Page 2 :

Introduction

Page 3 :

Reinforced Concrete, ❖Concrete is strong in compression and weak in tension., ❖Steel is strong in tension., ❖Reinforced Concrete uses concrete to resist compression, , and to hold bars in position and uses steel to resist tension., ❖Tensile strength of concrete is neglected (i.e. zero)., ❖R.C. beams allows cracks under service load.

Page 4 :

Pre-stressed Concrete, ❖Pre-stressed concrete is a method for overcoming, concrete’s natural weakness in tension., ❖In 1904, Freysinet attempted to introduce permanent, acting forces in concrete to resist elastic forces under loads, and called ‘pre-stressing’., ❖It can be used to produce beams, floors or bridges with a, longer span than in practical with ordinary reinforced, concrete.

Page 10 :

Basic concept of pre-stressing, There are three basic concepts of pre-stressing:, o First concept: Pre-stressing to transform concrete into an, , elastic material., o Second concept: Pre-stressing for combination of high, strength steel with concrete., o Third concept: Pre-stressing to achieve load balancing

Page 11 :

Advantages of pre-stressing, ❑Full section is utilized., ❑Reduction in steel corrosion., ❑Improved performance under dynamic and fatigue loading., ❑High span to depth ratio., ❑Rapid construction., ❑Better quality control., ❑Reduced Maintenance., ❑Availability of standard shapes.

Page 12 :

Limitations for pre-stressing, ✓Pre-stressing needs skilled technology., ✓The use of high strength material is costly., ✓There is additional cost in auxiliary equipment., ✓Harder to recycle., ✓There is need for quality control and inspection.

Page 13 :

Pre-stressing, Pre-tensioning: The tendons, are tensioned against some, abutments, before, the, concrete is placed. After the, concrete, hardened,, the, tension force is released. The, tendon tries to shrink back its, initial length but concrete, resists it through its bond, between, them., Thus, compressive force is induced, in concrete., , Post-tensioning:, In, posttensioning, the tendons are, tensioned after the concrete has, hardened. Commonly metal or, plastic ducts are placed inside the, concrete before casting. After the, concrete hardened and had enough, strength, the tendon was placed, inside the duct, stressed and, anchored against concrete. This, can be done either as pre-cast or, cast-in-place.

Page 14 :

Pre-tensioning, , Post-tensioning, , 1. Tension is applied on tendons, before concrete placement., , 1. Tensions is applied after the, concrete placement., , 2. Pre-stress loss due to anchorage, slip and friction loss is zero., , 2. Pre-stress loss occur due to, anchorage slip and friction., , 3. Pre-stress loss due to elastic, deformation occur., , 3. Pre-stress loss occur due to elastic, deformation if all the tendons are not, equally tensioned., , 4. Pre-stress is applied against the, abutment., , 4. Pre-tension is provided against the, concrete., , 5. Use- Prefabricated element., , 5. For cast-in-situ element (slab &, beam).

Page 15 :

Application, ❖Bridges., ❖Slab in buildings., ❖Water tank., ❖Repair and rehabilitations., ❖Nuclear power plant., ❖Off shore platform., ❖Thin sheet structure., ❖Concrete piles, etc.

Page 16 :

Concrete strain characteristics, In pre-stressed concrete, strain are produced as well as stresses., Such strain can be classified in 4 types:, ❖ Elastic strain, ❖ Lateral strain, ❖ Creep strain, ❖ Shrinkage strain

Page 18 :

Lateral strain, ❖ Lateral strains are computed by poison's ratio., ❖ Poison's ratio varies from 0.15 to 0.22, avg.=0.17

Page 19 :

Creep strain, ❖ Defined as time dependent deformation resulting from the, presence of stress., ❖ Creep continued over the entire period of the total creep., ✓18-35% occurred in the first 2 weeks of loading., ✓40-70% with in 3 months., ✓60-83% with in one year., ❖ Creep increase with a larger w/c ratio and with a lower, aggregate cement ratio.

Page 20 :

Shrinkage strain, ❖As distinguished from creep, shrinkage in concrete is the, contraction due to drying and chemical changes dependent, on time and on moisture condition, but not on stresses., ❖It may be ranges from 0.0000 to 0.0010 and beyond under, vary dry condition 0.0010 can be expected.

Page 21 :

Compaction, ❖Compacting the concrete by vibration is desirable and, necessary., ❖Usually without using an excessive amount of mortar, a low, w/c ratio and a low slump concrete must be chosen.

Page 22 :

Curing, ❖To early curing, , may results shrinkage cracks before, , applying pre-stress., ❖Only by the careful curing the specified high strength, concrete an be attained.

Page 23 :

Pre-stressing steel, ❖The development of pre-stressed concrete was introduced by, the invention of high strength steel., ❖It is an alloy of iron, carbon, manganese and optimal, materials.

Page 24 :

Wires, ❖A pre-stressing wire is a single unit made of steel. The, nominal diameter of the wires are 2.5, 3.0, 4.5, 5.0, 7.0 &, 8.0 mm., , Two types:, 1. Indented wire: There are circular or indentation on the, surface., 2. Plain wire: No indentation on the surface.

Page 25 :

Stands, ❖A few wires are spun together in a helical form to form a, pre-stressing stand. There are different types of stands are as, follows:, 1. Two wire stands., 2. Three wire stands.

Page 26 :

Tendons:, ❖A group of stands or wire are placed together to form a prestressing tendon. The tendons are used in post tensioned, member., , Cables:, ❖A group of tendon form a pre-stressing cable. The cables are, used in bridges.

Page 27 :

Problem-1:, A rectangular concrete beam is pre-stressed by means of 15 wires of 5 mm, diameter located 65 mm from the bottom of the beam and 3 wires of diameter, of 5 mm 25 mm from the top. Assuming the pre-stress in the steel as 840, N/𝑚𝑚2 , calculate the stresses at the extreme fibers of the of the mid-span, section when the beam is supporting its own weight over a span of 6 m., Evaluate the maximum working stress in concrete. The density of concrete is 24, kN/𝑚3 .

Page 28 :

Solution:, , y=[, , (15 𝑥 65+3 𝑥 275, 18, , ] = 100 mm, , e = 150 – 100 = 50 mm, 𝜋, 4, , 𝜋, 4, , 𝐴𝑠 = 18 x x 𝑑 2 = 18 x x 52 = 353.43 𝑚𝑚2, Pre-stressing force P = 840 x 353.43= 3 x 105 N, A = 300 x 200 = 6 x 104 𝑚𝑚2, 𝑏ℎ3 ℎ 𝑏ℎ2 200 𝑥 3002, Z = I/C =, / =, =, = 3 x 106 𝑚𝑚3, 12 2, 6, 6, , Self weight of beam = 0.3 x 0.2 x 24 = 1.44 kN/m

Page 30 :

5.0, , 5.0, , 5.0, , 5.0, , Prestress, , 11.16, , 9.0, , 2.16, , 2.16, , Self- weight, stress, , 9.0, , Live load, stress, , Analysis of stresses at Mid-Span, , 1.16, , Resultant, stress

Page 31 :

Problem-2:, A rectangular concrete beam 250 mm wide and 600 mm deep, is pre-stressed by, means of four 14 mm high-tensile bars located 200mm from the soffit of the, , beam. If the effective stress in the wires is 700 N/mm2 , what is the maximum, bending moment that can be applied to the section without causing tension at, the soffit of the beam?, Solution: A = 250 x 600 = 15 x 104 𝑚𝑚2, Z = I/C =, , =, , 𝑏ℎ3 ℎ, /, 12 2, , =, , 𝑏ℎ2, 6, , 250 𝑥 6002, 6, , = 15 x 106 𝑚𝑚3

Page 33 :

Problem-3:, An unsymmetrical I-section beam is used to support an imposed load of 2 kN/m, over a span of 8 m. The effective pre-stressing force is 100 kN. Estimate the, , stresses at the center of the span section of the beam., 300 mm, 60 mm, , 400 mm, , 80 mm, , 60 mm, , 50 mm, 100 mm

Page 34 :

300 mm, 60 mm, , 400 mm, , y, 80 mm, , 60 mm, , e = 194 mm, 50 mm, , 100 mm, , Solution: y =, , 60 𝑥 300 𝑥 30+80 𝑥 400−60−60 𝑥 60+, , 400−60−60, 2, , +60 𝑥 100 𝑥 [400−30], , 60 𝑥 300+80 𝑥 400−60−60 +60 𝑥 100, , = 156 mm, e = 400 – 156 – 50 = 194 mm

Page 35 :

300 mm, 60 mm, , 400 mm, , y = 156 mm, 80 mm, , 60 mm, , e = 194 mm, 50 mm, , 100 mm, , P = 100 KN, A = 60 𝑥 300 + 80 𝑥 400 − 60 − 60 + 60 𝑥 100 = 46400 𝑚𝑚2, I=, , 300 𝑥 603, 12, , + (60 x 300) x (156−30) +, , 100 𝑥 603, 12, , + (60 x 100) x (400−156−30) 2 = 75.7 x 107 𝑚𝑚4, , 2, , 80 𝑥 2803, 12, , + (80 x 280) x (200−156) 2 +

Page 38 :

Assignment-1, , 260 mm, , 300 mm, , 60 mm, , 60 mm, , 80 mm, , 400 mm, , 400 mm, , 80 mm, , 60 mm, , 50 mm, , 60 mm, , 50 mm, 300 mm, , 300 mm, , 400 mm, , 60 mm, , 300 mm, , 300 mm, 50 mm, , 80 mm

Page 39 :

300 mm, 70 mm, , 400 mm, , 80 mm, , 70 mm, 80 mm, 80 mm, , 50 mm, 300 mm

Page 40 :

260 mm, , 300 mm, 60 mm, , 60 mm, , 80 mm, , 60 mm, , 400 mm, , 60 mm, , 400 mm, 80 mm, 60 mm, , 50 mm, , 80 mm, , 50 mm, 300 mm, , 300 mm, , 400 mm, 70 mm, 80 mm, , 300 mm, , 300 mm, 50 mm, , 60 mm, , 80 mm

Page 41 :

Thrust Line

Page 42 :

Pressure line/ Thrust line:, At any given section of a pre-stressed concrete beam, the combined, effect of the pre-stressing force and the externally applied load will, result in a distribution of concrete stresses that can be resolved into, a single force. The locus of the point of application of this resultant, force in any structure is termed as the pressure line or thrust line.

Page 43 :

Problem-4:, A pre-stressed concrete beam of section 120 mm wide by 300 mm deep is used, over an effective span of 6 m to support a uniformly distributed load of 4 kN/m,, , which includes the self weight of the beam. The beam is pre-stressed by a, straight cable carrying a force of 180 kN and located at an eccentricity of 50, mm. Determine the location of the thrust line in the beam and plot its position at, quarter and central span locations., Solution: A = 120 x 300 = 36 x 103 𝑚𝑚2, F = 180 kN, , e = 50 mm

Page 45 :

Problem-5:, A pre-stressed concrete beam of section 250 mm wide by 400 mm deep is used, over an effective span of 4 m to support a point load of 70 kN. The beam is pre-, , stressed by a straight cable carrying a force of 600 kN and located at an, eccentricity of 65 mm. Determine the location of the thrust line in the beam and, plot its position at quarter, central and support sections for the concentrated load, only., Solution: A = 250 x 400 = 100 x 103 𝑚𝑚2, F = 600 KN, e = 65 mm

Page 46 :

70 KN, , 35 KN, , For Mid span:, , 2m, , Moment at mid span, 𝑀𝑚 = 35 x 2 = 70 KN-m, Location of the thrust line =, , 𝑀, 𝐹, , =, , 70, 600, , x 1000 = 116.67 mm, , For Quarter span:, Moment at mid span, 𝑀𝑞 = 35 x 1 = 35 KN-m, Location of the thrust line =, , 35 KN, , 𝑀, 𝐹, , =, , 35, 600, , x 1000 = 58.33 mm, , 2m

Page 48 :

Problem-6:, A pre-stressed concrete beam of section 250 mm wide by 400 mm deep is used, over an effective span of 4 m to support a point load of 70 kN at quarter span, , from left support. The beam is pre-stressed by a straight cable carrying a force, of 600 kN and located at an eccentricity of 65 mm. Determine the location of, the thrust line in the beam and plot its position at quarter, central and support, sections for the concentrated load only., Solution: A = 250 x 400 = 100 x 103 𝑚𝑚2, F = 600 kN, e = 65 mm

Page 49 :

70 kN, , For Mid span:, Moment at mid span, 𝑀𝑚 = 17.5 x 2 = 35 kN-m, Location of the thrust line =, , 𝑀, 𝐹, , =, , 35, 600, , 52.5 kN, , x 1000 = 58.33 mm, , 1m, , For Quarter span:, Moment at quarter span from right support, 𝑀𝑞 = 17.5 x 1 = 17.5 kN-m, Location of the thrust line =, , 𝑀, 𝐹, , =, , 17.5, 600, , x 1000 = 29.17 mm, , Moment at quarter span from left support, 𝑀𝑞 = 52.5 x 1 = 52.5 kN-m, Location of the thrust line =, , 𝑀, 𝐹, , =, , 52.5, 600, , x 1000 = 87.5 mm, , 17.5 kN, 3m

Page 50 :

For support:, Moment at support, 𝑀𝑠 = 17.5 x 0 = 0 kN-m, , Location of the thrust line =, , 𝑀, 𝐹, , 87.5 mm, , =, , 0, 600, , x 1000 = 0 mm, , 58.33 mm, , 29.17 mm, , P = 600 kN, , P = 600 kN, 1m, , 2m

Page 53 :

Pre-stress Loss, Pre-stress loss is the difference between initial pre-stress and, effective pre-stress that remains in a member., Pre-stress loss, , Short term or immediate losses:, ❖ Elastic shortening of concrete., ❖ Slip at anchorages immediately, after pre-stressing., ❖ Friction between tendon and, cable effect., , Long term or time dependent losses:, ❖ Creep and shrinkage of concrete., ❖ Relaxation of pre-stressing steel.

Page 54 :

Pre-stress Loss According to Material, Pre-stress loss, , Concrete, , Elastic, Shortening, , Steel, , Creep, , Shrinkage, , Friction, , Anchorage, slip, , Relaxation

Page 55 :

Problem-7:, A pre-tensioned concrete beam, 100 mm wide and 300 mm deep, is pre-stressed, by straight wires carrying an initial force 150 KN at an eccentricity of 50 mm., The modulus of elasticity of steel and concrete are 210 and 35 KN/mm2, respectively. Estimate the percentage of loss of stress in steel due to elastic, deformation of concrete if the area of steel wires is 188 mm2 ., , Solution:, F = 150 KN, 𝐸𝑠 = 210 KN/𝑚𝑚2, 𝐸𝑐 = 35 KN/𝑚𝑚2, 𝐴𝑠 = 188 mm2

Page 57 :

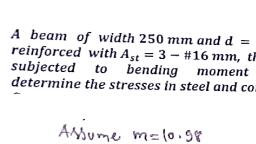

Problem-8:, A rectangular concrete beam is pre-stressed by means of 15 wires of 5 mm, diameter located 65 mm from the bottom of the beam and 3 wires of diameter, of 5 mm 25 mm from the top. Assuming the pre-stress in the steel as 840, N/𝑚𝑚2 , calculate the percentage loss of stress in steel immediately after, transfer, allowing for the loss of stress due to elastic deformation of concrete, only. 𝐸𝑠 = 210 kN/𝑚𝑚2 , 𝐸𝑐 = 31.5 kN/𝑚𝑚2

Page 58 :

Solution:, y=[, , (15 𝑥 65+3 𝑥 275, 18, , ] = 100 mm, , e = 150 – 100 = 50 mm, 𝜋, 4, , 𝜋, 4, , 2, , 𝐴𝑠 = 18 x x 𝑑 = 18 x x 52 = 353.43 𝑚𝑚2, Pre-stressing force P = 840 x 353.43= 3 x 105 N, A = 300 x 200 = 6 x 104 𝑚𝑚2, 𝑏ℎ3 200 𝑥 3003, I=, =, = 45 x 107 𝑚𝑚4, 12, 12, , Modular ration, n =, , 𝐸𝑠, 𝐸𝑐, , =, , 210, 31.5, , = 6.68

Page 59 :

Top fiber stress,, -, , 𝑃, 𝐴, , +, , 𝑃𝑒𝑦, 𝐼, , 3 x 105 3 x 105 𝑥 50 𝑥 125, 2, =+, =, 0.83, N/𝑚𝑚, 6 x 104, 45 x 107, , Bottom fiber stress,, -, , 𝑃, 𝐴, , -, , 𝑃𝑒𝑦, 𝐼, , 3 x 105 3 x 105 𝑥 50 𝑥 85, 2, ==, 7.85, N/𝑚𝑚, 6 x 104, 45 x 107, , Loss of stress in wires at top = 6.68 x 0.83 = 5.55 N/𝑚𝑚2, Loss of stress in wires at bottom = 6.68 x 7.85 = 52.5 N/𝑚𝑚2, Percentage loss of stress for wires at top =, , 5.55 𝑥 100, 840, , = 0.66 %, , Percentage loss of stress for wires at top =, , 52.5 𝑥 100, 840, , = 6.25 %

Page 60 :

Problem-9:, A post-tensioned concrete beam, 100 mm wide and 300 mm deep, is prestressed by three cables, each with a cross-sectional area of 50 𝑚𝑚2 and with, an initial stress of 1200 N/𝑚𝑚2 . All the three cables are straight and located, 100 mm from the soffit of the beam. If the modular ratio is 6, calculate the loss, of stress in the three cables due to elastic deformation of concrete for only the, following cases:, a) Simultaneously tensioned and anchoring of all the three cables; and, b) Successive tensioning of the three cables, on at a time.

Page 62 :

a) Under simultaneous tensioning and anchoring of all the three cables, there, will be no loss due to the elastic deformation of concrete., b) When the cables are successively tensioned:, , When cable-1 tensioned, When cable-2 tensioned, When cable-3 tensioned, Total loss, , Cable-1, 0, 16.2, 16.2, 32.4, , Loss (N/𝑚𝑚2 ), Cable-2, 0, 0, 16.2, 16.2, , Cable-3, 0, 0, 0, 0

Page 63 :

Problem-10:, A concrete beam is post tensioned by a cable carrying an initial stress of 1000, N/𝑚𝑚2 . The slip at the jacking end was observed to be 5 mm. The modulus of, elasticity of steel is 210 KN/𝑚𝑚2 . Estimate the percentage loss of stress due to, anchorage slip if the length of the cable is a) 30 m; b) 3 m., , Solution:, ∆ = 5 mm, 𝐸𝑠 = 210 KN/𝑚𝑚2, , a), , 𝑃, 𝐴, , =, , ∆𝐸𝑠, 𝐿, , =, , 5 𝑥 210 𝑥 103, 30 𝑥 103, , = 35 N/𝑚𝑚2, , ∴ percentage loss of stress =, 𝑃, 𝐴, , b) =, , ∆𝐸𝑠, 𝐿, , =, , 5 𝑥 210 𝑥 103, 3 𝑥 103, , 35, 1000, , x 100 = 3.5%, , = 350 N/𝑚𝑚2, , ∴ percentage loss of stress =, , 350, 1000, , x 100 = 35%

Page 64 :

Example 11:, A concrete beam is post tensioned by a cable carrying an initial stress of 600, N/𝑚𝑚2 . The slip at the jacking end was observed to be 3 mm. The modulus of, elasticity of steel is 210 KN/𝑚𝑚2 . Estimate the percentage loss of stress due to, anchorage slip if the length of the cable is a) 5 m; b) 8 m., , Solution:, ∆ = 3 mm, 𝐸𝑠 = 210 KN/𝑚𝑚2, , a), , 𝑃, 𝐴, , =, , ∆𝐸𝑠, 𝐿, , =, , 3 𝑥 210 𝑥 103, 5 𝑥 103, , = 126 N/𝑚𝑚2, , ∴ percentage loss of stress =, 𝑃, 𝐴, , b) =, , ∆𝐸𝑠, 𝐿, , =, , 3 𝑥 210 𝑥 103, 8 𝑥 103, , 126, 600, , x 100 = 21%, , = 78.75 N/𝑚𝑚2, , ∴ percentage loss of stress =, , 350, 600, , x 100 = 13.13%

Page 65 :

Problem-12:, A concrete beam is pre-stressed by a cable carrying an initial pre-stressing force, 300 KN. The cross-sectional area of the wires in the cable is 300 𝑚𝑚2 ., Calculate percentage loss of stress in the cable only due to shrinkage of concrete., 𝐸𝑠 = 210 KN/𝑚𝑚2 . Age of concrete at transfer = 8 days., a) For post tensioning., b) For pre tensioning., Solution:, a) For post tensioning,, , 200 𝑥 10−6, 𝜖𝑐𝑠 =, log10 (𝑡+2), , 200 𝑥 10−6, =, = 200 x, log10 (8+2), , ∴ Loss of stress = 𝜖𝑐𝑠 x 𝐸𝑠 = 200 x 10−6 x 210 = 0.042, 𝐹, 𝐴, , Initial stress, P = =, ∴ Percentage of loss, , 300, =1, 300, , KN/𝑚𝑚2, , 0.042 𝑥 100, =, = 4.2%, 1, , 10−6

Page 66 :

b) For pre tensioning, 𝜖𝑐𝑠 = 300 x 10−6, ∴ Loss of stress = 𝜖𝑐𝑠 x 𝐸𝑠 = 300 x 10−6 x 210 = 0.063, ∴ Percentage of loss =, , 0.063 𝑥 100, = 6.3%, 1

Page 67 :

Problem-13:, A concrete beam of rectangular section, 100 mm wide and 300 mm deep, is pre, stressed by five wires of 7 mm diameter located at an eccentricity of 50 mm, the, initial stress in the wires being 1200 N/𝑚𝑚2 . Estimate the loss of stress in steel, due to creep of concrete using the ultimate creep strain method and the creep, coefficient method (IS: 1343-1980). Use the following data:, 𝐸𝑠 = 210 kN/𝑚𝑚2, 𝐸𝑐 = 35 kN/𝑚𝑚2, Creep co-efficient, φ = 1.6, Ultimate creep strain, ∈𝑐𝑐 = 41 x 10−6 mm/mm per N/𝑚𝑚2

Page 69 :

1. Ultimate Creep Strain Method:, Loss of stress in steel = ∈𝑐𝑐 .𝑓𝑐 . 𝐸𝑠, , = (41 x 10−6 ) x (10.2) x (210 x 103 ), = 88 N/𝑚𝑚2, 2. Creep Co-efficient Method:, Loss of stress in steel =φ .𝑓𝑐 .∝𝑐, = 1.6 x 10.2 x 6, , = 97.92 N/𝑚𝑚2

Page 70 :

Problem-14:, A post-tensioned concrete beam of rectangular section, 100 mm wide and 300, mm deep, is stressed by parabolic cable with zero eccentricity at the supports, and an eccentricity of 50 mm at the centre of span. The area of the cable is 200, 𝑚𝑚2 and initial stress in the cable is 1200 N/𝑚𝑚2 . If the ultimate creep strain is, 30 x 10−6 mm/mm per N/𝑚𝑚2 of stress and modulus of elasticity of steel is 210, 𝑚𝑚2 , compute the loss of stress in steel only due to creep of concrete., 𝐸𝑠 = 210 kN/𝑚𝑚2, 𝐸𝑐 = 35 kN/𝑚𝑚2, Creep co-efficient, φ = 1.1

Page 72 :

2, 3, , Average stress at the level of steel 𝑓𝑐 = 8 + x 2.7 = 9.8 N/𝑚𝑚2, 1. Ultimate Creep Strain Method:, , Loss of stress in steel = ∈𝑐𝑐 .𝑓𝑐 . 𝐸𝑠, = (30 x 10−6 ) x (9.8) x (210 x 103 ), = 62 N/𝑚𝑚2, 2. Creep Co-efficient Method:, Loss of stress in steel =φ .𝑓𝑐 .∝𝑐, , = 1.1 x 9.8 x 6, = 64.68 N/𝑚𝑚2

Page 73 :

Problem-15:, A cylindrical concrete tank 40 m external diameter is to be Prestressed, circumferentially by means of a high strength steel wire (𝐸𝑠 = 210 kN/𝑚𝑚2 ), jacked at 4 points, 90 degree apart. If the minimum stress in the wires, immediately after tensioning is to be 600 N/𝑚𝑚2 and the coefficient of friction, is 0.5, calculate, a) The maximum stress to be applied to the wires at the jack, and, b) the expected extension at the jack.

Page 75 :

Ultimate Moment

Page 79 :

Problem-17: A box shaped pre-stressed beam with 𝐴𝑠𝑝 = 2400 𝑚𝑚2 ., Effective stress is 1100 MPa. Determine ultimate moment capacity of, ′, the beam. 𝑓𝑐 = 50 N/𝑚𝑚2 , 𝑓𝑝𝑢 = 2200 𝑁/𝑚𝑚2 ., 500 mm, , 175 mm, 100 mm, , 200 mm, , 100 mm, , 875 mm, , 100 mm

Page 83 :

Cracking Moment

Page 84 :

Cracking Moment, The bending moment at which visible cracks develop in pre-stressed, concrete members is generally referred to as cracking moment.

Page 85 :

Cracking Moment, Problem-18: A symmetrically I beam has the effective flange width, 400 mm, overall depth 800 mm, flange and web thickness are 160, mm each. Beam is post-tensioned by cables with 𝐴𝑠𝑝 = 2250 𝑚𝑚2 at, an eccentricity of 275 mm at mid span. Determine cracking moment., ′, ′, 2, 2, 2, 𝑓𝑐 = 40 N/𝑚𝑚 , 𝑓𝑝𝑢 = 1800 𝑁/𝑚𝑚 , 𝑓𝑝𝑒 = 1000 𝑁/𝑚𝑚 and 𝑓𝑡 =, 3.15 N/𝑚𝑚2, 400 mm, 160 mm, , 𝐴𝑠𝑝 = 2250 𝑚𝑚2, 160 mm, , 800 mm, , e = 275 mm, 160 mm

Page 86 :

Ac = 2 x 160 x 400 + 160 x 480 = 204.8 x 103 mm2, Ic =, , 400 x 8003, 12, , -2x, , 120 x 4803, 12, , = 1.49 x 1010 mm4, , Pe = Asp x fpe = 2250 x 1000 = 2.25 x 106 N, Kt =, , r2, cb, , =, , I, Ac cb, , 1.49 x 1010, =, 204.8 x 103 x 400, , = 181.33 mm, ∴ Cracking moment, Mcr = Pe (e + k t ) +, , = 2.25 x, , 106, , ft ′ Ic, cb, , (275 + 181.33) +, , 3.15 x 1.48 x 1010, 400, , = 1.143 x 109 N-mm = 1143 KN-m.

Page 87 :

Effective Stress

Page 88 :

Effective Stress, Problem-19: A pre-tensioned member has a section of 8 in by 12 in. It, is eccentrically pre-stressed with 0.8 𝑖𝑛2 of high tensile steel wire, which is anchored to bulkheads at a unit stress of 150000 psi. The, c.g.s. is 4 in above the bottom fiber. Assuming that, n = 6, compute, the effective stress in the concrete immediately after transfer., Solution: 𝐴𝑔 = 8 x 12 = 96 𝑖𝑛2, , 𝐴𝑠 = 0.8 𝑖𝑛2, 𝐴𝑡 = 𝐴𝑔 + (n-1) 𝐴𝑠 = 96 + (6-1) x 0.8 = 100 𝑖𝑛2, F = PA = 150000 x 0.8 = 120000 lb, (n-1) 𝐴𝑠 = (6-1) x 0.8 = 4 𝑖𝑛2, y=, , 8 𝑥 12 𝑥 6+4 𝑥4, 100, , = 5.92 in, , 12 in, 0.8 𝑖𝑛2, 4 in, 8 in

Page 90 :

Problem-20: A post-tensioned beam has a midspan cross section with, a duct of 2 in by 3 in to house the wires. It is prestressed with 0.8 𝑖𝑛2, , of steel to an initial stress of 150000 psi. Immediately after transfer, the stress is reduced by 5% owing to anchorage loss and elastic, shortening of concrete. Compute the stress in the concrete at transfer., Solution: 𝐴𝑐 = 8 x 12 – 2x 3 = 90 𝑖𝑛2, F = PA = 150000 x 0.8 x 0.95= 114000 lb, y=, , 8 𝑥 12 𝑥 6−2𝑥3𝑥3, 90, , 12 in, , 2 in, , = 6.2 in, , 3 in, , 3 in, 8 in

Page 92 :

Load Balancing

Page 93 :

Problem-21: The live load on the beam is 2.5 k/ft and L is 8 m., a) Determine the effective force in the cable for balancing the dead and live, , loads on the beam., b) Calculate the shift of the pressure line from the tendon center line., 250 mm, 80 mm, 80 mm, , 450 mm, , e = 150 mm, 80 mm

Page 94 :

250 mm, 80 mm, , Solution: 𝐴𝑐 = 2 x 250 x 80 + 80 x (450-80-80), , 80 mm, , 450 mm, , = 63200 𝑚𝑚2, Self weight = 24 x 63200 x, , 10−6, , = 1.52 KN/m, , e = 150 mm, 80 mm, , Total weight = 2.5 +1.52 = 4.02 KN/m, , Moment =, , 𝑤𝐿2, 8, , =, , 4.02 𝑥 82, 8, , = 32.16 KN-m, , e = 150 mm, P=, , 𝑀, 𝑒, , =, , 32.16 𝑥 103, 150, , = 214.4 KN, , ⸫Shift of the pressure line =, , 𝑀, 𝑃, , =, , 32.16, 214.4, , m = 0.15 m = 150 mm.

Page 95 :

Internal Resisting, Couple Method

Page 96 :

Problem-22: Calculate the resultant thrust by Internal resisting couple method., F = 7000 KN, eccentricity at mid span is 800 mm and concentric in support. The, , wall is of uniform thickness of 200 mm and the live load moment at mid span of, 40 m span is 2000 KN-m., 1200 mm, 200 mm, , 1800 mm, , e = 800 mm, , 200 mm

Page 97 :

1200 mm, 200 mm, , = 1.04 𝑚2, e = 800 mm, , 𝑀𝐿𝐿 = 2000 KN-m, , F = 7000 KN, e = 800 mm, Self weight = 1.04 x 24 = 24.96 KN/m, 𝑀𝐷𝐿 =, , 24.96 𝑥 402, 8, , = 4992 KN-m, , ⸫Total Moment, M = 4992 + 2000 = 6992 KN-m, Lever arm, a =, , 6992, 7000, , = 0.99 m, , ⸫𝑒 ′ = a – e = 0.99-0.8 = 0.19 m, , 200 mm, , 1800 mm, , Solution: 𝐴𝑐 = 1.2 x 1.8 – 0.8 x 1.4

Page 98 :

I, , 1.2 x 1.83, =, 12, , 0.8 x 1.4 3, 12, , = 0.4 m4, F, A, , fsup = +, , Fe′ y, I, , =, , 7000, 1.04, , +, , 7000 x 0.19 x 0.9, 0.4, , = 6730.77 + 2992.5 = 9723.27 KN/mm2, finf =, , F, A, , −, , Fe′ y, I, , =, , 7000, 1.04, , -, , 7000 x 0.19 x 0.9, 0.4, , = 6730.77 - 2992.5 = 3738.27 KN/mm2