Page 1 :

Synthetic, Polymers, , , , , , , , 9.1. INTRODUCTION, , Polymers may be define i Slibsianees i ., Polvine «ay be defined as the substances made up of giant molecules of high molecular mass,, , each molec ule of hich consists ofa very large number of simple molecules joined together through, covalent bonds in a regular manner: :, , ()) Monomers. The simple molecules which combine with one another repetitively to form the, polymers are called monomers., , (ii) Repeat Unit. Consider the case of polyethylene polymer. It is made from polymerizing, ethylene as shown below :, , Polymerization, aCH, = CH, ————_>» (- CH, — CH, -), Thus, we find that ethylene (CH, = CH,) is not the repeat unit in the polymer. Repeat unit is, —CH,-CH,- which is repeated over and over again to produce the polymer. Thus, repeat unit is the, smallest chain which is repeated to provide the polymer:, , n, , (iii) Degree of Polymerisation. It is the number of times a repeat unit is contained in the, polymer molecule. In the above example of polyethylene, denotes the degree of polymerisation., Usually, 27 is very large, of the order of a few thousands or tens of thousands., , 9.2. HOMOPOLYMERS AND COPOLYMERS, , Homopolymers. Polymers whose repeat-unit is derived from only one type of monomer are, called homopolymers. For example, in case of polyethylene, polymer which is obtained by, polymerization of ethylene molecules, the repeat unit, i.e., -CHy-~CH,~ is derived from only one type, of monomer, i.¢., ethylene., , Polyinerization, , nCH, = CH, —————> (-CH, - CH, -),,, Ethylene Polyethylene, (Monomer) (Polymer), , Polypropylene, polyvinyl chloride (PVC), polyisoprene, neoprene (polychloroprene),, polyacrylonitrile (PAN), nylon-6, polybutadiene, teflon (polytetrafluoroethylene), ete., are other, examples of homopolymers., , Copolymers. Polymers whose repeat units orn, an called copolymers. For example, in case of nylon-66, the repeat-unit, Le.,, ~ is derived fi / onomer, ie.,, ~ NH - (CH,), - NH — CO — (CH), - CO — is derived from two monomer, Le, , hexamethylenediamine and adipic acid., , are derived from two or more types of monomers, , RAR a, , Scanned by CamScanner

Page 2 :

a > CHEMIstp, Y, Rol ~, ; Polymenzation, MEN (CH, NUS + ntlooe (CH), Coon >, Nexamethylenidiamine Adipie acid, (Monomer) (Monomer), [= NH ~ (CH,), ~ NH — CO ~ (CH), ~ CO, + nip, * Nylon-66 a, , (Polymer), Buna-s, Polyesters, bakelite, melamine-formaldehyde polymer, ete., are other CXAMples, polymers, ; of, , 9.3, CLASSIFICATION OF POLYMERS, , Based on the source, , Depending upon the, , source from which they are obtained, polymers are broadly divided into, two classes:, , (lL) Natural polymers and (2) Synthetic polymers., , 1. Natural Polymers, Polymers which are obtained from animals and plants are, polymers, Starch cellulose, proteins, nucleic acids and natural rubber are some ex!, , called Natural, of polymers. A brief description of these natural polymers is given below :, , ‘amples of this type, , Starch. It is a polymer of a-glucose. It is the chief food reserve of the plants and is made y, , of two fraction — amylose and amylopectin. Amylose is a linear polyme, , amylopectin is a branched polymer of a-glucose., Cellulose. It is a polymer of -glucose., , obtained from wood and cotton. About 50%, cellulose., , rT of a-glucose and, , It is the chief structural material of the plants and is, of wood is cellulose. Cotton contains about 90-950,, , Both starch and cellulose are made by plants from glucose produced during Photosynthesis,, , Proteins. Proteins are polypeptides or polyamides. These polymers contain a large number of, @-amino acids joined together through peptide (NH-CO) bonds in a particular sequence. These are, either long chain or crossed linked polymers., , Natural rubber. It is prepared from latex which, in turn, is obtained from rubber trees. It isa, polymer of the hydrocarbon isoprene (2-methyl-1, 3-butadiene). Polymerization is illustrated as under, , CH;, , CH,, | . \, nCH, =C-CH= CH, Polymerization C CH, —C=CH= CH, -),, Isoprene Polyisoprene, , (2-Methyl-1, 3-butadiene) (Natural rubber), , 2. Sythetic polymers. Polymers which are made in the laboratory or industry are called synthetic, polymers. Natural rubber swells and loses elasticity after prolonged exposure to petrol and motor oil., Stability and melting points of many natural polymers are such that they cannot be melted and cast into, desired shapes. Further, natural fibres such as cotton, wool, silk, etc., cannot meet the increasing, demands. All these needs led man to synthesize polymers in the laboratory and industry. These mar, , made polymers are called synthetic polymers. Some important synthetic polymers are : polyethylen®, polystyrene, polyvinyl chloride (PVC), bakelite, nylon and dacron., , Based upon structure, , On the basis of structure, polymers are classified into three types :, , si ctrajoht chats, 1. Linear Polymers. In such polymers, the monomers are Joined together to form long ae ave, : : : ~ uly, of polymer molecules. The various polymeric chains are then stacked over one another to gi, , Scanned by CamScanner

Page 3 :

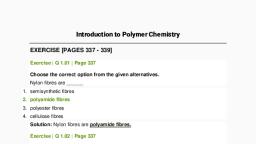

jsucture (Fig. 9.1a). Linear polymers have high melting, 2 , because of close packing of chains, Nylon and polyesters are examples of linear polymers., , “hain Polymere ar . ., ranched Chain t olymers. In such polymers, the Monomer units not only combine to form, pain but also form branches along the main chain (Fig. 9.1b)., , points, high densities and high tensile, , po, ‘ yl, , 3. B, elineat ©, me these polymer molecules do not pack well because of branches. As a result, branched chain, mers have lower melting points, densities and tensile strength compared to linear polymers. An, , oy at example of a branched chain polymer is low density polythene., i 3, Three-dimensional Network Polymers. In such polymers, the linear polymer chains formed, ; willy are joined together to farm a three-dimensional network structure (Fig. 9.1c). Because of, fs presence of crosslinks, these polymers are also called cross-linked polymers. These polymers, , shard, rigid and brittle. Bakelite, urea-formaldchyde polymer and melamine- formaldehyde polymer, 7 some examples of this class., are, , AAO, , (a) (b) (c), , Fig. 9.1. Different structures of polymers (a) linear structure. (d) branched.chain structure and (c), three-dimensional network structure., , , , Based on synthesis, , Polymerization mainly occurs by two modes :, , |, Addition polymerization and 2. Condensation polymerization, Corresponding to these two modes of synthesis, polymers have been classified into two types:, 1. Addition polymers and 2. Condensation polymers., , 1, Addition Polymerization. In this type of polymerization, the molecules of the same or, different monomers simply add to one another in repetition leading to the formation of a polymer, in which the molecular formula of the repeat unit is the same as that of the monomer. The polymers,, thus, formed are called addition polymers. , Addition polymerization generally occurs among molecules containing double bonds., nCH,=CH, —+ (-CH,-CH,-),, Ethylene Polyethylene, CH,, , |, — (CH,-CH-),, Polypropylene, , nCH, — CH = CH,, Propylene, , 2. Condensation Polymerization. In this type of polymerization, a large number of monomer, molecules combine together usually with the loss of simple molecules like water, alcohol, ammonia,, carbon dioxide, hydrogen chloride, etc., to form a polymer in which the molecular formula of the repeat, “nit is not the same as that of the monomer. The polymers thus formed are called condensation, Polymers, Condensation polymerization generally occurs between bifunctional compounds., , Nylon-66, obtained by the condensation between two monomers, viz. hexamethylenediamine, , dipic acid, each containing two functional groups with the loss of water molecules, is an example, ndensation polymer,, , and a, Fe,, , Scanned by CamScanner

Page 4 :

iY), , , 525K, MUN = (CH), — NE + nHOOC ~ (CHL), — COOH =>, Hexamethytonediamine Adipic acid, , 9 0, l ", , [NI (CH),— NH C= (CH), ~ C4}, Nylon-66, , Terylene and bakelite are other examples of condensation polymers,, , Int AEG, , Based on Mode of Addition of Monomer Units, , A more rational method of classification based upon the mode of addition of the monomer units, fo the growing chain has been proposed. According to this method of classification, there are ty, types of polymers:, , (i) Chain-growth polymers and (ii) Step-growth polymers., , (i) Chain-growth polymers (a/so called as addition polymers). These polymers are formeg, by the successive addition of monomer units to the growing chain carrying a reactive intermediate, such as a free-radical, a carbocation or a carbanion., , , , , , , , , , , , Monomer Polymer, Ethylene Polyethylene, Propylene Polypropylene, Butadiene Polybutadiene, Tetrafluoroethylene Polytetrafluoroethylene (PTFE), , or Teflon, , Vinyl chloride Polyviny! chloride (PVC), Isoprene cis-Polyisoprene (natural rubber), , , , Thus, chain-growth polymers are formed by a process which involves chain reactions., The most commonly used radical initiator is benzoyl peroxide., Examples of chain growth polymers are given in the table above :, , All the examples given in the table are those of homopolymers. An important example of a, chain-growth copolymer is Buna-S involving 1, 3-butadiene and styrene as monomers., , (ii) Step-growth polymers (also called as condensation polymers). These polymers are formed, through a series of reactions. Each such reaction involves the condensation (bond formation) between, two ditunctional monomer molecules to produce dimers which, in turn, produce tetramers and so on, with the loss of simple molecules like HO, NH;, HCl, etc. Since in this process, the polymer is, , formed in a step-wise manner, it is called step-growth polymer and the process is called step, growth polymerization., , In contrast to chain growth polymers, the formation of step-growth polymers does not occur, through chain reactions involving free radicals, carbanions or carbocations as reactive chemical, species. Some typical examples of step-growth polymers are given in the table below :, , , , , , S.No. Monomers Polymer, (i) Hexamethylenediamine and adipic: acid, Nylon-66, (ii) Phenol and formaldehyde. Bakelite, (iii) Terephthalic acid or its methyl ester and ethylene glycol. Polyester (Terylene), , , , , , , , , , Scanned by CamScanner

Page 5 :

I a RITE Fy 1G, pIFFERENT rYPES OF POLYMERS, 9." . jymer is a wide term involving a wide variety Of materials having different characteristics., ) :, me eof them are discussed as under :, some, , , , Istomers are those poly, , 1) Elastomers. f mers in which the intermolecular forces of attraction, , von the polymer chains are the weakest,, , ewer! stomers are amorphous polymers having high degree of elasticity. They have the ability to, a many times their normal length and return 0 original position when the force is withdrawn, sth viymers consist of randomly coiled molecular chains Of irregular shape having a few cross links, Lal 3), When the force applied, these coiled chains Open out and the polymer is stretched. Since, ee »y Naals ‘forces of attraction between the polymer chains are very weak, these cannot maintain, etched form. Therefore, as soon as the force is withdrawn, the polymer chains return to its original, o Se Thus, we observe that weak van der Waals’ forces of attraction allow the polymer chains, etched on applying the force but the cross links bring the polymer back to the original position, , he force is withdrawn. The most important example of an elastomer is natural rubber., , , , coiled, to bes, when t, , , , , , , , Stretch Cross links, ———, , ————, Unstretch, , , , xe, , Unstretched “SS links, , Stretched, , Fig. 9.2. Unstretched and stretched forms of an elastomer., , (2) Fibres. Polymers having the strongest intermolecular forces of attraction are called fibres. These, forces are either due to H-bonding or dipole-dipole interactions, In case of nylons, the intermolecular forces, are due to H-bonding (Fig. 9.3) while in polyesters and polyacrylonitrile they are due to powerful dipoledipole interactions between the polar carbonyl (C = O) groups and between carbonyl and cyano (-C = N), groups respectively., , Fibres show high tensile strength and minimum elasticity due to strong intermolecular forces., , The molecules of these polymers are long, thin and thread-like and, hence, polymer chains can, be easily packed over one another, As a result, they have high melting points-and low solubility., , ALAAA LIAS, , AINA LNA LN/, , Fig. 9.3. Hydrogen bonding in nylon-66., , t, t, , , , Scanned by CamScanner