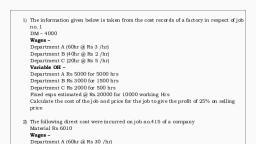

Page 1 :

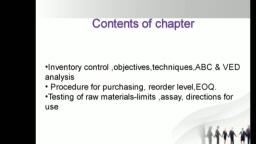

INVENTORY CONTROL TECHNIQUES, Inventory control techniques are employed by the inventory control organization, within the framework of one of the basic inventory models, viz., fixed order quantity, system or fixed order period system. Several techniques of inventory control are in use, and it depends on the convenience of the firm to adopt any of the techniques. The, techniques most commonly used are the following:, 1. ABC Analysis:, ABC analysis is a business term used to define an inventory categorization, technique often used in materials management. It is also known as ‘Selective Inventory, Control.’ ABC analysis provides a mechanism for identifying items which will have a, significant impact on overall inventory cost whilst also providing a mechanism for, identifying different categories of stock that will require different management and, controls. When carrying out an ABC analysis, inventory items are valued (item cost, multiplied by quantity issued/consumed in period) with the results then ranked. The, results are then grouped typically into three bands. These bands are called ABC codes., ABC – CODES:, "A class" inventory will typically contain items that account for 80% of total value,, or 20% of total items."B class" inventory will have around 15% of total value, or 30% of, total items. "C class" inventory will account for the remaining 5%, or 50% of total items., ABC Analysis is similar to the Pareto principle in that the "A class" group will, typically account for a large proportion of the overall value but a small percentage of the, overall volume of inventory., 2. High, Medium and Low Classification:, The High, medium and Low (HML) classification follows the same procedure as is, adopted in ABC classification. Only difference is that in HML, the classification unit value, is the criterion and not the annual consumption value. The items of inventory should be, listed in the descending order of unit value and it is up to the management to fix limits for, three categories.

Page 2 :

3. VED Classification:, While in ABC, classification inventories are classified on the basis of their, consumption value and in HML analysis, the unit value is the basis. Criticality of, inventories is the basis for vital, essential and desirable categorization. The VED analysis, is done to determine the criticality of an item and its effect on production and other, services. It is specially used for classification of spare parts., 4. SDE Classification:, The SDE analysis is based upon the availability of items and is very useful in the, context of scarcity of supply. In this analysis, items, generally imported, and those which, are in short supply. It refers to difficult items which are available indigenously but are, difficult to procure. Items which have to come from distant places or for which reliable, suppliers are difficult to come by fall into category. It also refers to items which are easy, to acquire and which are available in the local markets., The SDE classification, based on problems faced in procurement, is vital to the, lead time analysis and in deciding on purchasing strategies. SDE analysis is done based, on purchasing problems associated with items on day-to-day basis. Some of the, purchasing problems are as under: - Long Lead Times. Scarcity and hardly available,, Sourcing the same material from many geographically scattered sources Uncertain and, unreliable sources of supply, purchasing department classifies these materials and, formulates the strategy and policy of procurement of these items accordingly. So, classification of materials is done based on level of difficulty in sourcing., 5. FSN Classification:, FSN stands for fast moving slow moving and non-moving. Here, classification is, based on the pattern of issues from stores and is useful in controlling obsolescence. To, carry out an FSN analysis, the date of receipt or the last date of issue, whichever is later,, is taken to determine the number of months, which have lapsed since the last, transaction. The items are usually grouped in periods of 12 months., FSN analysis is helpful in identifying active items which need to be reviewed, regularly and surplus items which have to be examined further. Non-moving items may, be examined further and their disposal can be considered.

Page 3 :

6. SOS Analysis:, ‘S’ stands for Seasonal items and ‘OS’ stands for off-seasonal items. It may be, advantageous to buy seasonal items at low prices and keep inventory or buy at high price, during off seasons. Based on the fluctuation in prices and availability, suitable decision, has to be taken regarding how much to purchase and at what prices., 7. XYZ Analysis:, XYZ analysis is calculated by dividing an item's current stock value by the total, stock value of the stores. The items are first sorted on descending order of their current, stock value. The values are then accumulated till values reach say 60% of the total stock, value. These items are grouped as 'X'. Similarly, other items are grouped as 'Y' and 'Z', items based on their accumulated value reaching another 30% & 10% respectively. The, XYZ analysis gives an immediate view of which items are expensive to hold. Through this, analysis, firm can reduce its money locked up by keeping as little as possible of these, expensive items., 8. GOLF Analysis:, This stands for Government, Open market, Local or Foreign source of supply. For, many items imports are canalized through government agencies such as State Trading, Corporations,, , Mineral, , and, , Metals, , Trading, , Corporations,, , Indian, , Drugs, , and, , Pharmaceuticals etc. For such items, the buying firms cannot apply any inventory control, techniques and have to accept the quota allotted by the Government. ‘Open market’, categories are those who form bulk of suppliers and procurement is rather easy. ‘L’, category includes those local suppliers from whom items can be purchased off; they sell, on cash purchase basis. ‘F’ category indicates foreign suppliers. Since an elaborate, import procedure is involved, it is better to buy imported items in bigger lots usually, covering the annual requirements., 9. EOQ:, Economic order quantity is the level of inventory that minimizes the total, inventory holding costs and ordering costs. It is one of the oldest classical production, scheduling models. The framework used to determine this order quantity is also known as, Wilson EOQ Model or Wilson Formula. The model was developed by F. W. Harris in, 1913. But still R. H. Wilson, a consultant who applied it extensively, is given credit for his, early in-depth analysis of the model.

Page 4 :

EOQ is the economic quantity to order, so that ordering cost + carrying cost finds, its minimum. (A common misunderstanding is that formula tries to find when these are, equal.), EOQ is essentially an accounting formula that determines the point at which the, combination of order costs and inventory carrying costs are the least. The result is the, most cost effective quantity to order in purchasing, this is known as the order quantity, in, manufacturing it is known as the production lot size., The basic Economic Order Quantity (EOQ) formula is as follows:-, , EOQ, , =, , 2(Annual usage in units) (Order cost), (Annual Carrying cost per unit), , The Inputs:While the calculation itself is fairly simple, the task of determining the correct, data inputs to accurately represent the firm’s inventory and operation is a bit of a project., The following breaks down the data inputs in more detail and gives insight into the, aspects of each., , Annual Usage:Expressed in units, this is generally the easiest part of the equation. Firm can, simply use its forecasted annual usage data for computational purposes., , Order Cost:The cost of ordering includes the cost of acquisition of inventories. It is the cost of, preparation and execution of an order including cost of paper work and communicating, with the supplier., For the most part, order cost is primarily the labor associated with processing the, order; however, it can include the other costs such as the costs of phone calls, faxes,, postage, envelopes, etc.

Page 5 :

Carrying Cost, Also called Holding Cost, carrying cost is the cost associated with having inventory, on hand. It is primarily made up of the costs associated with the inventory investment, and storage cost. Below are the primary components of carrying cost., , , Interest:, If firm had to borrow money to pay for its inventory, the interest rate would be, , part of the carrying cost. If it did not borrow on the inventory, but have loans on other, capital items, it can use the interest rate on those loans since a reduction in inventory, would free up money that could be used to pay these loans. If by some miracle firms are, debt free, they would need to determine how much they could make if the money was, invested., , , Insurance:, Since insurance costs are directly related to the total value of the inventory, firm, , would include this as part of carrying cost., , , Taxes:, If firms are required to pay any taxes on the value of their inventory they would, , also be included., , , Storage Costs:, Mistakes in calculating storage costs are common in EOQ implementations., , Generally companies take all costs associated with the warehouse and divide it by the, average inventory to determine a storage cost percentage for the EOQ calculation. This, tends to include costs that are not directly affected by the inventory levels and does not, compensate for storage characteristics. Carrying costs for the purpose of the EOQ, calculation should only include costs that are variable based upon inventory levels., 10., , Minimum - Maximum Technique:, The minimum - maximum system is often used in connection with manual, , inventory control systems. In practice, a requisition is initiated when a withdrawal, reduces the inventory below the minimum level; the order quantity is the maximum, minus the inventory status after the withdrawal. If the final withdrawal reduces the stock, level substantially below the minimum level, the order quantity will be longer than the, calculated EOQ. The effectiveness of a minimum-maximum system is determined by the, method and precision with which the minimum and maximum parameters are

Page 6 :

established. If these parameters are based upon arbitrary judgments with a limited basis,, the system will be limited in its effectiveness. If the minimum are based on an objective, rational basis, the system can be very effective., 11., , Two-bin Technique:, One of the oldest systems of inventory control is the two bin system which is, , adopted to control ‘C’ group inventories. In the two – bin system, stock of each item is, separated into two bins. One bin contains stock, just enough to last from the date a new, order is placed until it is received in inventory. The other bin contains a quantity of stock, enough to satisfy probable demand during the period of replenishment.