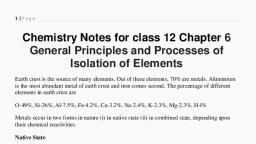

Page 1 :

METALLURGY

Page 2 :

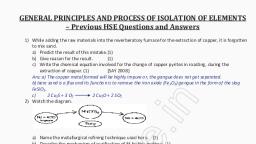

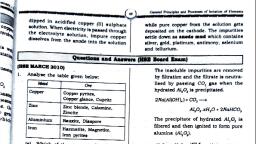

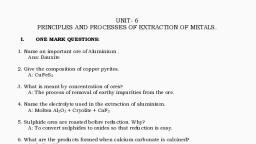

EXTRACTION OF METALS FROM ORE, The process of extraction of metal in the free state, from its ore is called metallurgy. The common steps, involved in the metallurgical process are :, , Crushing and grinding of the ore., Concentration (or) dressing of the ore., , Roasting and calcination., Reduction of concentrated ore to metal., Refining of the crude metal.

Page 3 :

Crushing and Grinding of The Ore, The ore is crushed into a fine powder in a big jaw, crushers and ball mills. This process is termed as, pulverisation.

Page 4 :

Concentration (or) Dressing of Ore, The process of removal of gangue from the ore is known, as concentration of an ore (or) Ore dressing., The purified ore is known as concentrate., The process commonly applied for the concentration of, sulphide ores is Froth Floatation.

Page 5 :

FROTH FLOTATION, Principle : The process depends on the preferential, wettability of the ore particles with oil and the gangue, particles by water., , Method : The powdered ore is taken in a tank, containing pine oil and water., The mixture is vigorously agitated with a current of, compressed air.

Page 7 :

The ore particles are wetted by the oil and raise to-tne, surface as froth., The gangue particles are wetted by water and will, settle down at the bottom., This process is commonly applied for the, concentration of sulphide ores of lead (galena), zinc, (zinc blende) and copper (copper pyrites).

Page 8 :

The following reagents are also added during this, process in certain cases., (i) Collectors : Compounds which increase the wetting, characteristics of ore particles with oil., , Ex : Ethyl xanthate and potassium ethyl xanthate. (ii), Activators : Compounds which activate the floating, properties of ore particles., Ex : Copper sulphate., (iii) Depressants : Compounds which depress the, floating properties of ore particles., Ex : Sodium cyanide and potassium cyanide.

Page 9 :

EXTRACTION OF CRUDE METAL, , Calcination, Calcination is the process of heating the ore, strongly in absence of air without fusion.

Page 10 :

The objectives of calcination are:, (i) Removes water from a hydrated oxide ore, , Removes carbon dioxide from carbonate ore, , Removes volatile impurities present in ore., (iv) Converts the mass in porous form.

Page 11 :

Roasting, , Roasting is the process of heating the ore strongly in, excess of air without fusion., The objectives of roasting are :, Converts sulphide ores to oxide forms, , Removes volatile impurities present in ore, Gets the mass in porous form.

Page 13 :

REDUCTION, Smelting, , Smelting is the process of reducing the roasted, oxide ore with a reducing agent and removes the, gangue with the help of an appropriate flux added, with the ore.

Page 14 :

REFINING (PURIFICATION) OF METALS, The process of purification of impure metals, obtained from ore by removing metallic and, non-metallic impurities is known as refining of, metals.