements, a mercury, lamp is used as a light source. After leaving the source, the light, then passes through condensing less via a monochromatic filter. It, , then goes through a slit and enters into an achromatic system., •, , It strikes against a beam splitter, and after passing through an, polariser, falls on the polymer sample solution, kept in the solution, cell. After leaving the cell, the incident beam is absorbed by a, , light-absorber, the scattered light both from the cell and calibrated, turbidity standard reaches the moveable and the reference, , photocell respectively.

Page 89 :

• The turbidity can be measured from the scattered intensity. The, standard solution generally used are organic liquids, colloidal, suspensions or well-calibrated polymeric substances., • The scattering values of these substances are obtained under the, , same conditions which are identical to the sample., • For determining Mw , apart from the scattering values, one has, to measure the concentrations of polymer solution, the refractive, index of the solvent and also the refractive index difference, , between the polymer solutions at different concentrations and, the solvent.

Page 90 :

• In light-scattering experiment, the sample solution should be, prepared completely dust free., • In light-scattering phenomenon, the amplitude of scattering is, found to be proportional to the mass M; of the particle which, scatters the beam of light.

Page 91 :

• In 1944, Debye expressed a relation between the molecular, weight of the solute particle to the intensity of scattered light., This is a Debye equation and good for particles which are, smaller than the wavelength of light used for the scattering, experiment :