Page 1 :

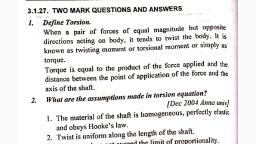

hoice of Mode of Entries of Underground Deposits Adits, Shafts,, , Inclines, Combined Modes_& Their Applicability Number &, Disposition, A deposit to be mined by underground methods can be accessed by a number of methods:, , Adit, Incline, , Shaft, Decline, Many factor influence the decision of selecting adit, shaft, Incline or decline to access an, , underground mine. Some of these factors include the depth of the deposit, geotechnical aspects,, production rate, dimensions, availability of capital, and operating costs., , ADIT, Adit, a horizontal or near-horizontal passage driven from the Earth's surface into the mountain, or hill to extract the mineral when an ore/mineral body is located inside the mountain/hill. It also, , used for ventilating, or removing water from a mine. Adit is employed when the deposit outcrop,, , uSually, , in, , shallow cover, , or, , dips steeply and, , can be, , intersected at, , relatively shallow depth., , The, , mouth of the adit should be located above the highest flood level of that area, , mine by adit, , has many, , aavantages over the vertical access, shafts used in shaft mining, n e r o v is required to transport miners dna neavy, equipment into and out of, the mine, It isS, lco much easier to bring mineral out of the mine., Horizontal travel by means n, of narrow, is, gauge, tramway or cable car also much safer and can move more, and mineral, than vertical, shaft. In combination with shafts, adits, an, Aeacs, , tO a, , people, , form important element in, the ventilation, through an adit, be, , in simple terms, cool air, air will, will enter throuual, , enter, , underground and will, will, for this purpose., , of, , a, , mine:, , warmed by the, naturally exhaust from, higher temperature, vertical shafts, some, of which, are sunk, , specifically

Page 2 :

The size and cross section of an adit, , depend upon its, especially, natural, , common., , rough, , rock, , concrete, wood,, , X-Sectional Shape of an, , use, with, , or, , a, , horseshoe shape, , The walls may be of the, or, , may be lined with, , steel., , Adit, , Incline/lncline Shaft, Inclined entry from surface to, offered, , quick, , access, , to, , underground is known, , the, , as, , incline/incline shaft. Incline/incline shaft, , and capital, mineral/orebody and minimized development, , expenditure, résulting in great saving of time and cost,, , as, , vertical shaft require considerable, , lateral development to access to the mineral/orebody., The benefits of incline/incline shaft over vertical shaft are summarized as:, Less development required to access the mineral/orebody., , Development kept close to the mineral/orebody., Smaller requirements for shaft headgear and winder installation., Incline is cheaper to sink than vertical shafts., , Despite these advantages,, , incline/incline shaft, , is, , regarded, , as, , labour intensive, and, , operationally, , not as efficient as a vertical shaft and the propensity for tracked equipment to suffer derailments., Incline/incline shaft is limited to relatively shallow deposits, and because they are developed on, an, , incline, development lengths for, , a, , given depth, , are, , the three to five times, , vertical shaft. The mouth of the incline should be located above the, area., , longer, , highest flood, , than tor, , a, , level of that

Page 3 :

Vertical Shaft, n, , e n t i c a l or, , ds shaft., , underground, nearly vertical opening, connecting the surface with, dip and, for deeper deposits having step, , Vertical shafts, , are, , working, br, , also, , preferred, , eco, , hoisting depth exceeding 500 m., ner, , considerations are, , y ., , down, , grade, , Ine shaft, , of, , that the shaft should be sunk, , depth, , should be sunk to where, , to reach the shaft, , near, , gravey, centre of, to the, or close, transportea, will be, , most or, , all of the, , ore, , loading stations., rate, , of the, , size, , ne, , ventilation, , they, , material,, , excavation, , of, The shape and size, , requirements., , in the calculation, , included, , that, , shaft, , support, , high, , of the final shaft, , (development, , determined, , by, , are, , d, dio, , shart, down a, be taken, to, equipment, sharts, of vertical, , dimensions., , and, production rates,, , and rock. Disadvantages, , production, , generally being, , the production, , are, , The, , efficient, , advantages, , for the, , initial capital, include the high, , in, and difficulty, rate of is slow),, , dre, , transportation, , expenditure,, , transporting, , of, , personnel,, , long lead, , time to, , equipment., , large, , Shaft cross sections:, cross-section, , 1. Rectangular shaft, Most, , shafts that, , because, , lot of, , was, , 2., , and, , Shaft, , counterweights, , to sink, , sense, , however, , Circular, , constructed, , in the 1900's, , were, , of, , rectangular, , shaft i.e., down the, , that w e r e taken, equipment, of, of the pieces, so, of the shape, in nature and, or rectangular, , cages, skips,, a, , were, , a, , or, , were, , made, , all square, , shafts., mine rectangular, , problematic and, , it, , Breaking, , a square, , /, , rectangular, , shutter, , rate of sinking., this slowed down the, , -, , hard rock mines now, Almost all the, , airflow and, e00d geometry for, , have circular shafts because the, , good rock support, , cross, , section, , provides, , characteristics. The circular shutter is, , ease to move when doing concurrent lining resulting in faster work progress during

Page 4 :

sinking operations., , This is, , an, , important aspect when, , it comes to the cash flow of the, , project., , 3., , Elliptical Shaft Elliptical shafts, half-moons, , were, , along the, , designed, , as an, , alternative to, , large circular shafts by simply adding, , main axis. This had the effect of, , reducing the, , circular excavation, , and therefore the cost of sinking the shaft., , Decline, , pooleul 9«ULW y,, , Declines can be a spiral entry which circles either the flank of the deposit or circles around the, , deposit. The decline begins with a box cut, which is theportal to the surface. Depending on the, amount of overburden and, , quality of bedrock, a galvanized steel arc may be required for safety, , purposes. They may also be started into the wall of an open pit mine., The gradient of decline ranges from 1 in 7 to 1 in 12 so that the trackless machineries can be, casly used in the mine and it is possible to handle ore directly from underground face to surface.