Page 1 :

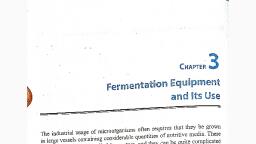

2.1 DESIGN AND BASIC FUNCTIONS OF FERMErzER, , A process in which a chemical product of human utility is produced involving microorganisms |, is called as fermentation. The vessel in which it is carried out is known as fermenter. An ideal, fermenter should provide congenial environmental conditions, which promote the optimum, growth of an organism and produce maximum product. Fermenter plays a critical role in the, product yield. Hence design of a fermenter is important in the process of fermentation., , The fermenter may be simple for fermentation products, which does not require aseptic ", conditions, while fermenter requiring an aseptic conditions have to be designed to joo :, interference by the contaminating organisms. P ¥

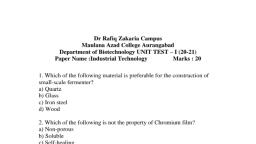

Page 2 :

Fermentation Process JEW, , 3. Coil, 6. Thermometer, , \ Fetimenter body 2. Agitator, "4. Gas outlet, , "7 + pH electrode, , - Hfaracteristic features of a good fermenter:, , , , , , 5. Inoculation port, , It must be strong enough to withstand pressure of large volume of aqueous medium., It must not corrode and contribute toxic ions to the growing microorganism., , Make provision for control or prevention of growth of contaminating microorganisms., Provision for rapid incorporation of sterile air into the medium., , Carbon dioxide released during fermentation must be flushed out., , auf ens, , Stirrer must be available to mix the medium and microorganisms to facilitate the, availability of nutrients and oxygen., , Intermittent addition of antifoaming agent., 8. Provision for controlling temperature., , N, , . Aseptic withdrawal of culture sample during fermentation and introduction of inoculum, at the initiation of fermentation., , 10. Determination of the pH and its adjust mentill, if required., , 11. Some means of sterilization of medium and addition of antifoaming agent., 12. Air filter., , 13. Drain in the bottom., , 14. Access to the inside of the fermenter to clean it., (ii) Fermentation vessel:, , Fermenters used in microbial fermentation represent a wide range of devices from a simple type, of tube aeration system fermenter operating on the air lift system or the deep jet principle or, , devices with rotary stirrers in which the air is sucked in or distributed under pressure into the, stirrer space., , There are wide variety of designs of fermenter (bioreactor) available. Selection of a fermenter, design for a particular process depends on a variety of factors such as mass transfer, considerations, mixing, sheer sensitivity, broth viscosity, oxygen demand, reliability of, operations, sterilization consideration’ “cost of construction and operation., , Stirred tank reactors use sparged air and submerged impellers to aerate and mix the broth., They are versatile and are specially adapted to highly aerobic cultures and highly viscous, fermentations, Even in this, there are many variations in design such as the style, number and, placement of impellers, the height to diameter ratio, the number and placement of coils or baffles, that affect the mixing characteristics of the vessels..The main drawbacks are high-energy input, and the use of rotating scale on the agitator shaft which may cause contamina, , tion risk., , a Alutann Lan an

Page 3 :

Gea Vosic inaustrial blotecnnology, , 211, , 2.1.2, , 2.1.3, , 214, , 2.1.5, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , Motor ;, Steam Pump Pressure indicator, = ~] Acid-base, Catalyst or reservoir, i o> pH recorder, nutrient addition e and control, > r| ;, Steam re) Exhaust line, A, Ss 1 Impeller, ‘ine > HN i Air filter, jem. fl Air flow, Fecorder. recorder and, | control, Cooling», -C, water in Air supply, SS, Steam —>, , q D Harvest line, , Fig. 2.8: Typical fermenter (stirred tanker fermenter), , Provision for control of microbial growth: Since most industrial fermentations utilize, pure cultures, fermenters should be designed in such a way that promotes luxuriant, growth of microbe but prevent the growth of contaminating microorganisms., , Provision for incorporation of sterile air (oxygen): Most aerobic fermentation processes, requires oxygen supply, which is called as aeration. Aeration is done by passing sterile, air under pressure into the fermenter. The required air is sterilized by passing it through, a sterile filter consisting of glass wool or some other finely powdered material that help, in trapping microorganisms present in the air. The sterile air bubbled into the liquid, medium through a sparger in order to make oxygen distributes uniformly in the medium., , A device for removal of CO,: During fermentation process carbon dioxide and hr dro:, , i i en, gases are liberated which collect in the head space of the fermenter. The feomenee Sheek id, be provided with a device to release these gases outside aseptically., , rs, anges i im o rOkaHNg device, is generally provided to most of the, fermenters, which accomplishes vigorous stirring and agitation of the ined =, rotation is carried out either by indirect or di im. The, , ndire rect methods. In indir, , impeller is mounted on a shaft, which is driven by an electric motor fied a veaat, , the fermenter. In direct method, impeller action is varied by using different cele, eller, , blades and is driven by a magnetic coupling fitted to a motor which j, , the fermenter. The impeller blades are arranged at different heights s pie ae beneath, , stirring and agitation of the medium. leve vigorous, + at f antifoam agent: Aerati: +. 2, , A device for addition o ben’ Aeration and agitatio: i 7, , causes the production of foam. Media with high levels of ree ' en medium, han with pure sugars and inorganic salts, Proteolytic tarts ones more, , yoteins int at degrade, , : aes foa, leads to problems like contamination of the medium and fenpedinent a ‘arance of foam, aeration.

Page 4 :

2.1.6, , 2.1.7, , 2.1.8, , Fermentation Process Ea, , The formation of foam is undesirable, can be prevented by the addition of antifoam, agents. An antifoam agent lowers surface tension of the foam and thereby it collapses,, which leads to the disappearance of foam. Antifoam agents may be added to the medium, either manually or mechanically. Manual addition requires the presence of some device, in the fermenter to add antifoam agent aseptically, whenever needed. In mechanical, addition, which is done automatically, an electrical sensing mechanism is provided at, the top of the fermenter. It consists of two electrodes projecting into the headspace of the, fermenter. They are connected to a pump of antifoam reservoir. When foam builds up in, the headspace and touches the electrodes, current flows between the electrodes and, activates the pump for addition of antifoam. When foam collapses the electrodes get, disconnected and addition of antifoam ceases., , A device for temperature control: Microorganisms widely differ in their temperature, dependence for growth. However, they grow well at optimum fermentation temperature,, which may be below or above ambient temperature. During fermentation lot of, temperature is generated due to metabolic activities of microorganism, which leads to a, rise in the temperature in the fermenter. For maintaining optimum temperature in the, fermenter, one of the following devices is provided (Fig. 2.9)., , Temperature probe, , , , , , Water, out LY, Cooling. Controller/computer, jacket, Fermenter, , , , , , Fig. 2.9: A scheme for controlling fermenter temperature, , 1. Sparging cold water on the fermenter,, , 2. By circulating cold water through the jacketed walls of fermenter, or, , 3. Through coils arranged along the inside walls of the fermenter., , A device for addition or withdrawal of inoculum: The fermenter should also be, provided with a device to introduce inoculum at the beginning of the fermentation, and, its withdrawal aseptically during fermentation., , A provision for pH adjustment: pH, which plays an important role in the growth and, metabolism of microbes, influences fermentation process. A mechanism for determining, pH of the fermentation broth intermittently and adjusting the values is often required., This is usually accomplished by withdrawing a sample from the fermenter for, pH measurement, followed by addition of alkali or acid to the fermentation medium to, adjust pH.

Page 5 :

asic Industrial Biotechnology, , 2.1.9, , , , : i reduce, Seed tanks: Inoculum of 1-10% is required to inoculate a seat small, incubation Period, They are also called as inoculum tanks. T ey oad one y, sized fermenters in which inoculum is produced under controlled condi :, , 2.1.10 Medium Preparation vessel: Fermentation requires additional vessels for the preparation, , of medium. Required nutrients for the medium is transferred to the fermenter from these, vessels,, , 2.1.11 ion of the medium: Most of the fermentations require pure culture and needs, , medium, For this purpose, the medium is passed through retention tubes and, heat exchangers before passing into the large, empty and sterilized fermentation tank., The retention tubes contain steam waters jet that inject high pressure steam into the, , Sterilizat;, Sterilized, , 2.1.12 Device for withdrawal of used medium: There must be, , and u:, involved largely depend on the bioreactor, its mode of Operation and the microorganism, being used. They are primarily aeration, mixing, temperature, pH an, control and maintenance at optimum levels inside the reactor is mediated by sensors, (electrodes) along with compatible control systems and data a), , 2.2 FERMENTATION PROCESSES, , Fermentation process can be conveniently div;, process. They are:, 1. The formulation media used for the growth of the microorganism to, inoculum and also in the production of fermentation products,, 2. The sterilization of the medium, fermenter and oth, 3. The preparation of adequate quantities of pure culture that is to be i i, the fermenter. toculated into, 4. The creation of optimum conditions in the fermenter foeeen, organism and for optimum output of the desired Product, ptimum 8rowth of the, 5. The extraction of the product and its pur, , 6. The disposal of effluents generated during fermentation,, , : A ong, these six phases are di ., inter relationships am : ‘agrammat, Thi ee varies with the type of organism used seat, s, , ly illustrateg in Fj, and in Fig. 2.10., ess can be discussed under two headings, Product to be Produced, The entire, proce ne, , be employed as, , er associated equipment., , ification,